Accessories for Drilling machines, Machine Shop Accessories, Tools & Instruments

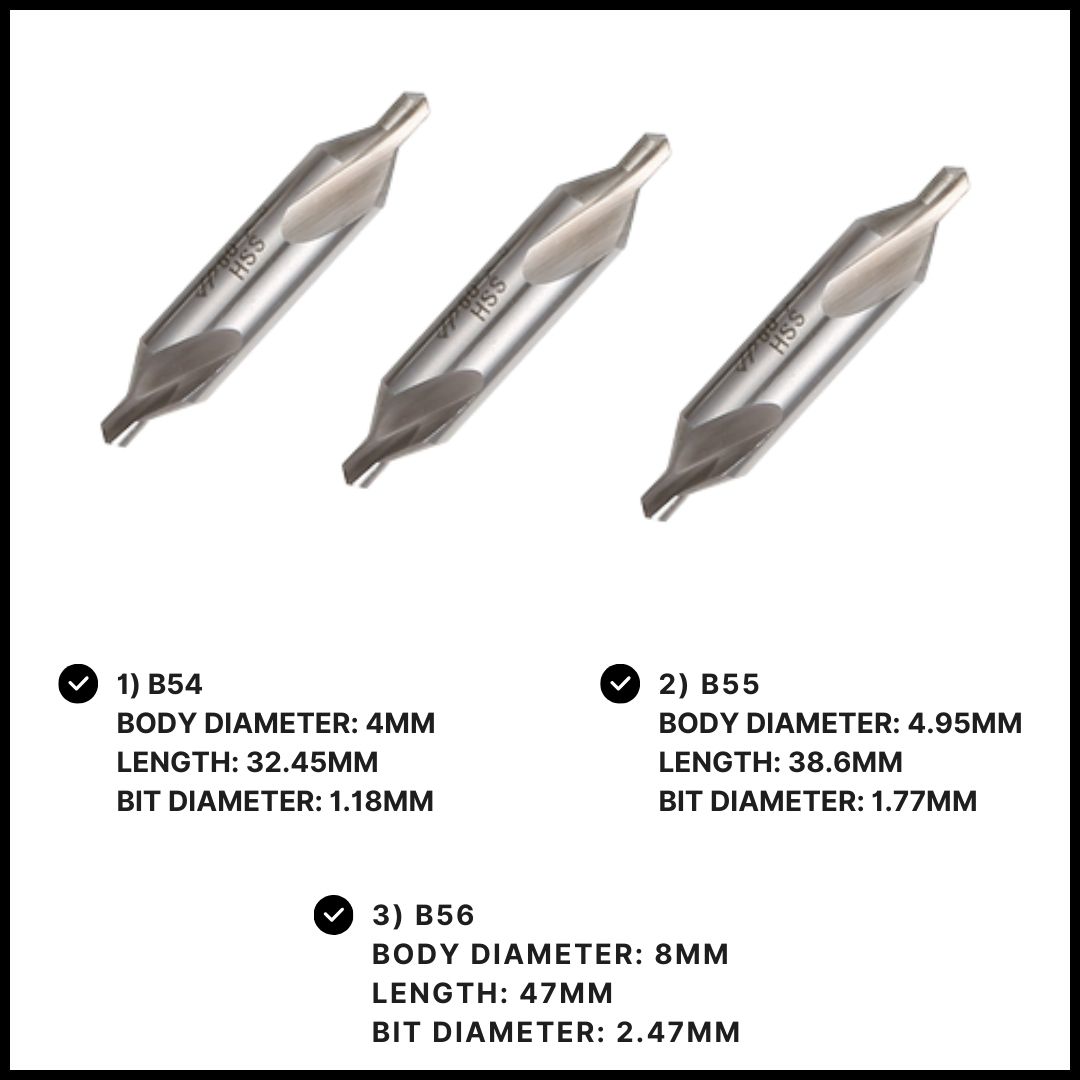

Centre Drill Bit

Tag: Popular Tools

₹1,500

Center Drill bit for drilling components that require machining between centers. Has a 120 & deg point angle with a 60 ° included countersink.

Pack size: 3 drill bits

1) B54

- Body diameter: 4mm

- Length: 32.45mm

- Bit diameter: 1.18mm

2) B55

- Body diameter: 4.95mm

- Length: 38.6mm

- Bit diameter: 1.77mm

3) B56

- Body diameter: 8mm

- Length: 47mm

- Bit diameter: 2.47mm

A center drill bit, also known as a center drill or a center punch drill, is a specialized tool used primarily in metalworking and machining. Its primary function is to create a precise, conical hole or indentation in the surface of a workpiece. Here’s a more detailed look at its uses and applications:

Uses of a Center Drill Bit:

- Creating Center Holes:

- Purpose: The main purpose of a center drill bit is to create a small, accurately located center hole. This hole serves as a guide for subsequent drilling operations, especially when working with a lathe.

- Benefit: This helps in aligning the workpiece and ensuring that the drill bit drills straight and true.

- Preventing Bit Wander:

- Purpose: When drilling large holes, especially in metal, a center drill helps prevent the larger drill bit from wandering off center.

- Benefit: This is crucial for maintaining precision and accuracy in the final hole.

- Starting Holes for Tapping:

- Purpose: A center drill bit can be used to create a small, accurate hole before tapping for threads.

- Benefit: This ensures that the tap starts correctly and threads are cut accurately.

- Preparing for Further Machining:

- Purpose: Center drills are often used as a preliminary step before performing other machining operations like boring or turning.

- Benefit: This initial hole provides a reference point for further machining.

- Creating Pilot Holes:

- Purpose: In some cases, a center drill bit can be used to create pilot holes for larger drills or cutting tools.

- Benefit: This helps guide the larger drill and reduces the risk of drilling errors.

Characteristics of Center Drill Bits:

- Design:

- Tip: The tip of a center drill bit is usually conical and has two cutting edges that allow it to drill a small, accurate hole.

- Body: It often has a smaller diameter shank that fits into the drill chuck and a larger diameter body that supports the cutting edges.

- Sizes:

- Variety: Center drill bits come in various sizes and configurations, typically designated by number or letter gauges.

- Materials:

- Construction: They are usually made from high-speed steel (HSS) or carbide to handle the hardness of metal and other materials.

How to Use a Center Drill Bit:

- Mount the Bit:

- Securely: Mount the center drill bit in the drill chuck or collet of your machine, ensuring it is securely held.

- Position the Workpiece:

- Align: Place the workpiece on the machine bed or lathe, aligning it properly to ensure accurate drilling.

- Drill the Center Hole:

- Start: Begin drilling at a slow speed, applying steady pressure. The center drill will cut into the material and create a precise center hole.

- Check the Hole:

- Verify: After drilling, check the center hole for accuracy and alignment before proceeding with further machining.

Using a center drill bit effectively can significantly enhance the precision and quality of your machining projects.

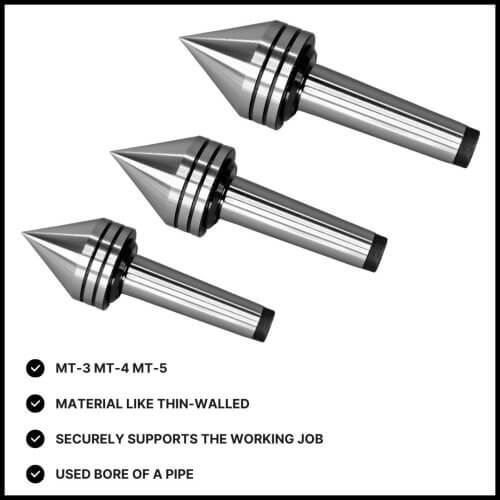

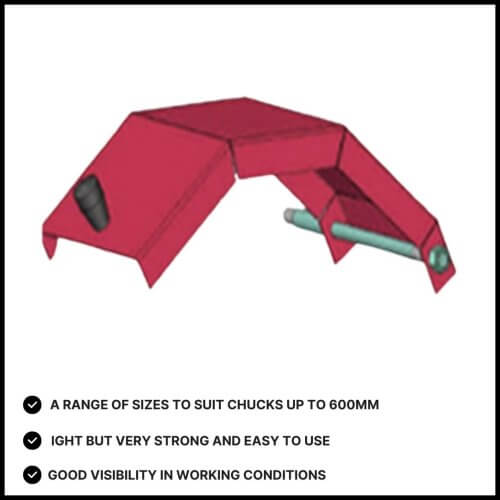

Related Products

Lathe Pipe Center

Sale

Efficient