Accessories for Milling machines, Machine Shop Accessories, Tools & Instruments

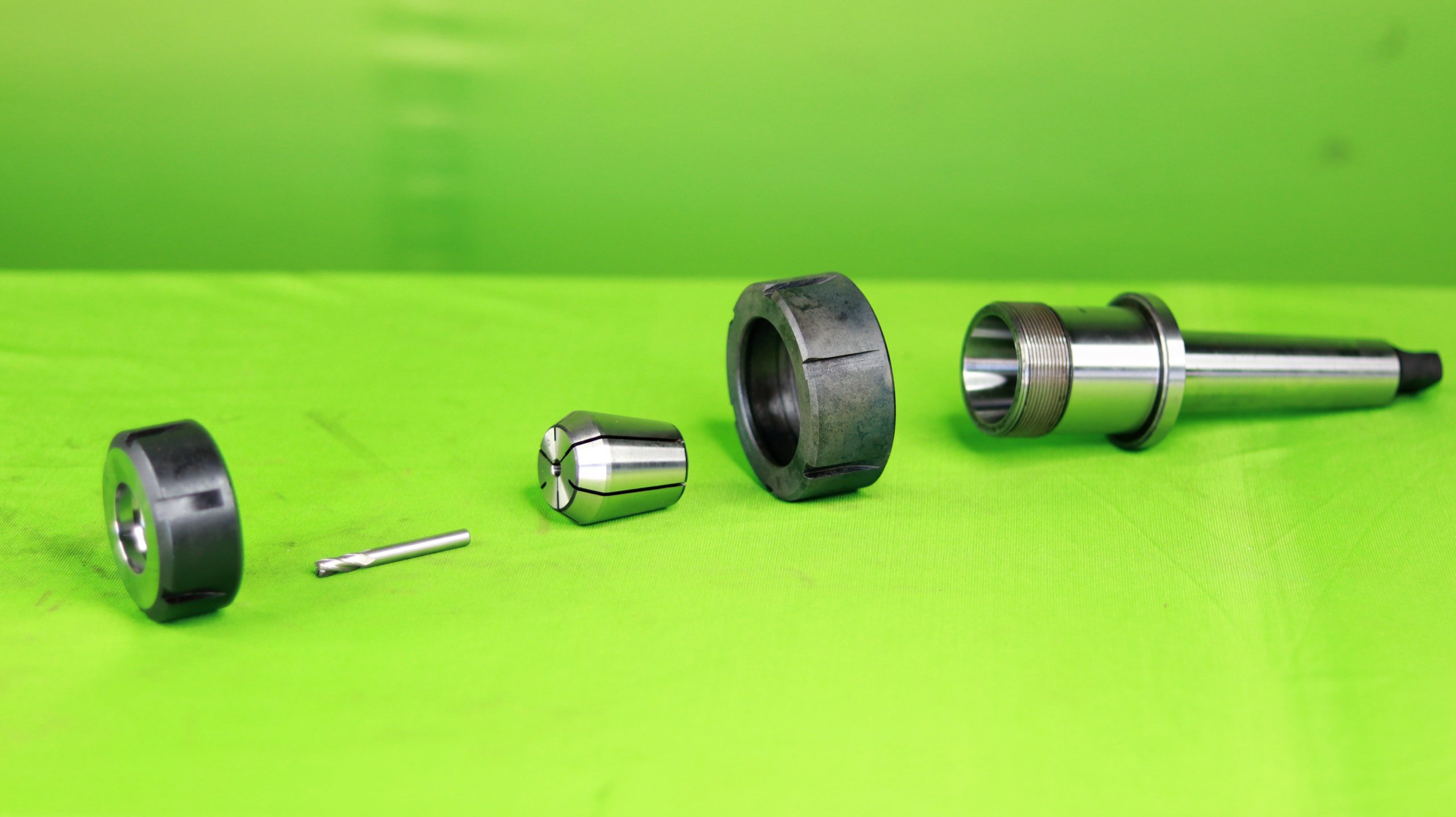

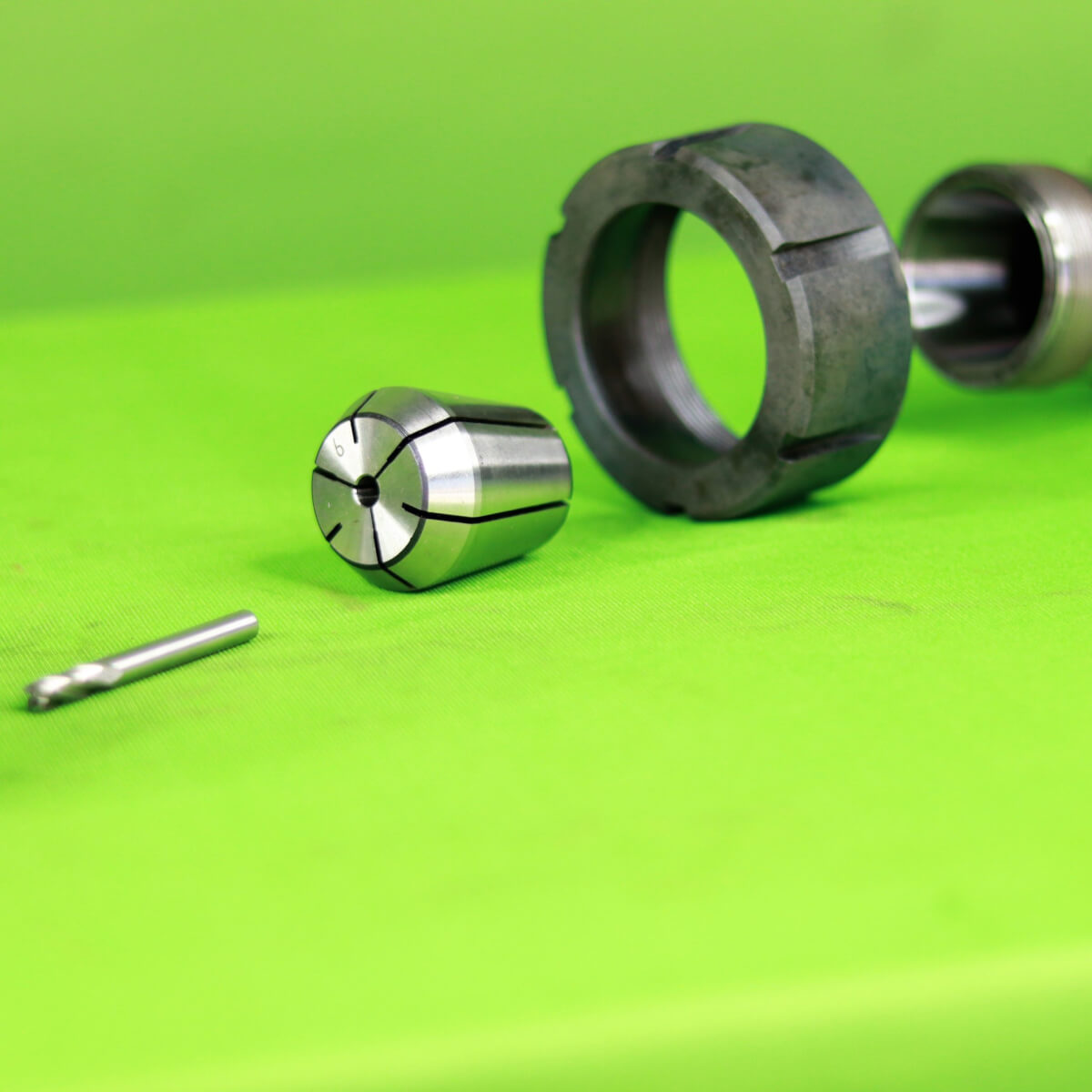

Milling Drilling MT-4 Collect Adopter E Type Collect

Tag: Popular

₹2,650 Original price was: ₹2,650.₹2,350Current price is: ₹2,350.

- Morse Taper Collect Adoptor E

- Made from 16mnCr5, case hardened to 55-58 HRC.

- Precision ground to an accuracy of 0.15 mm TIR.

- Quality spring steel EN-47

- MT-2 M-10 (Draw Bolt Type) E-40 /MT-6 (Tang Type With Cotter Slot) E-45

- Colour – Silver

When dealing with a milling/drilling machine that uses an MT-4 (Morse Taper #4) spindle and requires an E type collet, you will need a collet adapter that facilitates the use of E type collets with an MT-4 spindle. Here’s a comprehensive guide on how to handle this setup:

Understanding MT-4 and E Type Collets

- MT-4 (Morse Taper #4): A Morse taper is a standard taper shank used in machine tools. The MT-4 taper is one of the larger sizes and is commonly used in larger machines like certain milling and drilling machines.

- E Type Collets: These are precision collets used for holding tools and workpieces. They have a specific design for high accuracy.

What is a MT-4 Collet Adapter for E Type Collets?

A MT-4 collet adapter is a device that allows you to use E type collets with a milling or drilling machine that has an MT-4 spindle. The adapter fits into the MT-4 taper of the machine spindle and provides a collet holder compatible with E type collets.

Features of the Adapter

- Material: Typically made from high-strength steel or tool steel to handle machining forces.

- Precision: Should be manufactured with high precision to ensure accurate tool holding.

- Fit: Must securely fit into the MT-4 spindle and hold the E type collet firmly.

How to Use the MT-4 Collet Adapter

- Insert the Adapter:

- Slide the MT-4 collet adapter into the MT-4 spindle of your milling or drilling machine. Ensure it is seated properly and firmly.

- Install the E Type Collet:

- Place the E type collet into the adapter. The collet should fit snugly within the adapter.

- Secure the Collet:

- Tighten the collet using the appropriate method provided with the adapter. This might involve a drawbar or a collet nut, depending on the adapter design.

- Insert the Tool:

- Place the tool or workpiece into the collet and secure it by tightening the collet.

Choosing the Right Adapter

When selecting a collet adapter for your MT-4 spindle and E type collets, consider the following:

- Compatibility: Ensure the adapter is specifically designed for MT-4 spindles and E type collets.

- Quality: Opt for a high-quality adapter to maintain accuracy and durability.

- Precision: Check the tolerance and precision of the adapter to ensure it meets your machining needs.

Maintenance

- Regular Inspection: Check the adapter for wear, damage, or contamination. Replace it if necessary.

- Cleaning: Keep the adapter clean and free of debris to ensure smooth operation and accurate performance.

Related Products

Sale

Efficient

Lathe Revolving Center

Sale

Best Seller