Accessories for Milling machines, Machine Shop Accessories, Tools & Instruments

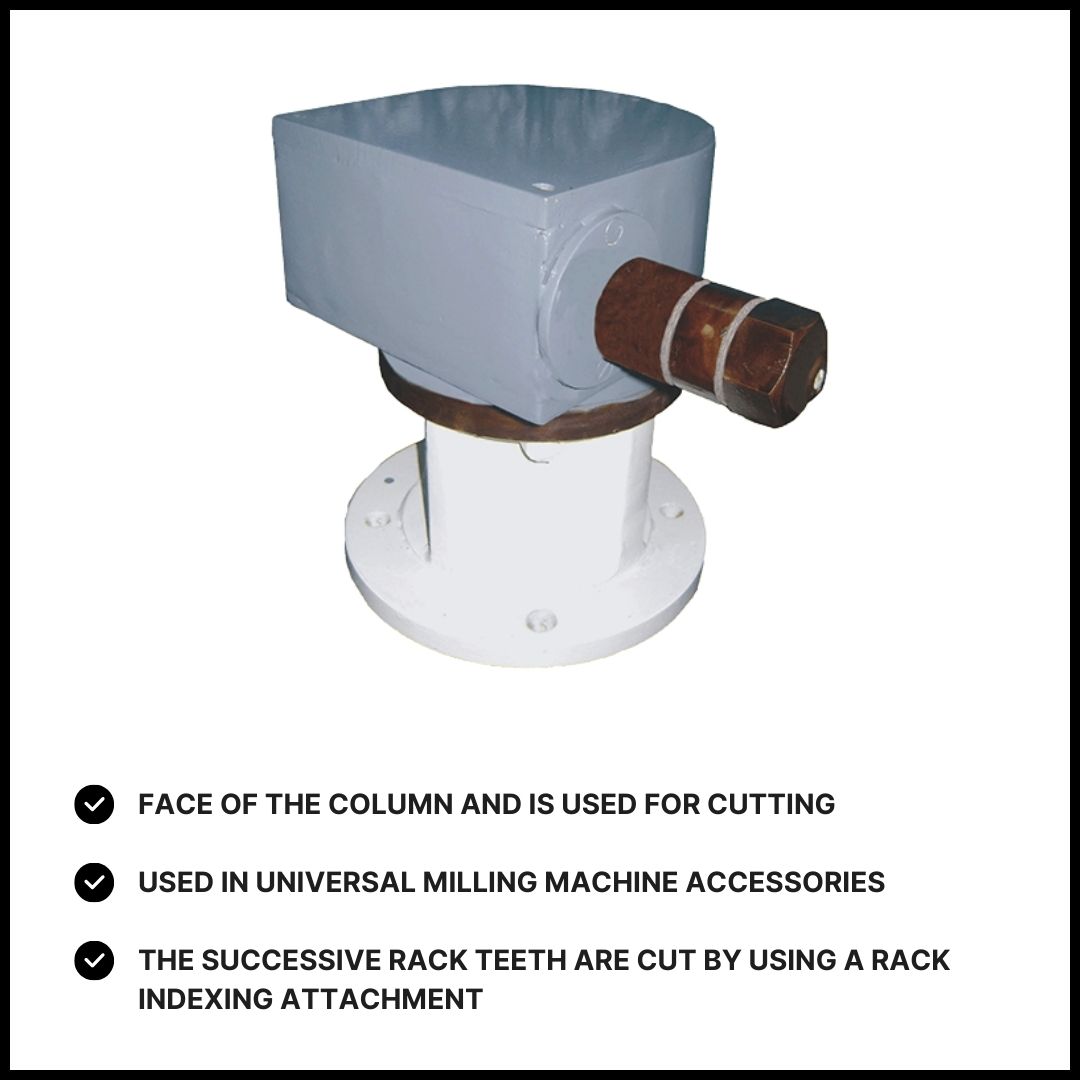

MIlling – Reck Cutting Attachment

Tag: Popular

₹11,500

- Rack Cutting

- Face of the column and is used for cutting

- Used in Universal Milling Machine Accessories

- The successive rack teeth are cut by using a rack indexing attachment

- Colour – Gray & White

A “Reck cutting attachment” for milling machines is a specific tool designed to enhance the capabilities of a milling machine, particularly for precision cutting and finishing. Here’s a general overview of how to use a Reck cutting attachment:

Overview of the Reck Cutting Attachment:

- Purpose: The Reck cutting attachment is primarily used for fine, precise cutting operations. It is particularly useful for complex geometries and high-precision tasks.

- Components: This attachment typically includes a set of gears, a cutting head, and an adjustable mechanism for fine-tuning the cutting depth and angle.

Setting Up the Attachment:

- Installation:

- Mounting: Attach the Reck cutting attachment to the milling machine’s spindle or table, depending on the design. Ensure it is securely fastened to avoid any movement during operation.

- Alignment: Properly align the attachment with the milling machine to ensure accurate cutting. Misalignment can lead to poor results and potential damage.

- Adjustment:

- Cutting Depth: Set the desired cutting depth using the adjustment mechanisms on the attachment. This is crucial for achieving the correct dimensions and finishes.

- Angle: Adjust the cutting angle if the attachment allows for angular cuts. This is important for complex shapes and ensuring that the cut is made at the right orientation.

Operating the Attachment:

- Preparation:

- Tool Selection: Choose the appropriate cutting tool for your specific task. The Reck attachment may come with different tool options for various types of cuts.

- Material Setup: Secure the material you are cutting firmly on the milling table or fixture. Proper clamping prevents movement during the cutting process.

- Cutting:

- Speed and Feed Rates: Set the milling machine to the correct speed and feed rates for the material and cutting tool you are using. Refer to the Reck attachment’s manual for recommended settings.

- Monitoring: Continuously monitor the cutting process. Look for any signs of issues, such as excessive noise or vibration, and make adjustments as needed.

- Post-Cutting:

- Inspection: After cutting, inspect the workpiece for accuracy and finish. Check that the dimensions are correct and that the surface finish meets your requirements.

- Clean Up: Clean the attachment and the work area to ensure everything is in good condition for the next use.