Accessories for Drilling machines, Machine Shop Accessories, Tools & Instruments

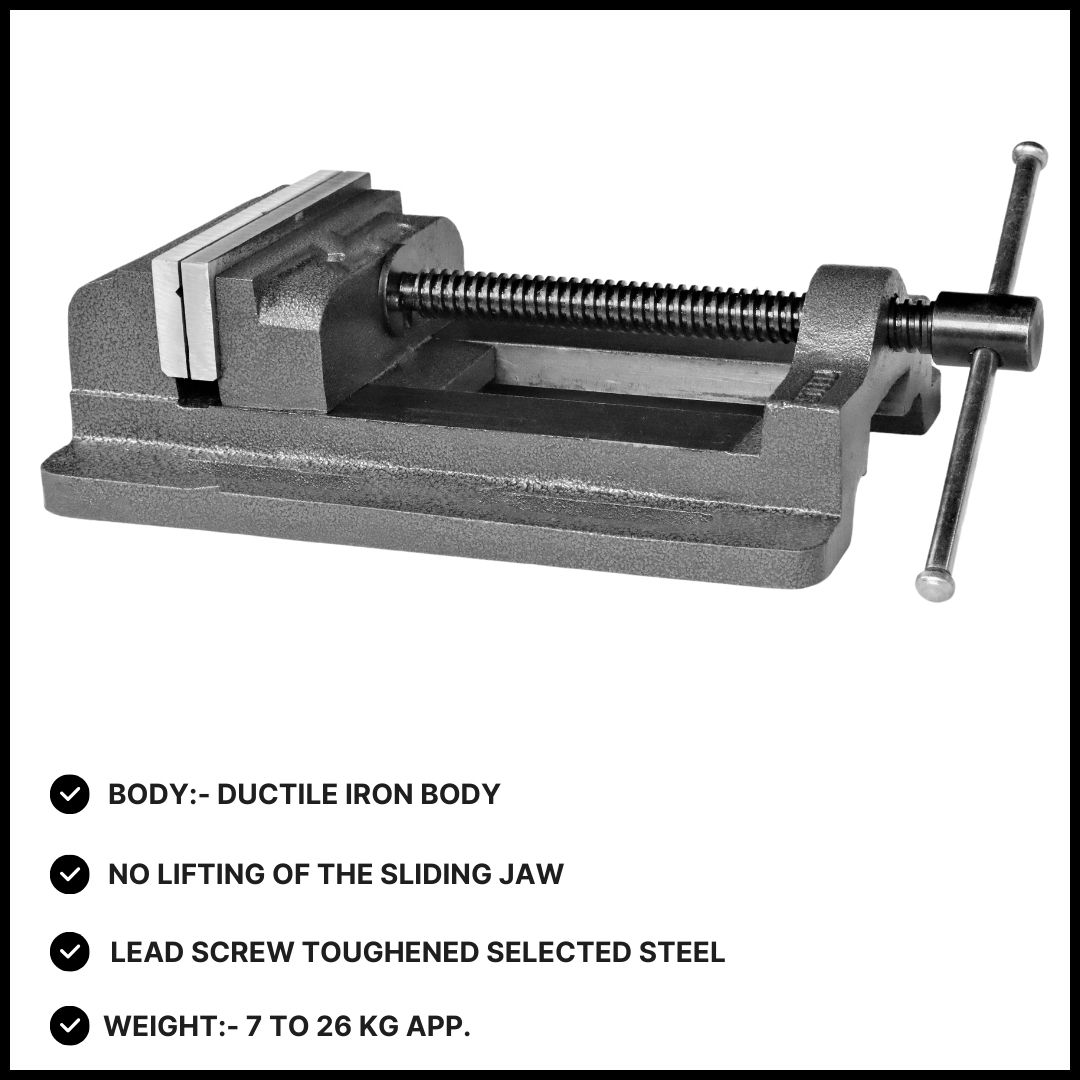

Drill Machine Vice

₹3,500 Original price was: ₹3,500.₹3,000Current price is: ₹3,000.

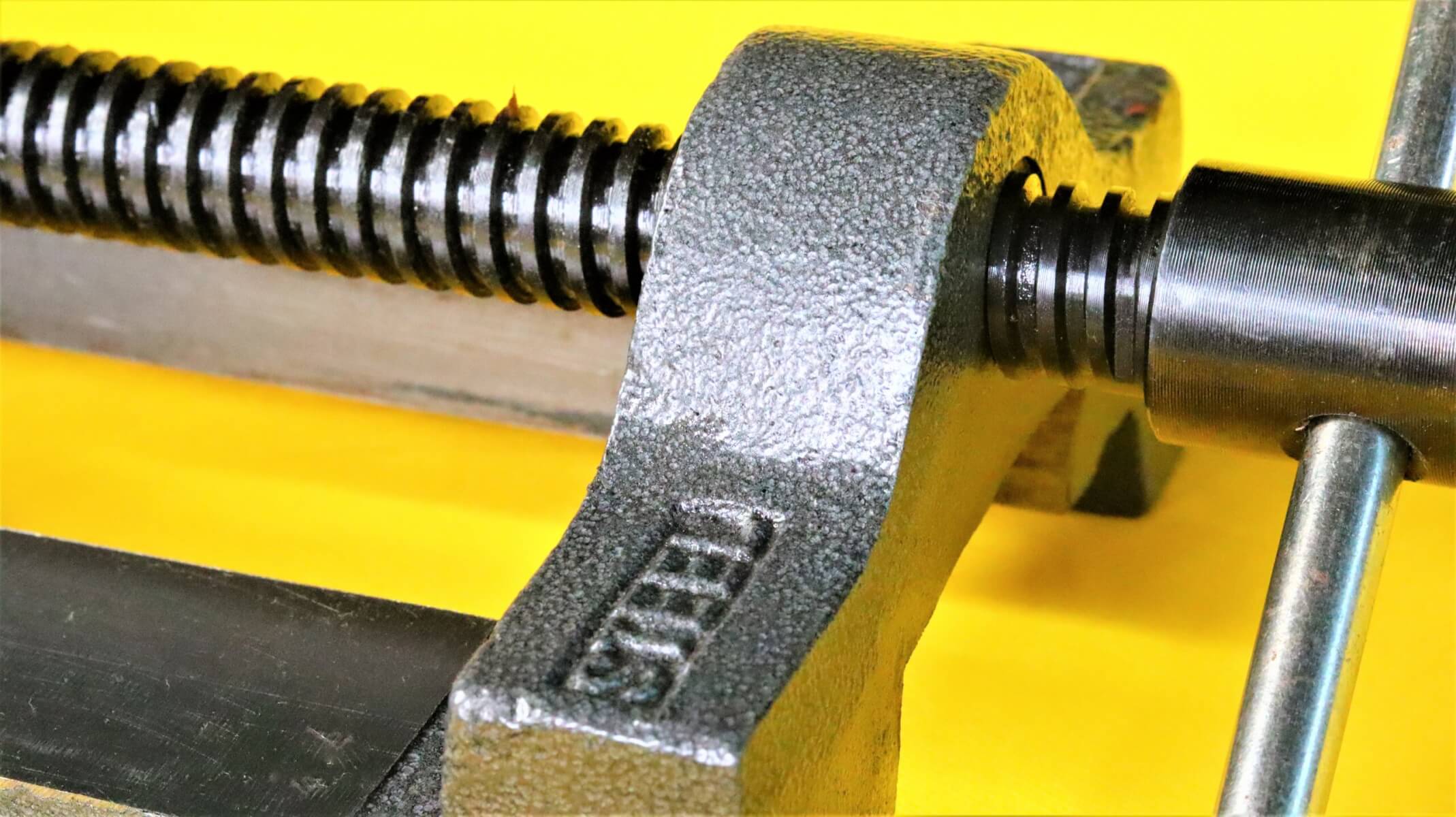

Drill Machine Vice

Size:–

100 MM – 3000

150 MM – 5500

200 MM- 10500

Body:- Ductile Iron Body.

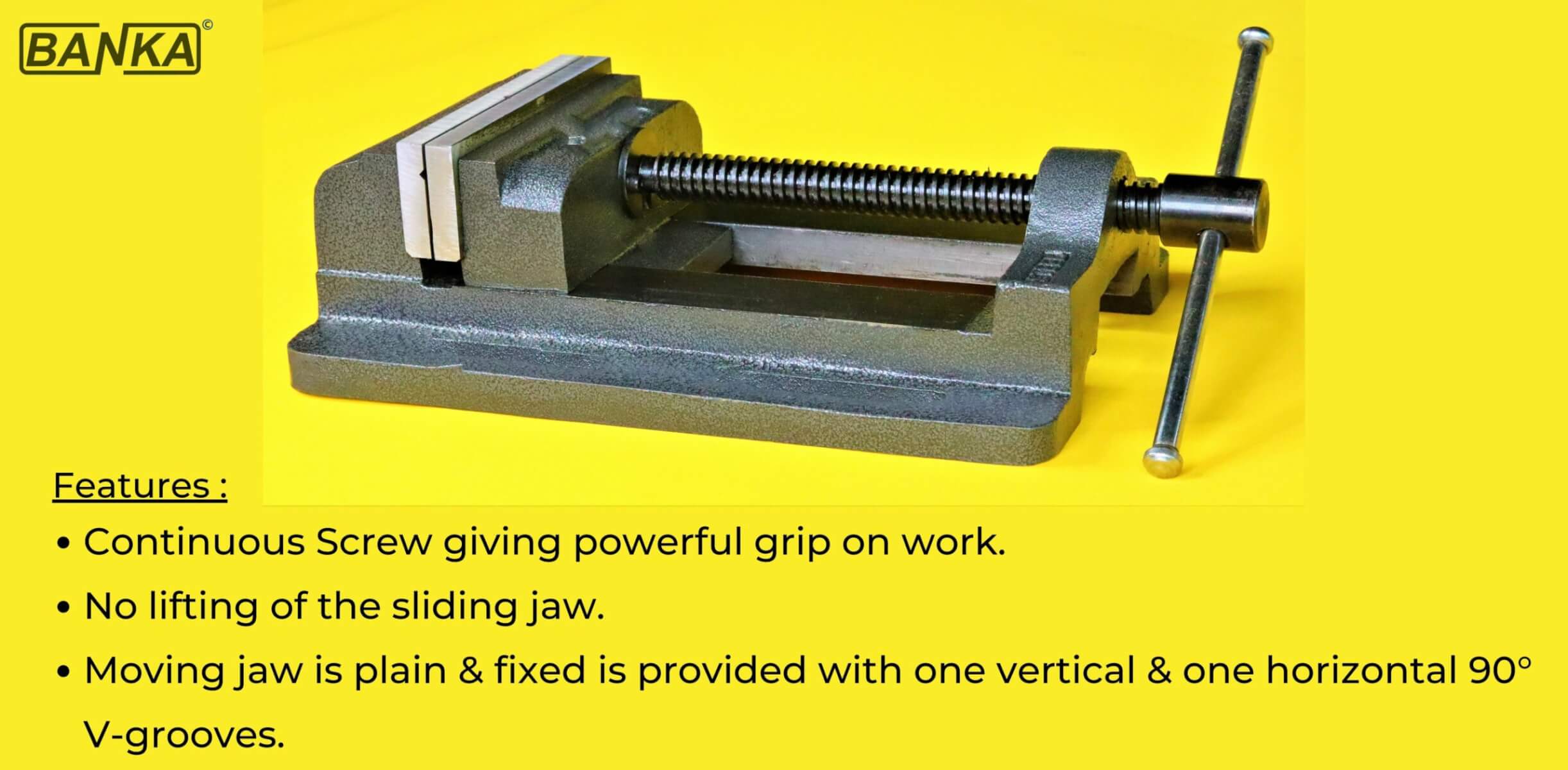

- Continuous Screw gives a powerful grip on work.

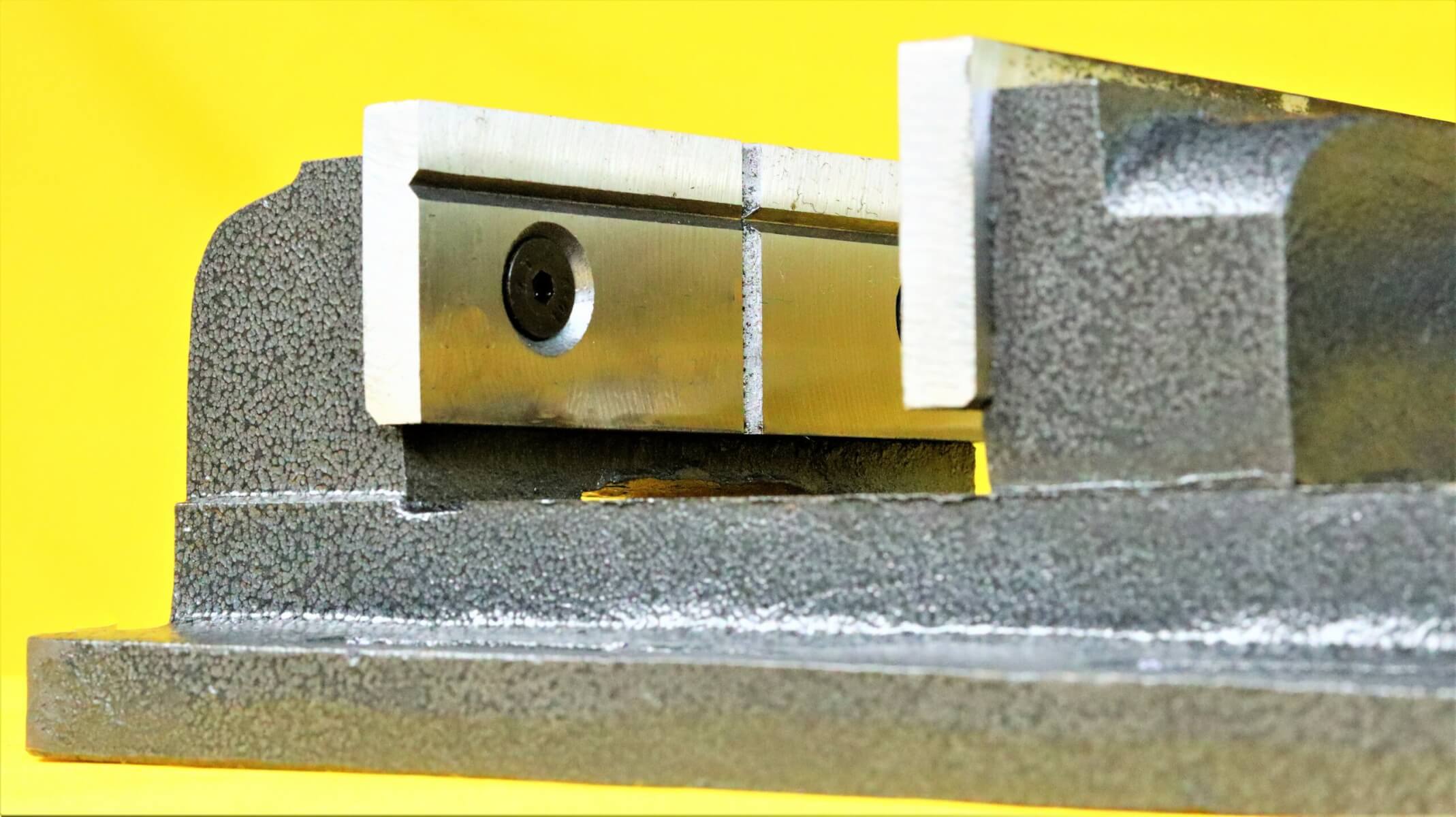

- No lifting of the sliding jaw.

- The moving jaw is plain & fixed is provided with one vertical & one horizontal 90° V-grooves.

- Body graded Cast Iron dully stress relieved.

- Lead Screw toughened selected steel.

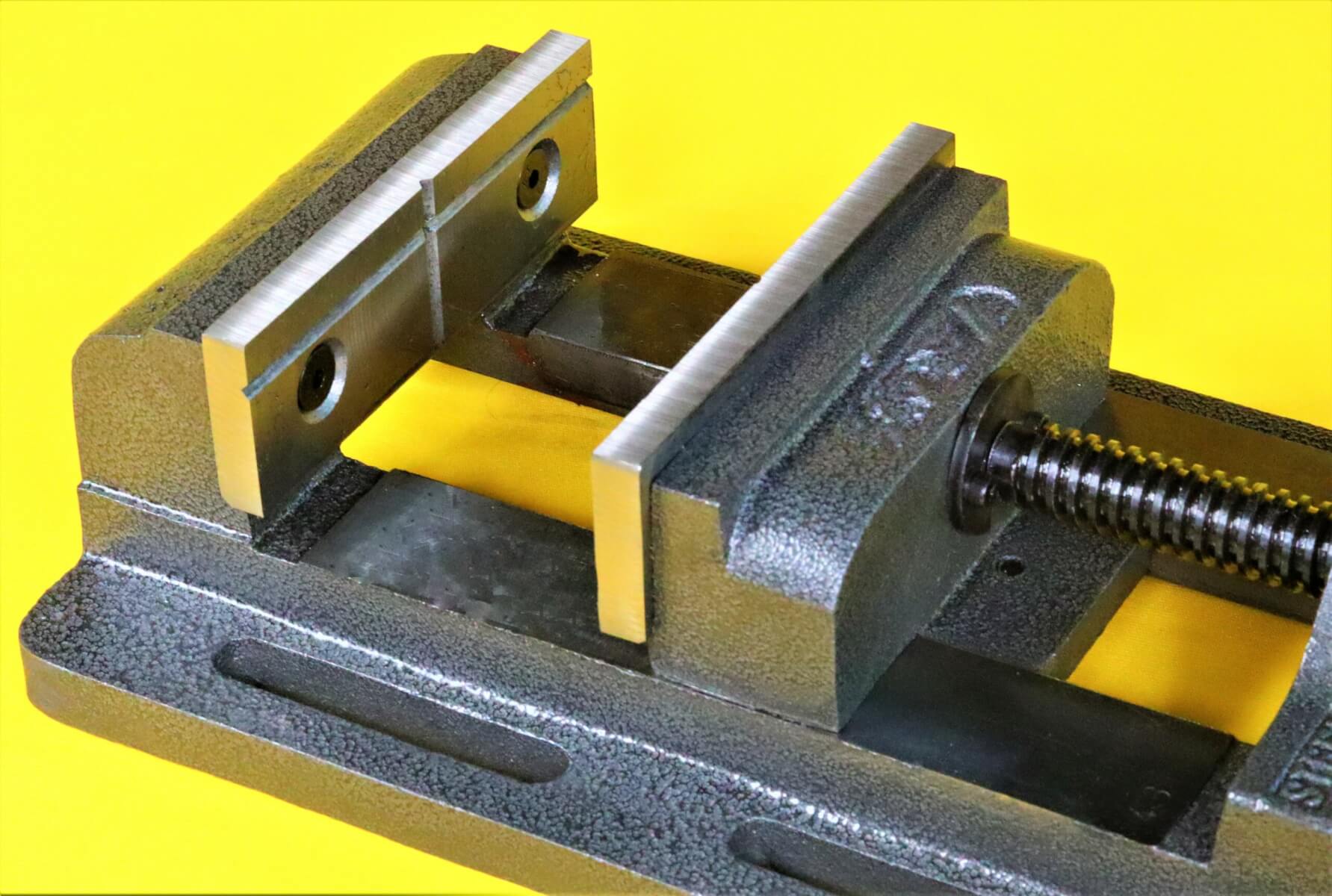

- Precision ground hardened & tempered tool steel jaws.

A drill machine vice, also known simply as a drill vice or drill press vice, is an essential tool used to securely hold workpieces during drilling operations on a drill press or milling machine. Here’s an overview of what a drill machine vice is, its features, and its importance in machining:

Definition and Purpose

A drill machine vice is a mechanical device designed to firmly clamp and hold workpieces in place on a drill press or milling machine table. Its primary purpose is to provide stability and precision during drilling, tapping, reaming, and similar operations.

Key Features

- Construction: Drill machine vices are typically made from high-quality cast iron or steel to provide durability and rigidity. Some models may feature hardened jaws for enhanced wear resistance and gripping strength.

- Jaw Design: The jaws of a drill machine vice are designed with serrations or grooves to securely grip the workpiece without slipping. They may also have protective jaw caps or inserts to prevent marring or damaging delicate surfaces.

- Clamping Mechanism: Most drill vices use a screw mechanism (often an acme or lead screw) to move the movable jaw towards or away from the fixed jaw. This allows for precise adjustment and secure clamping of workpieces of various sizes.

- Mounting Options: Drill vices are equipped with mounting slots or holes on the base for securely attaching them to the drill press or milling machine table. Some may feature swivel bases or angle adjustments to facilitate positioning.

- Size and Capacity: Drill machine vices come in various sizes to accommodate different workpiece dimensions and weight capacities. The throat depth and jaw opening size determine the maximum workpiece size the vice can handle.

Importance in Machining

- Stability: Provides a stable platform for drilling operations, preventing workpiece movement and ensuring accurate hole placement.

- Precision: Enables consistent drilling depths and hole diameters by securely holding the workpiece in place.

- Safety: Reduces the risk of accidents by securely clamping the workpiece, preventing it from shifting or spinning during drilling.

- Versatility: Suitable for a wide range of drilling tasks, including through holes, blind holes, and angled drilling operations.

Related Products

Sale

Best Seller

Lathe Quick Change Tool Post With 3 Holder

Lathe Dog Chuck

Lathe Square Tool Post

Sale

Efficient