Accessories for Lathe machines, Machine Shop Accessories, Tools & Instruments

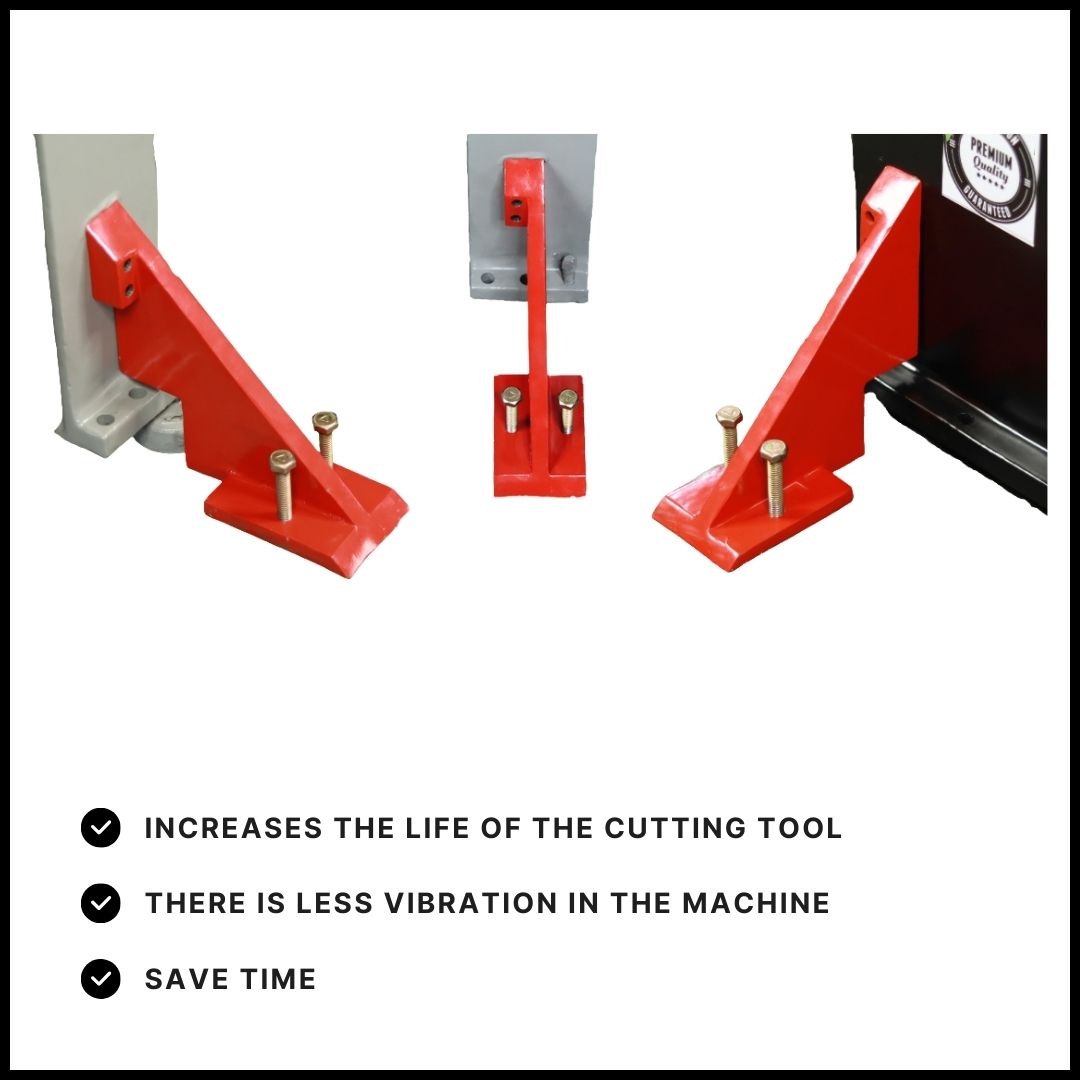

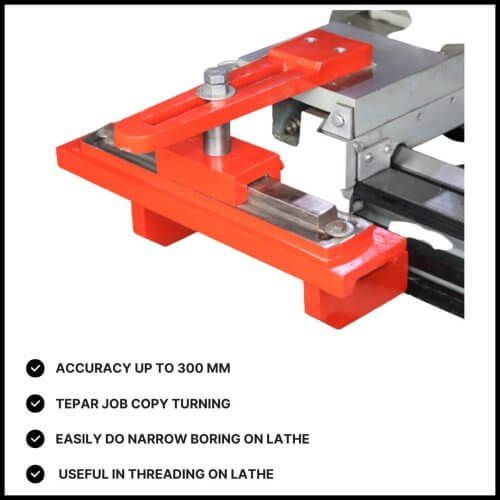

Lathe Vibration Support – 4 Pcs. Set

₹3,500

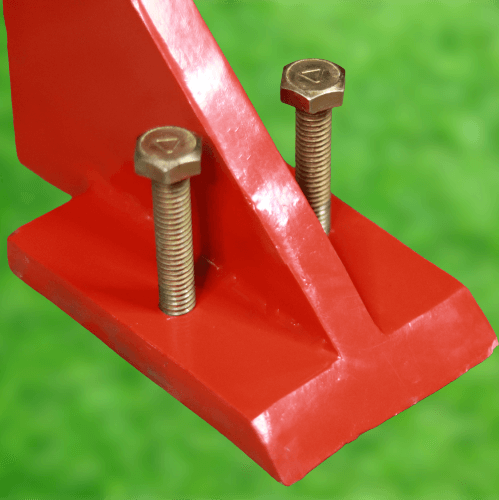

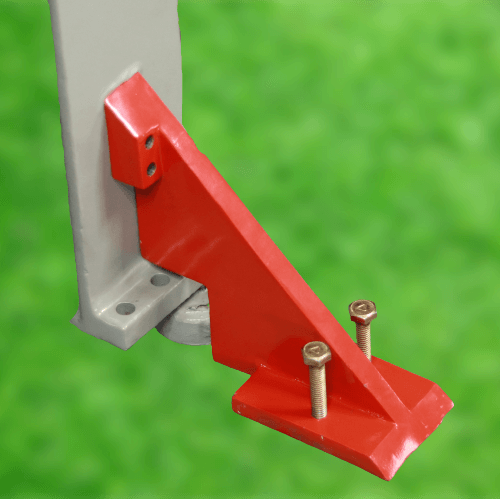

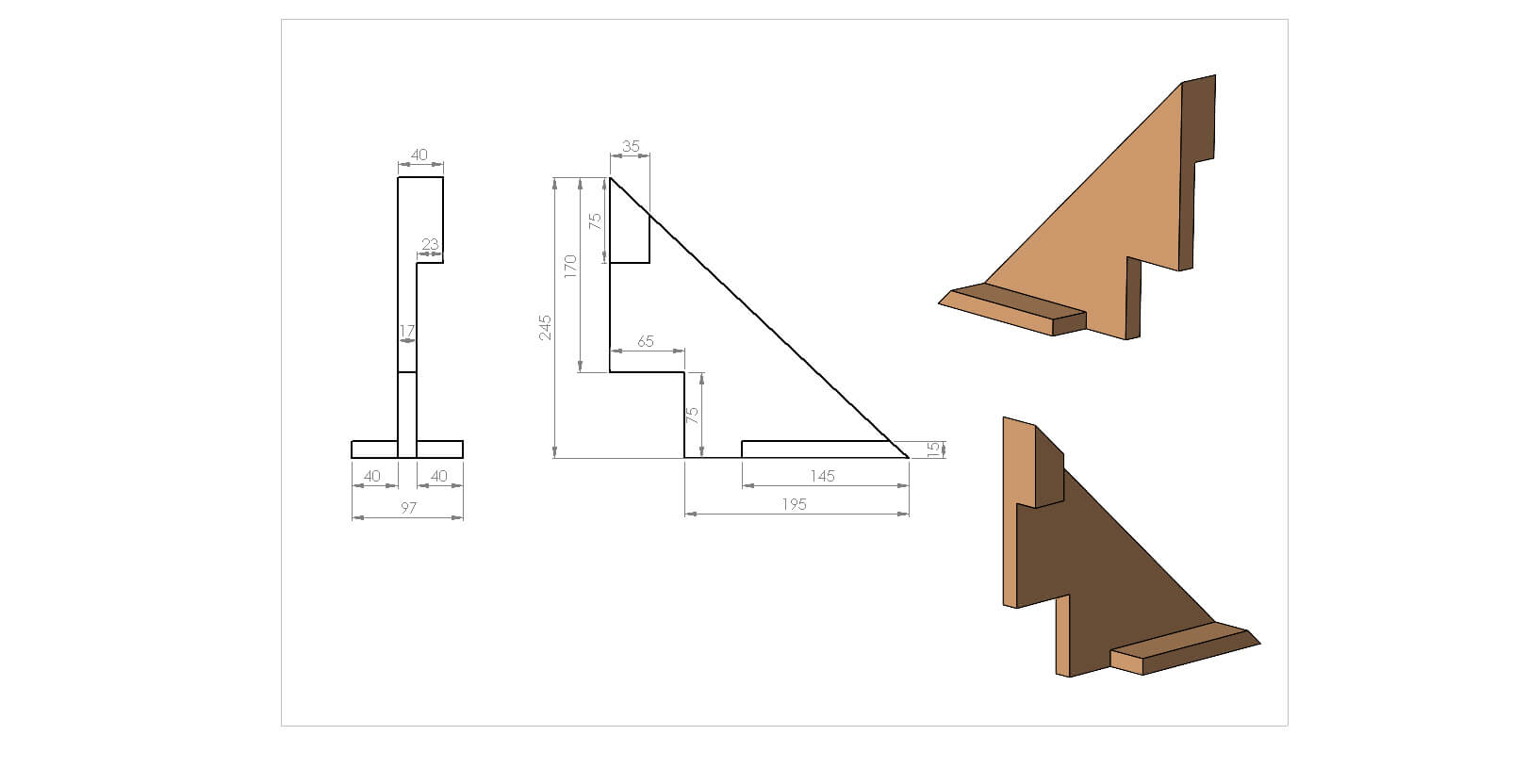

- Lathe Vibration support is essential while turning an eccentric job.

- It was made from a Cast Iron Material and fitted on a Machine base.

- Must buy 4 piece lathe vibration support to improve your production speed.

- Buy lathe vibration support to reduce your production cycle.

- Useful while dog chuck used on a lathe.

- Useful while high-speed turning on the lathe.

- Save time while turning on a lathe

- Increase production on the lathe.

Lathe vibration support is essential for achieving high precision and quality in machining operations. Vibration can cause several problems, including poor surface finish, dimensional inaccuracies, and reduced tool life. Here’s a brief overview of how vibration support can be used effectively:

Types of Vibration Support for Lathes

- Anti-Vibration Mounts:

- Purpose: These are often used to isolate the lathe from external vibrations that might be transmitted through the floor or workbench.

- Features: Made from materials like rubber or polymer composites that absorb and dissipate vibrations.

- Tool Holders and Inserts:

- Purpose: High-quality tool holders and inserts can reduce vibrations at the cutting edge.

- Features: Designed to maintain rigidity and reduce the effects of tool deflection.

- Lathe Stands and Bases:

- Purpose: A sturdy and stable base helps in reducing vibrations by providing a solid foundation.

- Features: Can be made from heavy materials like cast iron, which helps dampen vibrations.

- Vibration Damping Systems:

- Purpose: Advanced systems can be installed on the lathe to actively counteract vibrations.

- Features: These might include dynamic dampers or tuned mass dampers.

- Workpiece and Tool Setup:

- Purpose: Proper setup of workpieces and tools can reduce vibrations caused by imbalance.

- Features: Balancing workpieces and ensuring proper tool alignment and clamping can significantly reduce vibration.

- Machine Maintenance:

- Purpose: Regular maintenance can prevent issues that might lead to increased vibrations.

- Features: Includes checking for wear and tear on bearings, ensuring proper lubrication, and tightening loose components.

Practical Tips for Using Vibration Support

- Ensure Proper Installation: Follow the manufacturer’s guidelines for installing anti-vibration mounts and damping systems. Improper installation can lead to ineffective vibration control.

- Regular Maintenance Checks: Frequently inspect the lathe and its supports for wear and damage. Replace components as needed to maintain optimal performance.

- Balance Workpieces and Tools: Before starting a machining operation, ensure that workpieces and tools are properly balanced and securely mounted.

- Monitor Vibration Levels: If possible, use vibration sensors to monitor the levels of vibration during operation. This data can help in adjusting settings or making modifications to reduce vibrations.

- Optimize Machining Parameters: Adjust cutting speeds, feeds, and depths to minimize vibrations. Experiment with different parameters to find the optimal settings for your specific operations.