Universal Milling Machine – Die Work – Teeth Cutting – Key Way – Slotting – Rack Cutting – Mass Production – Model M2

₹2,95,000

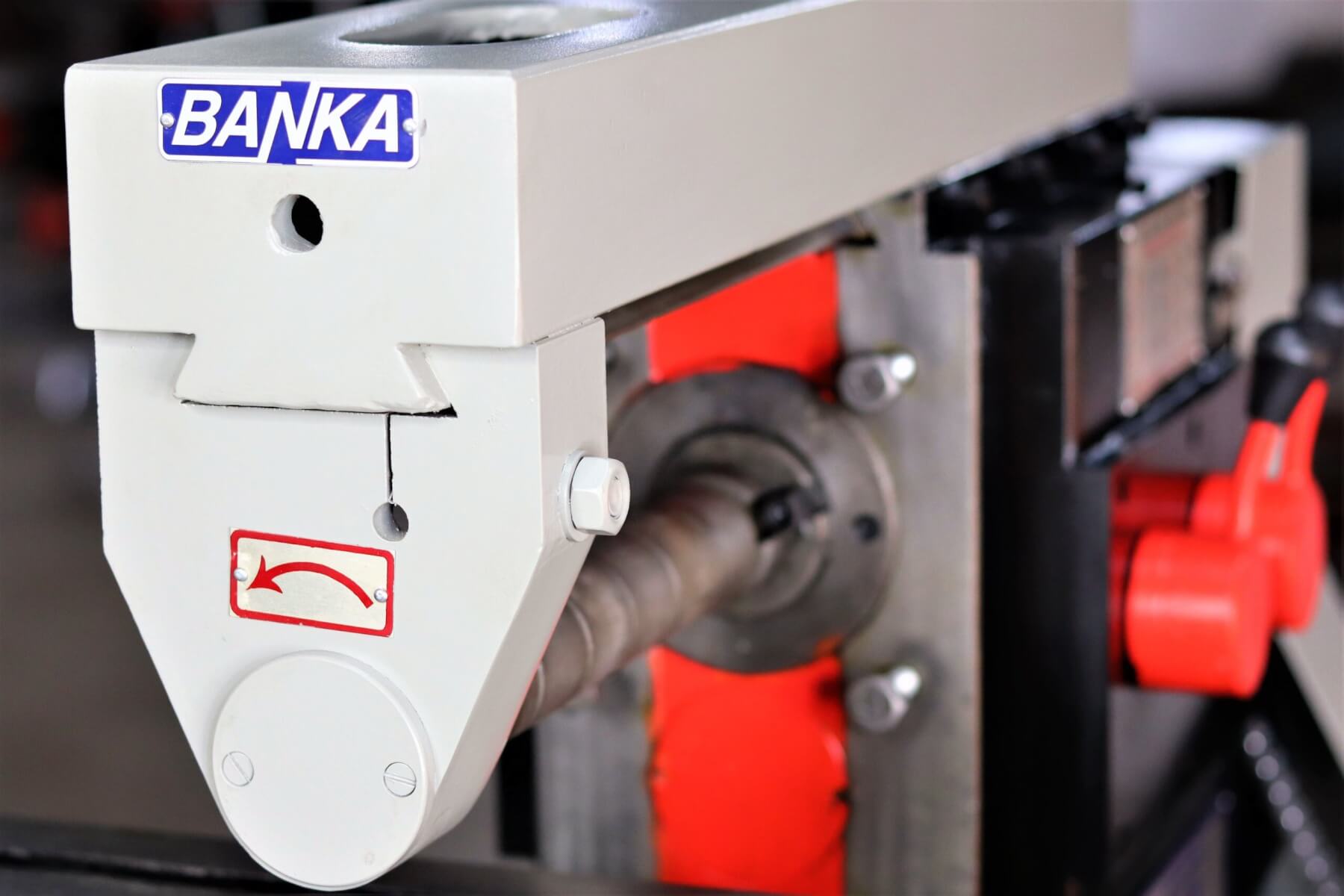

- Model Type: Universal Gear Head Milling Machine – MM 2

- Category: Workshop Machine

- Colour: AD Grade Gray & Nikal Grade White

- Table Size : 1050X 250 mm

- Spindle Bore: ISO 40

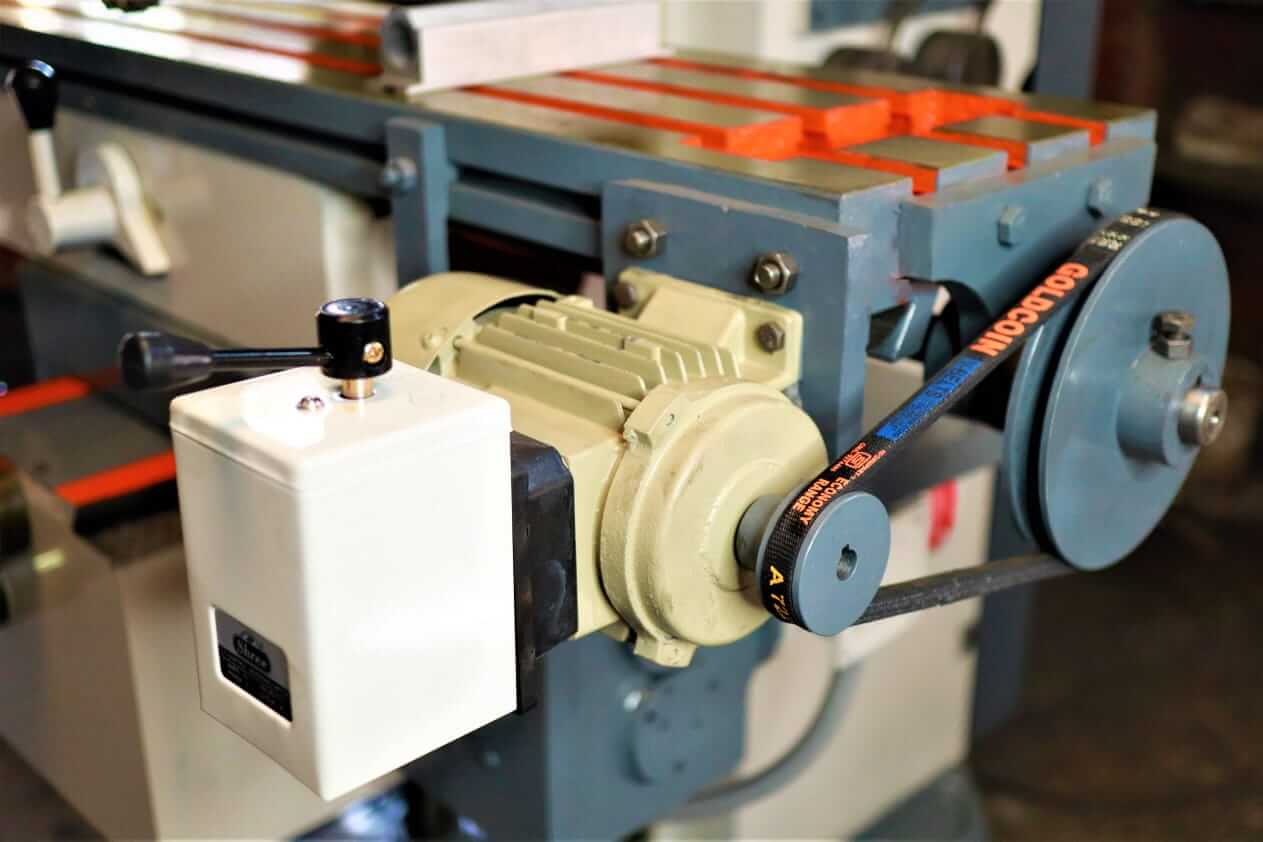

- Electricals : 2 HP – 1440 RPM – 3 PHASE

- Weight : 1200 kg

- Optional: Motorised X-Axis, Y-Axis

- Ductile Cast Iron Nut

Separate us from others

|

Universal Gear Head Milling Machine – One feed Automatic : Our milling machine is one feed automatic. One axis can moves automatically. As per customer’s requirement, we can also customize with 2 feed automatic at extra cost. – Use of our Milling Machine : Our milling machine is more famous in Automobile, Diemaking, Submersible pump, small workshop, fabricators etc. – Operations can do on our Milling Machine :

|

||||||||

|

Inbuilt Base Coolant

|

||||||||

|

Jack Screw

|

||||||||

|

Table Size

|

||||||||

|

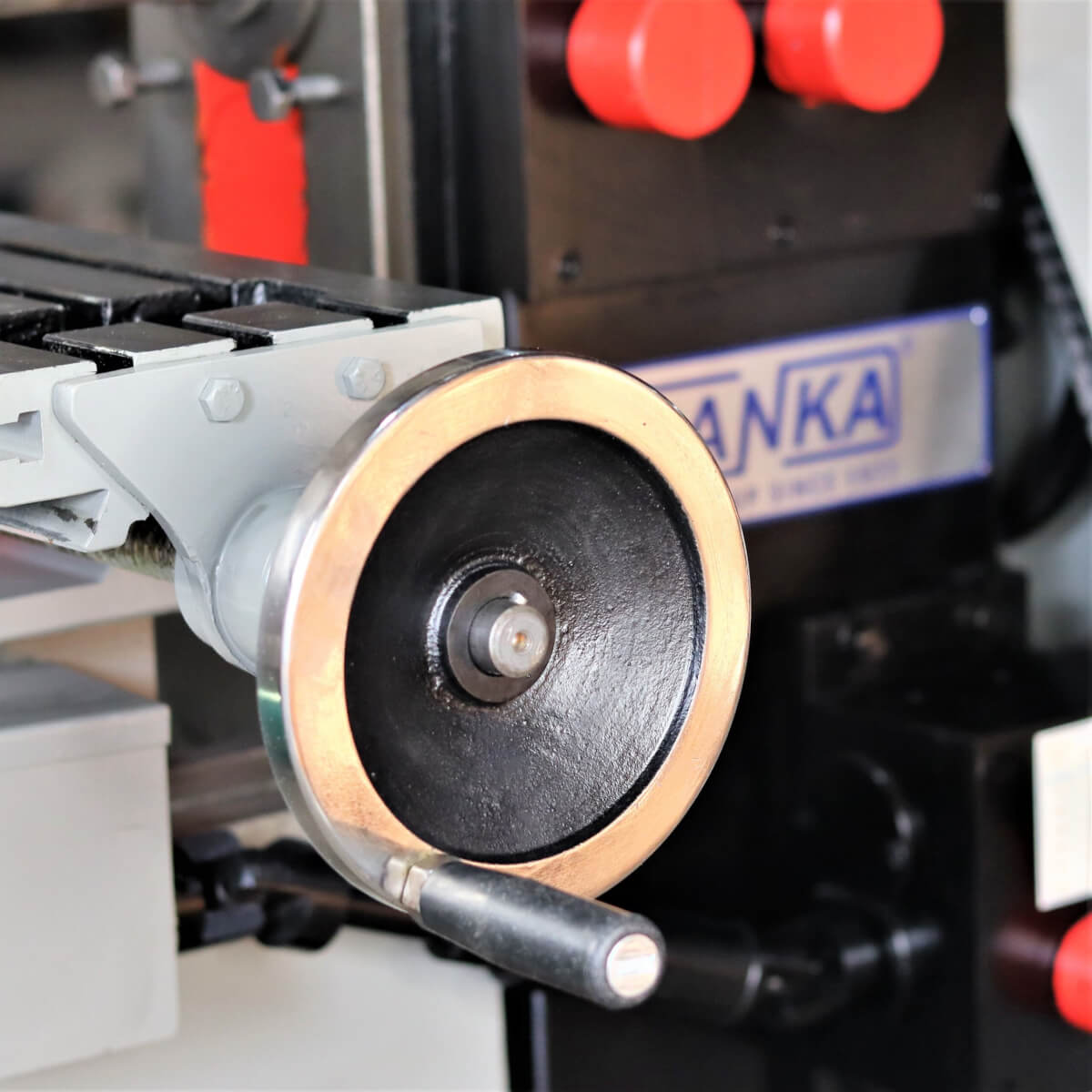

Milling Gear Box (Feed Gear Box)

. |

||||||||

|

Vertical Head Sometimes horizontal milling machine has to cut vertically also. At that time we need Vertical Head attachment. So we are giving rigid vertical head with our Milling Machine.

|

||||||||

|

Rigid & Precision Bed We have made our Milling Machine with High precision and heavy bed.

We are doing Seasoning Process. It helps to maintain accuracy against climate change. |

||||||||

|

Extra Heavy Weight

|

||||||||

|

Experts in Specialized & customized Machines

|

|||||||||

Helps you to find your goal

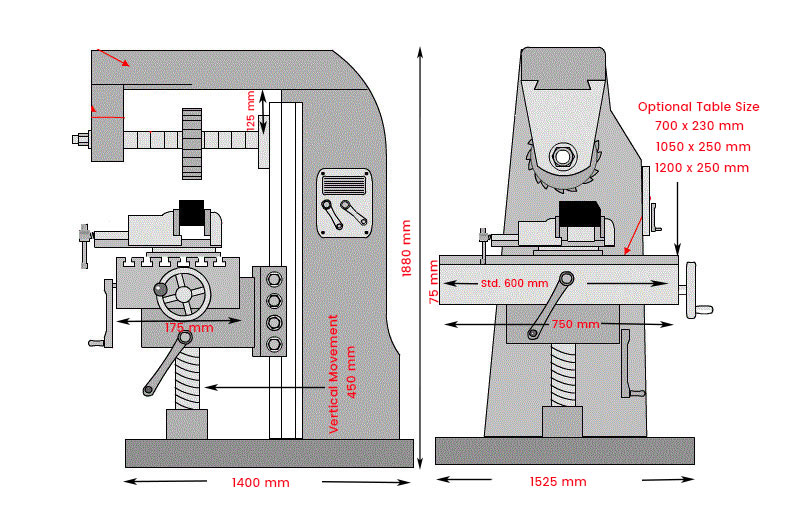

| Specification | Model :- MM 0A/1 |

| Working Surface | 1050 * 250 mm |

| Distance from Spindle centre to underside of over support | 125 mm |

| Longitudinal feed | 600 mm |

| Cross feed | 230 mm |

| Vertical feed | 450 mm |

| Spindle Speed | 65-725 RPM |

| Number of feed | Three |

| Arbour | 25.4 mm |

| Spindle Bore | ISO – 40 |

| Electric Motor | 2 hp * 1440 RMP 3 Phase |

We are here to Help you

1) How Many types are available in Milling Machine?

Generally, there are mainly 3 types of Milling machine are popular in the Market

- Universal Gear Head Milling Machine

- Vertical Milling Machine

- Horizontal Milling Machine

- Turret type Milling Machine

2) How many models are available in the Milling Machine?

- Milling machine no. 0A

- Milling machine no. 1

- Milling machine no. 2

- Milling machine no. 3

- Milling machine no. 4

3) Which accessories should I buy with Milling Machine?

Auto feed, Electric Motor, Vertical attachment, Rack cutting attachment, slotting attachment, dividing head, coolant pump with fittings, true chuck, Milling Adaptor, face mill cutter, milling vice, milling collet etc.

4) What are the basic clarifications customers should clarify at the time of purchasing Milling machine?

- Table size

- Spindle Taper

- Ram Travel

- X-Axis longitudinal travel

- Y – Axis Cross Travel

- Z – Axis Vertical Travel

- Guide Way – XYZ

- Motor Power

5) What will be the warranty Period of this Milling Machine?

Generally, Suppliers of the lathe machine are providing only one year warranty period in the lathe machine. And it is not the proper return according to your investment. While We are providing 3 years warranty in our products. If there any parts damaged in your machine than we also provide free parts service in warranty period by fastest courier service.

6) What are the confusions raised in the mind of customer at the time of purchasing Drill Machine ?

1) Drilling Capacity requirement

2) Which type of drill is required?

6) Do you accept Domestic LC ?

Yes, accept domestic LC for 60 days on credit. Generally our 75 % customers are purchasing Machine from us with 60 days Credit through a Simple Process of LC. When the Seller is Unknown or New to the Buyer, Letter of Credit is one good Alternative to do the Business with Such New Seller Because Buyer can Avoid Risk by such Letter. Letter of Credit is one Additional Benefit to the Buyer by which they can protect Loss against Goods and Finance Also.The buyer can build safeguards into the letter of credit, including inspection of the goods and quality control, and set production and delivery times.