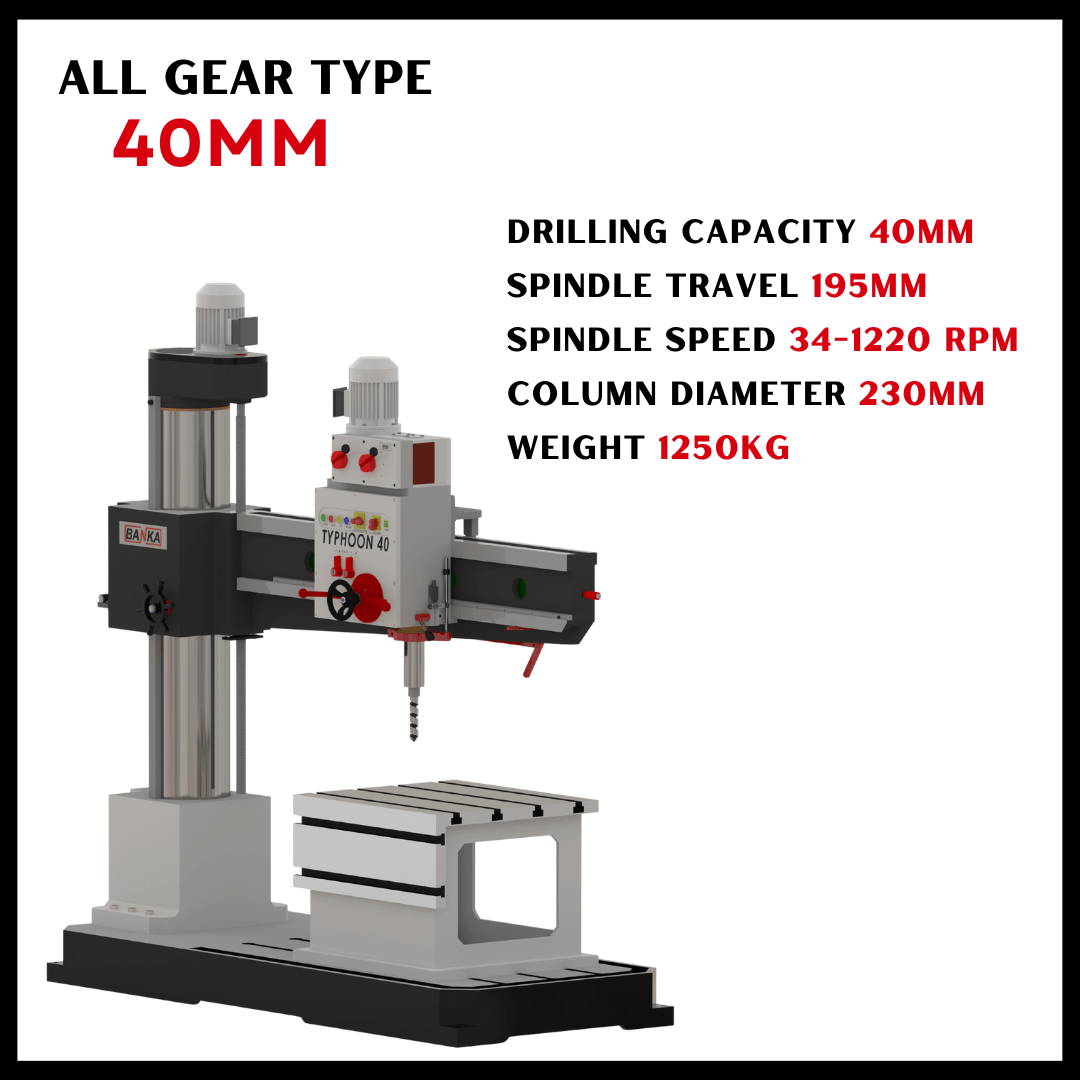

HEAVY DUTY ALL GEAR RADIAL DRILL MACHINE 40 MM – INDUSTRIAL USE – BANKA

₹3,75,000

- Drilling Capacity: 40 mm

- Spindle Travel: 195 mm

- Spindle Speed: 34-1220 RPM

- Column Diameter: 230 mm

- Weight: 1250 KG

- Warranty : 3 Years

Key Features of BANKA Typhoon All Gear Radial Drill 40MM

- High Drilling Capacity: Capable of drilling up to 40 mm in mild steel, with some models able to handle slightly more in cast iron

- All-Geared Transmission: Uses a fully geared head/gearbox for smooth, powerful, and reliable torque delivery. Gears are often hardened and ground for durability.

- Multiple Spindle Speeds: Typically,4–8 spindle speeds for different operations (drilling, reaming, tapping). Example speed range: BANKA 40 mm model supports 34 – 1220 RPM in 8 steps.

- Power / Auto Feed Options: Auto feed is available (on many “extra heavy” versions), with disengagement when a preset depth is reached or under high drilling pressure.

- Accurate and Rigid Spindle: The Spindle is made from high-strength material (e.g., EN8) in many models. Spindle taper/bore is precision-ground (e.g., MT-4) for consistent tool holding

- Column / Arm Design: he arm may be able to rotate (e.g., 180° each way) to provide flexibility in work positioning.

- Work Table / Base Features: A Working table usually has T-slots to secure workpieces. The base is large and strong to support heavy workpieces and high cutting forces

- Versatile Applications: Capable of not just drilling but also reaming, boring, tapping, spot-facing, milling, etc.Useful in large workpiece / heavy industry setups (fabrication, tool rooms, maintenance).

- Flexibility in Accessories: Often comes with or has options for extras: drill chuck, arbor, extra-long column, machine lamp, coolant pump, extra table. Option for manual or automatic feed.

| TECHNICAL SPECIFICATION | BANKA TYPOON 40MM |

| DRILL CAPACITY MS | 40 MM |

| TAPPING CAPACITY | 25MM |

| DRILL CAPACITY CI | 45-50 MM |

| MACHINE DIMENSIONS [L x W x H] | 1750 x 770 x 2250 |

| LIFTING MOTOR POWER | 1.5HP |

| MAIN MOTOR | 3HP |

| ARM ROTATION ANGLE | ± 180 |

| FEED LEVEL 3 | 0. 10-0. 2 |

| SPINDLE SPEED [12 r/min] | 34-1220 |

| SPINDLE TAPER | MT-4 |

| COLUMN DIA | 230 MM |

| SPINDLE TRAVEL | 195 MM |

| SPINDLE FACE TO BASE | 300 MM MIN. |

| SPINDLE FACE TO BASE | 1110 MM MAX. |

| HORIZONTAL TRAVEL OF SPINDLE | 880 MM |

| DISTANCE BETWEEN SPINDLE CENTER TO COLUMN MIN / MAX. | 315 – 1195MM |

| NEIGHT WEIGHT | 1250 KG |

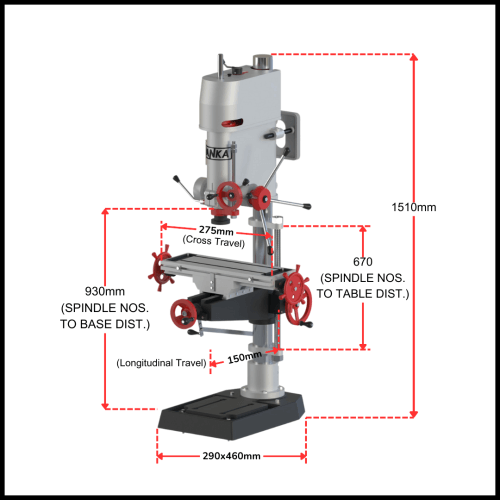

A Radial Drill Machine is designed primarily for drilling holes in large and heavy workpieces. Here are some key features and descriptions of an All Gear Radial Drill Machine:

High Versatility and Reach (Radial Arm): The defining feature is the radial arm, which supports the drill head. This arm can rotate 360 degrees around the vertical column and move up and down, allowing the operator to position the drilling spindle precisely over any point on a large, stationary workpiece. This eliminates the need to reposition the heavy job.

Robust All-Gear Drive: The “All Gear” mechanism uses hardened and ground alloy steel gears within an oil bath for transmitting power. This design ensures high efficiency, smooth operation, and minimal wear and tear compared to belt-driven systems. It allows for a wide range of precise, easily selectable spindle speeds and automatic feeds

Maximum Drilling Capacity (40mm): The 40mm designation specifies the machine’s substantial power and rigidity, typically allowing it to drill a hole up to 40mm in diameter in mild steel. This makes it suitable for heavy-duty industrial work

Heavy-Duty Construction and Stability: These machines feature a robust and heavy cast iron construction for the base, column, and arm. This weight and rigidity are crucial for absorbing vibrations and maintaining accuracy and stability during demanding, heavy-load drilling operations

Multi-Function Capability: Beyond standard drilling, the multiple gear-driven speed and feed combinations and high torque capacity enable a range of other precision operations, including:

-

Tapping (Cutting internal threads).

-

Boring (Enlarging an existing hole).

-

Reaming (Finishing a hole to an exact size and smooth finish).

These machines are widely used in industries such as manufacturing, construction, and metalworking, where precise and efficient drilling operations are required. They are essential for tasks like hole drilling, tapping, reaming, and countersinking in various types of materials.

Standard Accessories:

- Box Table

- Coolant System

- Machine Lamp

- Drill Chuck with Arbor

- Reduction Sleeve

- Wedge

- Tool Box

- Instruction Manual

- Foundation Bolt

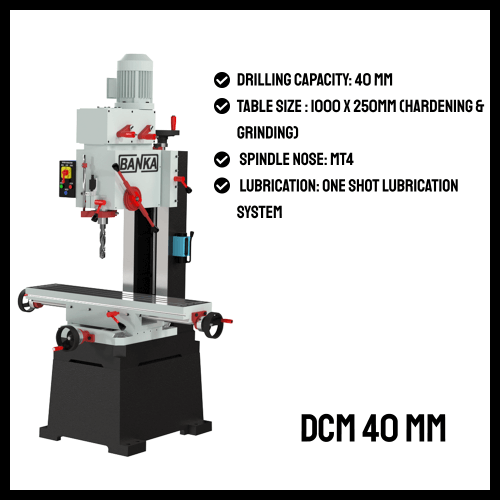

Related Products

Cost Saving

RADIAL DRILL MACHINE-ALL GEAR-50MM- 2 SPEED MOTOR