QUICK CHANGE CHUCKS & COLLET SPLIT SLEEVE

₹14,000

SIZE

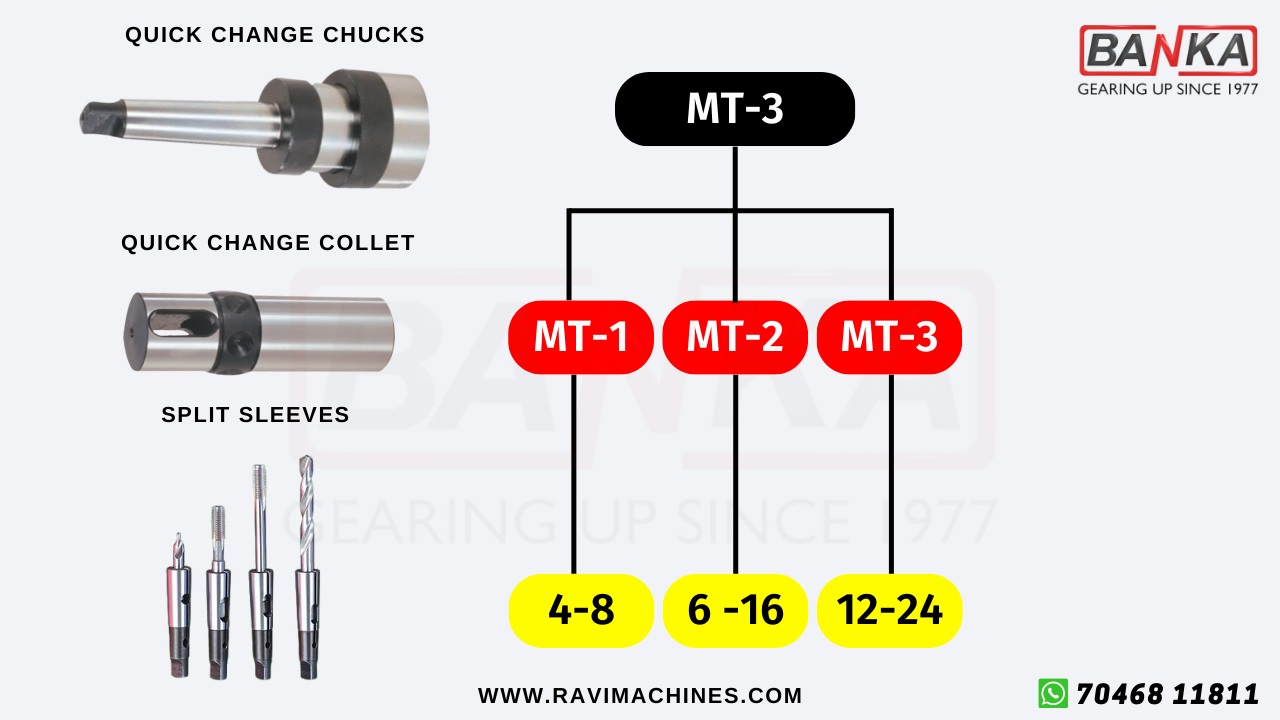

MT-3

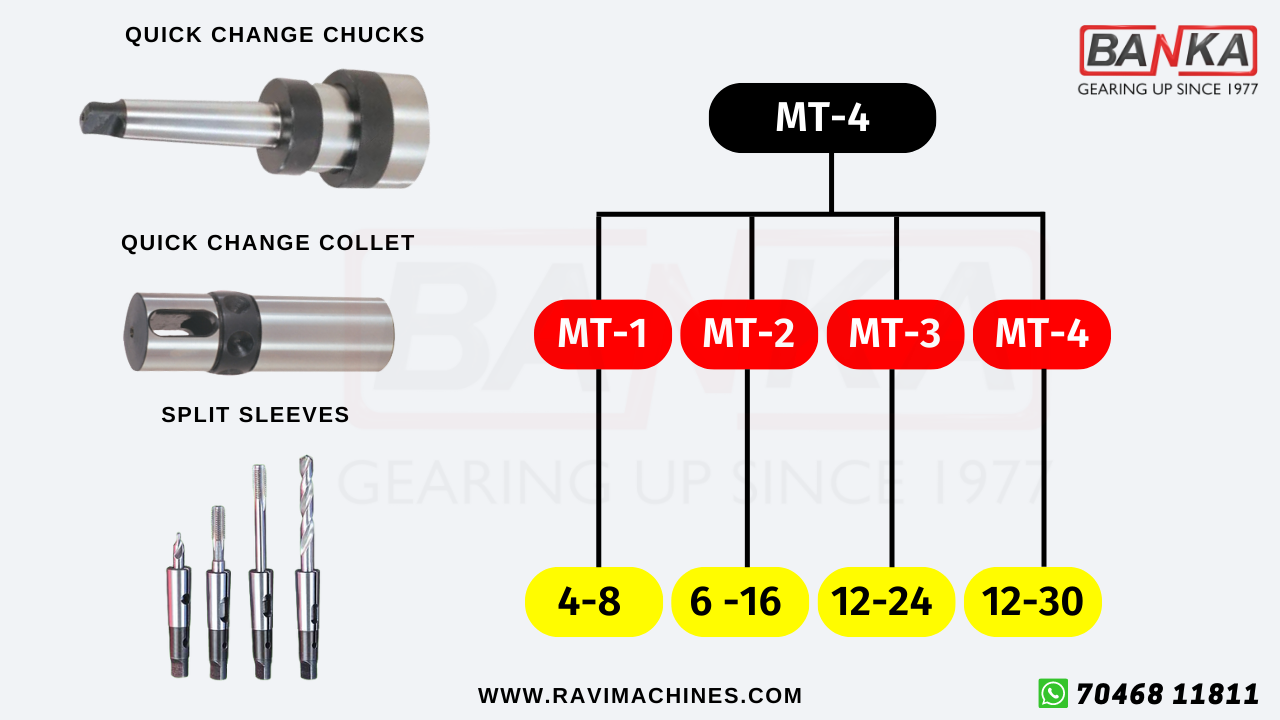

MT-4

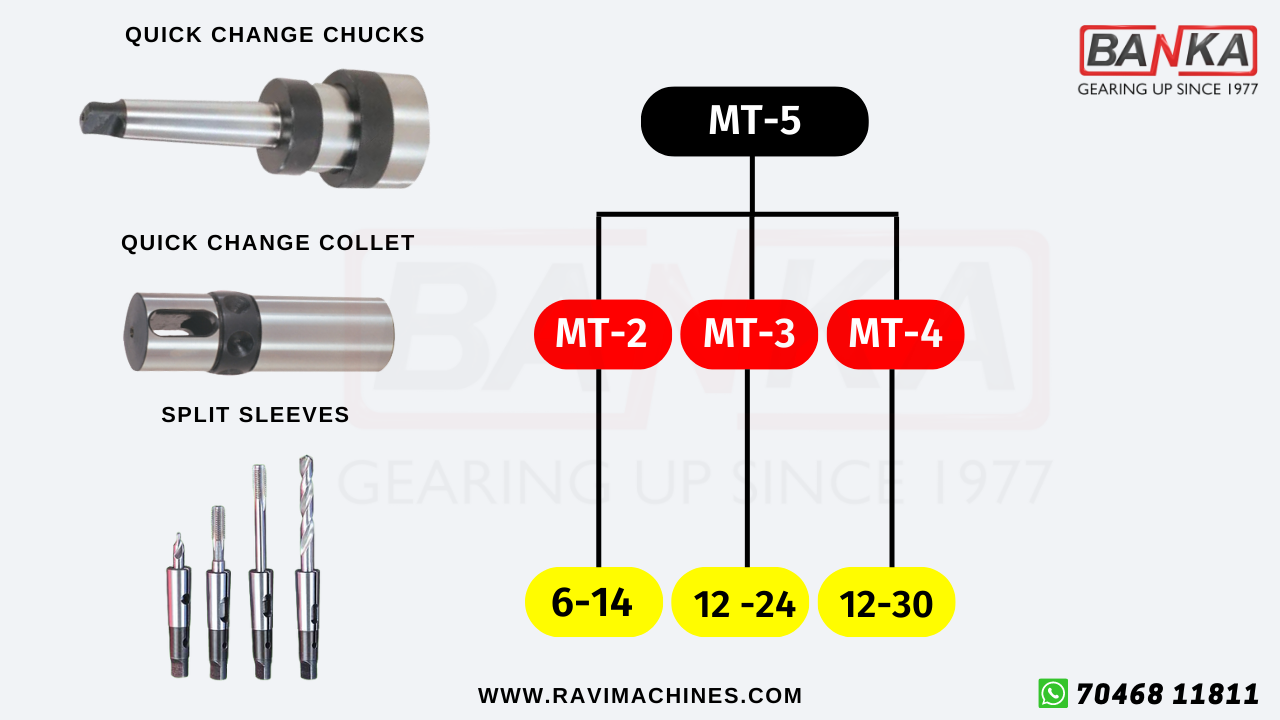

MT-5

Quick change chucks, collets, and split sleeves are important accessories used in machining and manufacturing processes. They offer efficiency, flexibility, and precision in securing workpieces and tooling on machine tools like lathes and milling machines. Here’s a breakdown of each:

Quick Change Chucks

Definition: Quick change chucks are mechanisms designed to rapidly change tools or work-holding devices on machine tools without the need for extensive manual adjustments.

Types:

- Quick Change Tool Holders: These allow for rapid tool changes on CNC machines or manual mills and lathes. They typically use a standardized interface such as HSK, BT, or CAT tapers for easy tool exchange.

- Quick Change Collet Chucks: These chucks use collets to grip and secure tools or workpieces quickly. They are often used in operations requiring frequent tool changes or where precise concentricity is critical.

Advantages:

- Time Savings: Reduce downtime associated with tool changes, thereby increasing productivity.

- Accuracy: Maintain consistent tool positioning and concentricity, crucial for achieving precise machining operations.

- Flexibility: Enable operators to switch between tools or work-holding setups efficiently, enhancing operational versatility.

Collets

Definition: Collets are specialized clamping devices used to hold tools or workpieces in place within a machine tool spindle or chuck.

Types:

- Spring Collets: Commonly used in milling machines and lathes, spring collets compress around the tool or workpiece to secure it firmly.

- ER Collets: A popular type of spring collet with a standard range of sizes, suitable for a variety of machining applications.

- Dead-Length Collets: Provide precise axial positioning without compressing, ideal for applications where repeatability and accuracy are critical.

Applications:

- Tool Holding: Secure cutting tools such as drills, end mills, and reamers in milling machines and CNC machining centres.

- Workpiece Clamping: Grip workpieces in lathe spindles for turning, facing, and other operations.

Split Sleeves

Definition: Split sleeves, also known as split bushings or split collets, are used to adapt smaller-diameter tools or workpieces to fit into larger-diameter collets or chucks.

Functionality:

- Adaptability: Allow tools or workpieces with different diameters to be clamped securely within a chuck or collet.

- Precision: Ensure concentricity and accuracy when holding smaller components within larger collets or chucks.

Related Products

Key Way Attachment On Lathe