- Sorry, this product cannot be purchased.

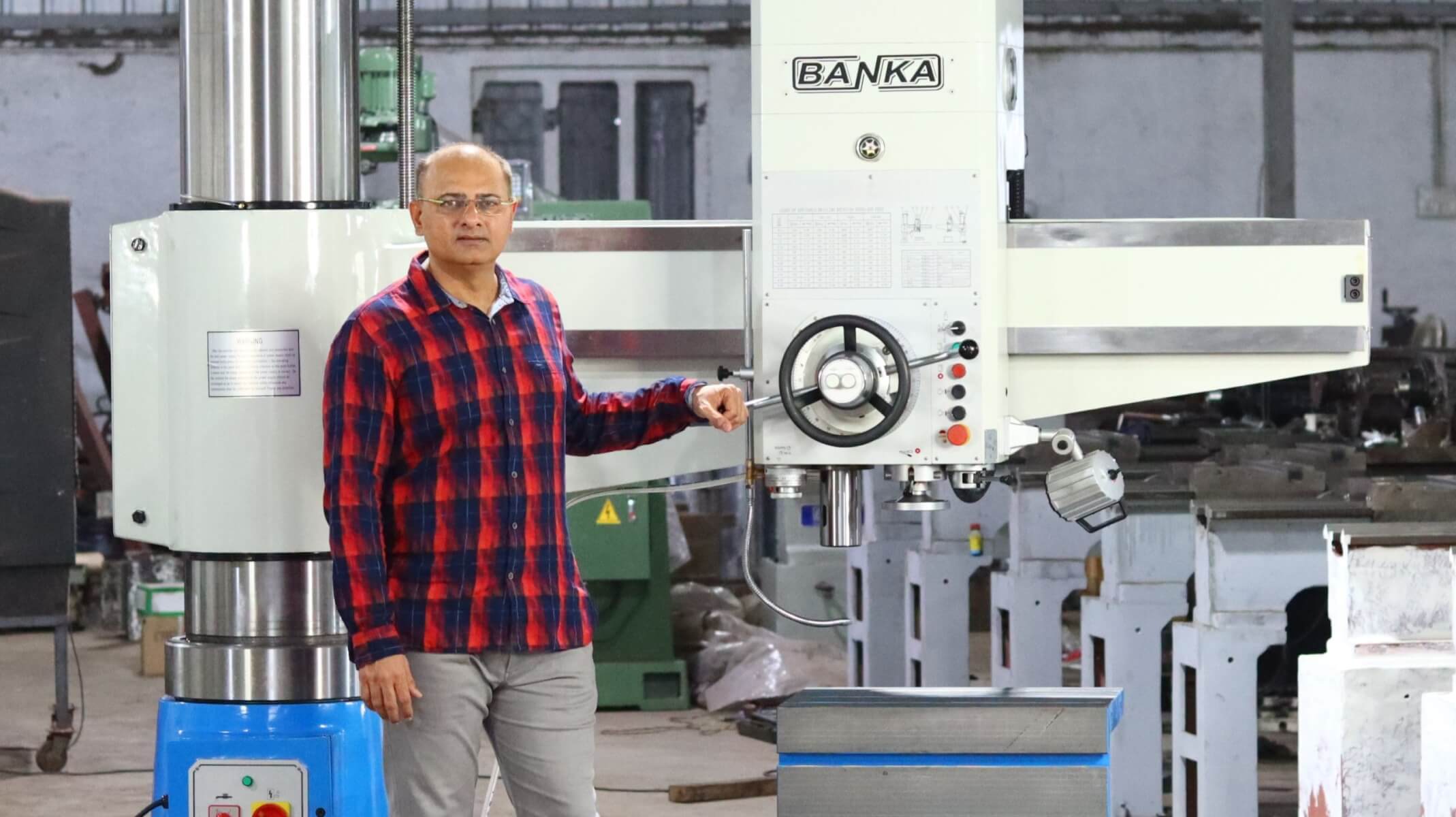

RADIAL DRILL MACHINE-ALL GEAR-50MM-WITH HYDRAULIC CLAMPING

₹10,55,000

- Drilling Capacity: 50 mm

- Spindle Travel: 315 mm

- Spindle Taper: MT-5

- Spindle Speed: 25-2000 RPM

- Column Diameter : – 350 mm

- Max. Mini. Distance Spindle center to column center: 1600/350 mm

- Horizontal Movement of drilling Head: 1250 mm

- Max.Mini Distance Spindle Nose of base plate: 1270/370 mm

- There is a wiper on the column

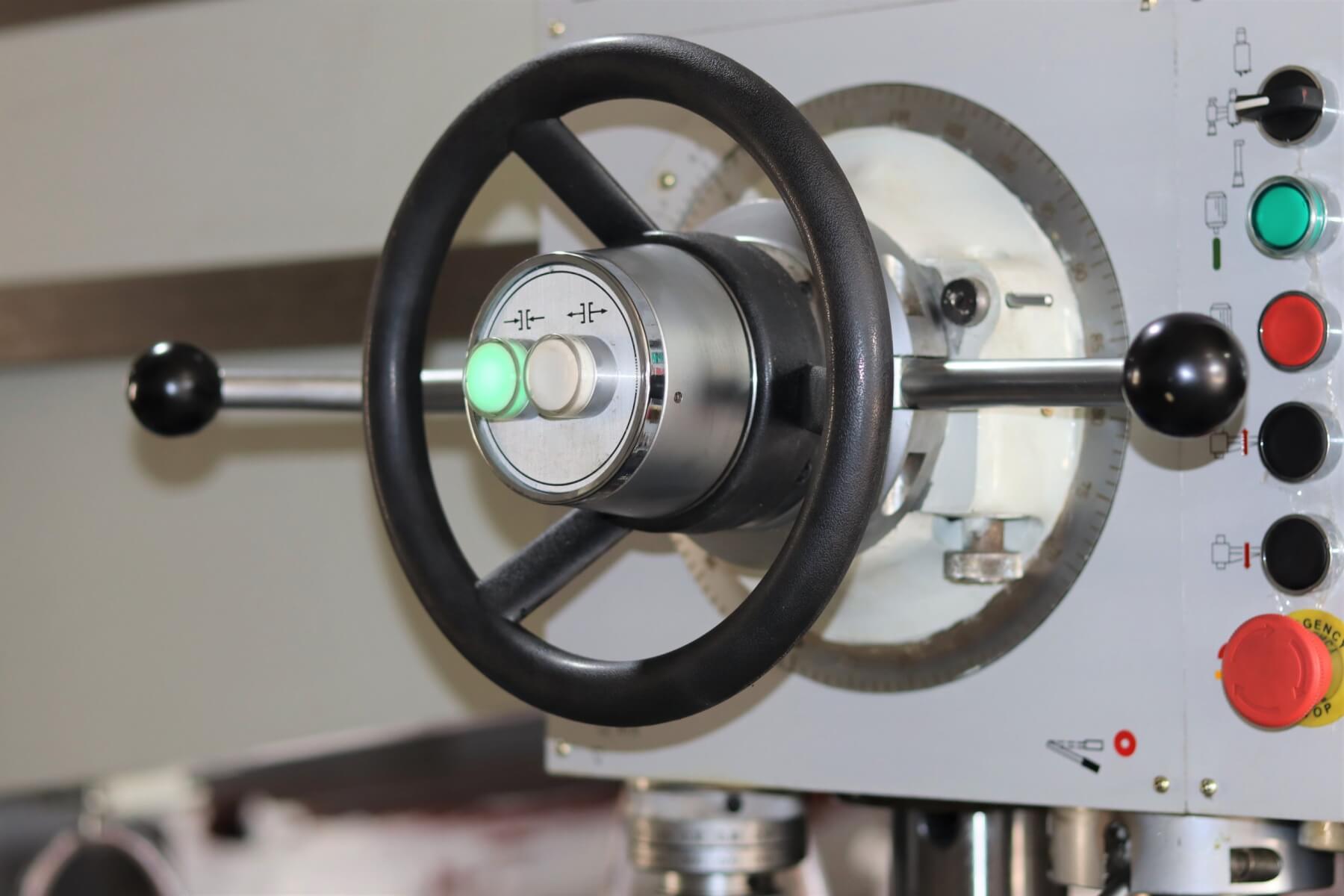

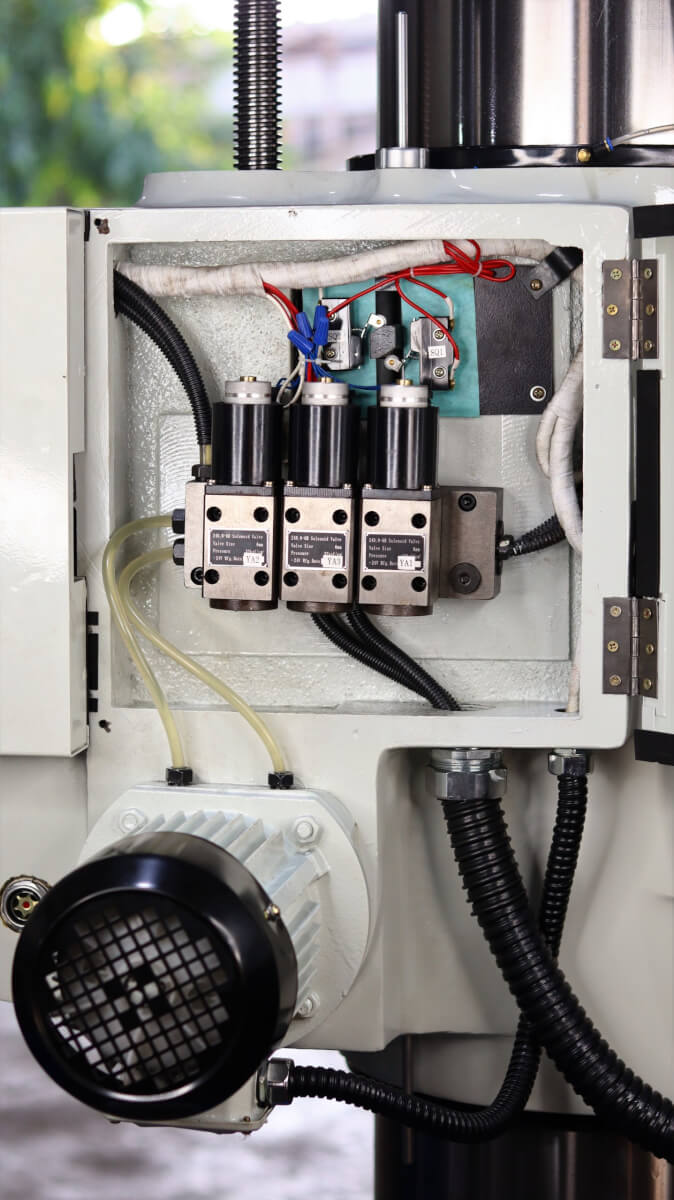

- Hydraulic lock system

- There is an adjustment given in the auto feed as if the drill is drilled in the depth, then the machine stops automatically.

- Machine weight 3500 KG

- The liver hydraulic system is given

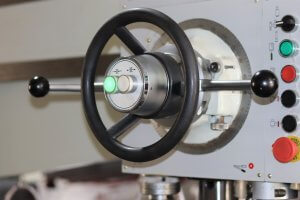

- The automatic system is provided for speed feed and liver feed

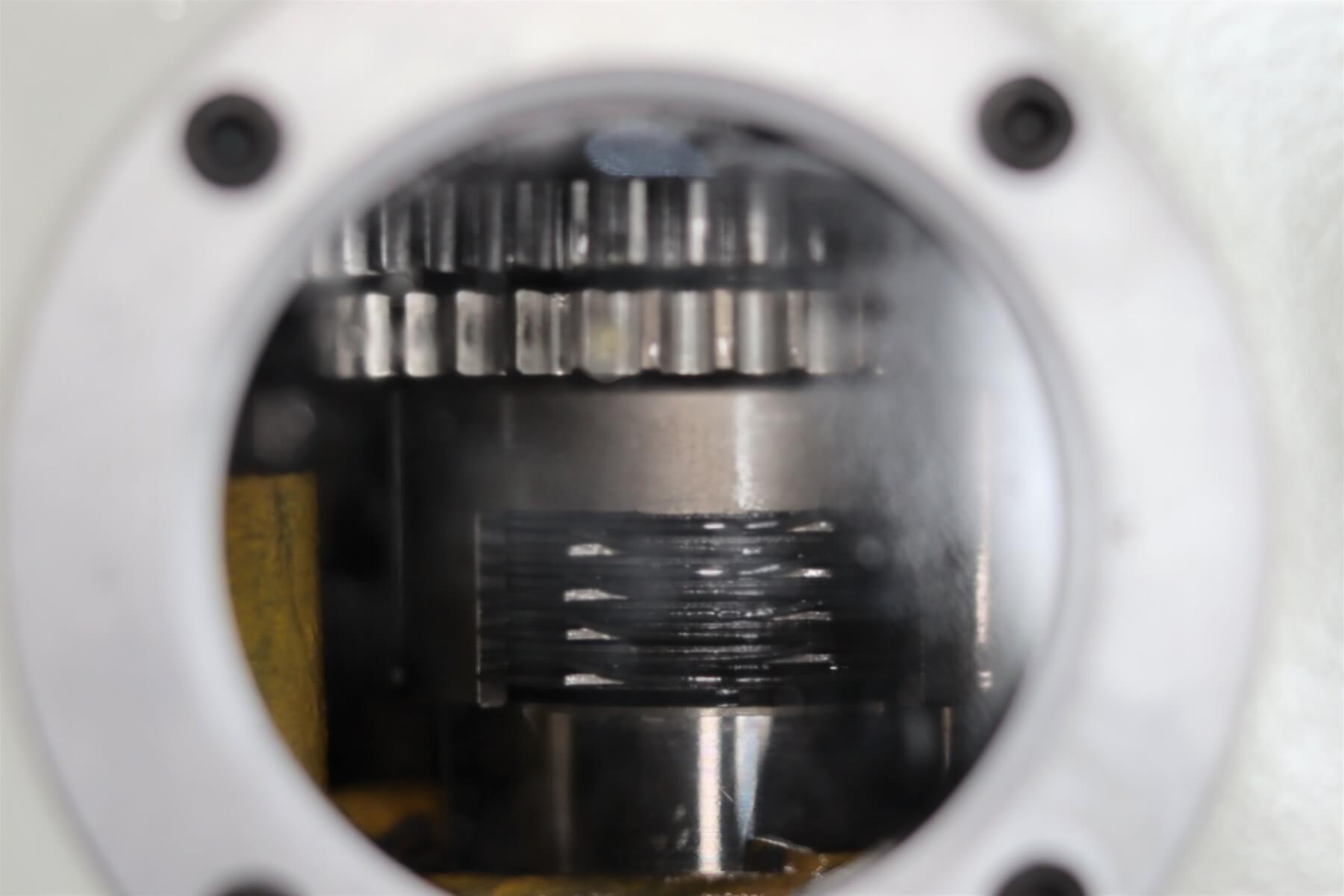

- Lubrication Pump Oil Provided, One Shot Lubrication System

- A coolant pump is provided at the base of the machine

- The machine lamp is good quality

- When the pillar is up and down, the oil is done automatically.

| Particulars | BANKA IR 50-MM | BANKA IR 65-MM | ||

|---|---|---|---|---|

| CAPACITY | ||||

| Drilling Capacity | 50mm | 65mm | ||

| Tapping Capacity | M36 | M42 | ||

| Boring Capacity | 120mm | 150mm | ||

| DRILL HEAD | ||||

| Taper in Spindle | MT5 | MT5 | ||

| Spindle Travel | 315mm | 400mm | ||

| Number of Spindle Speeds | 16 | 16 | ||

| Range of Spindle Speeds | 25-2000rpm | 20-1600rpm | ||

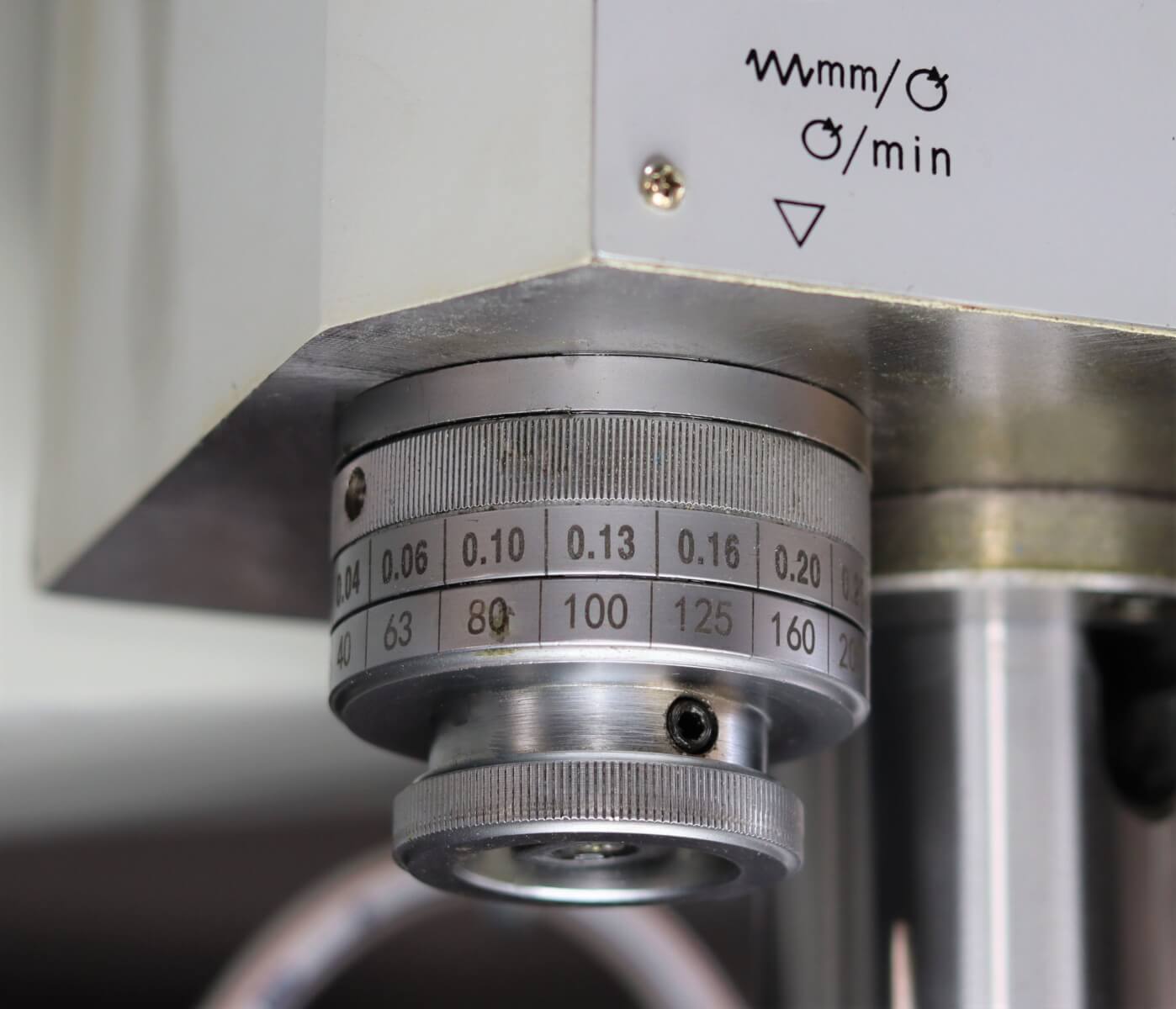

| Number of Spindle Auto Feeds | 16 | 16 | ||

| Range of Spindle Auto Feeds | 0.04-3.20mm/rev. | 0.04-3.20mm/rev. | ||

| Drill Head & Column Locking | Hydraulic | Hydraulic | ||

| WORKING RANGE | ||||

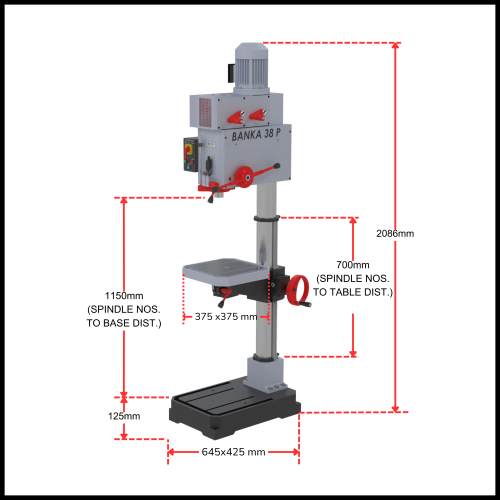

| Arm Lenght | 1770mm | 2000mm | ||

| Travel of Drill Head | 1250mm | 1550mm | ||

| Drilling Radius Min./Max. | 525/1775mm | 675/2275mm | ||

| Dist. Spindle Axis and Column. | 350/1600mm | 450/2000mm | ||

| Dist. Spindle and Base Plate | 320/1220mm | 450/1650mm | ||

| Diameter od Column | 350mm | 450mm | ||

| BOX TABLE | ||||

| Box Table Size | 630 x 500 x 500mm | 630 x 800mm | ||

| Number Of T Slots Box Table | 5 | 7 | ||

| Size in T Slots in Box Table | 22mm | 22mm | ||

| ELECTRICAL | ||||

| Power Supply of Main Motor | 5HP | 7.5HP | ||

| Power Supply of Elevating Motor | 2.5HP | 2.5HP | ||

| DIMENSION & WEIGHT | ||||

| Length x Width x Height | 2500 x 1070 x 2550 mm | 3080 x 1250 x 3245 mm | ||

| Next Weight | 3500Kgs. | 7300Kgs. | ||

A Radial Drill Machine is designed primarily for drilling holes in large and heavy workpieces. Here are some key features and descriptions of an All Gear Radial Drill Machine:

-

Versatile Drilling Capability: These machines are capable of drilling holes of various sizes and depths due to their adjustable arm and spindle.

-

Adjustable Arm: The arm can be moved around the column, providing flexibility in positioning the drill over the workpiece. This makes it suitable for drilling multiple holes in different locations without repositioning the workpiece.

-

Heavy-Duty Construction: Typically made from robust materials like cast iron, these machines are capable of handling large and heavy workpieces with ease.

-

Powerful Motor: Equipped with a powerful motor, All Gear Radial Drill Machines can drill through tough materials such as metals efficiently.

-

Rotating Table: Some models come with a rotating table, allowing for angular drilling and precise positioning of the workpiece.

-

Automatic Feed: Many modern radial drill machines offer automatic feed settings, which can be adjusted for different drilling speeds and depths.

-

Safety Features: They are equipped with safety features such as emergency stop buttons and protective covers over the drilling mechanism.

These machines are widely used in industries such as manufacturing, construction, and metalworking, where precise and efficient drilling operations are required. They are essential for tasks like hole drilling, tapping, reaming, and countersinking in various types of materials.

Standard Accessories:

- Box Table

- Coolant System

- Machine Lamp

- Drill Chuck with Arbor

- Reduction Sleeve

- Wedge

- Tool Box

- Instruction Manual

- Foundation Bolt

Related Products