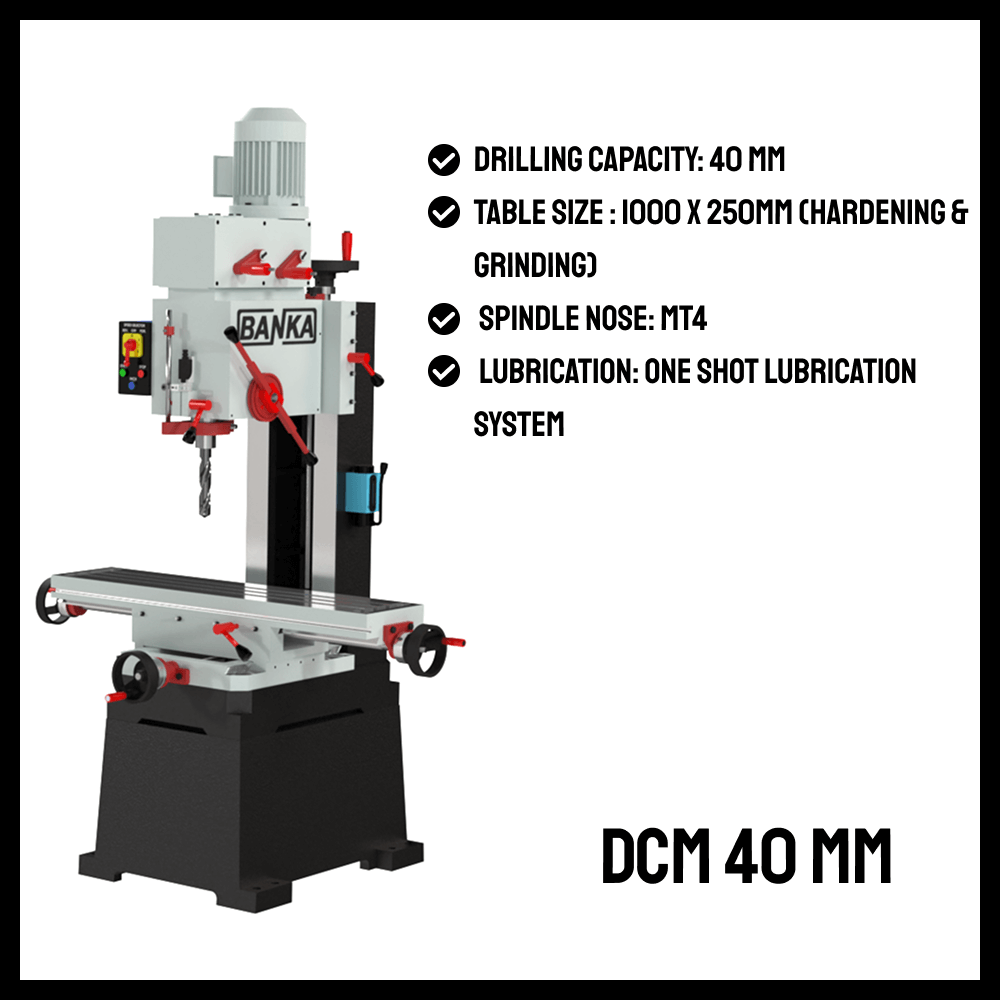

DCM 40 MM – DRILLING CUM MILLING MACHINE – BANKA 40MM AUTO FEED

₹1,69,000 Original price was: ₹1,69,000.₹1,59,000Current price is: ₹1,59,000.

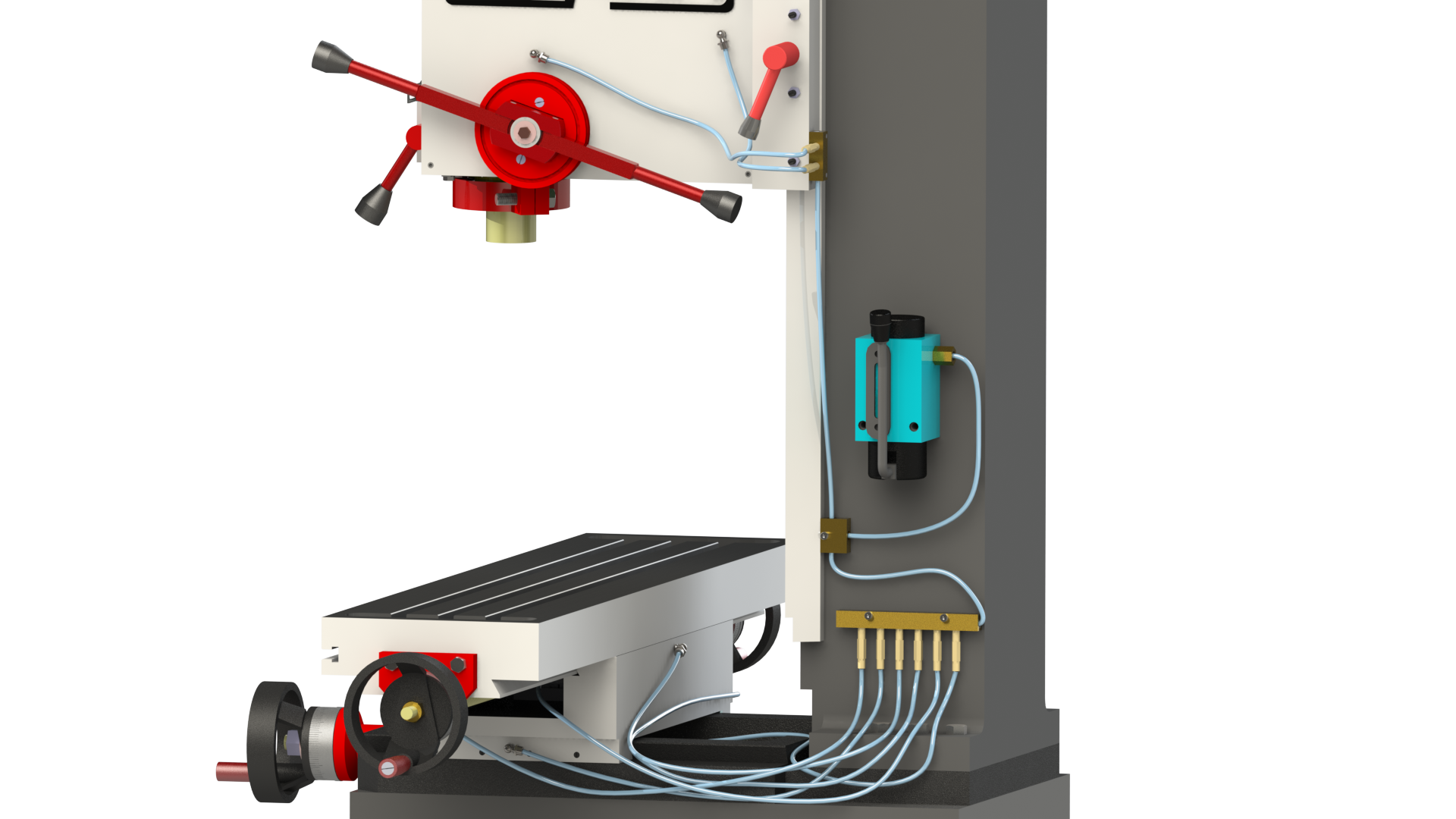

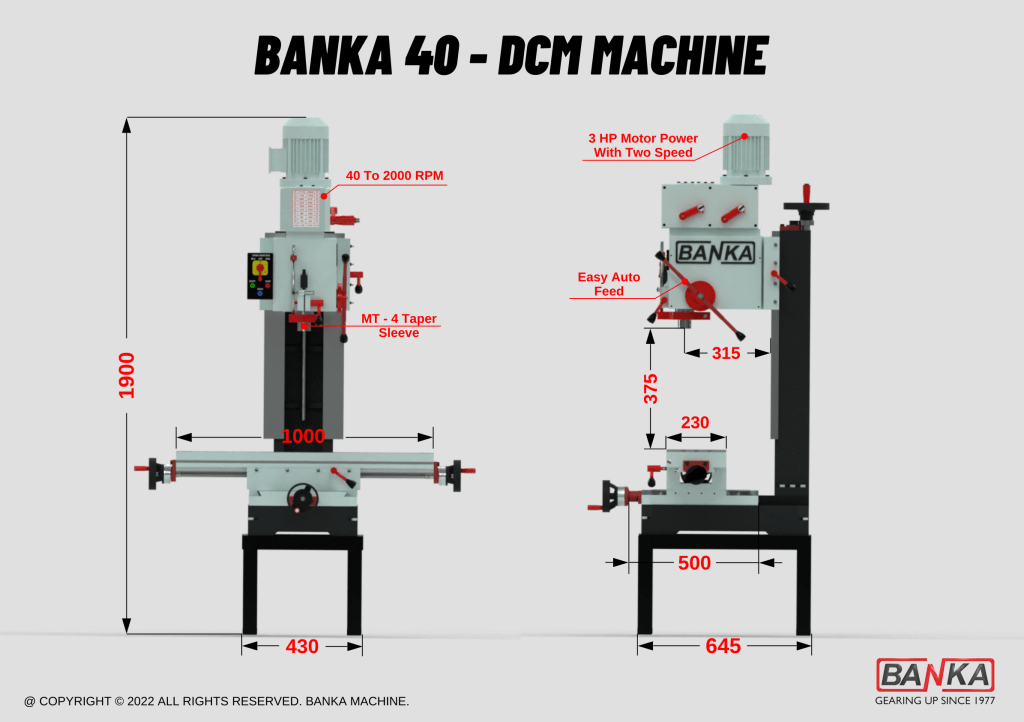

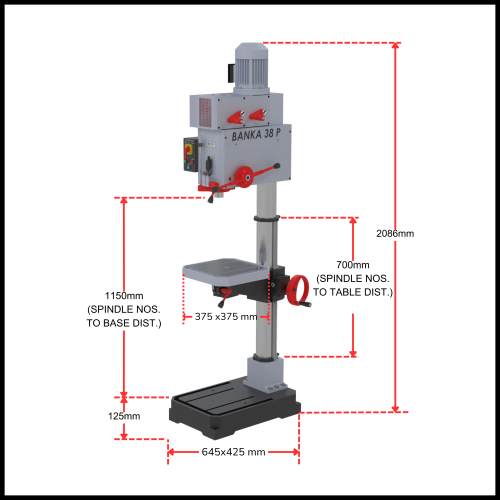

BANKA 40 Drilling Cum Milling Machine

- Drilling Capacity: 40 mm

- Table Size : 1000 x 250MM (Hardening & Grinding)

- Spindle Nose: MT4

- Lubrication: One Shot Lubrication System

- Max. Spindle Travel (Drilling Depth): 170 mm

- Spindle Speed: 22-2000 RPM

- Spindle to base distance: 550 mm

- Distance from column to spindle: 300 mm

- Cross Slide travel: 525 x 300 mm

- Motor: 2HP (2-Speed)

- Weight: 690KG

Essential Features :

Special Features :

- Geometric Progression Speed & Feed

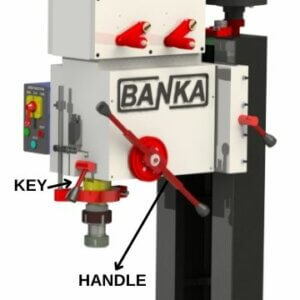

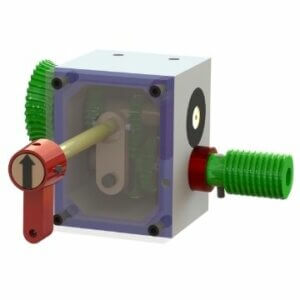

- Easy Auto Feed System

- 2 Speed Motor with 40-2000 RPM

- Easy Power Feed by Hand Lever

- Easy Tapper Shank Release

- Accuracy Tested as per IS 2425-1963

- Collet Chuck For Cutters

You may also like

RADIAL DRILL 38 MM – ALL GEAR DRILL – 1.5 INCH – RADIAL TYPE –

MEDIUM DUTY WITH DRILL CHUCK

₹

₹1,99,000

| Drill Specification | Size |

| Capacity | |

| Drilling Capacity in Cast Iron (241 BHN) | 40 |

| Drilling Capacity in Mild Steel | 32 |

| Tapping Capacity in Cast Iron (241 BHN) | 20 |

| Tapping Capacity in Mild Steel | 15 |

| Boring Capacity in Mild Steel | 75 |

| Drilling Head | |

| Morse Tapper in Spindle Nose | MT4 |

| Max. Spindle Travel (Drilling Depth) | 170 |

| Spindle Sleeve Diameter | 75 |

| No. of Spindle Speeds | 18 |

| Spindle Speed Range (RPM) | 22-2000 |

| No. of Power Feeds | 3 |

| Feed Range per Revolution | 0.08-0.02-0.04 |

| Lubrication | Lithium Grease |

| Milling Specification | SIZE |

| Spindle to base distance | 550 mm |

| Distance from column to spindle | 300 mm |

| Column diameter | 150 x 150 Square |

| Max. spindle Travel | 170 mm |

| Cross Slide travel | 525 x 300 mm |

BANKA Machines is a juncture where Machines gets shaped up into the line of the optimum productive element. We eye to develop such machines that not only are compatible for its efficient manufacturing but also competent to undertake parallel progression too. For Instance, BANKA’s Milling Machine, which not only undertakes Milling process but also carries out Drilling process simultaneously.

BANKA’s Milling Machine adds the feather to our exhibition of ideal manufacturing with its exceptional features. It possesses Auto Feed Gear Box that adds to technological input and correspondingly minimizing manual effort. E-Type spindles nose assists in conducive shaping up the workpiece. BANKA’s Milling Machine acts by International Standards. It transmits the speed of 1440 RPM.

The rigidity of BANKA’s Milling Machine is remarkable enough as it is made from quality, graded and standard parts and materials.

It has Auto-feed Gear Box that assists time-saving aspect and proves cost effective since it minimizes labour overheads.

E-Type Spindle nose helps in the dynamic shaping of a workpiece with high speed.

1) What are the basic clarifications customers should clarify at the time of purchasing the Milling machine?

A:

- Table size

- Spindle Taper

- Ram Travel

- X-Axis longitudinal travel

- Y-Axis Cross Travel

- Z-Axis Vertical Travel

- Guide Way – XYZ

- Motor Power

2) Which accessories should I buy with Milling Machine?

A: 1) Auto feed, Electric Motor, Vertical attachment, Rack cutting attachment, slotting attachment, dividing head, coolant pump with fittings, true chuck, Milling Adaptor, face mill cutter, milling vice, milling collet, etc.

3) What will be the warranty Period of this Milling Machine?

A: Generally Suppliers of the lathe machine are providing only one year warranty period in the lathe machine. And it is not the proper return according to your investment. While We are providing 3 years warranty in in Gear, Guideway, spindle and Barrings. If there any parts damaged in your machine then we also provide free parts service in warranty period by fastest courier service.

4) Which are the accessories I Should Buy with Drill Machine?

A: Key Less Dill Chuck

Electrical Motors

Keyless Drill Chuck & Arbor

Drill Chuck & Arbor

Coolant Pump with Coolant Tank

Multi Spindle Drilling

Tapping Attachment

Tinting Table

6) Do you accept Domestic LC ?

A: Yes, accept domestic LC for 60 days on credit. Generally, 75 % of customers are purchasing Machines from us with 60 days of Credit through a Simple Process of LC. When the Seller is Unknown or New to the Buyer, Letter of Credit is one good Alternative to do the Business with Such New Seller Because Buyer can Avoid Risk by such Letter. Letter of Credit is one Additional Benefit to the Buyer by which they can protect Loss against Goods and Finance Also. The buyer can build safeguards into the letter of credit, including inspection of the goods and quality control, and set production and delivery times.

You may also like…