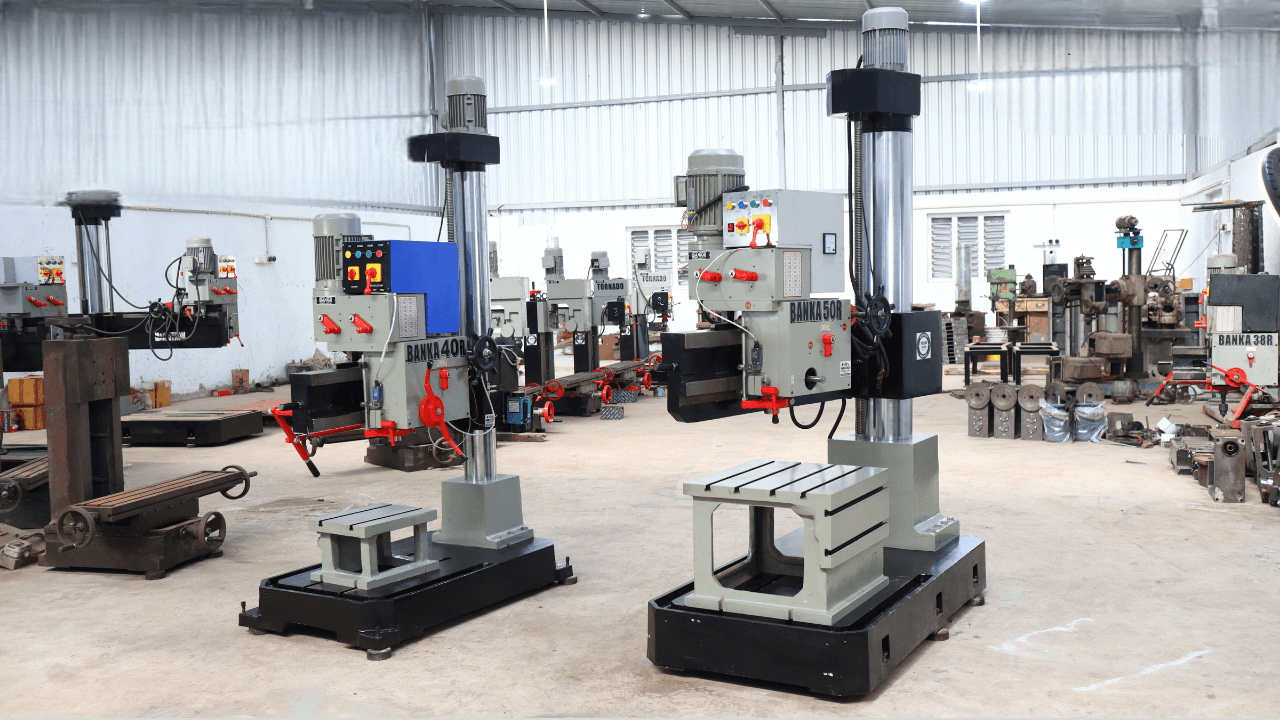

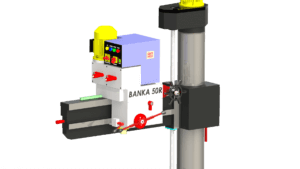

RADIAL DRILL MACHINE-ALL GEAR-40MM- 2 SPEED MOTOR

₹2,19,000 Original price was: ₹2,19,000.₹1,99,000Current price is: ₹1,99,000.

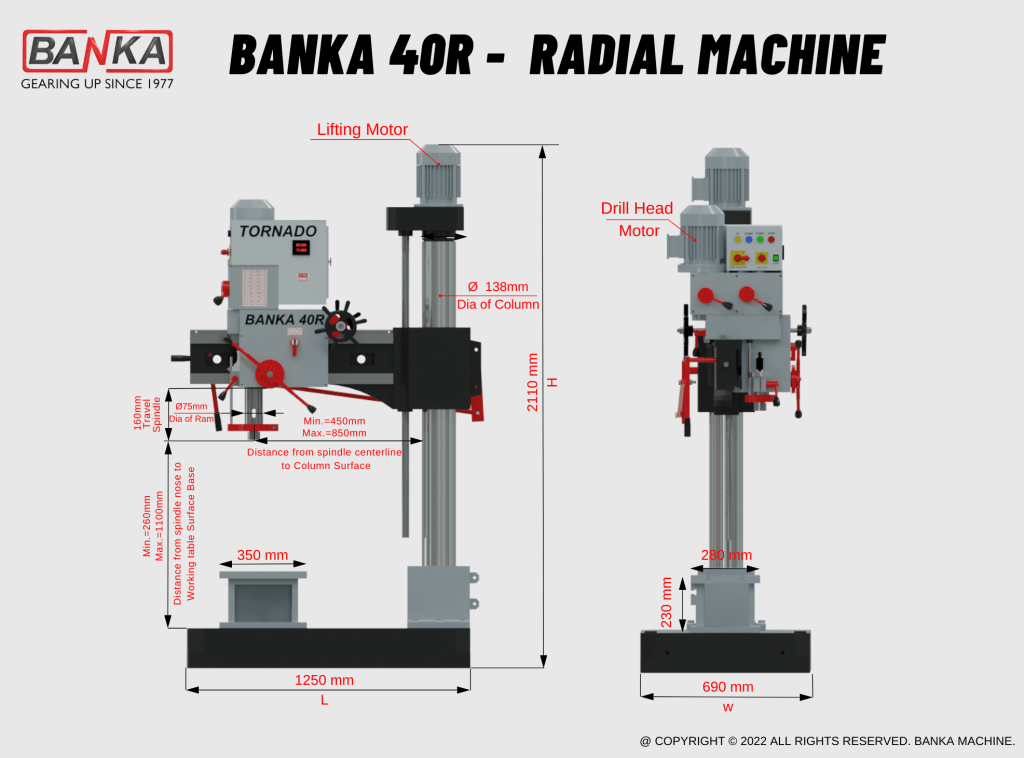

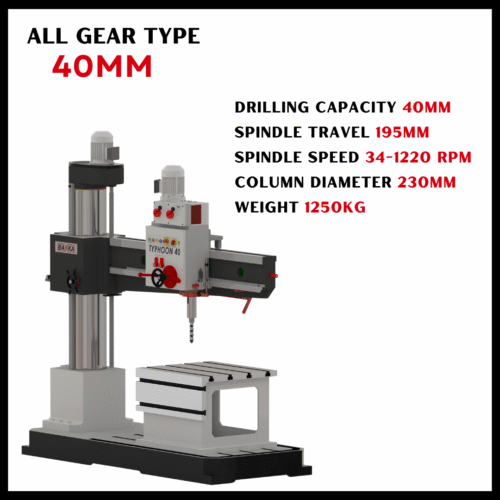

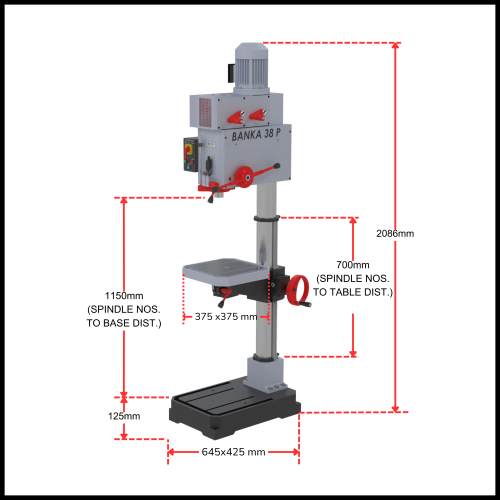

- Drilling Capacity: 40 mm

- Spindle Travel: 170 mm

- Spindle Taper: MT-4

- Spindle Speed: 40-2050 RPM

- Column Diameter: 138 mm

CALL US FOR MORE INFORMATION: +91 93770 93780

SPECIAL FEATURES

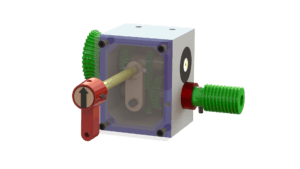

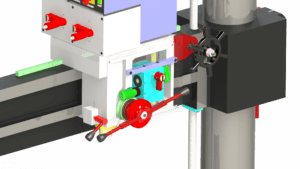

- Easy Autofeed System

- Y-axis locking alarm (Prevention).

- Spindle stopper to adjust bore depth.

- Photo true drilling shank pointer.

- Hard Chrome plated pillar (Y-axis).

- Very low-cost tilting table.

- 4-X feed.

- 2 Speed Motor with 40-2000 RPM.

- Easy Power Feed.

- Easy Tapper Shank Release.

- Accuracy Tested as per IS 2425-1963.

- Geometric Progression Speed & Feed.Limit switch and auto stop for the Y-axis extreme point.

- It prevents mishandling by an operator. Auto-stop of the spindle motor to operate more drills by one operator.

| Specification | Size |

| Capacity | |

| Drilling Capacity in Cast Iron | 40 |

| Drilling Capacity in Mild Steel | 32 |

| Tapping Capacity in Cast Iron (241 BHN) | 20 |

| Tapping Capacity in Mild Steel | 15 |

| Boring Capacity in Mild Steel | 75 |

| Drilling Head | |

| Morse Tapper in Spindle Nose | MT4 |

| Max. Spindle Travel (Drilling Depth) | 170 |

| Spindle Sleeve Diameter | 75 |

| No. of Spindle Speeds | 18 |

| Spindle Speed Range (RPM) | 40-2050 |

| No. of Power Feeds | 3 |

| Feed Range per Revolution | 0.08-0.02-0.04 |

| Lubrication | Lithium Grease |

| Working Range | |

| Distance From Column to Spindle | 850 |

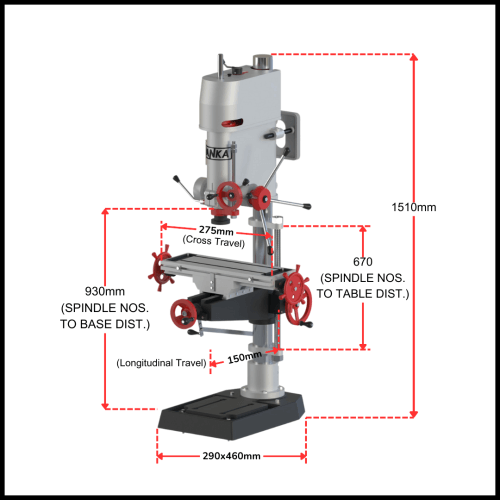

| Spindle Radius (Column to Spindle) | 930 |

| Spindle to Base Distance (Max./Min.) | 1260 |

| Column Diameter | 138 |

| Vertical Movement of Arm | 1000 |

| Vertical Movement Of Spindle | 200 |

| Working Surface of Base (L x W) | 870 x 685 |

| Working Surface of Table (L x W) | 350 x 280 |

| Width of “T” Slots | 11+2 |

| Drilling Motor (HP/RPM) | 1/ 1400-2/2800 |

| Shipping Dimension (L x W x H) | 1260 x 690 x 2125 |

| Weight of Machine Kg.(Approx) | 750 kgs. |

A Radial Drill Machine is designed primarily for drilling holes in large and heavy workpieces. Here are some key features and descriptions of an All Gear Radial Drill Machine:

-

Versatile Drilling Capability: These machines are capable of drilling holes of various sizes and depths due to their adjustable arm and spindle.

-

Adjustable Arm: The arm can be moved around the column, providing flexibility in positioning the drill over the workpiece. This makes it suitable for drilling multiple holes in different locations without repositioning the workpiece.

-

Heavy-Duty Construction: Typically made from robust materials like cast iron, these machines are capable of handling large and heavy workpieces with ease.

-

Powerful Motor: Equipped with a powerful motor, All Gear Radial Drill Machines can drill through tough materials such as metals efficiently.

-

Rotating Table: Some models come with a rotating table, allowing for angular drilling and precise positioning of the workpiece.

-

Automatic Feed: Many modern radial drill machines offer automatic feed settings, which can be adjusted for different drilling speeds and depths.

-

Safety Features: They are equipped with safety features such as emergency stop buttons and protective covers over the drilling mechanism.

These machines are widely used in industries such as manufacturing, construction, and metalworking, where precise and efficient drilling operations are required. They are essential for tasks like hole drilling, tapping, reaming, and countersinking in various types of materials.

FREE ACCESSORIES ALL GEAR DRILL MACHINES

- Arm lifting Wheel

- Grease Gun

- Drill Wedge

- 2 Speed Motor

- Lock Bolt Stick

- Spanner Set

- Eye Safty Glass

- Vibration Pads

- Oil Cane

- El. Penal Board

- Auto Feed Lever

- Apron

- Gasket Salak

- Machine Lamp

- lifting motor

- Working table (Box Table)

- T nut

- Hand Gloss

- Manual Book For Installation & Parts Details

We are here to Help you

1) What will be the warranty Period of this Drill Machine?

A: Generally Suppliers of the Drill machine are providing only one year warranty period in the Drill machine. And it is not the proper return according to your investment. While We are providing 3 years warranty in Gear, Guidway, spindle and Barrings. If there any parts damaged in your machine than we also provides free parts service in warranty period by fastest courier service.

2) How many types are there in the Drill Machine?

A: 1) All Gear Auto feed Radial Drill Machine

2) Back Geared Fine feed Radial Drill Machine

3) Back Geared Auto feed Radial Drill Machine

4) All geared Fine Feed Radial Drill Machine

5) Back Geared Fine Feed Pillar Drill Machine

3) How many popular models are there in the Drill Machine?

A : 65 mm Capacity All geared Auto feed Radial Drill Machine

50 mm Capacity All geared Auto feed Radial Drill Machine

40 mm Capacity All geared Auto feed Radial Drill Machine

40 mm Capacity All geared Fine feed Radial Drill Machine

40 mm Capacity Back geared Fine Feed Radial Drill Machine

40 mm Capacity All geared Auto feed Pillar Drill Machine

40 mm Capacity Back geared Autofeed Radial Drill Machine

38 mm Capacity All geared auto feed Radial Drill Machine

38 mm Capacity All geared auto feed Pillar Drill Machine

38 mm Capacity Back geared Fine feed Pillar Drill Machine

25 mm Capacity Back Geared Fine Feed Radial Drill Machine

25 mm Capacity Back Geared Fine Feed Pillar Drill machine

20 mm Capacity Back geared Pillar drill Machine

4) Which are the accessories I Should Buy with Drill Machine ?

A : Key Less Dill Chuck

Electrical Motors

Keyless Drill Chuck & Arbor

Drill Chuck & Arbor

Coolant Pump with Coolant Tank

Multi Spindle Drilling

Tapping Attachment

Tinteling Table

5) What are the confusions raised in the mind of customer at the time of purchasing Drill Machine ?

A: 1) Drilling Capacity requirement

2) Which type of drill is required?

6) Do you accept Domestic LC ?

A: Yes, accept domestic LC for 60 days on credit. Generally our 75 % customers are purchasing Machine from us with 60 days Credit through a Simple Process of LC. When the Seller is Unknown or New to the Buyer, Letter of Credit is one good Alternative to do the Business with Such New Seller Because Buyer can Avoid Risk by such Letter. Letter of Credit is one Additional Benefit to the Buyer by which they can protect Loss against Goods and Finance Also.The buyer can build safeguards into the letter of credit, including inspection of the goods and quality control, and set production and delivery times.

You may also like…

Cost Saving