Machine Shop Accessories, Tools & Instruments

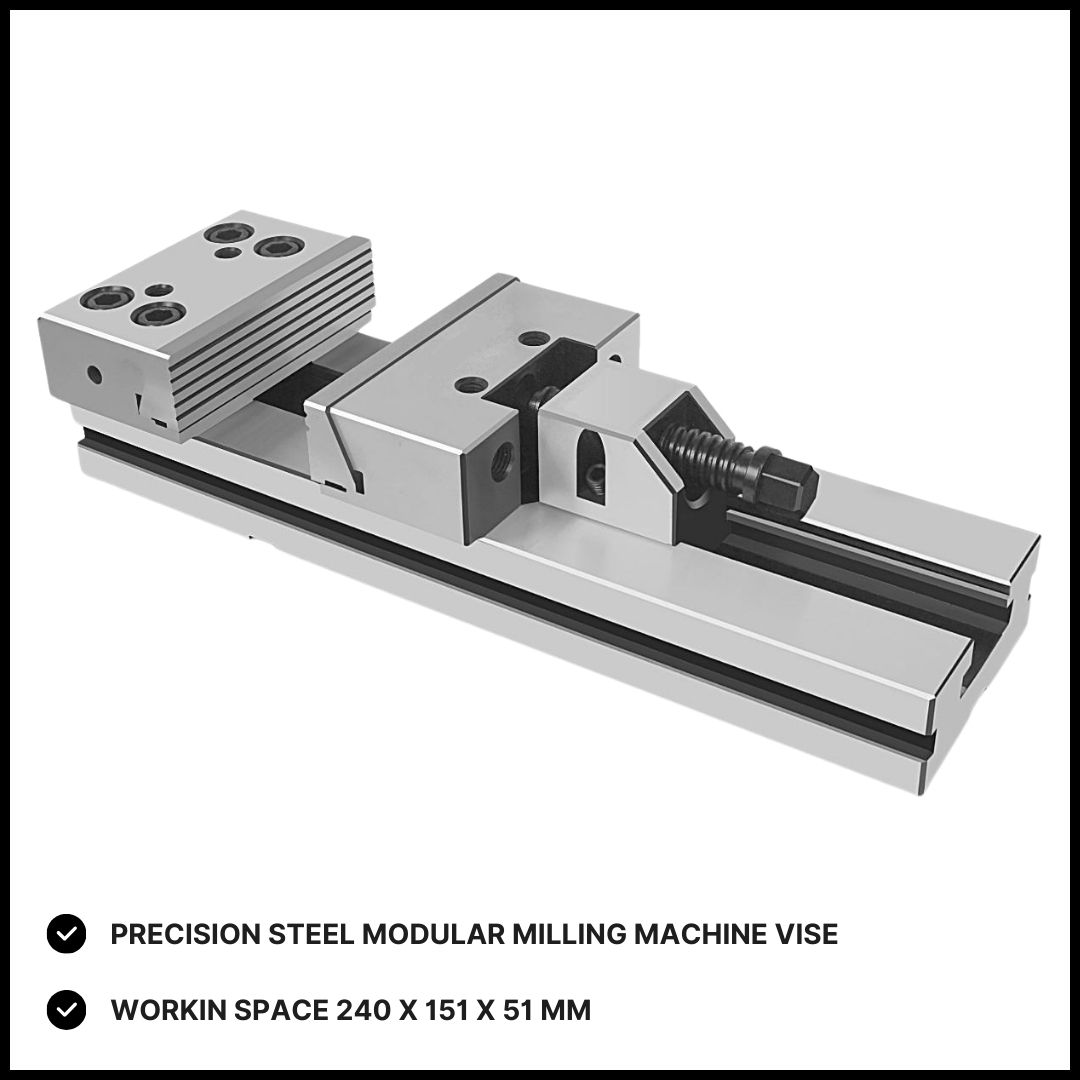

PRECISION STEEL MODULAR MILLING MACHINE VISE

₹33,500

- Material and Construction

- Precision and Accuracy

- Modularity

- Clamping Mechanism

- Compatibility

- High-precision Machining

- Versatility

- Repeatable Setup

A precision steel modular milling machine vise is a specialized tool used in machining operations, particularly in milling machines, where precise positioning and clamping of workpieces are essential. Here’s a detailed look at what this type of vise entails:

Definition and Purpose

A precision steel modular milling machine vise is designed to securely hold workpieces during milling operations with a high degree of accuracy and repeatability. Its modular nature typically means it can be customized or expanded with additional features or accessories to suit different machining needs.

Key Features

- Material and Construction: These vises are usually made from high-quality steel to provide durability and stability. The steel construction ensures that the vise can withstand the forces generated during milling, maintaining rigidity and precision.

- Precision and Accuracy: The design of these vises incorporates features such as hardened and ground ways, precision-machined surfaces, and fine-pitch screws for smooth and precise adjustment. This allows for accurate positioning of workpieces to achieve tight tolerances in machining.

- Modularity: Modular milling vises often come with interchangeable jaws or additional features like swivel bases, quick-change mechanisms, or adjustable clamping force settings. This modularity enhances versatility and adaptability to different machining tasks.

- Clamping Mechanism: Typically, these vises utilize a screw mechanism (often with fine-pitch threads) to move the jaws relative to each other, allowing for secure clamping of workpieces. Some may feature hydraulic or pneumatic clamping systems for even greater holding force and ease of use.

- Compatibility: They are designed to be compatible with various types of milling machines, ensuring that they can be securely mounted and used effectively across different machining setups.

Related Products

Sale

Ready Stock