- Sorry, this product cannot be purchased.

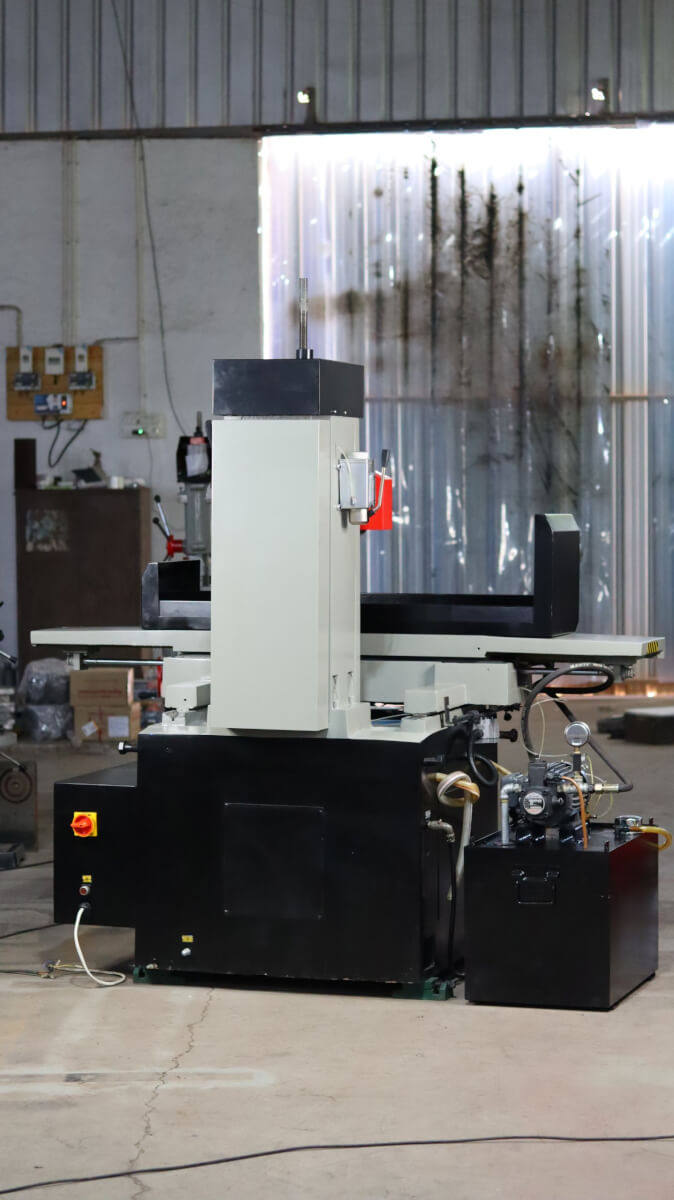

HYDRAULIC SURFACE GRINDER MACHINE – MODEL SCOUR 600

₹8,25,000

- MODEL SCOUR 600

- TABLE SIZE 600 x 300 MM

- SPINDLE MOTOR 2 HP

- GRINDING WHEEL SIZE 200 x 16 x 32 MM

- JOB WORKLOAD CAPACITY 200 KG

- NET WEIGHT 2200 KG

- WARRANTY 3 YEARS

- DELIVERY FREE

BANKA Scour Model Hydraulic surface grinders come with several key features that make them efficient and precise for grinding operations:

-

Hydraulic System: This is the core feature that allows for smooth and consistent movement of the grinding wheel and workpiece. Hydraulic systems provide precise control over the grinding process, which is crucial for achieving accurate surface finishes.

-

Automatic Cross Feed: Many hydraulic surface grinders have automatic cross feed mechanisms, which can be programmable. This feature enables the grinder to automatically feed the grinding wheel across the workpiece, ensuring uniform material removal and reducing operator fatigue.

-

Variable Speed Spindle: Some models offer variable speed spindles, allowing operators to adjust the rotational speed of the grinding wheel based on the material being ground and the desired surface finish.

-

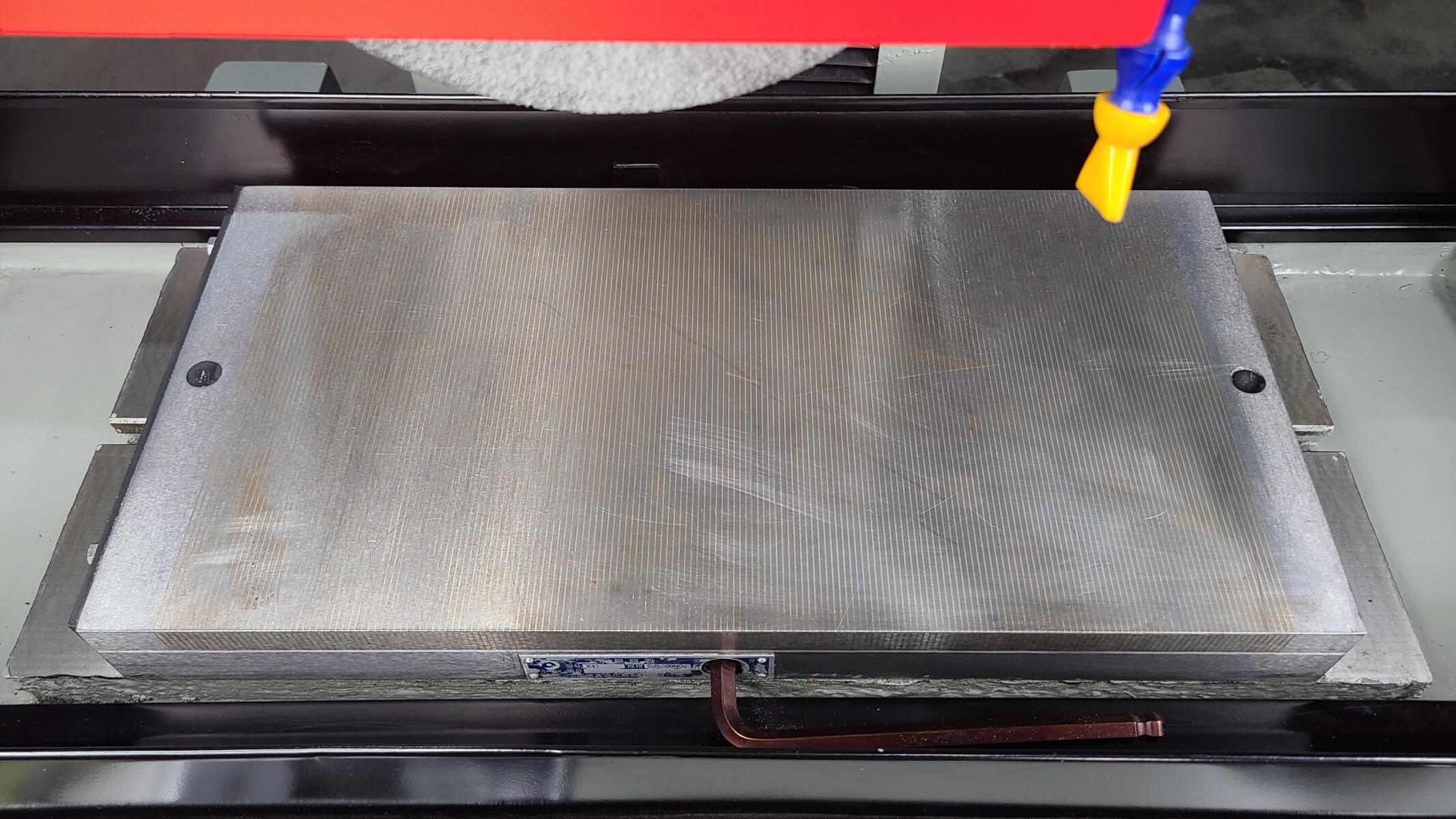

Magnetic Chuck: Hydraulic surface grinders typically include a magnetic chuck that securely holds the workpiece in place during grinding. This ensures stability and precision during the grinding process.

-

Coolant System: To prevent overheating and maintain consistent grinding performance, hydraulic surface grinders often come with a built-in coolant system. This helps in flushing away debris and maintaining the temperature of the grinding wheel.

-

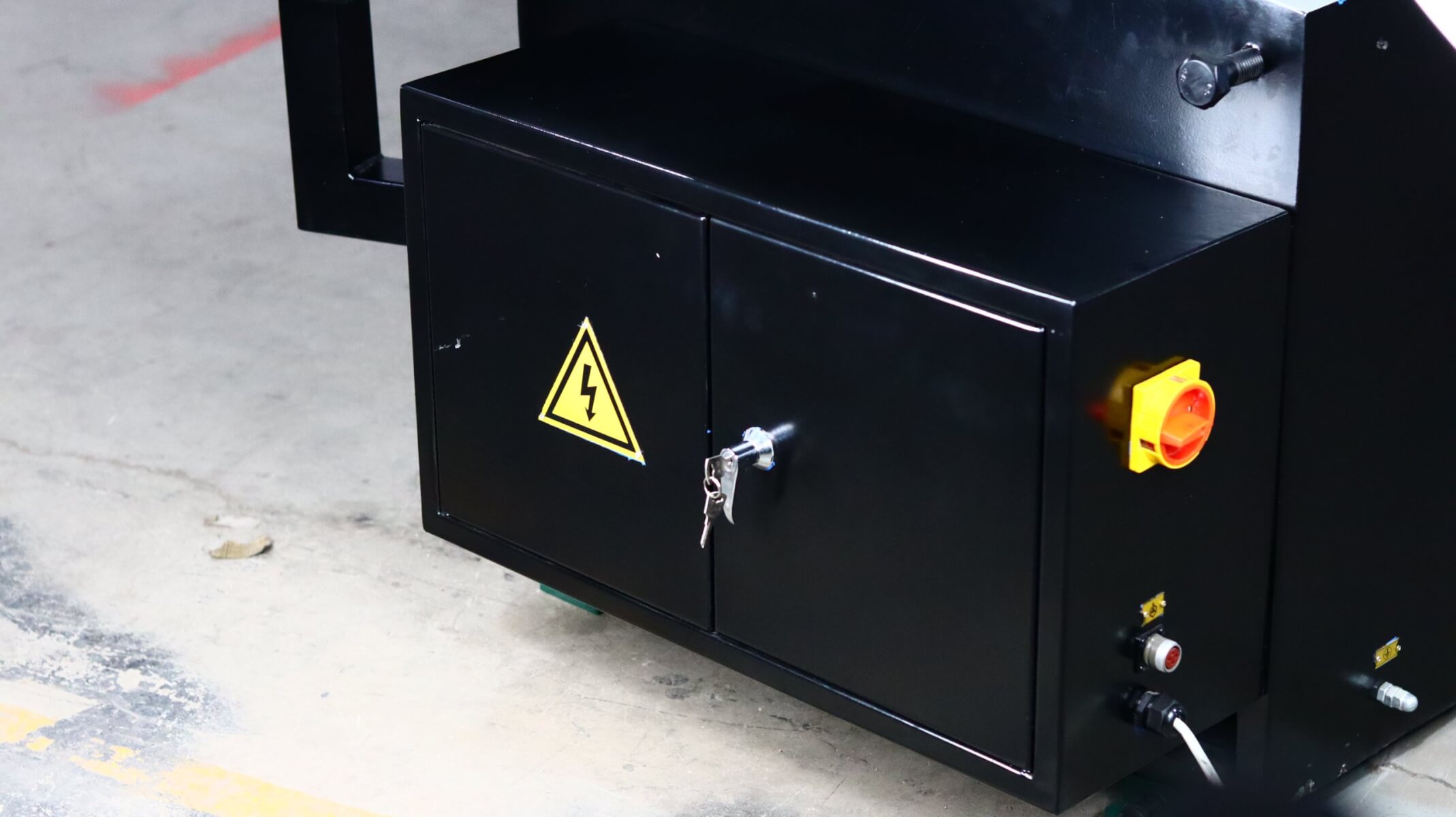

Safety Features: Important safety features such as emergency stop buttons, protective guards, and interlocks are standard on hydraulic surface grinders to ensure operator safety during operation.

These features collectively make hydraulic surface grinders versatile and capable of handling a wide range of grinding tasks with high precision and efficiency.

HYDRAULIC SURFACE GRINDER SPECIFICATION

| MODEL NO | SCOUR 450 | SCOUR 500 | SCOUR 600 | SCOUR 1000 |

| Table Size | 450 x 230mm | 500 x 250mm | 600 x 300mm | 1000 x 400mm |

| Longitudinal table Travel | 500 mm | 520mm | 620mm | 1020mm |

| Cross Table Travel | 250 mm | 270mm | 325mm | 440mm |

| Max. Distance From the spindle center to the worktable Surface | 430 mm | 430 mm | 430 mm | 580mm |

| Safety Load of Bench(in max.) | 100 kg | 100 kg | 150 kg | 400 kg |

| Grinding Capacity: L x W x H | 450 x 230 x 330mm | 500 x 250 x 330mm | 600 x 300 x 300mm | 1000 x 400 x 430mm |

| T-slot | 12 x 1 | 12 x 1 | 14 x 1 | 18×3 mm |

| Net Weight | 1200 KG | 1700 KG | 2200 KG | 4200Kg |

| Cross-hand wheel per Graduation | 0.02 mm/Div | 0.02 mm/Div | 0.02 mm/Div | 0.02 mm/Div |

| Spindle motor | 1.5Hp | 1.5HP- | 2 HP | 7 Hp |

| Lifting motor | 0.25 HP | 0.25 HP | 0.25 HP | 0.25Hp |

| Grinding Wheel size (D x W x D) | 200 x 16 x 32 mm | 200 x 16 x 32 mm | 200 x 16 x 32 mm | 350 x 32 x 127 MM |

| Spindle Speed | 2850 r/min | 2850 r/min | 2850 r/min | 1450 r/min |

| Max. Movement of Vertical mechanism | 430 mm | 430 mm | 400 mm | – |

| Vertical fine adjustment revolution | 0.15 mm | 0.15 mm | 0.15 mm | 0.04 mm |

| Vertical per fine adjustment graduation | 0.002 mm | 0.002 mm | 0.002 mm | 0.001 mm |

| Coolant Motor | 0.5HP | 0.5HP | 0.5 HP | 0.5HP |

| All Over Dimensions- MM | 1200 x 1050 x 1500 | 1250 x 1200 x 1700 | 1900 x 1200 x 1900 | 2700 x 1790 x 1950 MM |

| Price | 5,25,000 | 6,25,000 | 8,25,000 | 16,25,000 |

HYDRAULIC SURFACE GRINDER MACHINE

A Hydraulic Surface Grinder is a precision machining tool used for achieving high-quality surface finishes on metallic and non-metallic materials. It operates using a hydraulic system to control the movement of the grinding table and wheel, ensuring smooth and accurate grinding operations. These machines are widely used in tool rooms, manufacturing units, and industrial workshops for applications requiring fine surface finishes and tight tolerances.

KEY FETURES & COMPONENTS

-

BASE & STRUCTURE

- Constructed from high-grade cast iron to absorb vibrations and enhance durability.

- Rigid structure ensures stability during grinding operations.

-

HYDRAULIC SYSTEM

- Provides automatic table movement for smooth and precise operation.

- Offers adjustable speed control for enhanced accuracy.

-

WORKTABLE

- Moves longitudinally and transversely for precise positioning.

- Often equipped with a magnetic chuck to securely hold the workpiece.

-

GRINDING WHEEL & SPINDLE

- High-speed abrasive grinding wheel ensures efficient material removal.

- Precision spindle with dynamically balanced bearings for smooth operation.

-

COOLANT SYSTEM

- Integrated cooling mechanism to prevent overheating.

- Ensures smooth cutting and enhances tool life.

-

SAFETY MECHANISM

- Emergency stop switch for immediate halting of operations.

- Protective covers and interlocks for operator safety.

APPLICATIONS OF USE

- Precision surface finishing for tools, dies, and molds.

- Grinding hardened materials for automotive, aerospace, and industrial parts.

- Sharpening cutting tools for machine shops.

- Flattening and smoothing metal surfaces for fabrication work.

A Hydraulic Surface Grinder is an essential tool in modern machining industries, offering high accuracy, consistency, and automation in surface grinding tasks.

STANDARD ACCESSORIES

- Permanent Magnetic Chuck

- Machine Lamp

- Lubrication System for Oil

- Coolant System with complete Assembly

- Tool Box

- Manual Book for Machine Guidance

We are here to Help you

1) What will be warranty period of this surface grinder machine ?

A:Generally Suppliers of the Surface Grinder Machines are providing only one year warranty period in the lathe machine. And it is not the proper return according to your investment. While We are providing 3 years warranty in our products. If there any parts damaged in your machine than we also provides free parts service in warranty period by fastest courier service for One year.

2) How Many types of Surface Grinder Machines are available in the Market?

A:

- Manual Surface grinder Machine

- Hydraulic Surface Grinder Machine

3) How many popular models are available for the Surface grinder Machine?

A :

1) 200 x 450 MM

2) 250 x 450 MM

3) 300 x 450 MM

4) 250 x 600 MM

5) 300 x 600 MM

6) 600 X 300 MM

7) 500 X 250 MM

8) 450 X 230 MM

4) Which accessories I Should buy with Surface grinder Machine?

A :

1) Diamond Tools

2) Electrical Coolant Pump

3) Magnetic Chuck

4) Work Light

5) Do you accept Domestic LC ?

A: Yes, accept domestic LC for 60 days on credit. Generally our 75 % customers are purchasing Machine from us with 60 days Credit through a Simple Process of LC. When the Seller is Unknown or New to the Buyer, Letter of Credit is one good Alternative to do the Business with Such New Seller Because Buyer can Avoid Risk by such Letter. Letter of Credit is one Additional Benefit to the Buyer by which they can protect Loss against Goods and Finance Also.The buyer can build safeguards into the letter of credit, including inspection of the goods and quality control, and set production and delivery times.