Accessories for Lathe machines, Machine Shop Accessories, Tools & Instruments

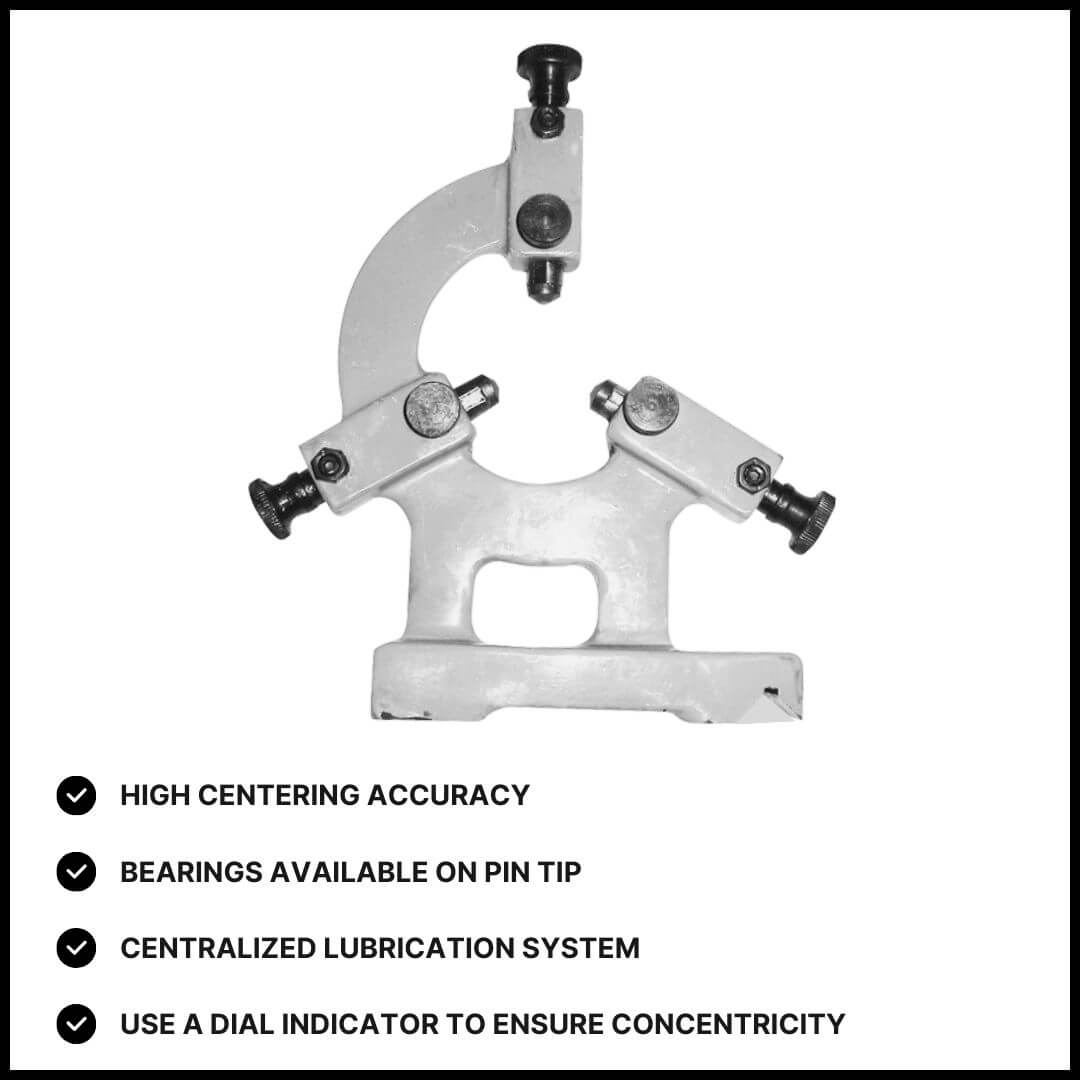

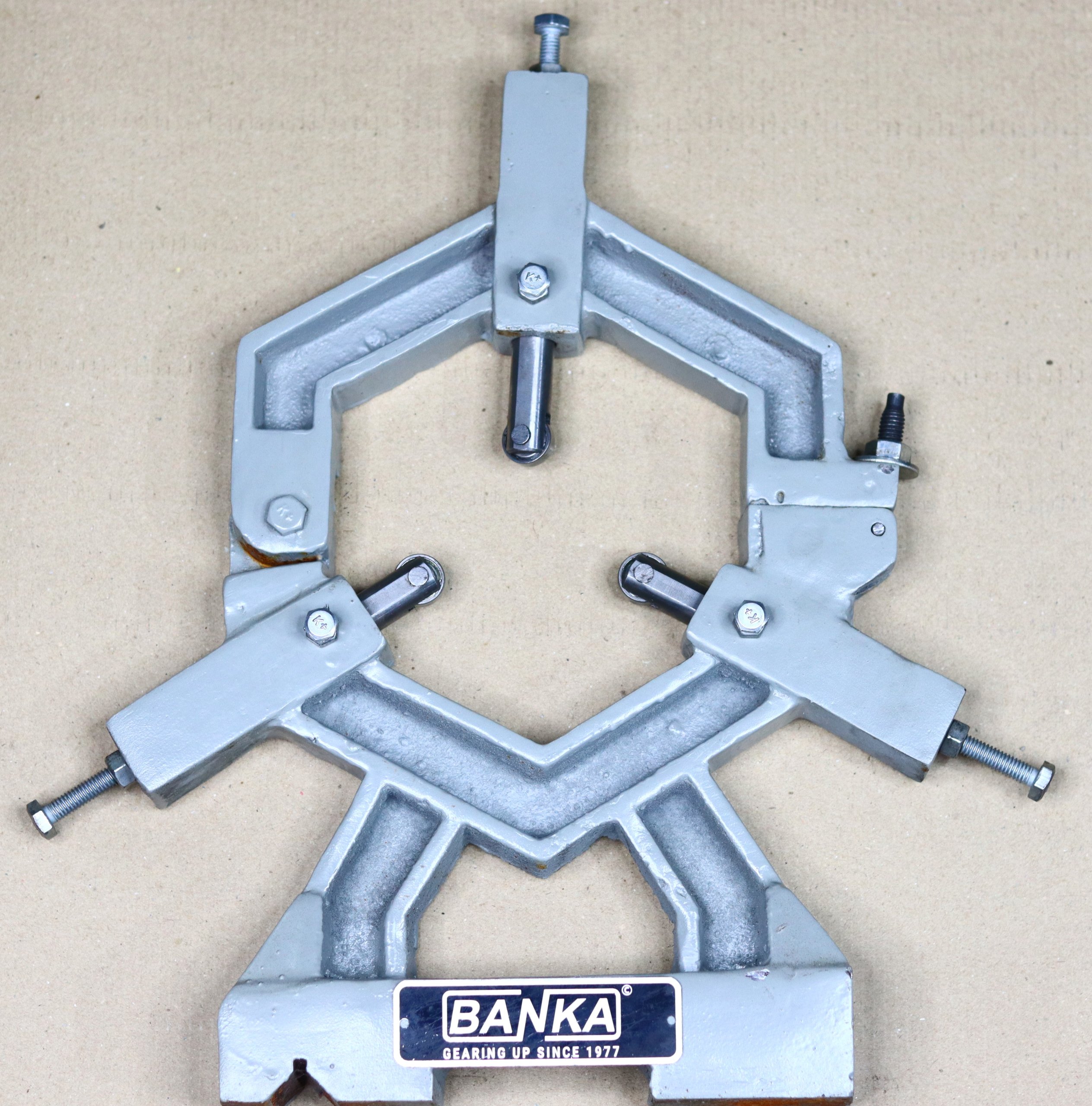

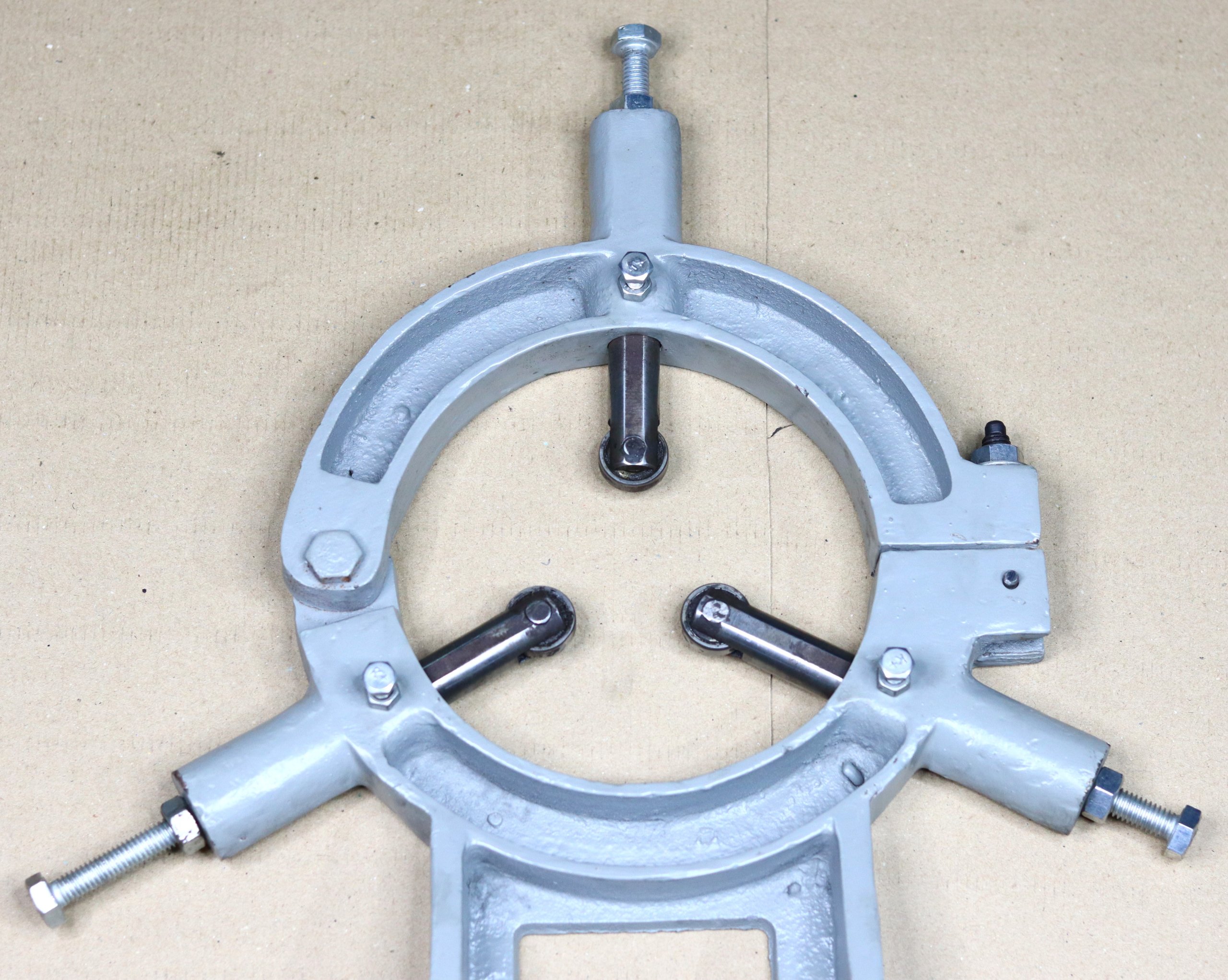

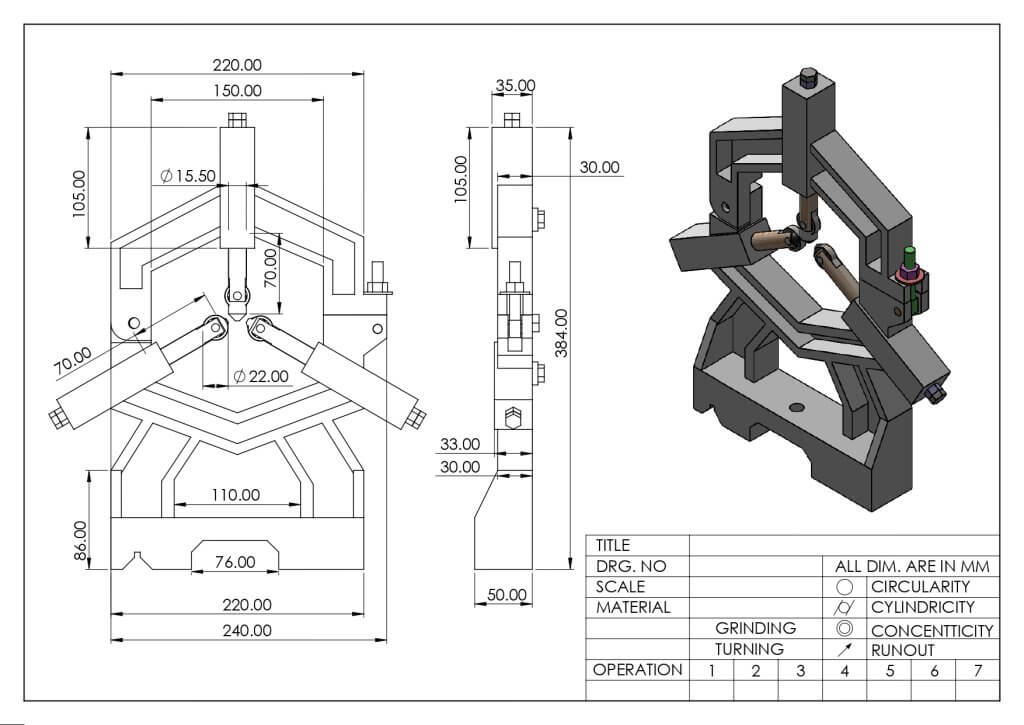

Steady Rest For Lathe

Tag: Popular Tools

₹3,200 Original price was: ₹3,200.₹2,800Current price is: ₹2,800.

– Makes Lengthy Job ‘Steady’ – Prevents unwanted movement of job – Bearings Available On Pin Tip. To setup the rest, first machine and polish the portion of the work that is to be used as the bearing surface. Clean the portion of the ways where the steady rest is to be mounted, place the steady rest on the ways and clamp loosely. Open the top of the steady rest and place the workpiece in the chuck with the bearing surface over the adjustable jaws. Clamp the steady rest securely to the ways. Close the top of the steady rest and adjust the jaws to the workpiece.

Weight: 10 Kg

Advantages of Stady Rest

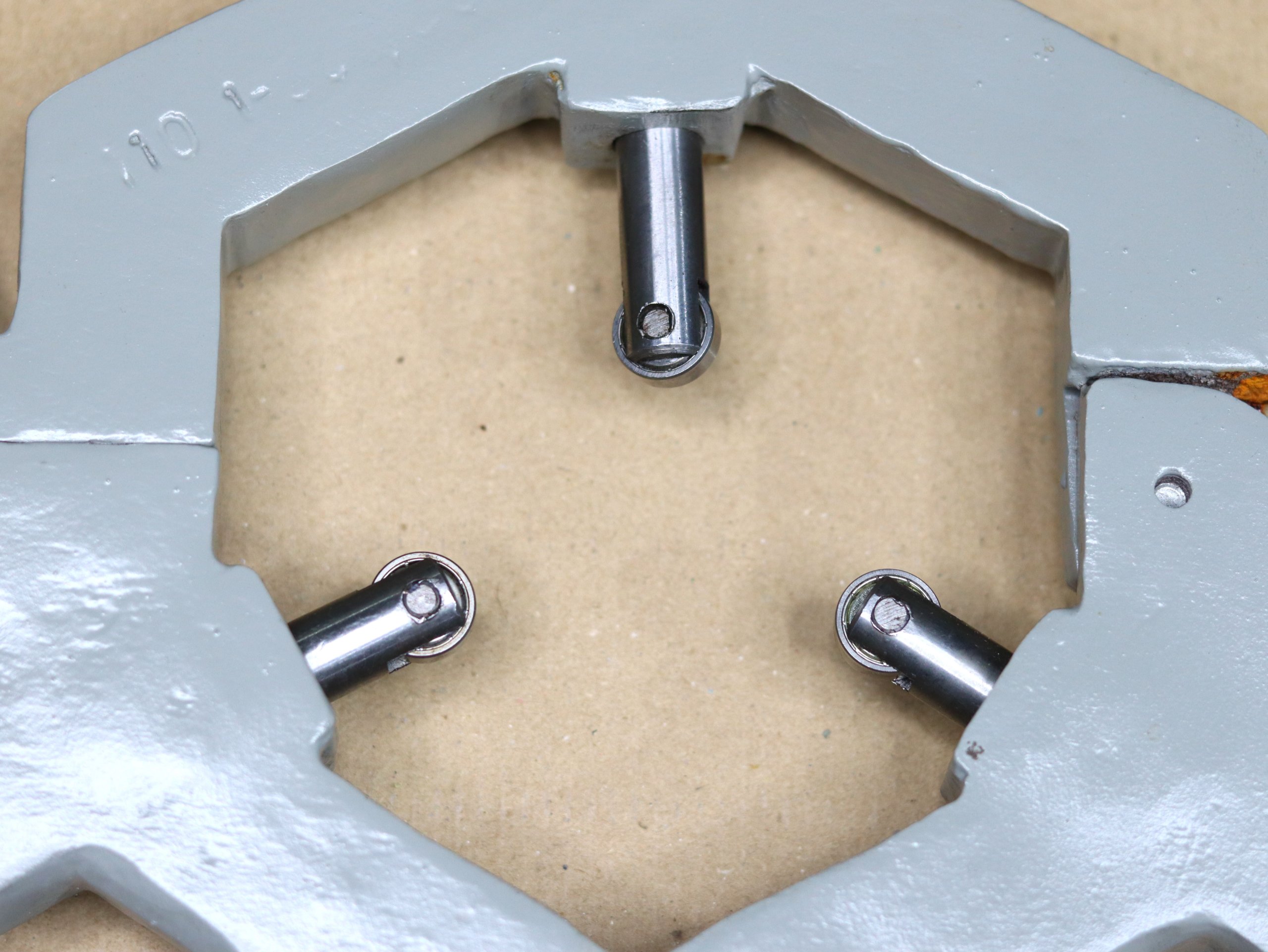

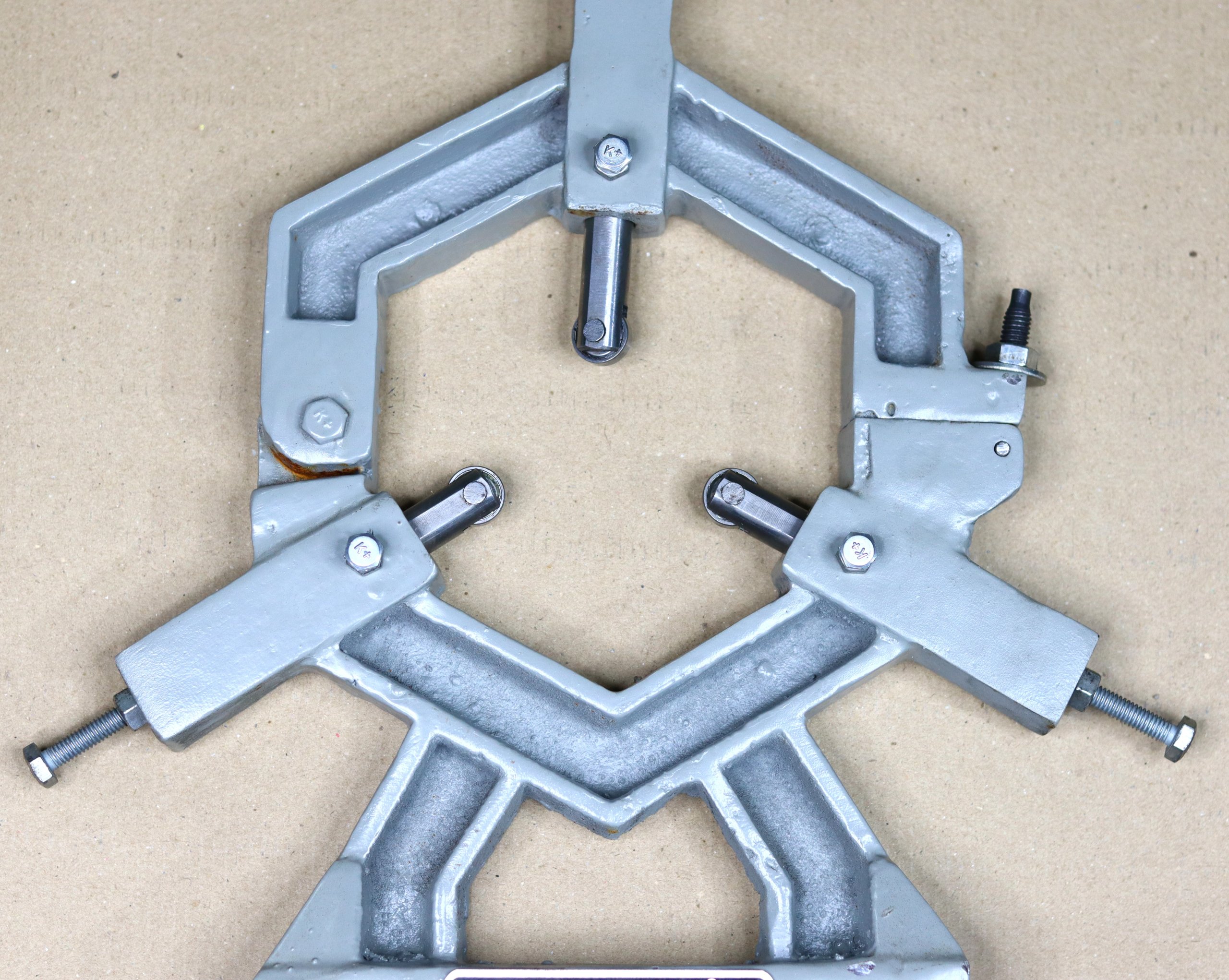

- The steady rest consists of a frame and three adjustable jaws which support the work, as shown One purpose of the steady rest is to prevent springing or deflection of slender, flexible work; another is to furnish auxiliary support for the work to permit heavy cuts to be made; a third is to support work for drilling, boring, or internal threading. The over arm containing the top jaw can be unfastened and swung out of the way so that identical pieces can be removed and replaced without adjusting the jaws.

- To setup the rest, first machine and polish the portion of the work that is to be used as the bearing surface. Clean the portion of the ways where the steady rest is to be mounted, place the steady rest on the ways and clamp loosely. Open the top of the steady rest and place the workpiece in the chuck with the bearing surface over the adjustable jaws. Clamp the steady rest securely to the ways. Close the top of the steady rest and adjust the jaws to the workpiece.

- There should be 0.001 inch clearance between the jaws and the workpiece. Tighten the locking screws on the adjustable jaws. Lubricate the bearing surface generously with a heavy oil before turning the lathe on. Proceed with the machining operation Continuously watch the bearing surface and the adjustable jaws to ensure a film of heavy oil is between them. As the machining operation continues, also check the bearing surface and adjustable jaws as when the workpiece heats up it will expand, closing the distance between the jaws and the workpiece.

- A bearing surface must be provided for the steady rest jaws. The bearing surface is usually machined directly on the work, as shownWhen the work is too small in diameter to machine the bearing surface or shaped so that it would be impractical to machine one, you can use a cathead to provide the bearing surface. The cathead, has a bearing you surface, a hole through, which the work extends, and adjusting screws. The adjusting screws fasten the cathead to the work. They are also used to align the bearing surface so can use a cathead to provide the bearing surface so that t is concentric to the work axis. Use a dial indicator to ensure concentricity.

To protect your job from over hanging while lengthy job turning.

- Automatic centering to reduce cycle time increased productivity.

- High centering accuracy.

- All standard steady rest have provision for centralized lubrication system

- Actuating cylinder is provided with integral safety valve ensure support of the work under sudden pressure drops.

- These are based on special cam design, which is proved in the field

- Adjustable 3 piece chip guard for outer rollers with minimum reduction of clamping range

- These steady rests can be mounted either on slant or flat bed lathes. Rigid and precisely made bracket ensure centering accuracy

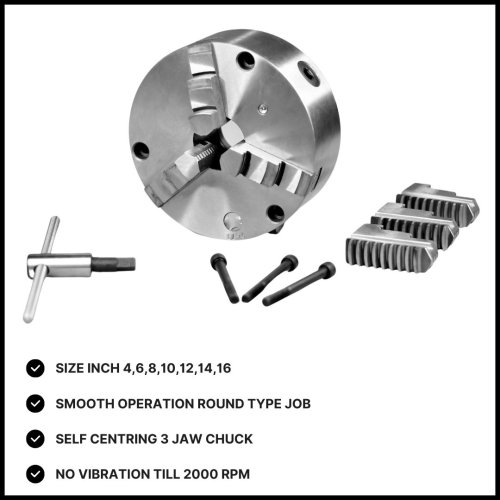

Related Products

Coolant Pump Fittings – Reduces your expense and save your time

Sale

Ready Stock