Bandsaw Machines

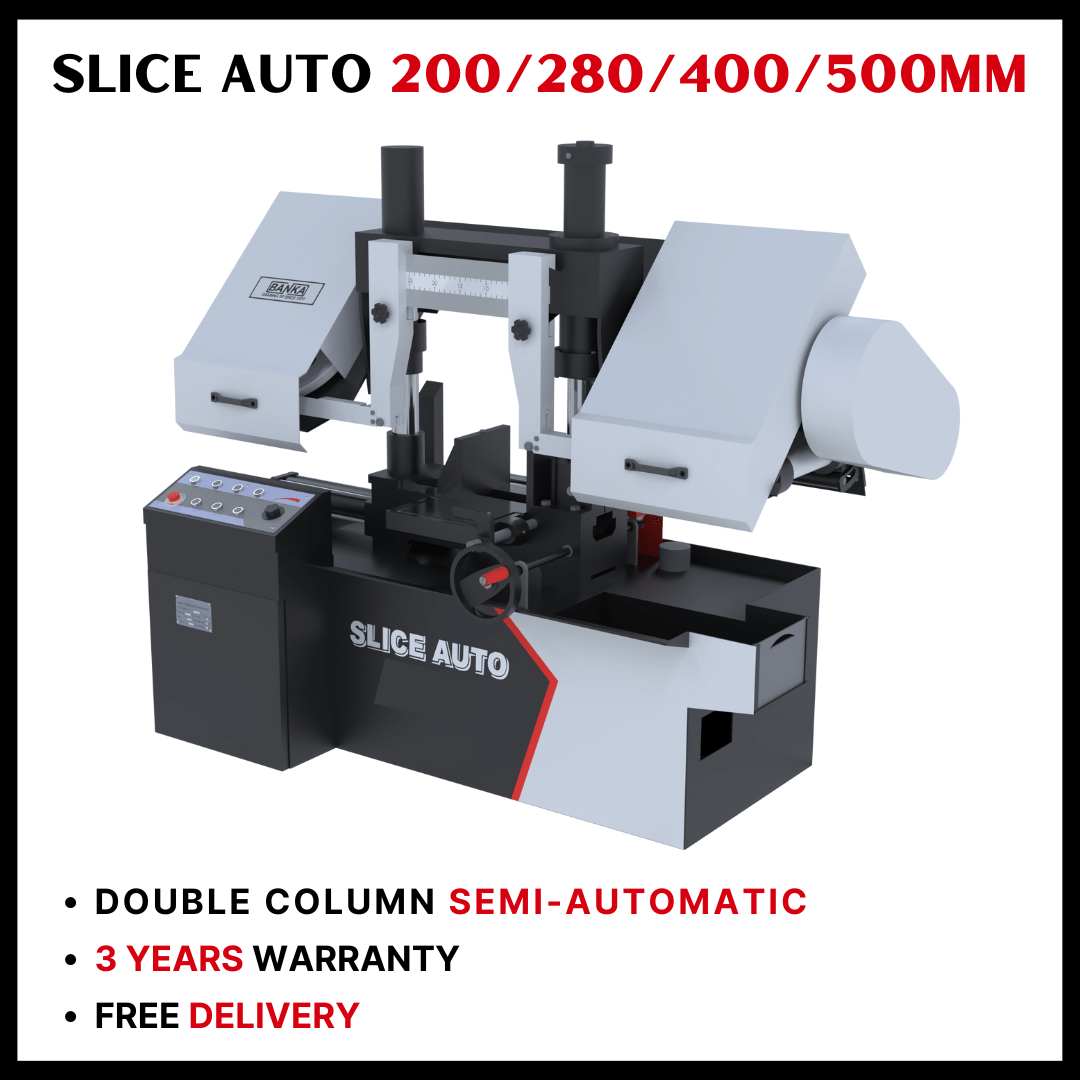

Bandsaw Machine Double Column Semi Automatic – Slice Auto 200MM To 500MM

₹2,65,000

- Cutting Capacity Round: 200 mm

- Cutting Capacity square: 200×200 mm

- Blade size: 2800X27X0.9 mm

- Clamping Type: Hydraulic

- Hydraulic Motor Power: 2HP

- Power Supply : 3 PHASE

- Check The specifications with Other Models (280 MM, 350 MM, 400MM, 500MM)

SALIENT FETURES :

- Stress-Relieved Fabrication Steel Structure.

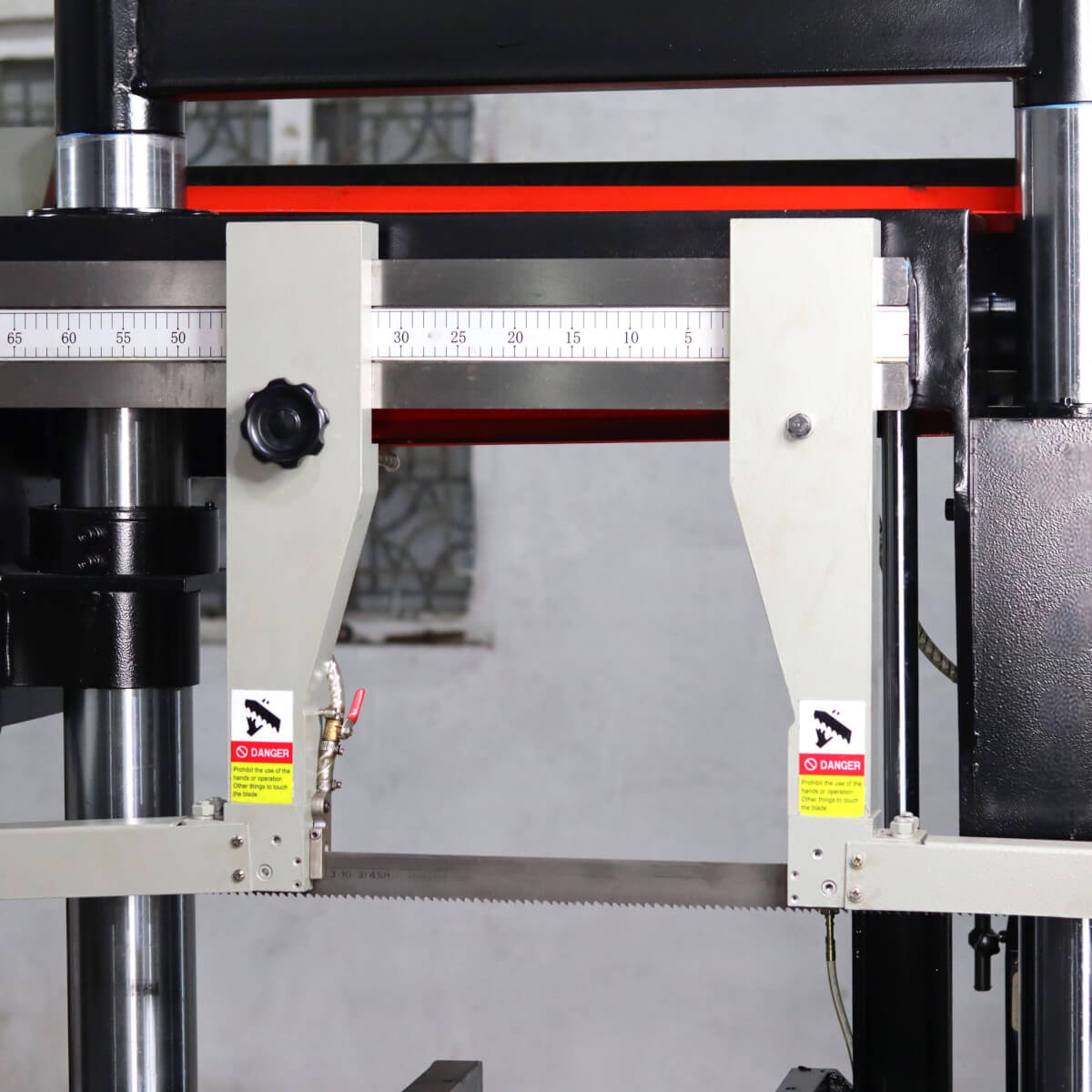

- Hard Chrome Plated Ground Column.

- Automatic Height Adjustment For Saw Frame.

- Variable Pressure Control For Cutting Feed.

- Auto Cutting Stop.

- Push Button Type Operating Panel Board.

- Heavy Duty Works Gear Box.

- Moveable Blade Tensioning Arrangement.

- Material Feeding Manually.

- Swing Mode Changes Are Flexible, Manual & Automatic Combined.

- The PLC Controller Completes The Automatic Sawing Process.

| MODEL | SLICE AUTO 200MM | SLICE AUTO 280MM | SLICE AUTO 350MM | SLICE AUTO 400MM | SLICE AUTO 500MM |

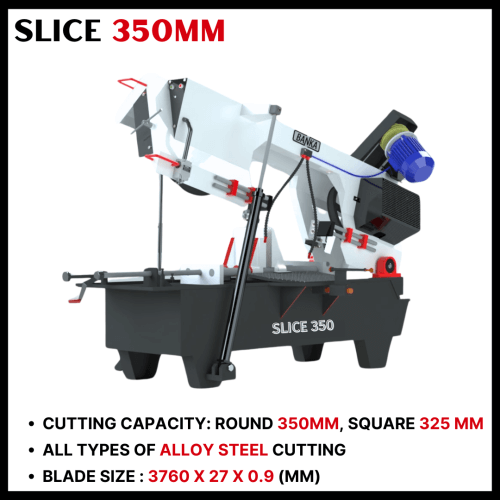

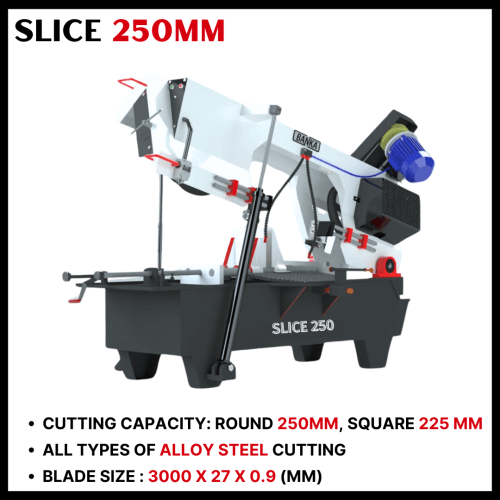

| Cutting Capacity Round | 200MM | 280MM | 350MM | 400MM | 500MM |

| Cutting Capacity square | 200x200MM | 280x280MM | 350x350MM | 400x400MM | 500x500MM |

| Blade size | 2800 x 27 x 0.9MM | 3480 x 34 x 1.1MM | 4140 x 34 x 1.1MM | 5000 x 34 x 1.1MM | 5800 X 27 X 0.9MM |

| Blade speed | 27,45,69M/MIN | 27,45,69M/MIN | 27,45,69M/MIN | 27,45,69M/MIN | 27,45,69M/MIN |

| Clamping type | Hydraulic | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

| Main Motor power | 2HP | 3HP | 5HP | 5HP | 7 HP |

| Hydraulic Motor power | 0.5HP | 0.5HP | 0.5HP | 1HP | 1HP |

| Coolant Motor | 0.05HP | 0.05HP | 0.25HP | 0.25HP | 0.25HP |

| Power supply | 3 PHASE | 3 PHASE | 3 PHASE | 3 PHASE | 3 PHASE |

| Overall Dimension | 1400 x 900 x 1150 MM | 1860 x 1000 x 1400 MM | 2000 x 1100 x 1500 MM | 2500 x 1300 x 1600 MM | 2800 x 1300 x 2000 MM |

| Price | Rs 265000/- | Rs 355000/- | Rs 545000/- | Rs 645000/- | Rs 795000/- |

Bandsaw Machine Semi Automatic Double Column- Slice Auto 200MM To 500MM

A Double-Column Bandsaw Machine is a type of bandsaw that features a robust, stable design due to its two-column construction. Here are some typical details and features & These machines are valued for their ability to handle heavy-duty cutting tasks efficiently and accurately, making them essential in many industrial settings.

- Structure: It has two vertical columns that provide strong support and stability, allowing for the cutting large, heavy materials with high precision.

- Cutting Capacity: These machines are capable of cutting large workpieces, often with variable cutting angles and heights.

- Blade Type: Uses a continuous loop blade with teeth designed for cutting various materials such as metals, wood, and plastics.

- Control and Automation: Modern models may feature programmable controls for blade speed, feed rate, and cutting angles, enhancing efficiency and precision.

- Applications: Commonly used in industries such as metalworking, fabrication, and woodworking for cutting large sections of material into smaller pieces or specific shapes.

- Safety Features: Includes features like blade guards, emergency stop buttons, and sometimes automatic shutdown in case of blade breakage or other issues.

STANDARD ACCESSORIES ARE FREE WITH THIS MACHINE.

- Saw Blade

- Coolant System

- Machine Lamp

- Blade Tensioning Wrench

- Adjustable Bar Support Stand (Bar Stand)

- Toolkit

- Operating & Instruction Manual (How to Care Machine)