Machine Shop Accessories, Tools & Instruments

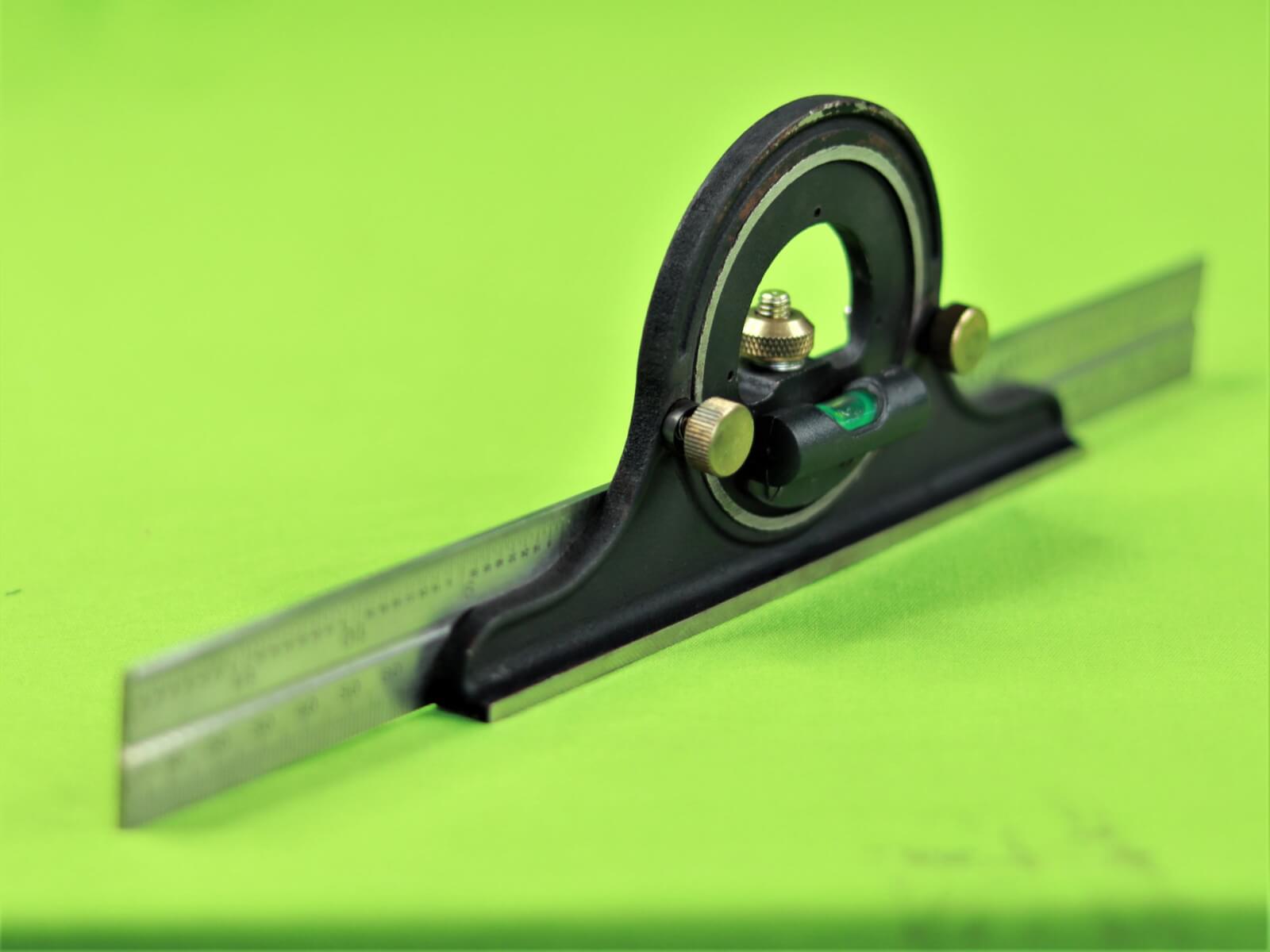

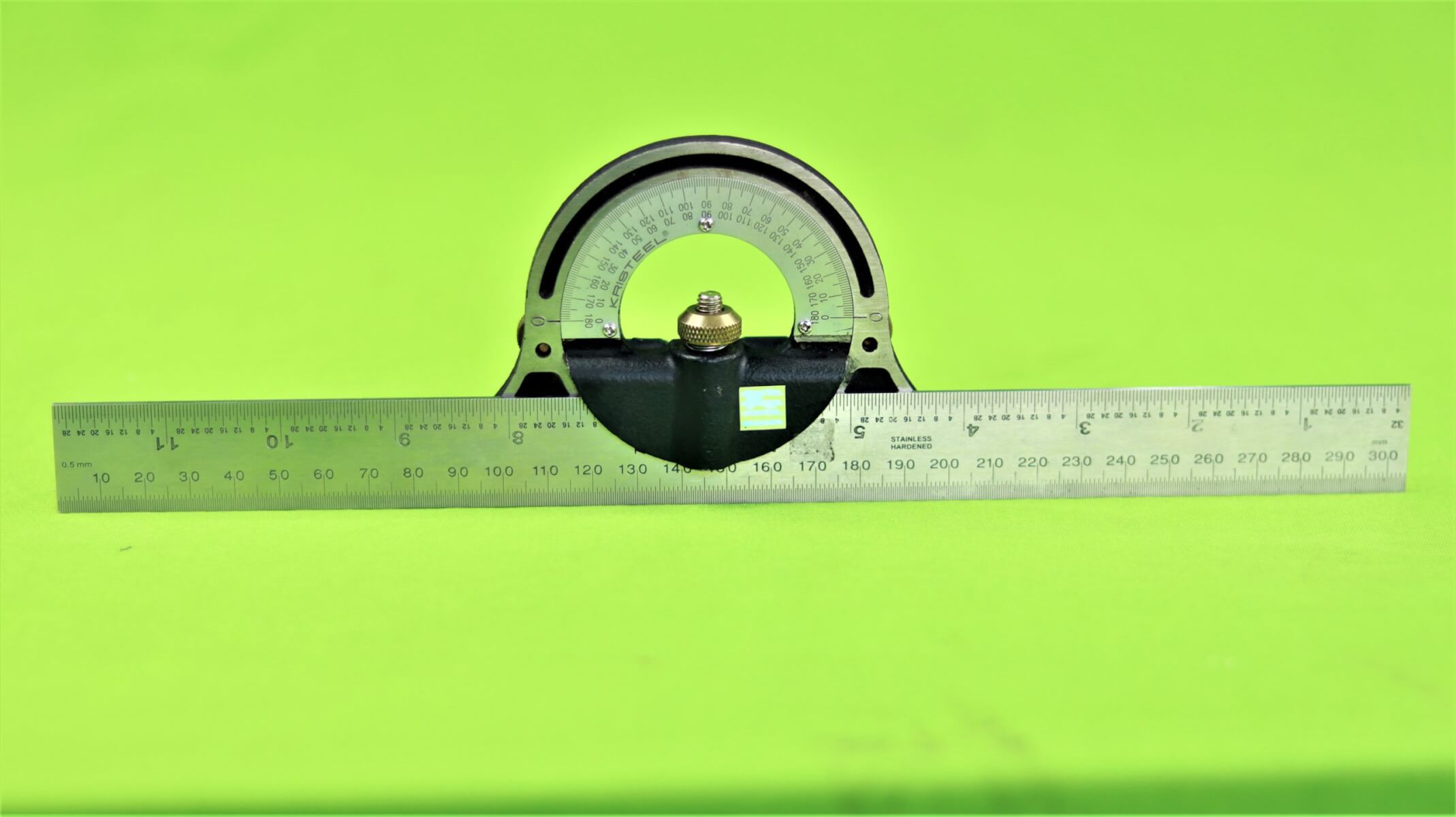

Combination Try Square Digital

Tag: Popular Tools

₹4,450

-12-inch Heavy-Duty Professional Combination Square with Etched Stainless Steel Blade and True Blue® Vial. -The e250 Combination Square features a stainless steel blade and matte finish that will never rust or corrode. -The True Blue® vial is guaranteed accurate to within .00050 inch and It carries a lifetime guarantee.

Weight: 1.215 Kg

e250 Professional Combination Square:

12-inch Heavy-Duty Professional Combination Square with Etched Stainless Steel Blade and True Blue® Vial.

The e250 Combination Square features a stainless steel blade and matte finish that will never rust or corrode.

The True Blue® vial is guaranteed accurate to within .00050 inch and It carries a lifetime guarantee.

- Measuring angles — A combination square can reliably measure 90° and 45° angles. The 45° angle is used commonly in creatingmiter joints.

- Determining flatness — When working with wood the first step is to designate a reference surface on a board which is known as the face side. The rest of the workpiece is measured from the face side

- Measuring the center of a circular bar or dowel. The rule is assembled through the center of the center square, the two cast iron legs of the center square are then placed against the outside of the bar (dowel) allowing a center line to be scribed alongside the ruler. Perform this action at two locations and the intersecting lines will approximate the center of the bar (dowel).

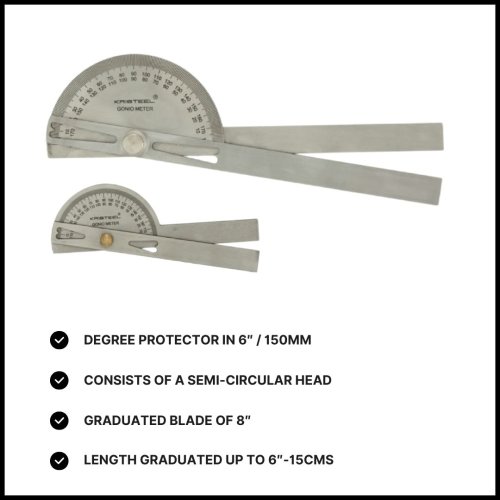

- Protractor head allows angles to be set and measured between the base and ruler.

- A rudimentary level for approximating level surfaces is incorporated in the protractor and also the 45° holder.

- By moving and setting the head, it can be used as a depth gauge or to transfer dimensions.

- Marking the work surface; with the included Scribe Point stored in a drilled hole in the Square Base.

- It is used to find the center of the round jobs.

- for measuring angles.

A combination try square is a tool used in woodworking and metalworking for ensuring the accuracy of right angles and checking the squareness of joints. When you add a digital component to it, you get a digital combination try square, which enhances its functionality with electronic precision.

Features and Benefits:

- Digital Readout: Provides a precise digital measurement of angles, usually displayed in degrees. This eliminates the guesswork and makes it easier to achieve exact angles.

- Incremental Measuring: Allows for quick and easy angle adjustments and readings, which is especially useful for complex tasks requiring multiple precise angles.

- Easy Calibration: Many digital try squares have a calibration feature to ensure accuracy over time.

- Versatility: Can be used for measuring angles, checking squareness, and sometimes even for measurements in addition to the standard tasks of a regular try square.

- User-Friendly: Digital displays are often easier to read than traditional scales, especially in low light conditions or for those with visual impairments.

How to Use:

- Set the Angle: Depending on the model, you might need to set the desired angle digitally before you start measuring.

- Check for Squareness: Place the try square against the edge or surface you want to check. The digital readout will show if the surface is square (90 degrees) or indicate any deviation.

- Measure Angles: For measuring angles, align the try square with the reference surface. The digital display will show the angle relative to the reference.

- Calibration: Ensure the tool is calibrated correctly. This is usually done through a reset or calibration function in the digital settings.

- Battery Maintenance: Keep an eye on the battery level of the digital component and replace or recharge as needed to maintain functionality.