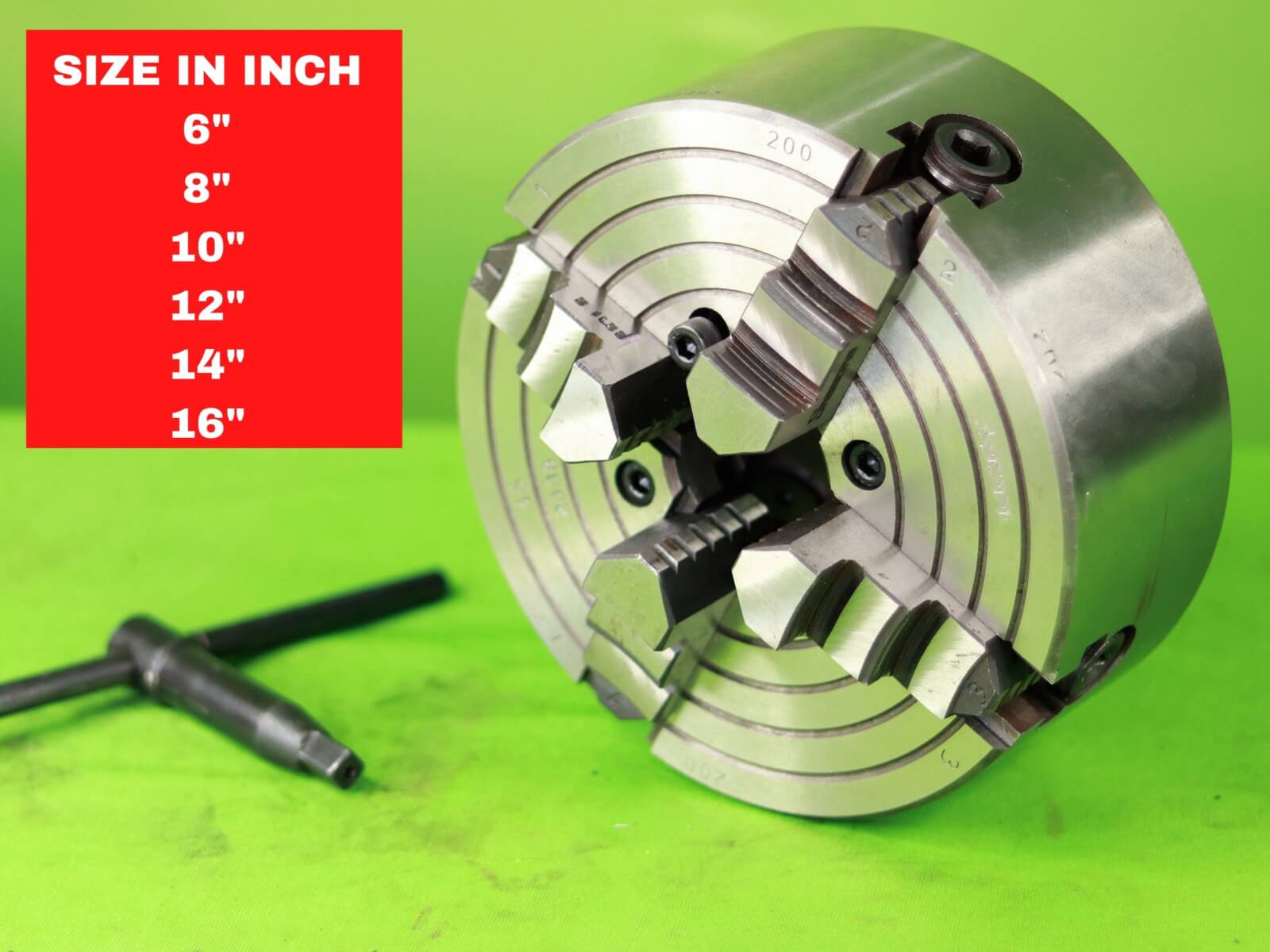

Lathe Dog Chuck

₹9,500 Original price was: ₹9,500.₹9,200Current price is: ₹9,200.

- Lathe with an independent-jaw chuck, each jaw can be moved independently.

- Because they most often have four jaws, the term four-jaw chuck without other qualifications is understood by machinists to mean a chuck with four independent jaws.

- The independence of the jaws makes these chucks ideal for (a) gripping non-circular cross sections and (b) gripping circular cross-sections with extreme precision (when the last few hundredths of a millimeter [or thousandths of an inch] of runout must be manually eliminated).

A four-jaw chuck has independently adjustable jaws. It can be used to centre parts that are not round. All jaws are adjusted according to part and the part is verified to be on center.

A chuck is a specialized type of clamp used to hold an object, usually an object with especially an object. It is most commonly used to hold a rotating tool (such as the in or a rotating workpiece (such as the bar or blank in the headstock spindle of a lathe). Some chucks can also hold irregularly shaped objects (ones that lack radial symmetry). In some applications, the tool or workpiece being held by the chuck remains stationary while another tool or workpiece rotates (for example, a drill bit in the tailstock spindle of a lathe, or a round workpiece being

A spider is a simple, relatively inexpensive, limited-capability version of an independent-jaw chuck. It typically consists of a ring of metal with screw threads tapped radially into it, in which screws (hex cap, socket hex cap, or set screws) serve as independent jaws.

Advantages of a 4-jaw:

- We can do high-precision work.

- We can handle or turn square/rectangular bar. in it.

- We can have slightly more grip on the round stock work bar.

- We can hold irregularly shaped parts with this chuck.

- By Dial Indicator we can use to center part with an accuracy.

- It can be used to deliberately hold a part off-centre.

It is also known as independent Jaw Chuck, It is useful to hold Square type job.

- Weight : 16Kg etc…

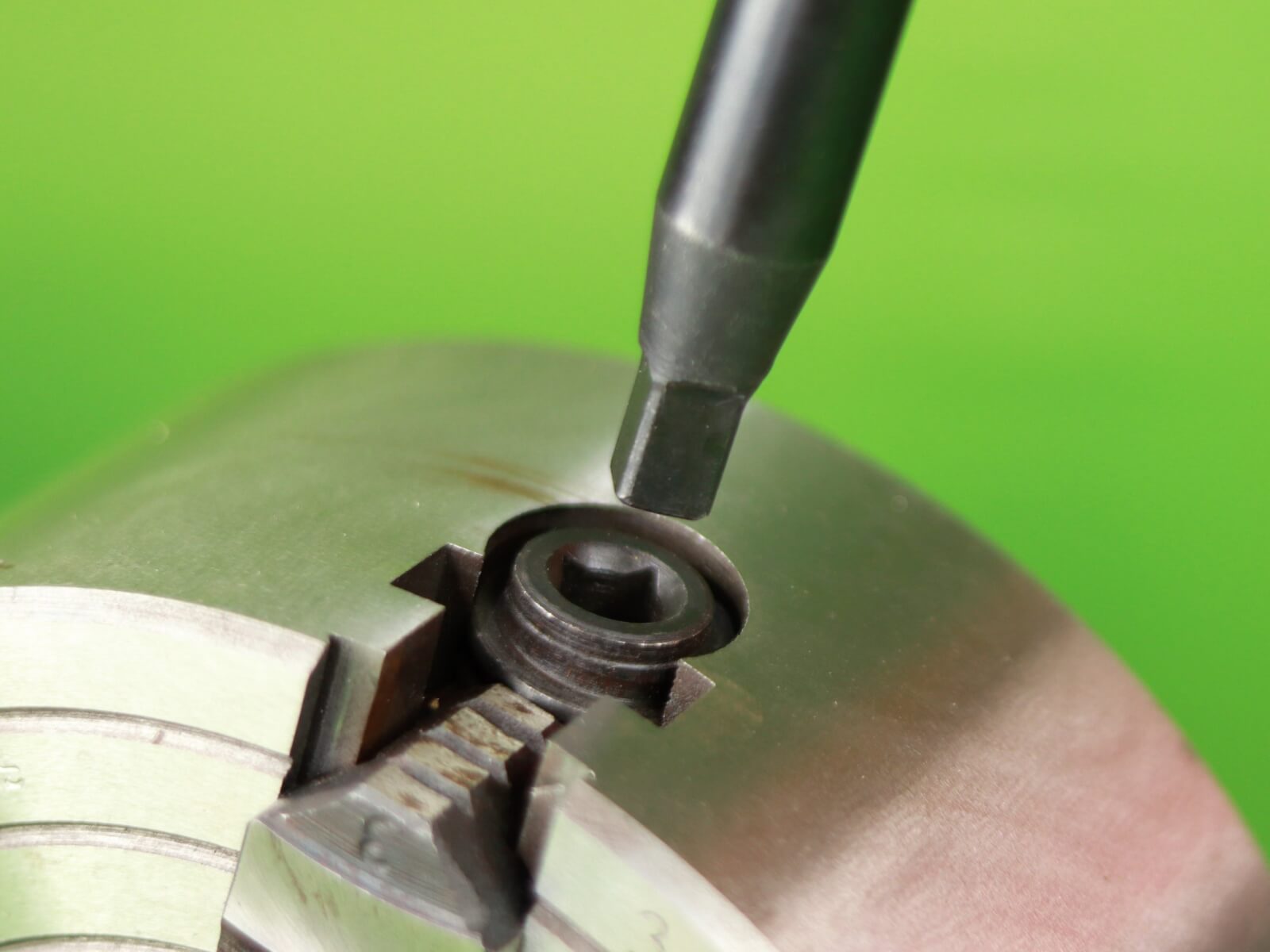

- Smooth Operation

- Superior GRIP

- Piece to Piece Replacement Guarantee

- Independent Jaw Chuck

- Square/Angular Type Job

Spiders can serve various purposes:

- As auxiliary features that complement the main lathe chuck:

- To hold the bar or workpiece at the back end of the spindle bore and support it concentrically, so that it resists wobbling or whipping while the spindle is turning. Gun barrels and oil pipes are examples of workpieces that benefit.

- To hold the bar or workpiece at the tailstock end (thus serving as a steady rest) or following the tool (thus serving as a follower rest).

- In place of the main lathe chuck (for particular workpieces that can benefit—for example, in some gunsmithing work)

- On an independent-jaw chuck, each jaw can be moved independently. Because they most often have four jaws, the term four-jaw chuck without other qualifications is understood by machinists to mean a chuck with four independent jaws. The independence of the jaws makes these chucks ideal for (a) gripping non-circular cross sections and (b) gripping circular cross sections with extreme precision (when the last few hundredths of a millimetre [or thousandths of an inch] of runout must be manually eliminated). The non-self-centring action of the independent jaws makes centring highly controllable (for an experienced user) but at the expense of speed and ease. Four-jaw chucks are almost never used for tool holding. Four-jaw chucks can be found on lathes and indexing heads.

- Self-centring chucks with four jaws also can be obtained. Although these are often said to suffer from two disadvantages: inability to hold hex stock, and poor gripping on stock which is oval, only the latter is true. Even with three jaw self-centring chucks, work that is not of a uniform section along the work (and which is not free of spiral or ‘wind’)should not be gripped, as the jaws can be strained and the accuracy permanently impaired.

- Four-jaw chucks can easily hold a workpiece eccentrically if eccentric features need to be machined

| Accessory | Suitable Model |

| Lathe Dog Chuck 8″ | 34, 35 |

| Lathe Dog Chuck 10″ | 40, 43, 50, 60 |

| Lathe Dog Chuck 12” | 50, 60 |

| Lathe Dog Chuck 14” | 60 |

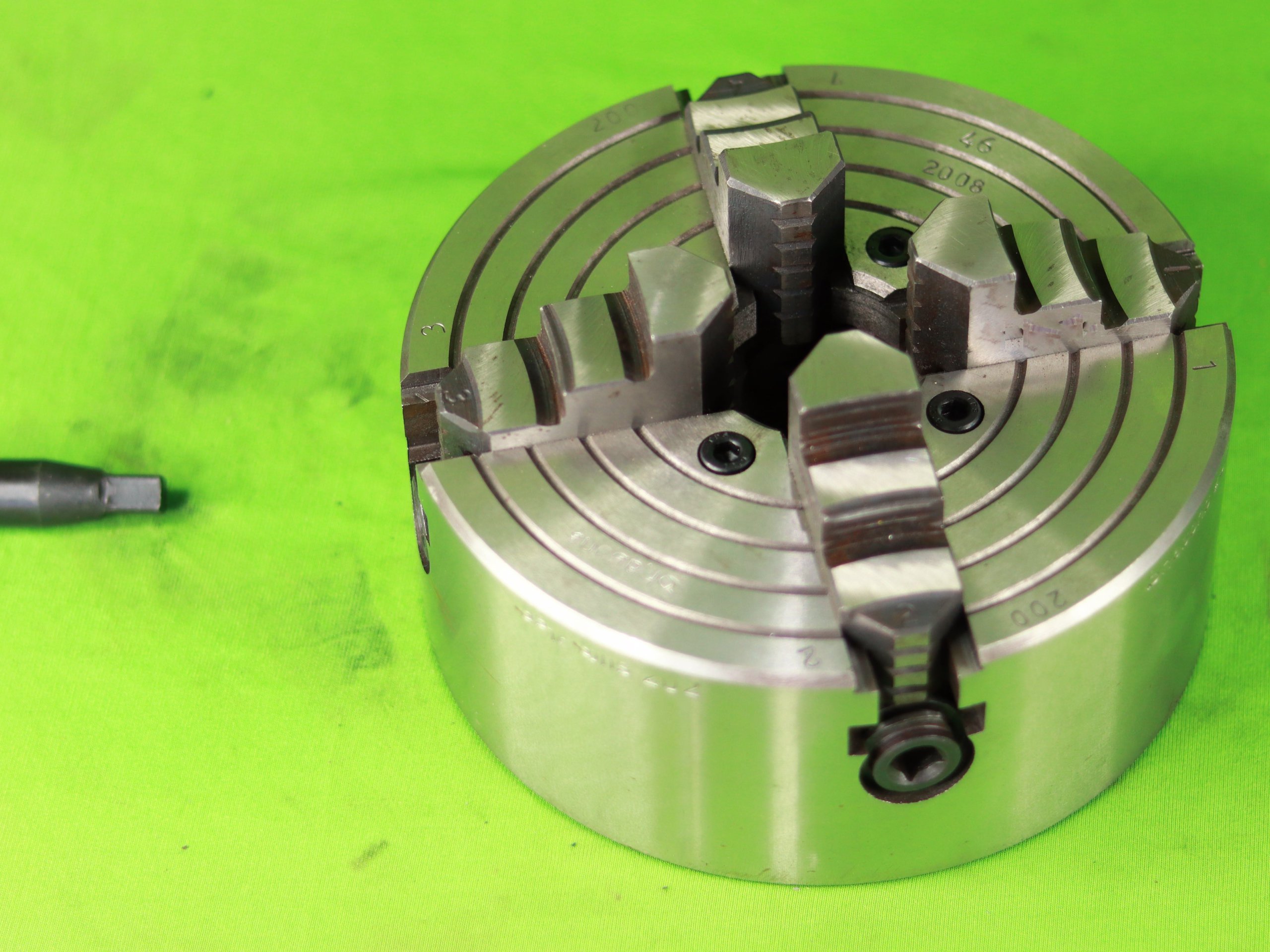

TECHNICAL SPECIFICATION :

| Size | Body OD | BH | PCD | CH | ID | JW | SQH |

| 160 MM | 160 | 70 | 140 | 40 | 125 | 24 | 8 |

| 200 MM | 200 | 84 | 80 | 50 | 95 | 29 | 10 |

| 250 MM | 250 | 84 | 105 | 60 | 125 | 29 | 10 |

| 305 MM | 305 | 94 | 130 | 80 | 160 | 34 | 12 |

| 350 MM | 350 | 94 | 130 | 80 | 160 | 34 | 12 |

| 400 MM | 400 | 103 | 170 | 100 | 200 | 40 | 14 |

| 450 MM | 450 | 103 | 170 | 100 | 200 | 40 | 14 |

4-inch, 4-jaw independent lathe chuck for square or octagonal work:

- The through the bore of this chuck is 20 mm (0.79″).

- The chuck can hold work up to 80 mm (3.15″) in diameter.

- The radial run out of a test bar held in this chuck, when the chuck is mounted true, is 0.004″ maximum

We are here to help you

Q1:What is Dog Chuck?

A: Dog chuck is also called an independent chuck.

Q2:How is the dog chuck operated?

A: Dog chuck is a manual head-operated chuck.

Q3:How many jaws are there in a dog chuck?

A: Dog chuck has 4 jaws and they are independent.

Q4:Dog chuck is used in which machine?

A: Dog chuck is used in lathe machines.

Q5:What is the size of the dog chuck?

A: Size of the dog chuck from 6 inches to 30 inches is available in regular.

Q6:How many slots are in dog chuck?

A: Dog chucks come in two types, single-slot, and double slot.

Q7:What is the difference between a single slot and a double slot in a dog chuck?

A: The difference between a single slot and a double slot in dog chuck is that one is the price and the other double slot has more power than a single slot chuck.

Q8:What material is a dog chuck made of?

A: Dog chuck body is made from alloyed high-strength cast iron.

Q9:How to pack dog chuck?

A: Packing of dog chuck in a carton box and wooden box.

Q10:In how many days do dog chuck dispatch after payment?

A: Dog chuck is dispatched within 2 days after payment is done.

Q11:What to do if the dog chuck doesn’t work properly?

A: If dog chuck doesn’t work well then you can return us within 7 days.

Q12:Why should anyone buy a chuck from Banka Machine?

A: Any chuck should be bought from Banka Machine because Banka checks all the chucks and gives them to you after buying them from the right manufacturer.