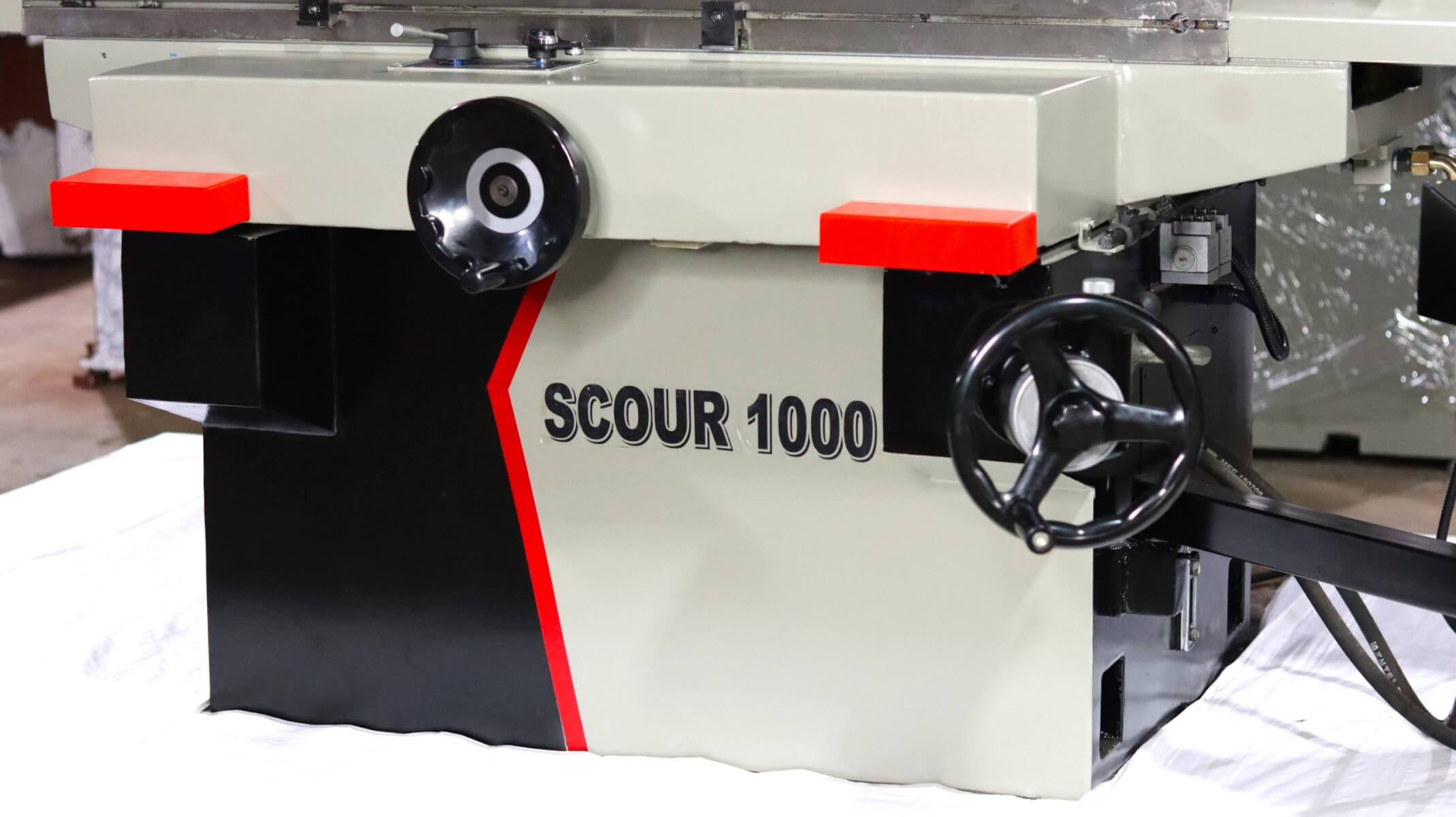

SCOUR 1000 – HYDRAULIC SURFACE GRINDER MACHINE Backup

- Table Size (1000) mm

- Total 4 Models Available

- 3 Years warranty

- Delivery Free

- Transportation Free

- 100% Responsibility

Separate us from others

- What is the use of a Surface Grinder: A surface grinder is a machine tool used to provide precision ground surfaces, either to a critical size or for the surface finish.

- What are the different types of surface grinding machines: There are three basic types of surface grinders: horizontal-spindle, vertical-spindle, single-disc grinders, and double-disc grinders.

- What is the principle of a grinder: A coil is positioned between the magnetic field. Whenever a current flows through the coil, it encounters a magnetic force that causes it to rotate. This mechanical energy turns the blades into the of mixer and grinder, which grinds the ingredients.

- High surface finish and accuracy are produced.

- Ability to machine hard material.

- Less pressure can be applied to work.

- Ability to work at high temperatures.

- Offers highly accurate dimensions.

- Ability to cut any type of metal at a speed rate.

- It can produce a smooth surface.

HYDRAULIC SURFACE GRINDER SPECIFICATION

| MODEL NO | SCOUR 450 | SCOUR 500 | SCOUR 600 | SCOUR 1000 |

| Table Size | 450 x 230mm | 500 x 250mm | 600 x 300mm | – |

| Longitudinal table Travel | 500 mm | 520mm | 620mm | – |

| Cross Table Travel | 250 mm | 270mm | 325mm | – |

| Max. Distance From the spindle center to the worktable Surface | 430 mm | 430 mm | 430 mm | – |

| Safety Load of Bench(in max.) | 100 kg | 100 kg | 150 kg | – |

| Grinding Capacity: L x W x H | 450 x 230 x 330mm | 500 x 250 x 330mm | 600 x 300 x 300mm | – |

| T-slot | 12 x 1 | 12 x 1 | 14 x 1 | – |

| Net Weight | 1200 KG | 1700 KG | 2200 KG | – |

| Cross-hand wheel per Graduation | 0.02 mm/Div | 0.02 mm/Div | 0.02 mm/Div | – |

| Spindle motor | 1.5Hp | 1.5HP- | 2 HP | – |

| Lifting motor | 0.25 HP | 0.25 HP | 0.25 HP | – |

| Grinding Wheel size (D x W x D) | 200 x 16 x 32 mm | 200 x 16 x 32 mm | 200 x 16 x 32 mm | – |

| Spindle Speed | 2850 r/min | 2850 r/min | 2850 r/min | – |

| Max. Movement of Vertical mechanism | 430 mm | 430 mm | 400 mm | – |

| Vertical fine adjustment revolution | 0.15 mm | 0.15 mm | 0.15 mm | – |

| Vertical per fine adjustment graduation | 0.002 mm | 0.002 mm | 0.002 mm | – |

| Coolant Motor | 0.5HP | 0.5HP | 0.5 HP | – |

| All Over Dimensions- MM | 1200 x 1050 x 1500 | 1250 x 1200 x 1700 | 1900 x 1200 x 1900 | – |

| Price | – | – | 638000 | – |

Innovation with a Purpose

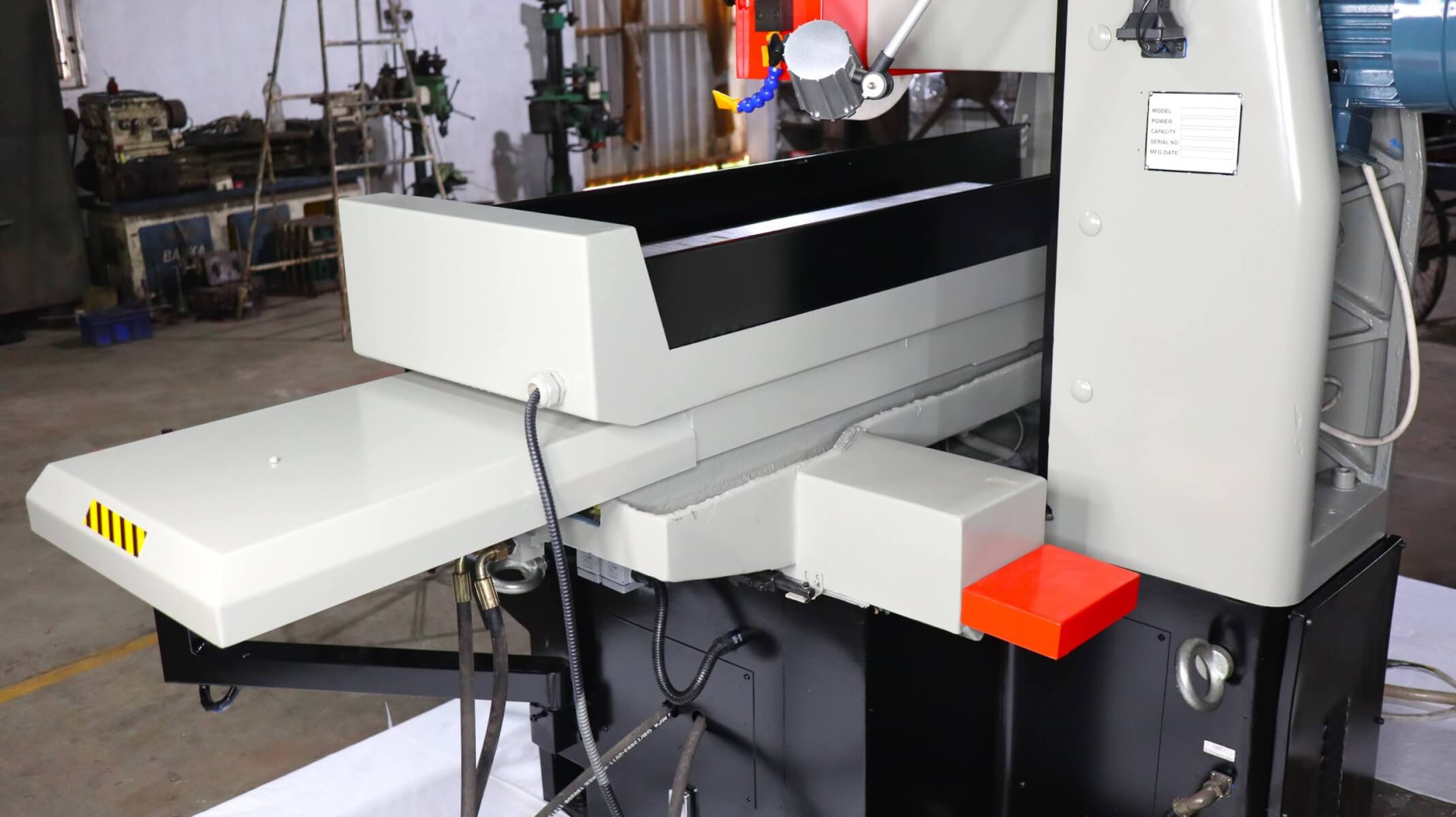

Wide use (The designed hand operating surface grinder is full think over to suitable for the need of all grades of the customers. ) Compact structure with smaller installation area and very easy to operations, but which provide the greater grinding regions with nice appearance, light and facile.

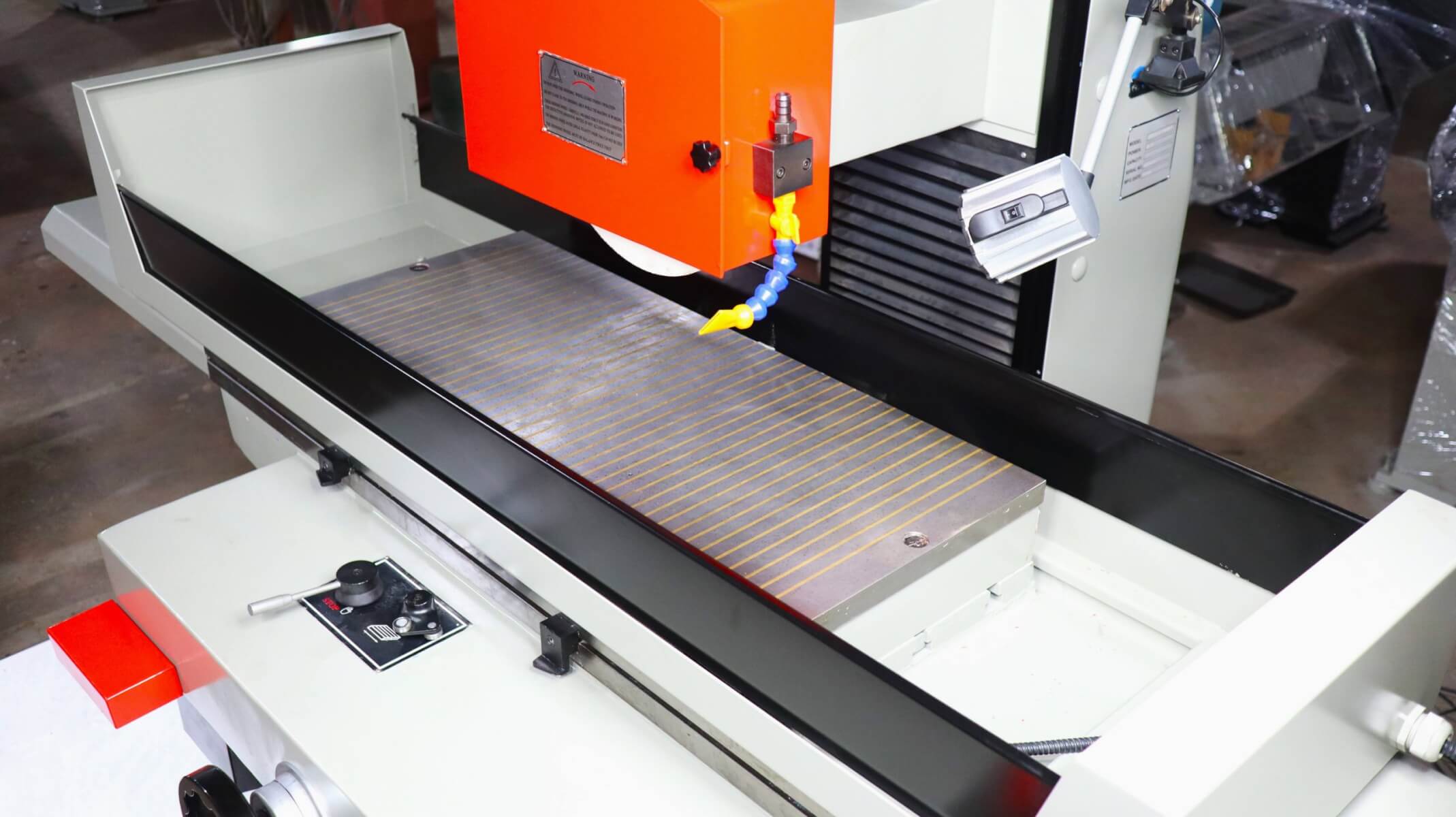

Longitudinal table travel on precision roller balls, light and flexible, cross rail with plastic-iron lining wearable, rapid up and down movement with fine adjustment to control the feed exactly.

Working Principle:

Longitudinal table travel on precision roller balls, light and flexible, cross rail with turcite lining wearable, rapid up and down movement with fine adjustment to control the feed exactly.

Installation & Start Up:-

Our Service technician ensure a fast and smooth installation and start up of your machine with top quality and to your complete satisfaction. Our Installation managers can gladly advise you in a timely manner about preparations for the installation.

Technical Support:-

Our service office is ready to advise you on any questions about your machine. Remote service gives us the ability to make a direct connections between your machine and our consultants. Remote diagnostics allows us to correct errors fast, reducing downtime.

You can speak to our service technician 24 x 7 on mobile as well as land lines avail on day time.

We track every request in our service information system, which shows us the entire history of your machine. The transparency leads to unambiguous diagnoses and fast responses times.

Annual Maintenance Contract

We also Offer AMC at 10% of the Machine value include 2 free service on your floor. You can contact us anytime for any complain from anywhere.

Lead us to serve more

Standard Accessories :

- Permanent Magnetic Chuck

- Machine Lamp

- Lubrication System for Oil

- Coolant System with complete Assembly

- Tool Box

- Manual Book for Machine Guidance

We are here to Help you

1) What will be warranty period of this surface grinder machine ?

A:Generally Suppliers of the Surface Grinder Machines are providing only one year warranty period in the lathe machine. And it is not the proper return according to your investment. While We are providing 3 years warranty in our products. If there any parts damaged in your machine than we also provides free parts service in warranty period by fastest courier service for One year.

2) How Many types of Surface Grinder Machines are available in the Market?

A:

- Manual Surface grinder Machine

- Hydraulic Surface Grinder Machine

3) How many popular models are available for the Surface grinder Machine?

A :

1) 200 x 450 MM

2) 250 x 450 MM

3) 300 x 450 MM

4) 250 x 600 MM

5) 300 x 600 MM

6) 600 X 300 MM

7) 500 X 250 MM

8) 450 X 230 MM

4) Which accessories I Should buy with Surface grinder Machine?

A :

1) Diamond Tools

2) Electrical Coolant Pump

3) Magnetic Chuck

4) Work Light

5) Do you accept Domestic LC ?

A: Yes, accept domestic LC for 60 days on credit. Generally our 75 % customers are purchasing Machine from us with 60 days Credit through a Simple Process of LC. When the Seller is Unknown or New to the Buyer, Letter of Credit is one good Alternative to do the Business with Such New Seller Because Buyer can Avoid Risk by such Letter. Letter of Credit is one Additional Benefit to the Buyer by which they can protect Loss against Goods and Finance Also.The buyer can build safeguards into the letter of credit, including inspection of the goods and quality control, and set production and delivery times.