- Sorry, this product cannot be purchased.

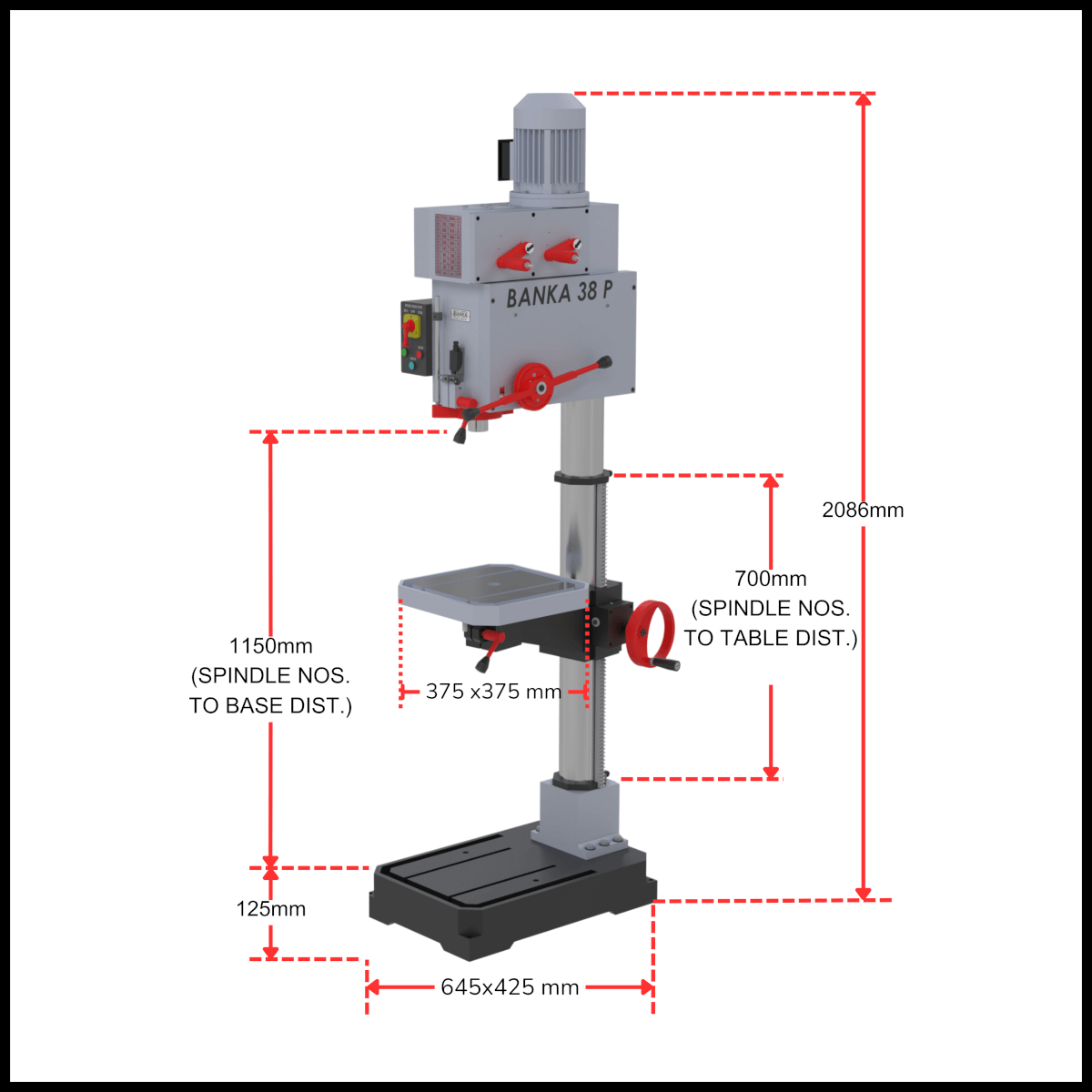

ALL GEARED PILLAR DRILL 40mm-Auto-Feed – Stand Type – Medium Duty

₹1,39,000

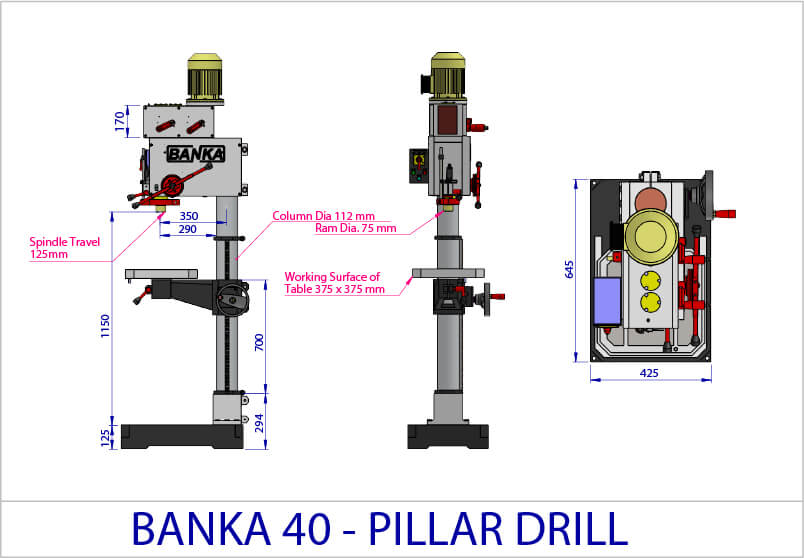

- Drilling Capacity: 40 mm

- Column Dia: 112 mm

- Spindle Hole Taper: MT-4

- Spindle Speeds: 40-2050 RPM

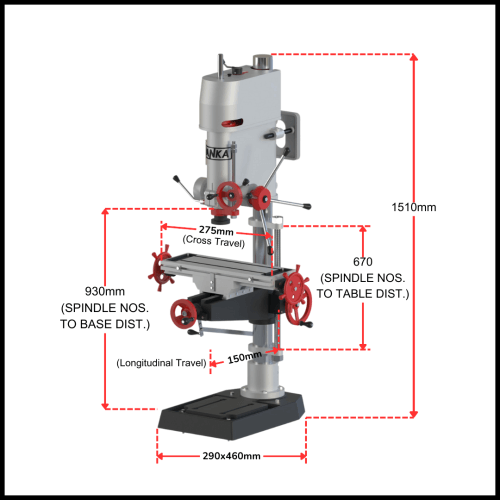

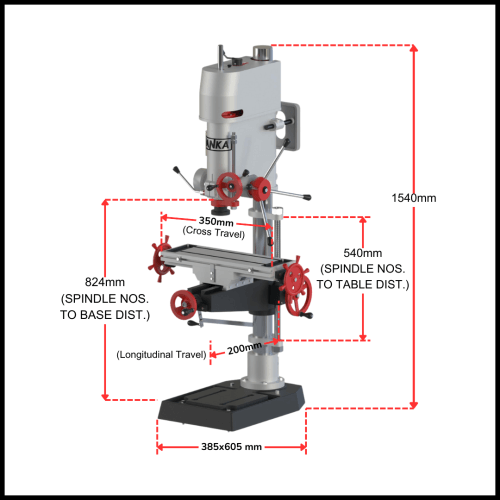

- Spindle Nos. To table Dist. : 620 mm

- Spindle Center To Pillar: 290 mm

- Table Size: 375 mm

- Motor: 2 HP-2 Speed

The fastest, The most powerful, The rarest, and more economical

Special Features :

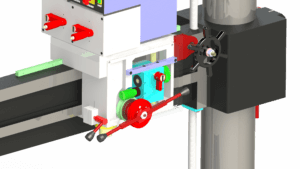

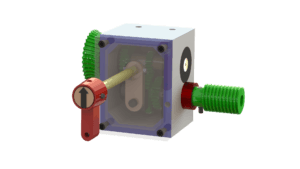

- Geometric Progression Speed & Feed

- Easy Auto Feed System

- 2 Speed Motor with 40-2000 RPM

- Easy Power Feed by Hand Lever

- Easy Tapper Shank Release

- Accuracy Tested as per IS 2425-1963

| Specification | Size |

| Capacity | |

| Drilling Capacity in Cast Iron (241 BHN) | 40 |

| Drilling Capacity in Mild Steel | 32 |

| Tapping Capacity in Cast Iron (241 BHN) | 20 |

| Tapping Capacity in Mild Steel | 15 |

| Boring Capacity in Mild Steel | 75 |

| Drilling Head | |

| Morse Tapper in Spindle Nose | MT4 |

| Max. Spindle Travel (Drilling Depth) | 170 |

| Spindle Sleeve Diameter | 75 |

| No. of Spindle Speeds | 18 |

| Spindle Speed Range (RPM) | 40-2050 |

| No. of Power Feeds | 3 |

| Feed Range per Revolution | 0.08-0.02-0.04 |

| Lubrication | Lithium Grease |

| Working Range | |

| Distance From Column to Spindle | 290 |

| Spindle Radius (Column to Spindle) | 350 |

| Spindle to Base Distance (Max./Min.) | 1150 |

| Column Diameter | 112 |

| Vertical Movement of Arm | 700 |

| Vertical Movement Of Spindle | 200 |

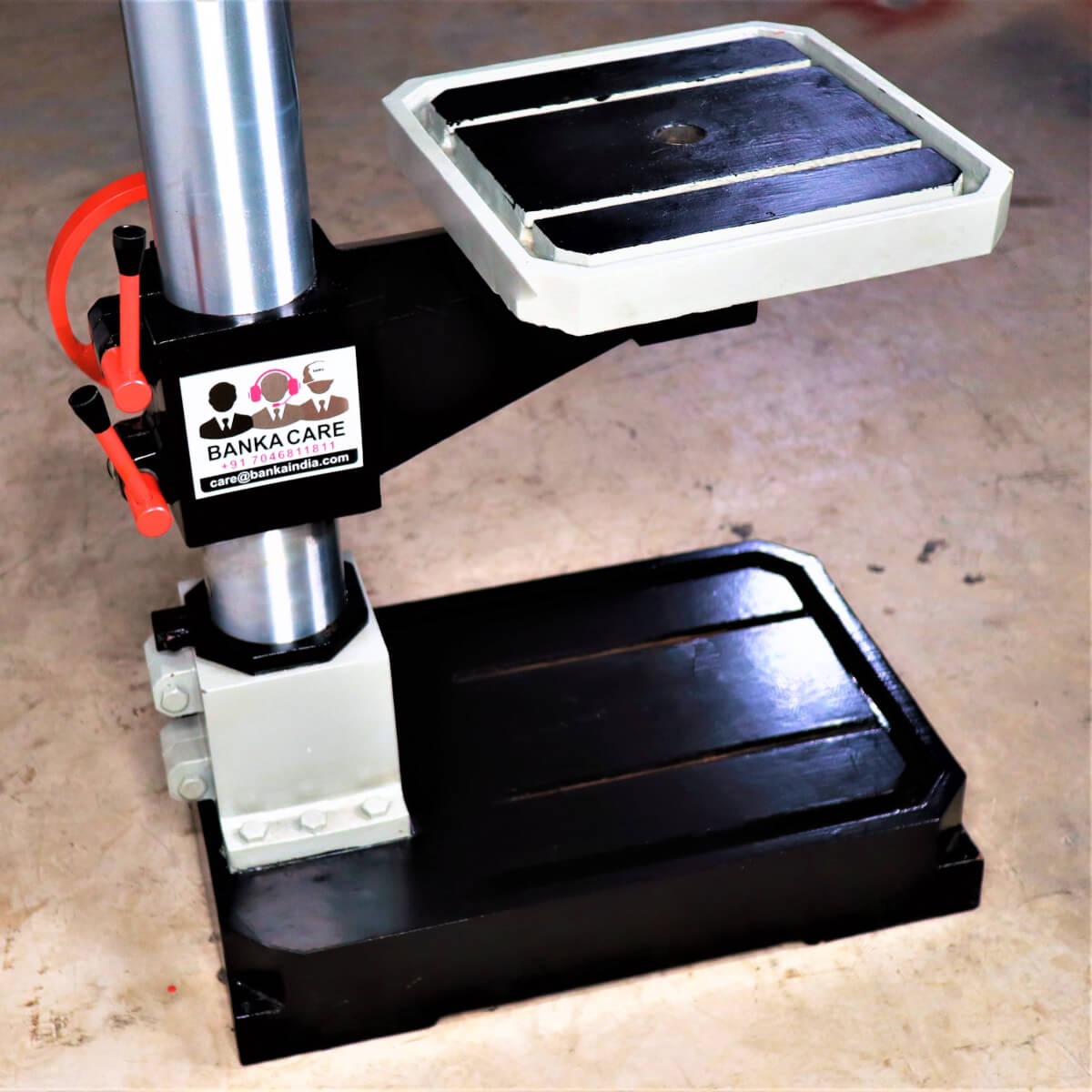

| Working Surface of Base (L x W) | 645 x 425 |

| Working Surface of Table (L x W) | 375x 375 |

| Width of “T” Slots | 11+2 |

| Drilling Motor (HP/RPM) | 1-2 / 1400-2800 |

| Shipping Dimension (L x W x H) | 430 x 700 x 2130 |

| Weight of Machine Kg.(Approx) | 500 |

Innovation with a Purpose

Quality

We maintain our drills quality by 4 stage inspection. as manufacturing process goes ahead each stage our inspector check all parameters. Though our metal drilling drill performance and accuracy are better than other industrial drill machine manufacturer. BANKA Pillar drills have auto feed drilling system with high-speed motor. We had fitted 2 Speed Motor in our drill, it runs from 40 – 2000 RPM spindle speed.

Our toolroom drill is manufactured as per Indian Standard Test by testing instruments like,

Straight Edge Meter:

A straightedge is a tool with an edge free-form curves or straight, used for transcribing straight lines. Straightedges are used in the automotive service and machining industry to check the flatness of machined mating surfaces of base as well as the drill arm. it should not be concave and convex.

True straightness can in some cases be checked by using a laser line level as an optical straightedge: it can illuminate an accurately straight line on a flat surface such as the edge of a plank or shelf. It effects in the production schedule, time schedule, time saving and increase the quality of our products.

Sound Level Decibel Meter:

As per the IS test our Tool drill head sound is measured by Decibel Meter and it should be up to 85 to 90 lbs. In every Drill Machine, it should be 85 lbs and our each Drill Machine noise level is under 85 lbs.

Dial Indicator Micrometers:

Dial Indicator Micrometers is used for precise measurement of components which are done on the Drill. It’s also used to measure the apparent diameter of celestial bodies or microscopic objects and used to check test the runout of the internal taper of spindle. As per IS Test each drill machine spindle internal taper near the spindle nose should be 0.02 mm and up to end of the spindle should be 0.03 mm.

Amperemeter:

It is used to measures the current in a circuit is to break the circuit open and insert an “ammeter” in line with the circuit so that all electrons flowing through the circuit also have to go through the meter. When an ammeter is placed in series with a circuit, it ideally drops no. voltage as current goes through Drill machine main motor.

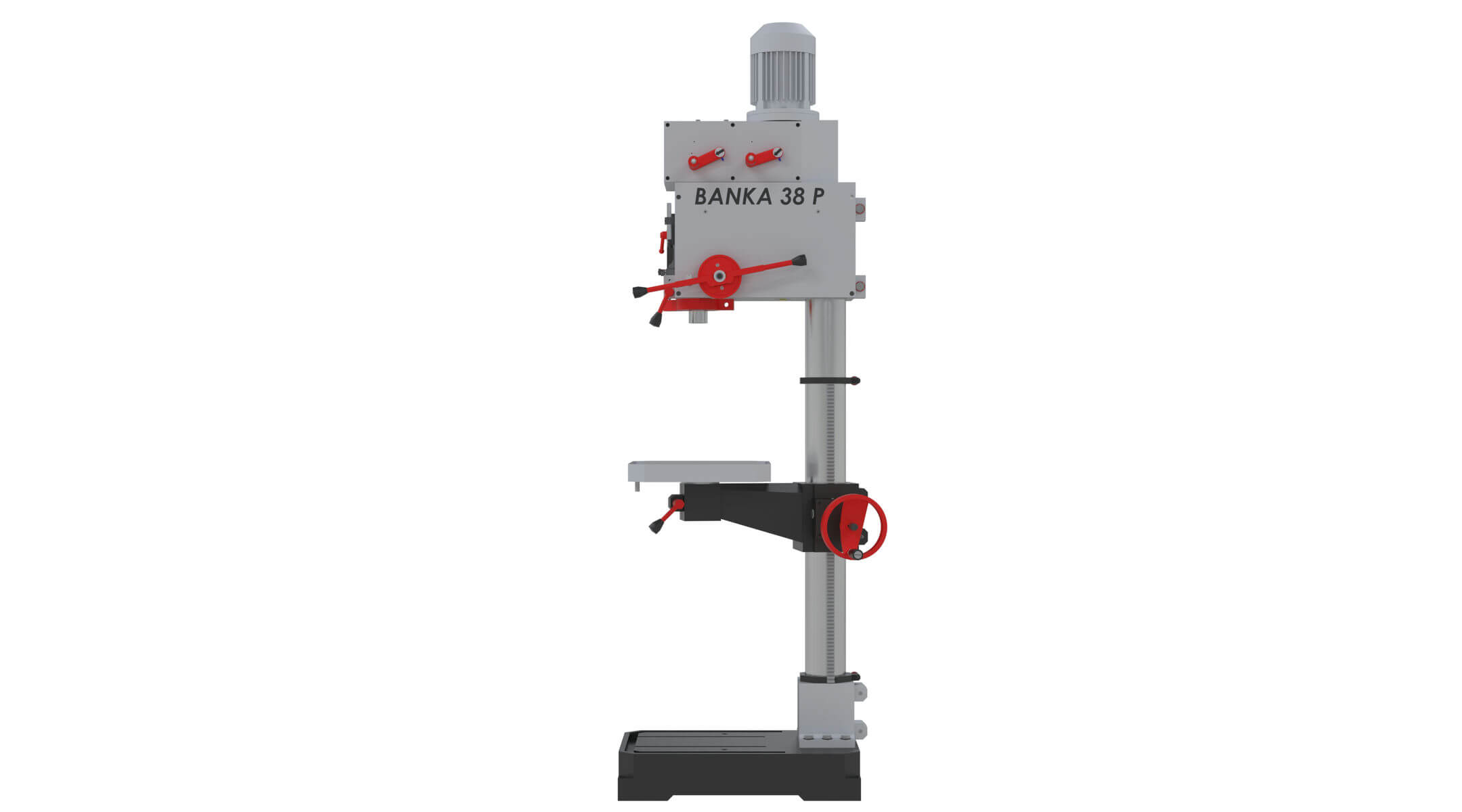

BANKA is most popular for its quality and uniqueness of our services towards their customers. Our service engineers are highly trained and skilled to design BANKA products and to serve timely services. BANKA 38 Pillar Drill is generally designed low maintenance, time saving, suitable for reckless operation and heavy metal removal.

Our Deep Drilling machine is designed for drilling medium and large parts, as well as boring, counter boring, reaming, tapping and surfacing to done with different parts and different angles. Its arm is made from solid material casting and hardened & ground. We are using the gears hardened & ground for smooth running. All control levers are quick to operate and are properly guarded against accident.

Each machine is properly checked as per IS Test Chart by our experienced engineers through testing and inspection process before dispatch from our factory. We are also using the material as Indian Standard which is used while manufacturing.

Lead us to serve more

| No | Images | Accessories | Description |

| 1 |  |

Allen Key Set | Useful tools when maintenance required. |

| 2 |  |

Spanner Set with Oil Can | Tools used for maintenance and operating machine. |

| 3 |  |

Vibration Dumping Pad | It was made from rubber material and fitted on machine base.Use for anti- vibration when machine in running mode and increases the machine’s cutting capacity. |

| 4 |  |

Foundation Bolt | Use to clutch the machine in self-position at the time of operation and maintenance. |

| 5 |  |

Manual Book | All details are provides in this book like installation, maintenance,training and parts. |

| 6 |  |

L Clamp | It’s useful in foundation to support the legs. |

| 7 |  |

Color Brush | A tool to paint the machine or any other tools to repair while parts are damaged in transportation. |

| 8 |  |

Industrial Apron | Apron wear for safety and keep the small tools in that while operating machines. |

| 9 |  |

Oil Funnel | A tool for filling and filtering the oil which is essential for machine. |

| 10 |  |

Safety Glasses | To protect eyes while operating machines. |

| 11 |  |

Slinging Belt | For the safety of machines while loading and unloading the machine. |

| 12 |  |

Tools Bag | To save all the small and big tools needed to operate machine. |

| 13 |  |

Machine Lamp | Improve operator vision Fits oncarriage,moves, Parallel withcarriage, Essential While Bore Cutting. |

| 14 |  |

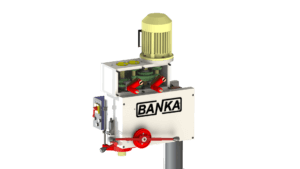

Speed Motor | To run the machine and by 2 speed motor you can work faster than normal speed. |

We are here to Help you

1) What will be the warranty Period of this Drill Machine?

A: 1) All Gear Auto feed Radial Drill Machine

2) Back Geared Fine feed Radial Drill Machine

3) Back Geared Auto feed Radial Drill Machine

4) All geared Fine Feed Radial Drill Machine

5) Back Geared Fine Feed Pillar Drill Machine

2) How many types are there in the Drill Machine?

A: 1) All Gear Auto feed Radial Drill Machine

2) Back Geared Fine feed Radial Drill Machine

3) Back Geared Auto feed Radial Drill Machine

4) All geared Fine Feed Radial Drill Machine

5) Back Geared Fine Feed Pillar Drill Machine

3) How many popular models are there in the Drill Machine?

A : 40 mm Cap. All geared Auto feed Radial Drill Machine

40 mm Cap. All geared Fine feed Radial Drill Machine

40 mm Cap. Back geared Fine Feed Radial Drill Machine

40 mm Cap. All geared Auto feed Pillar Drill Machine

40 mm Cap. Back geared Auto feed Radial Drill Machine

38 mm Cap. All geared Auto feed Radial Drill Machine

38 mm Cap. All geared auto feed Pillar Drill Machine

38 mm Cap. Back geared Fine feed Pillar Drill Machine

25 mm Cap. Back Geared Fine Feed Radial Drill Machine

25 mm Cap. Back Geared Fine Feed Pillar Drill machine

20 mm Cap. Back geared Pillar drill Machine

4) Which are the accessories I Should Buy with Drill Machine?

A : Key Less Dill Chuck

Electrical Motors

Keyless Drill Chuck & Arbor

Drill Chuck & Arbor

Coolant Pump with Coolant Tank

Multi Spindle Drilling

Tapping Attachment

5) What are the confusions raised in the mind of customer at the time of purchasing Drill Machine ?

A: 1) Drilling Capacity requirement

2) Which type of drill is required?

6) Do you accept Domestic LC ?

A: Yes, accept domestic LC for 60 days on credit. Generally our 75 % customers are purchasing Machine from us with 60 days Credit through a Simple Process of LC. When the Seller is Unknown or New to the Buyer, Letter of Credit is one good Alternative to do the Business with Such New Seller Because Buyer can Avoid Risk by such Letter. Letter of Credit is one Additional Benefit to the Buyer by which they can protect Loss against Goods and Finance Also.The buyer can build safeguards into the letter of credit, including inspection of the goods and quality control, and set production and delivery times.