Machine Shop Accessories, Tools & Instruments

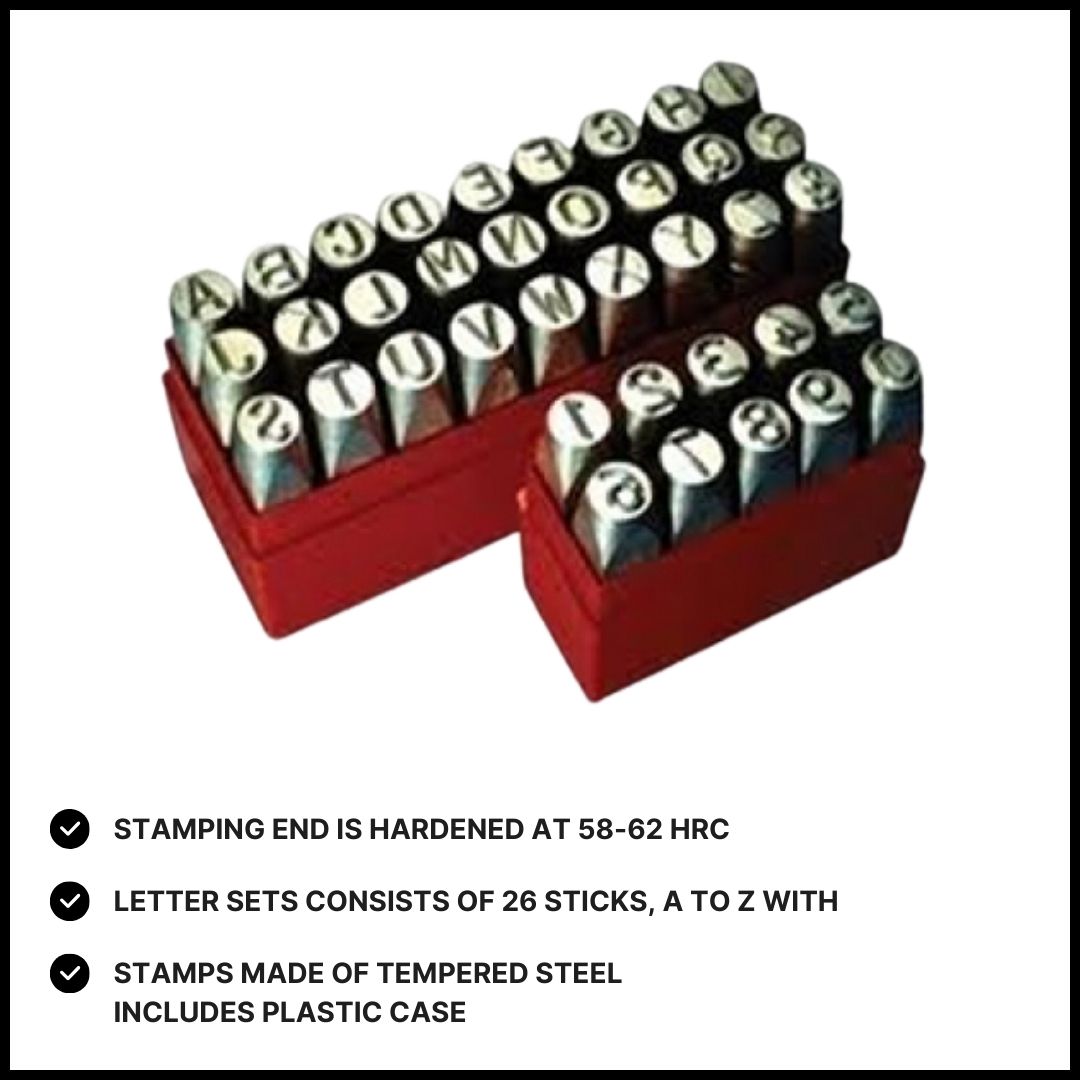

Letter Punch Set (Alphabets)

Tag: Popular Tools

₹1,999

Manufactured by making use of quality approved carbon steel and innovative technology under the strict vigilance of our diligent professionals, the punch set provided by is highly preferable for the installation in various punching machines.his Letter Punch Set in different specifications at rock bottom prices within the estimated time span

Weight: 1.64 Kg

Letter punches are tools used to stamp letters, numbers, or symbols onto various materials such as metal, leather, or wood. They are commonly used for marking, engraving, or personalizing items. Here’s how to use letter punches effectively:

How to Use Letter Punches

- Select the Right Punch:

- Character Choice: Choose the letter or symbol punch that corresponds to the character you want to stamp.

- Size and Style: Ensure the punch size and style are appropriate for the material and the level of detail you need.

- Prepare Your Work Area:

- Workspace: Use a sturdy, non-marring surface, such as a steel or hardwood block, to absorb the impact and avoid damaging your workbench.

- Material Placement: Secure the material you’re stamping. For metals or hard materials, a vise or clamp can help hold the material steady.

- Position the Punch:

- Alignment: Position the punch on the material where you want to make the mark. Align it carefully to ensure the character is placed accurately.

- Straightness: Hold the punch perpendicular to the surface to ensure a straight and clear imprint.

- Apply the Impact:

- Hammer Choice: Use a heavy hammer or mallet designed for use with metal punches. For softer materials like leather, a mallet with a softer striking surface is preferable.

- Striking Technique: Hold the punch firmly and strike it with a single, firm blow. Avoid multiple blows or excessive force, as this can distort the punch mark or damage the material.

- Check the Imprint:

- Inspect the Result: After stamping, check the imprint for clarity and completeness. If necessary, you can re-strike the punch carefully to enhance the imprint, but be cautious not to overdo it.

- Clean Up:

- Material Debris: Remove any material debris around the stamped area.

- Tool Maintenance: Clean the punch after use to prevent rust and ensure longevity. Store it in a dry, safe place to avoid damage.

Tips for Effective Use

- Consistent Pressure: Apply consistent and firm pressure when striking the punch. Inconsistent blows can result in uneven or unclear impressions.

- Pre-Stamp Practice: If you’re working on a high-visibility project, practice on a scrap piece of the same material first to get a feel for the tool and technique.

- Use Guides: For precise placement or repeated stamping, consider using guides or templates to ensure accuracy and consistency.

Applications

- Metalworking: Used for marking or personalizing metal items, such as tools, jewelry, or machinery.

- Leatherworking: Used for stamping initials or designs into leather goods, like belts or wallets.

- Woodworking: Used for marking or creating designs in wooden projects.

Maintenance and Care

- Regular Cleaning:

- Wipe the punches clean after use to remove any debris or residue that could affect performance.

- For metal punches, occasional rust prevention treatments may be necessary, such as applying a light coat of oil.

- Proper Storage:

- Store punches in a dry, cool place to prevent rust and damage.

- Keep punches organized to avoid misplacement and ensure easy access.

- Inspection:

- Regularly inspect punches for signs of wear or damage. Replace any that are chipped, cracked, or otherwise compromised.

Related Products

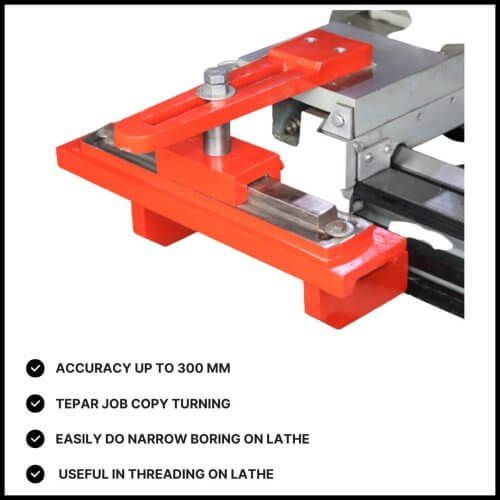

Taper Turning Attachment For Lathe Machine

Sale

Best Seller

Lathe Quick Change Tool Post With 3 Holder

Sale

Efficient