Accessories for Lathe machines, Machine Shop Accessories, Tools & Instruments

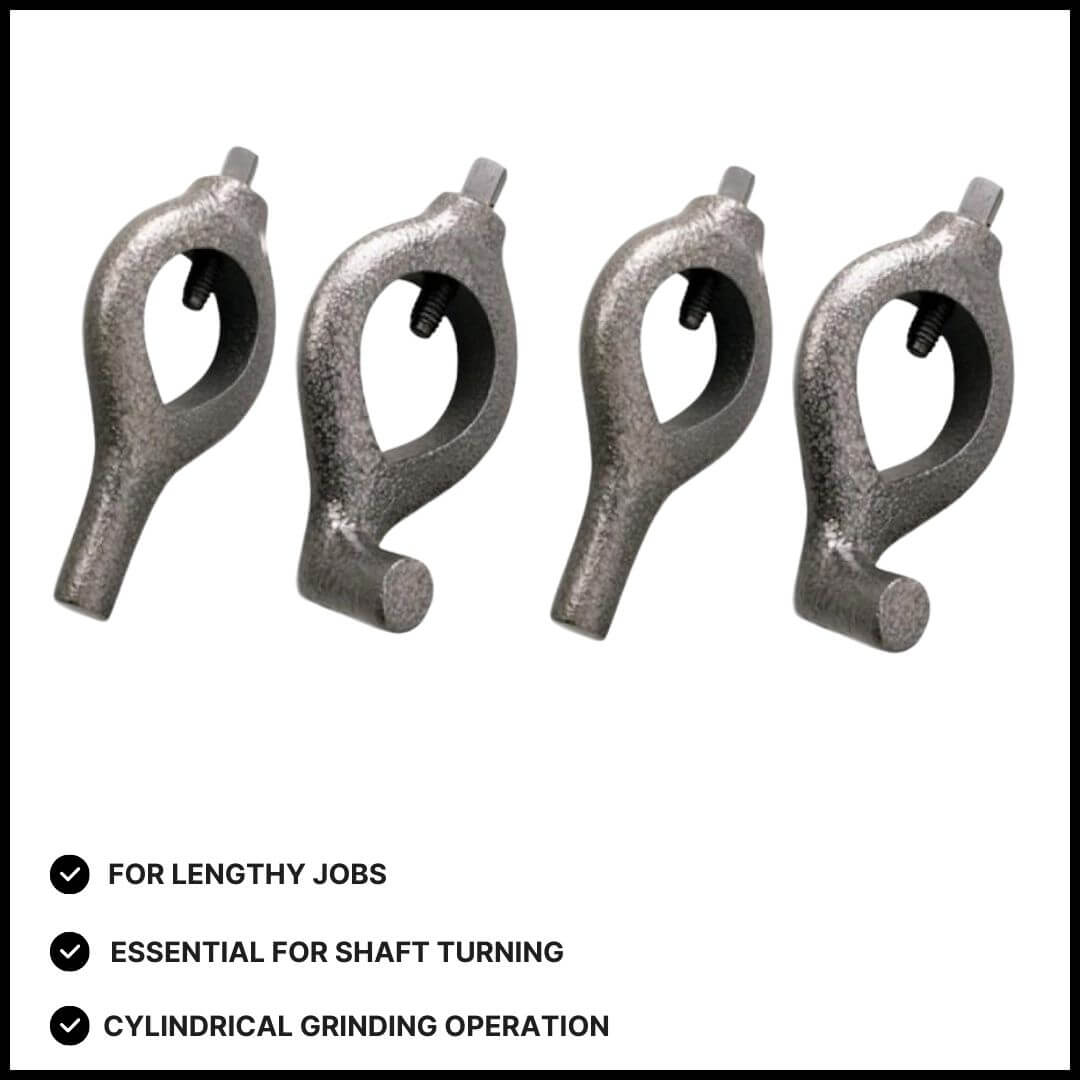

Lathe Dog Carriers Straight & Bend

Tag: Popular Tools

₹1,800

– For Lengthy Jobs – Essential for Shaft Turning – Between center job – Cylindrical grinding operation -A carrier is most often used when turning between centers on a lathe. but it may be used on dividing heads or any similar situation. It is used in conjunction with a drive plate and drives pins: the plate is mounted directly on the machine spindle (as with a chuck) and the drive pin is attached to the plate. In use the carrier and workpiece are inserted between centers and the leg of the carrier rests against the drive pin.

Weight: 1 Kg

Lathe dog carriers, including both straight and bent types, are essential accessories in a lathe setup used for driving workpieces on a lathe. They help transmit rotational motion from the lathe’s spindle to the workpiece. Here’s a guide on how to use straight and bent lathe dog carriers effectively:

Lathe Dog Carriers: Overview

- Straight Lathe Dog Carriers:

- Design: Straight carriers are typically used for workpieces that are centered and aligned with the lathe spindle. They feature a straight arm that holds the lathe dog in a linear configuration.

- Use Case: Ideal for turning operations where the workpiece is aligned directly with the spindle axis.

- Bent Lathe Dog Carriers:

- Design: Bent carriers have an angled or offset design, which allows the lathe dog to engage the workpiece at an angle. This is useful for workpieces that are not perfectly aligned with the spindle or for certain types of machining operations.

- Use Case: Suitable for operations where the workpiece needs to be positioned or aligned differently from the lathe spindle.

How to Use Lathe Dog Carriers

1. Prepare the Lathe

- Safety First: Ensure that the lathe is turned off and disconnected from the power source before making any adjustments or installing accessories.

- Clean the Work Area: Keep the lathe bed and other components clean and free from debris.

2. Select and Install the Lathe Dog Carrier

- Choose the Appropriate Carrier: Decide whether a straight or bent lathe dog carrier is needed based on your workpiece alignment and machining requirements.

- Install the Lathe Dog Carrier: Attach the lathe dog carrier to the lathe’s carriage or tailstock, following the manufacturer’s instructions for secure mounting.

3. Attach the Lathe Dog

- Position the Lathe Dog: Attach the lathe dog (which is a type of clamp or holder) to the workpiece. Ensure that the dog is securely fastened and aligned with the lathe dog carrier.

- Align the Lathe Dog: For a straight carrier, align the lathe dog directly with the spindle axis. For a bent carrier, position the lathe dog according to the angle or offset required.

4. Secure the Workpiece

- Clamp the Workpiece: Ensure that the workpiece is properly secured in the lathe’s chuck or between centers. The lathe dog should engage the workpiece firmly without slippage.

5. Operate the Lathe

- Engage the Lathe: Turn on the lathe and gradually increase the speed to the desired level. The lathe dog carrier will help transmit rotational motion from the spindle to the workpiece.

- Monitor the Operation: Observe the machining process to ensure that the workpiece is rotating correctly and that the lathe dog is properly engaged.

6. Adjust and Maintain

- Check Alignment: Periodically check the alignment of the lathe dog and carrier during operation to ensure consistent performance.

- Maintenance: Regularly inspect and clean the lathe dog carrier and lathe dog for wear or damage. Lubricate moving parts if necessary.

Tips for Effective Use

- Proper Alignment: Ensure proper alignment between the lathe dog, carrier, and workpiece to avoid uneven wear or machining errors.

- Secure Fastening: Double-check that all components are securely fastened and tightened to prevent slippage or misalignment during operation.

- Regular Maintenance: Keep the lathe dog carrier and lathe dog clean and well-maintained to ensure reliable performance and longevity.

Applications

- Turning Operations: Useful for turning operations where precise control and alignment of the workpiece are crucial.

- Machining Complex Parts: Essential for machining complex or non-standard workpieces that require specific alignment or positioning.

Maintenance and Care

- Cleaning:

- Wipe down the lathe dog carrier and lathe dog after use to remove any chips, debris, or residues.

- Ensure that no debris is obstructing the alignment or movement of the lathe dog carrier.

- Inspection:

- Regularly inspect the lathe dog carrier and lathe dog for signs of wear, damage, or misalignment.

- Address any issues promptly to maintain accuracy and safety.

- Storage:

- Store lathe dog carriers and accessories in a clean, dry place to prevent rust and damage.

- Keep components organized to ensure easy access and prevent misplacement.

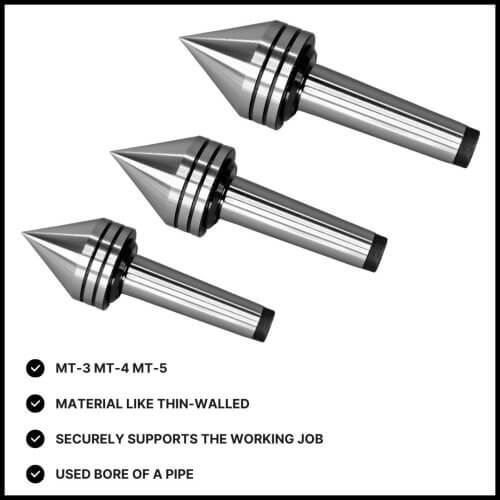

Related Products

Lathe Pipe Center

Sale

Best Seller