SURFACE GRINDER MACHINE-SCOUR 450 MANUAL

₹3,25,000

- MODEL SCOUR 450 MANUAL

- TABLE SIZE 450 x 230 MM

- SPINDLE MOTOR 1.5HP

- GRINDING WHEEL SIZE 200 x 16 x 32 MM

- JOB WORKLOAD CAPACITY 80 KG

- NET WEIGHT 1000 KG

- WARRANTY 3 YEARS

- DELIVERY FREE

BANKA Manual Surface Grinders typically have several key features that make them versatile and effective tools for grinding operations:

-

MANUAL OPERATIONS: They are operated manually, which gives the operator control over the grinding process, including feed rate and depth of cut.

-

ADJUSTABALE TABALE: The table can be adjusted both longitudinally and across the width of the grinder, allowing for precise positioning of the workpiece.

-

GRINDING WHEEL : Equipped with a grinding wheel that rotates at high speeds to grind the surface of the workpiece. The size and type of the grinding wheel can vary based on the application.

-

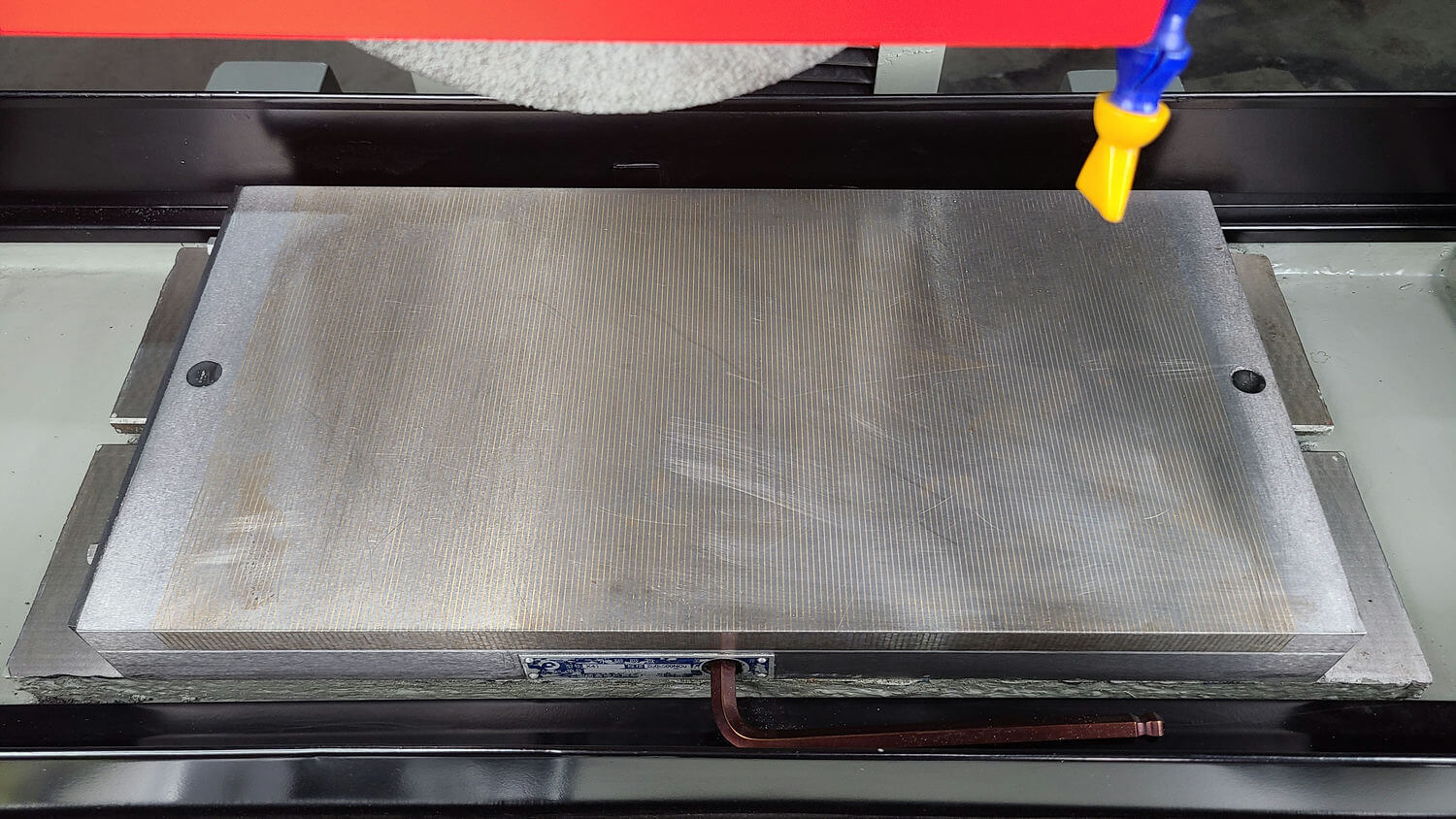

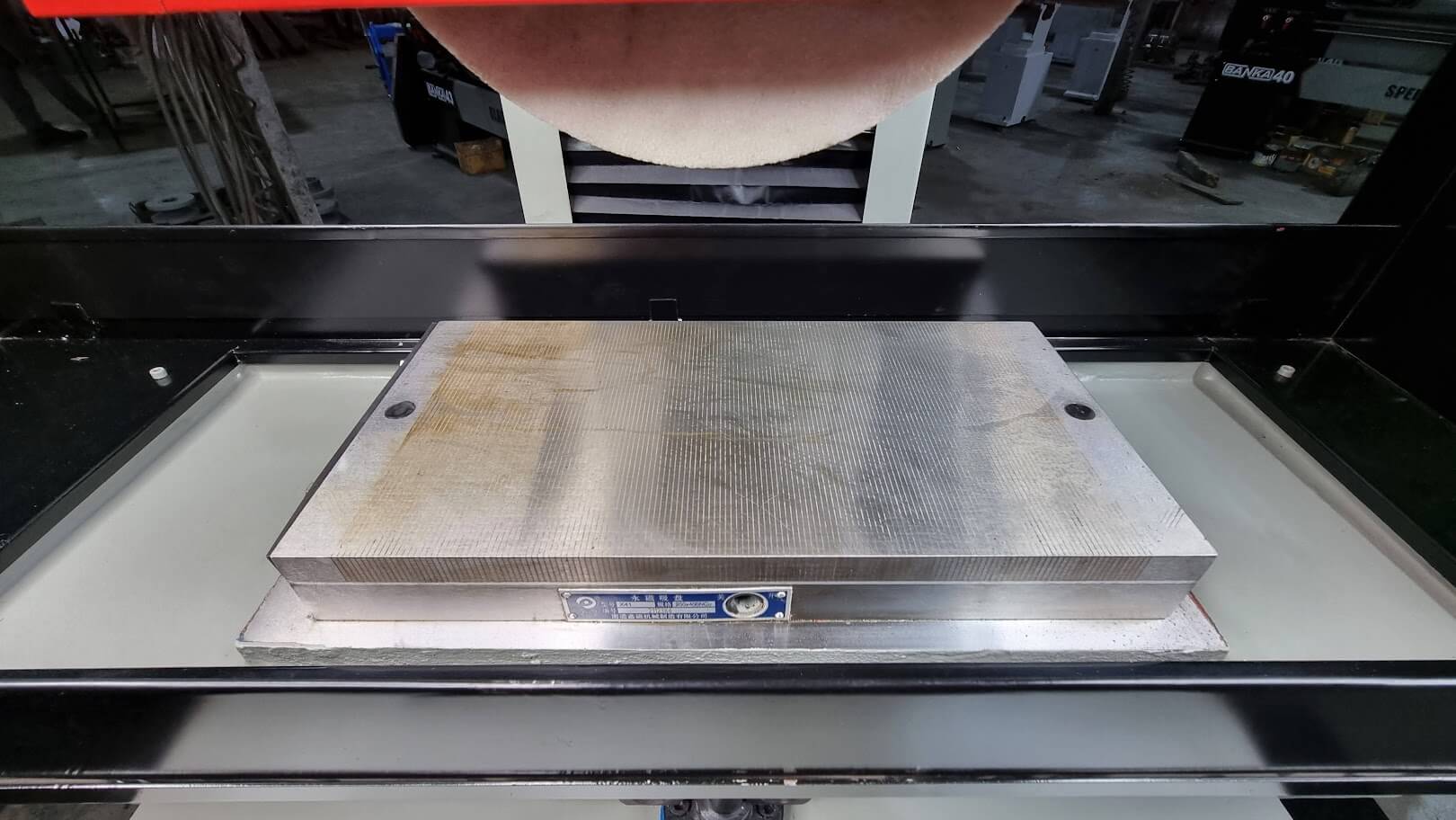

MAGNETIC CHUCK: Often equipped with a magnetic chuck that securely holds ferromagnetic materials in place during grinding, ensuring stability and accuracy.

-

WHEEL GUARD: A protective cover around the grinding wheel to ensure operator safety and to contain debris.

-

COOLANT SYSTEM : Some models may have a coolant system to keep the grinding area cool and to wash away grinding swarf, which helps to prolong the life of the grinding wheel.

-

HANDWHEEL CONTROLS : Handwheels or levers are used to manually control the movement of the grinding wheel and the table, allowing for precise adjustments.

These features combine to make manual surface grinders essential tools in various industries where precision grinding of metal surfaces is required.

MANUAL SURFACE GRINDER SPECIFICATION

| MODEL NO | SCOUR 450 | SCOUR 500 | SCOUR 600 |

| Table Size | 450 x 230mm | 500 x 250mm | 600 x 300mm |

| Longitudinal table Travel | 500 mm | 520mm | 620mm |

| Cross Table Travel | 250 mm | 270mm | 325mm |

| Max. Distance From the spindle center to the worktable Surface | 430 mm | 430 mm | 430 mm |

| Safety Load of Bench(in max.) | 100 kg | 100 kg | 150 kg |

| Grinding Capacity: L x W x H | 450 x 230 x 330mm | 500 x 250 x 330mm | 600 x 300 x 300mm |

| T-slot | 12 x 1 | 12 x 1 | 14 x 1 |

| Net Weight | 1000 KG | 1600 KG | 2000 KG |

| Cross-hand wheel per Graduation | 0.02 mm/Div | 0.02 mm/Div | 0.02 mm/Div |

| Spindle motor | 1.5Hp | 1.5HP- | 2 HP |

| Lifting motor | 0.25 HP | 0.25 HP | 0.25 HP |

| Grinding Wheel size (D x W x D) | 200 x 16 x 32 mm | 200 x 16 x 32 mm | 200 x 16 x 32 mm |

| Spindle Speed | 2850 r/min | 2850 r/min | 2850 r/min |

| Max. Movement of Vertical mechanism | 430 mm | 430 mm | 400 mm |

| Vertical fine adjustment revolution | 0.15 mm | 0.15 mm | 0.15 mm |

| Vertical per fine adjustment graduation | 0.002 mm | 0.002 mm | 0.002 mm |

| Coolant Motor | 0.5HP | 0.5HP | 0.5 HP |

| All Over Dimensions- MM | 1200 x 1050 x 1500 | 1250 x 1200 x 1700 | 1900 x 1200 x 1900 |

| Price | 325000 | 375000 | 395000 |

BANKA MANUAL SURFACE GRINDER

A Manual Surface Grinder is a precision machine tool used for grinding flat surfaces on metal and other materials. It is manually operated, allowing the operator to control the grinding process by adjusting the table movement, feed rate, and depth of cut.

The machine consists of a rotating grinding wheel mounted on a spindle, which removes material from the workpiece to achieve high-precision finishes. The workpiece is typically held in place by a magnetic chuck or other clamping methods. The operator moves the table back and forth, while the grinding wheel gradually removes material, ensuring a smooth and accurate surface finish.

KEY COMPONENTS

- GRINDING WHEEL – Used for cutting and finishing surfaces.

- MAGNETIC CHUCK – Holds ferromagnetic materials securely in place.

- HANDWHEEL CONTROL – Adjust the movement of the table and grinding wheel.

- WORK TABLE – Supports and moves the workpiece during grinding.

- WHEEL GUARD – Ensures safety by covering the grinding wheel.

- COOLANT SYSTEM (Optional) – Helps reduce heat and remove grinding debris.

APPLICATIONS OF USE

- Precision machining of flat surfaces.

- Tool and die-making.

- Grinding hardened steel, cast iron, and other metals.

- Refinishing worn-out machine parts.

Manual surface grinders are commonly used in workshops, tool rooms, and small manufacturing units, where high-precision surface grinding is required at an affordable cost.

STANDARD ACCESSORIES

- Permanent Magnetic Chuck

- Machine Lamp

- Lubrication System for Oil

- Coolant System with complete Assembly

- Tool Box

- Manual Book for Machine Guidance

We are here to Help you

1) What will be warranty period of this surface grinder machine ?

A:Generally Suppliers of the Surface Grinder Machines are providing only one year warranty period in the lathe machine. And it is not the proper return according to your investment. While We are providing 3 years warranty in our products. If there any parts damaged in your machine than we also provides free parts service in warranty period by fastest courier service for One year.

2) How Many types of Surface Grinder Machines are available in the Market?

A:

- Manual Surface grinder Machine

- Hydraulic Surface Grinder Machine

3) How many popular models are available for the Surface grinder Machine?

A :

1) 200 x 450 MM

2) 250 x 450 MM

3) 300 x 450 MM

4) 250 x 600 MM

5) 300 x 600 MM

6) 600 X 300 MM

7) 500 X 250 MM

8) 450 X 230 MM

4) Which accessories I Should buy with Surface grinder Machine?

A :

1) Diamond Tools

2) Electrical Coolant Pump

3) Magnetic Chuck

4) Work Light

5) Do you accept Domestic LC ?

A: Yes, accept domestic LC for 60 days on credit. Generally our 75 % customers are purchasing Machine from us with 60 days Credit through a Simple Process of LC. When the Seller is Unknown or New to the Buyer, Letter of Credit is one good Alternative to do the Business with Such New Seller Because Buyer can Avoid Risk by such Letter. Letter of Credit is one Additional Benefit to the Buyer by which they can protect Loss against Goods and Finance Also.The buyer can build safeguards into the letter of credit, including inspection of the goods and quality control, and set production and delivery times.