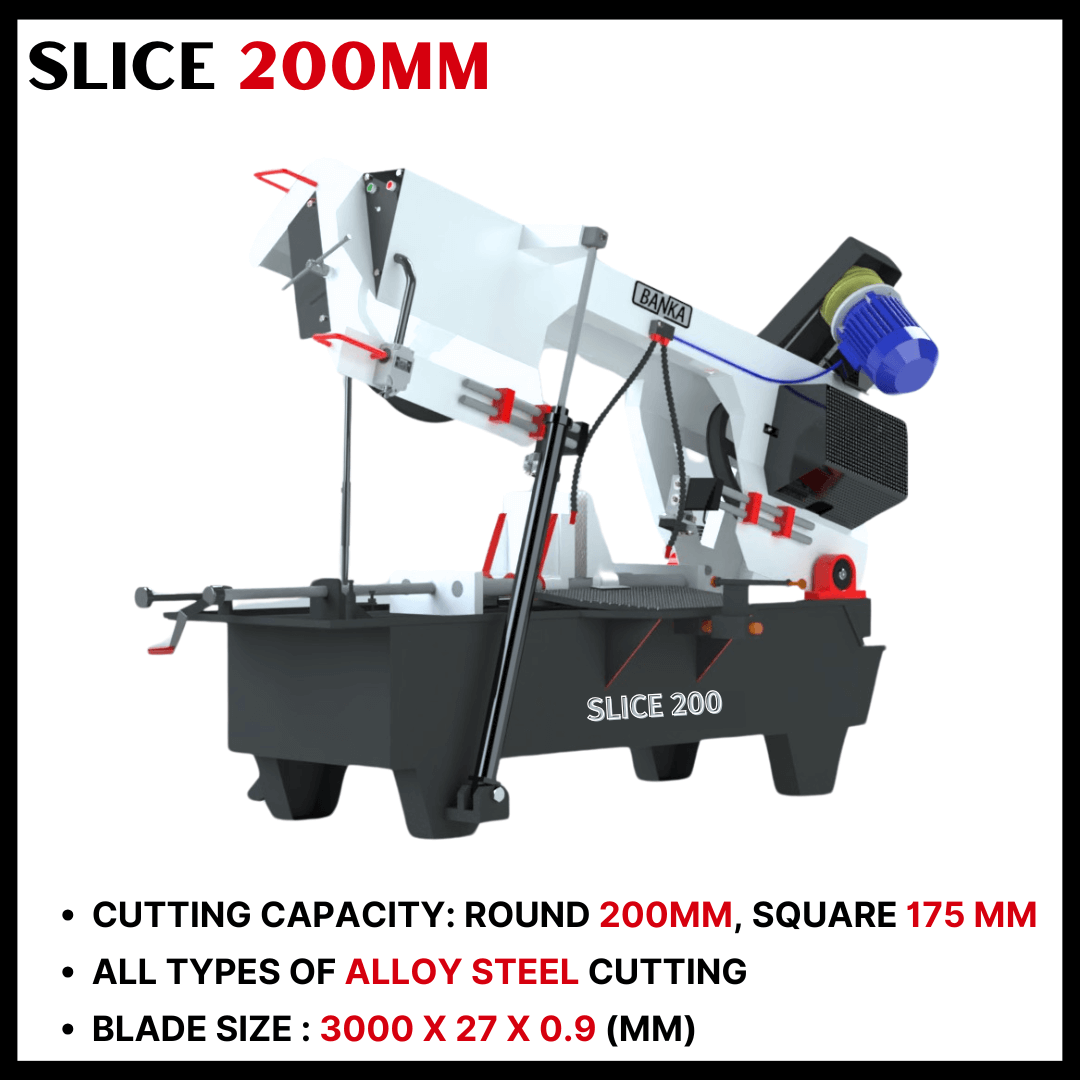

Bandsaw Machine -Metal Cutting – Alloy Steel Cutting- SLICE 200

₹1,39,000

- BANDSAW MACHINE SLICE 200 MM

- Model: Semi-Hydraulic Metal Cutting Bandsaw Machine

- Category: Metal Cutting Machine / All Types of Alloy Steel Cutting

- Colour: Black with Gray Colour

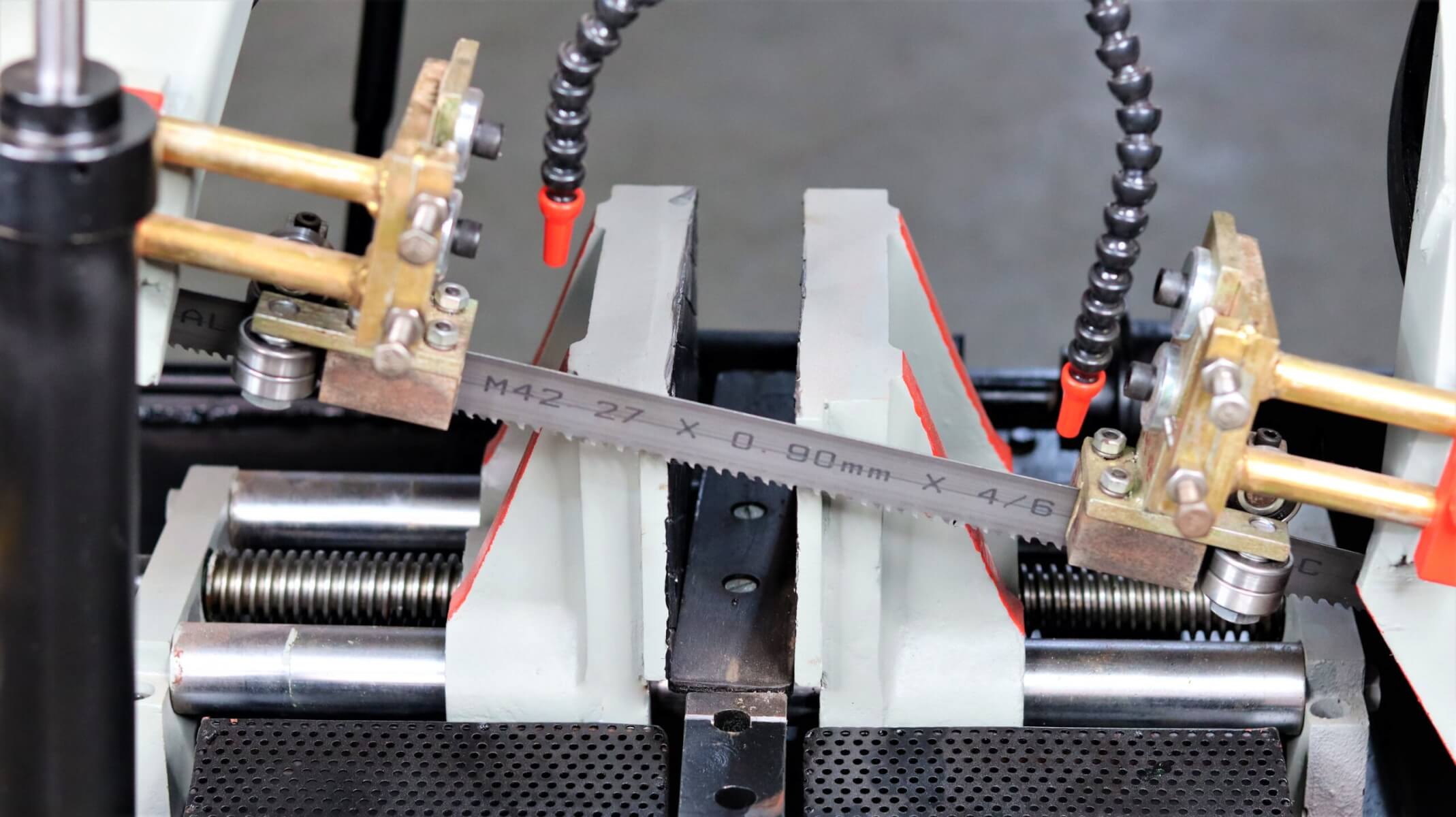

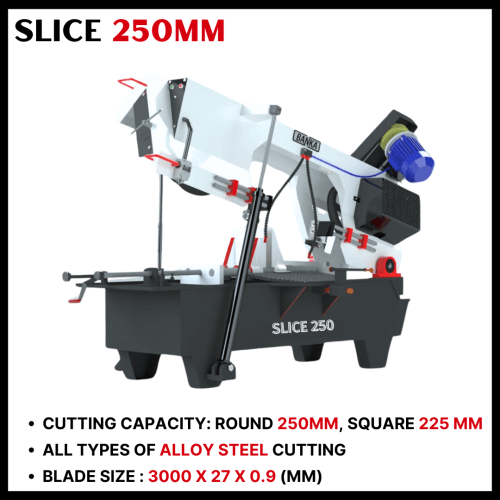

- Blade Size : 3000 x 27 x 0.9 (mm)

- Electricals: 1.5 HP

- Cutting Stroke Capacity in Materials: Round 200mm, Square 175 x 175, Casting, EN8, WPS Hard materials

- Body: Box Structure Body with 5mm Plate

Helps you find the Best Bandsaw

| MODEL | BANKA SLICE 200 |

| Round Job | 200MM |

| Square Job | 175 x 175MM |

| Drive Motor | 1.5 HP |

| RPM | 1440 |

| Coolant Pump | 0.25 H.P |

| First Pully Speed | 20 |

| Second Pully Speed | 40 |

| Third Pully Speed | 60 |

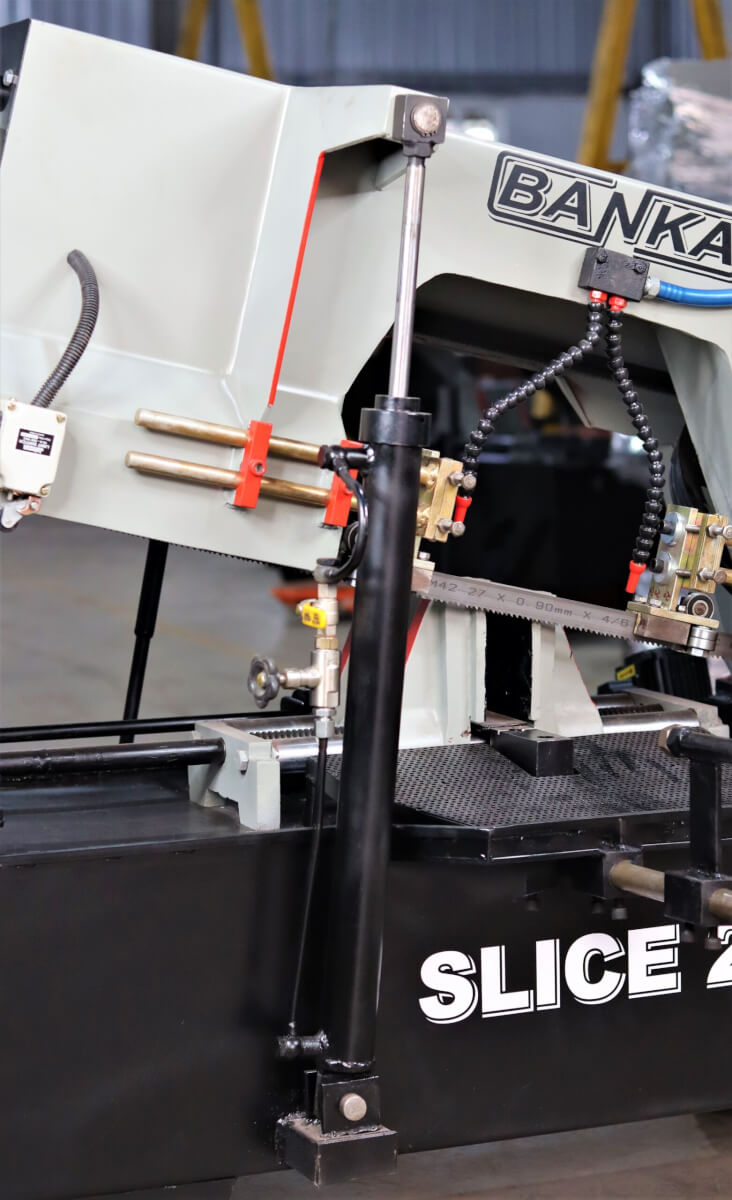

| Blade size | 3000 x 27 x 0.9MM |

| Floor space L x W x H | 1600 x 700 x 1330MM |

| Job Holding Height | 450MM |

A metal-cutting bandsaw machine is a specialized tool used for cutting various types of metal materials. It typically consists of a sturdy base with a horizontal platform for placing the metal workpiece. The key features include:

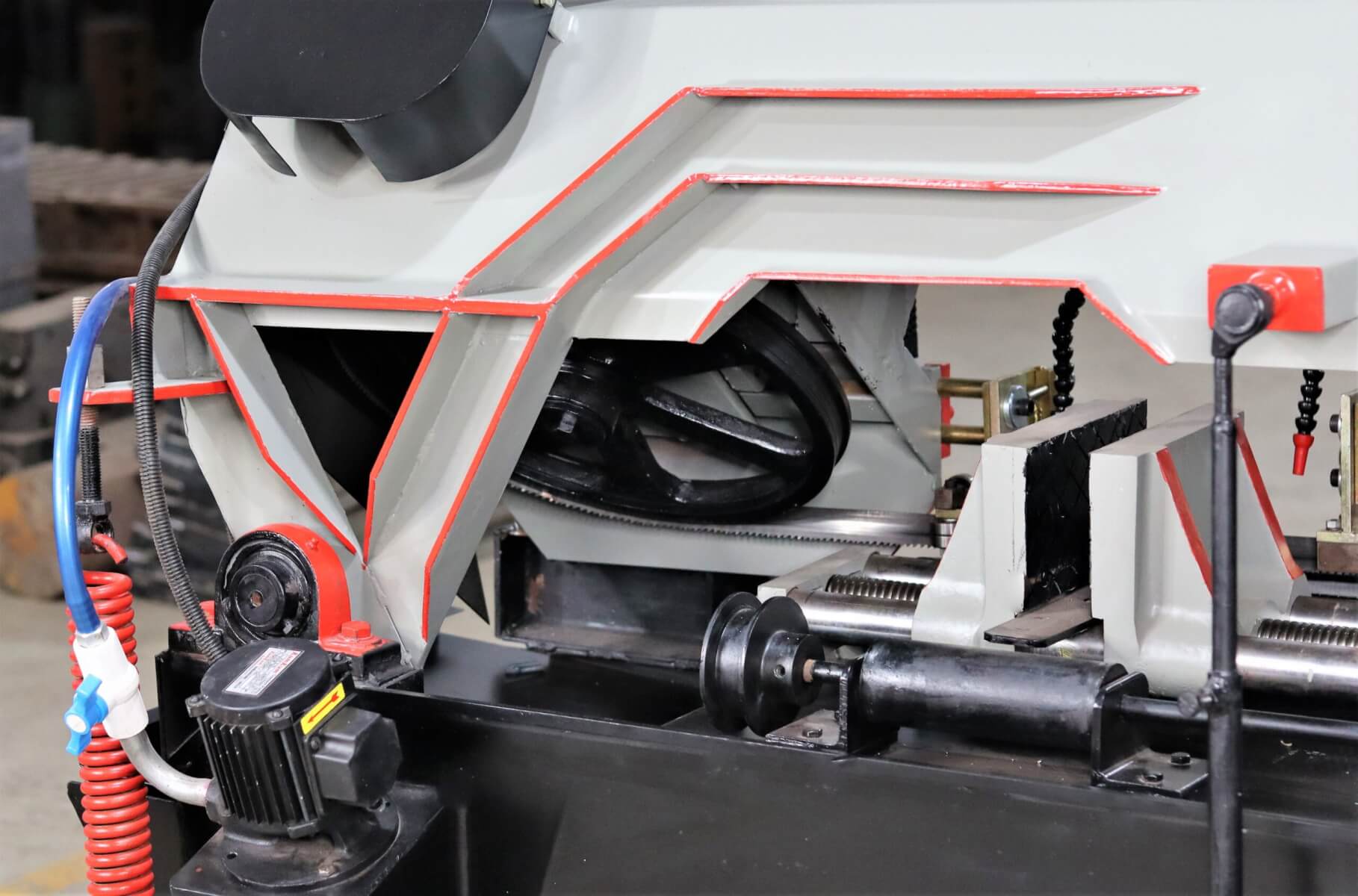

- Blade: Equipped with a continuous metal cutting blade that rotates around two wheels to create a continuous cutting motion.

- Cutting Capacity: Capable of cutting through various metals such as steel, aluminum, brass, and others with precision.

- Adjustable Features: Adjustable blade speed and cutting angles to accommodate different materials and cutting requirements.

- Safety Features: Includes safety guards and mechanisms to ensure operator safety during operation.

- Coolant System: Some models have a coolant system to keep the blade and workpiece cool during cutting, reducing friction and extending blade life.

| WHY CUSTOMERS LIKE BANKA BANDSAW | |

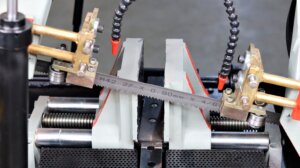

| Machine Vice |

|

| We Use UC Bearing | Backless Free / No Vibration |

| Hydraulic Cylinder |

|

| Gear Box |

|

| Gear Box Oil Capacity |

|

| Bearing of Blade Support |

|

| High Adjustment Capacity |

|

| Weight of Machine |

|

Lead us to serve more

Free Accessories:

- Complete with Electricals

- Coolant Pump With Assembly

- On-Off Contactor with Push Buttons

- V-Belt Pulleys with V-Belt

- Job Stopper

- Oil Field Gearbox

- Vice Handle

- One Blade Including

We are here to Help you

1) What will be the warranty Period of this Bandsaw Machine?

A:Generally Suppliers of the Bandsaw machine are providing only one year warranty period in the Bandsaw machine. And it is not the proper return according to your investment. While We are providing 3 years warranty in our products. If there any parts damaged in your machine than we also provides free parts service in warranty period by fastest courier service.

2) How Many types are available in Bandsaw Machine?

A:Generally there are mainly 3/4 types of Bandsaw machine are popular in the Market.

Manual Bandsaw Machine

Semi Automatic Bandsaw Machine

Single Column Bandsaw Machine

Double Column Bandsaw Machine

Fully Automatic Bandsaw Machine

3) What are the confusions raised in the mind of customer at the time of purchasing Bandsaw Machine ?

A :1) Cutting Capacity requirement

2) Light duty / Heavy Duty

3) Hydraulic OR Semi – Hydraulic

4) Single Column OR Double Column

4) Which Accessories I Should buy with the Hacksaw Machine?

A : Coolant Pump, Electric Motor, etc..

5) Do you accept Domestic LC ?

A: Yes, accept domestic LC for 60 days on credit. Generally our 75 % customers are purchasing Machine from us with 60 days Credit through a Simple Process of LC. When the Seller is Unknown or New to the Buyer, Letter of Credit is one good Alternative to do the Business with Such New Seller Because Buyer can Avoid Risk by such Letter. Letter of Credit is one Additional Benefit to the Buyer by which they can protect Loss against Goods and Finance Also.The buyer can build safeguards into the letter of credit, including inspection of the goods and quality control, and set production and delivery times.