Accessories for Lathe machines, Machine Shop Accessories, Tools & Instruments

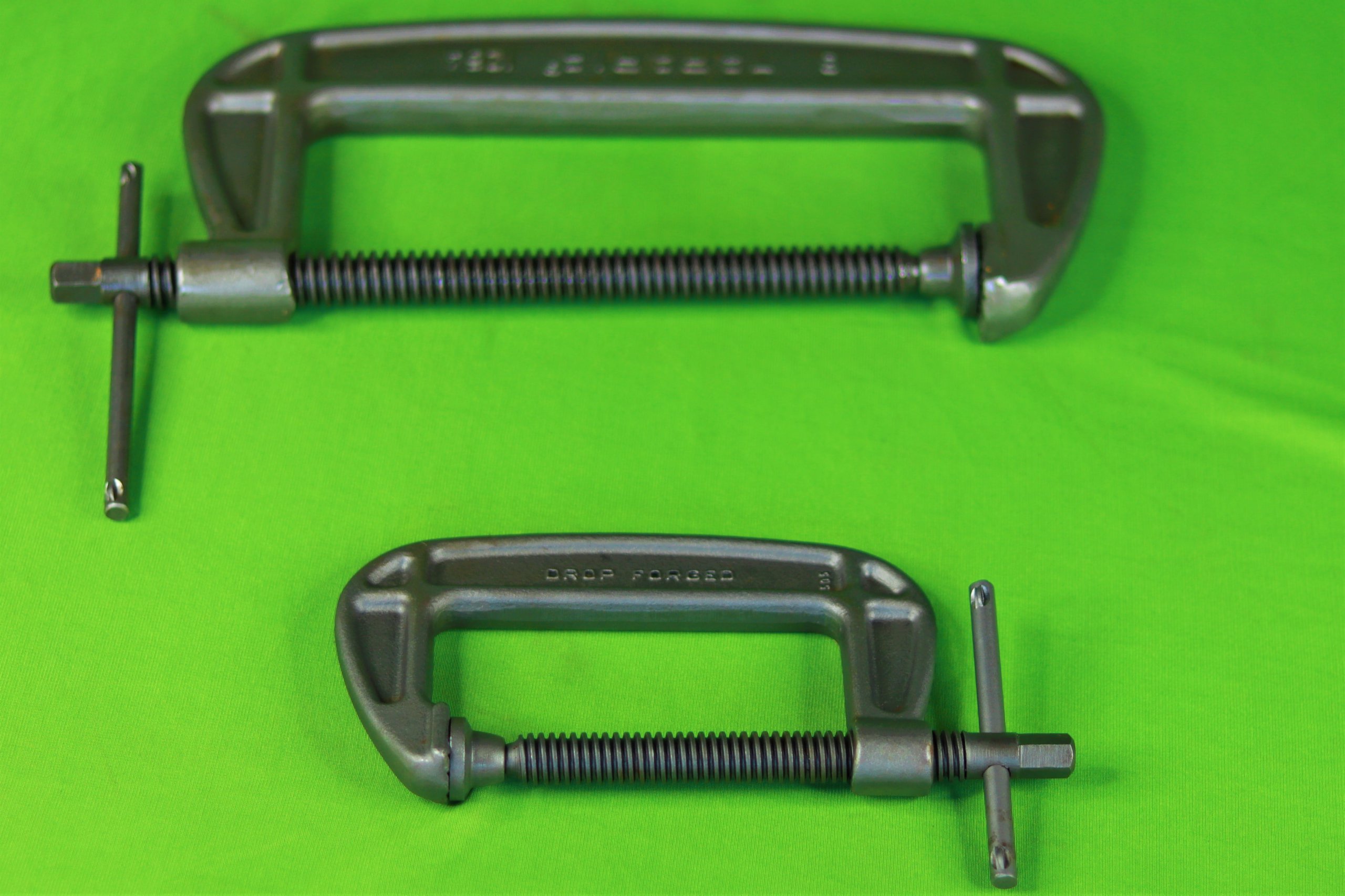

C Clamp

Tag: Popular Tools

₹3,000

C-clamps are typically made of steel or cast iron though smaller clamps may be madeof At the top of the “C” is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes.When the clamp is actually used, it is very rare that this occurs. Generally some other object or objects will be contained between the top and bottom flat edges. C Clamp Set 4″ 6″ 8″

Weight: 5.8 Kg

Industrial grade construction

Heavy-duty cast iron body

Machined steel screw

A C-clamp is a versatile tool used primarily for clamping and holding objects securely in place. Here are some common uses and tips for using a C-clamp effectively:

- Woodworking: It’s often used to hold pieces of wood together while glue dries or while screws are being installed. This helps ensure a tight, precise joint.

- Metalworking: In metalworking, C-clamps are used to hold metal parts in place for welding or cutting. This ensures the pieces don’t shift, which is crucial for accurate work.

- Drilling: When drilling holes into materials, a C-clamp can hold the material steady, reducing movement and helping to ensure a clean, accurate hole.

- Repairs: For repairs involving various materials, C-clamps can hold parts together until adhesive sets or until the repair is completed.

- Stabilizing Workpieces: It can be used to stabilize workpieces on a workbench or surface, preventing them from moving during operations.

Tips for Using a C-Clamp:

- Choose the Right Size: Ensure the C-clamp is the right size for the job. It should be large enough to span the objects you’re clamping and strong enough to hold them securely.

- Apply Even Pressure: Tighten the clamp slowly and evenly to avoid damaging the workpieces or the clamp itself.

- Protect Surfaces: Use pads or pieces of scrap material between the clamp and the workpieces to prevent damage or indentations.

- Check for Stability: Make sure the workpieces are stable and aligned before fully tightening the clamp.

Using a C-clamp effectively can make a big difference in the accuracy and quality of your work, whether you’re doing woodworking, metalworking, or general repairs.