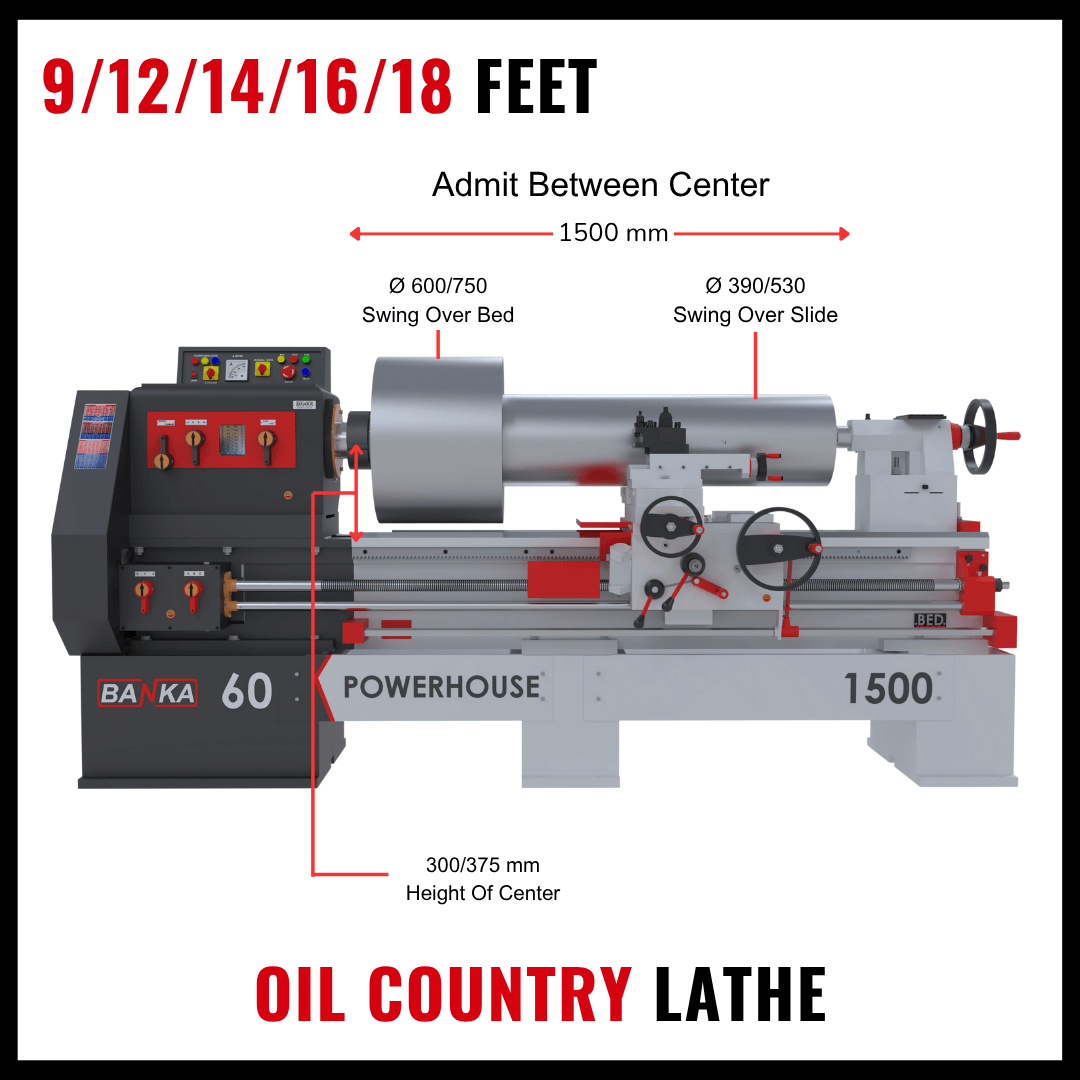

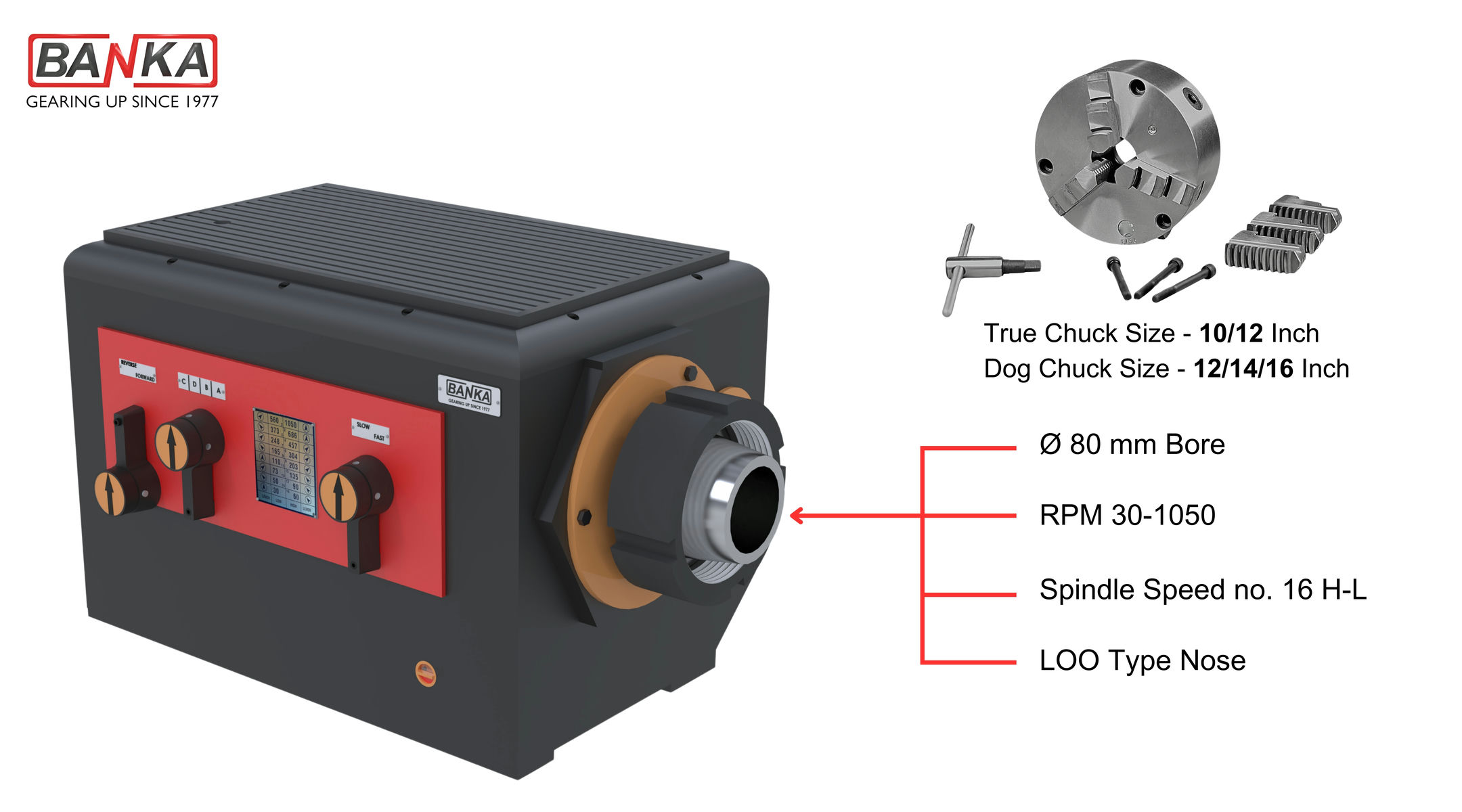

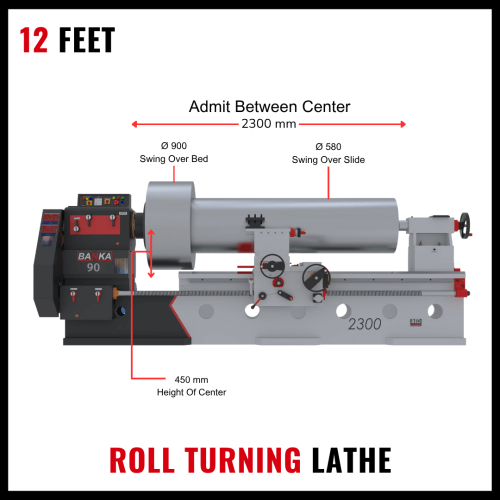

Banka 60 – HEAVY DUTY ALL GEAR LATHE MACHINE – 9 / 12 / 14 / 16 / 18 Feet Swing Dia 600 / 750 mm – With 80 / 100 mm / 3 Inch / 4 Inch Bore – Center 300 and 375 mm/12 and 15 Inch – For Production / Maintenance

₹4,95,000

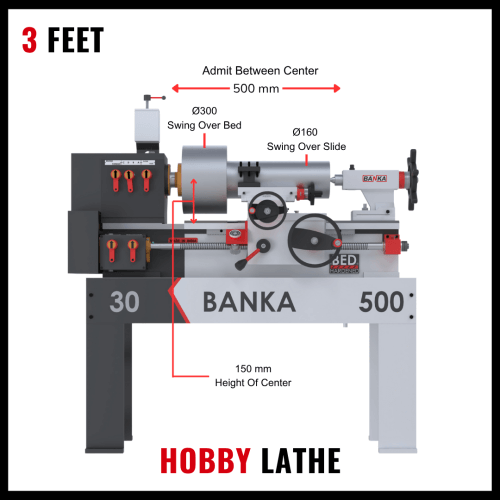

- Height Of Center: 300 mm

- Spindle Bore: 80/100 mm

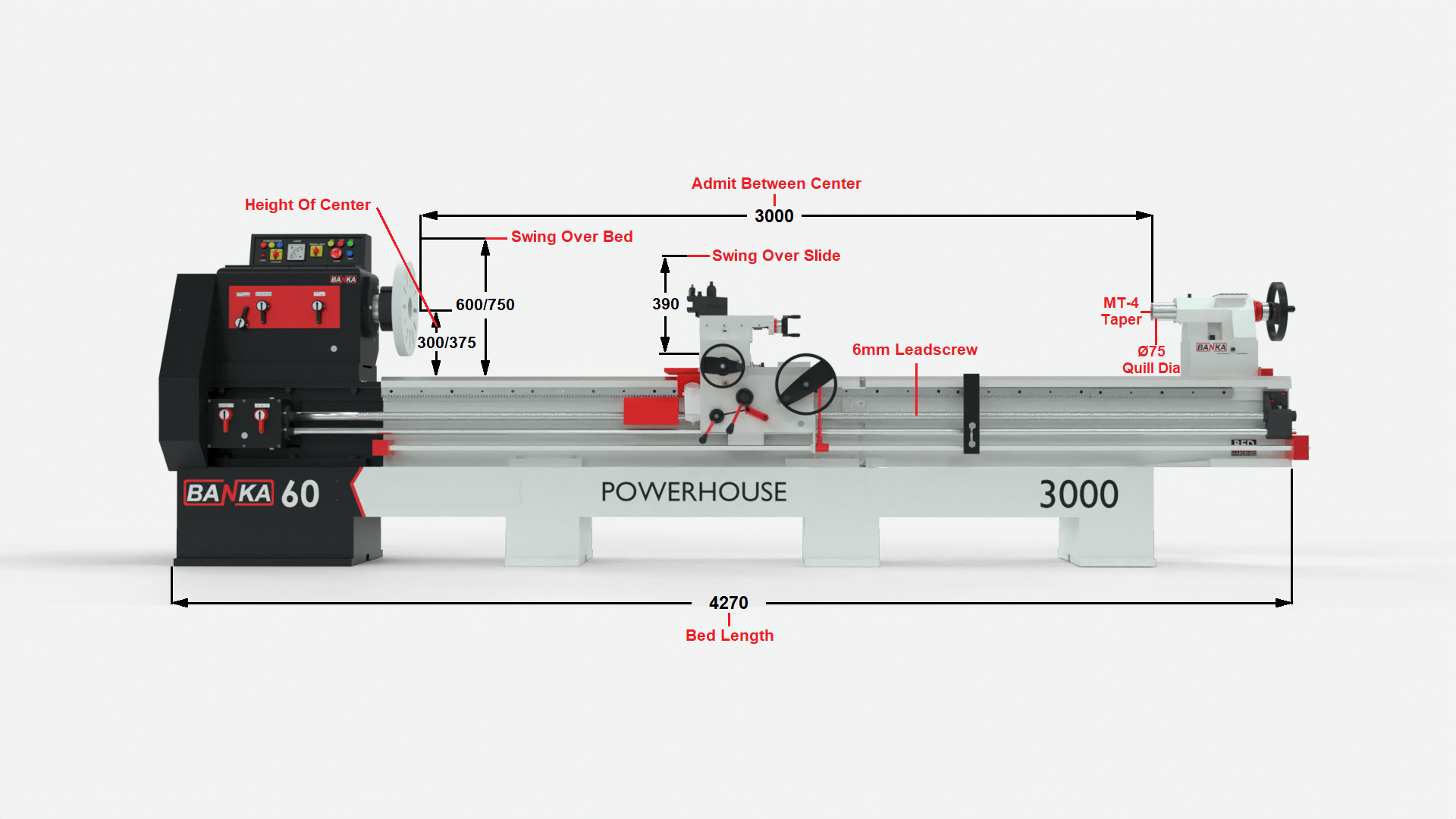

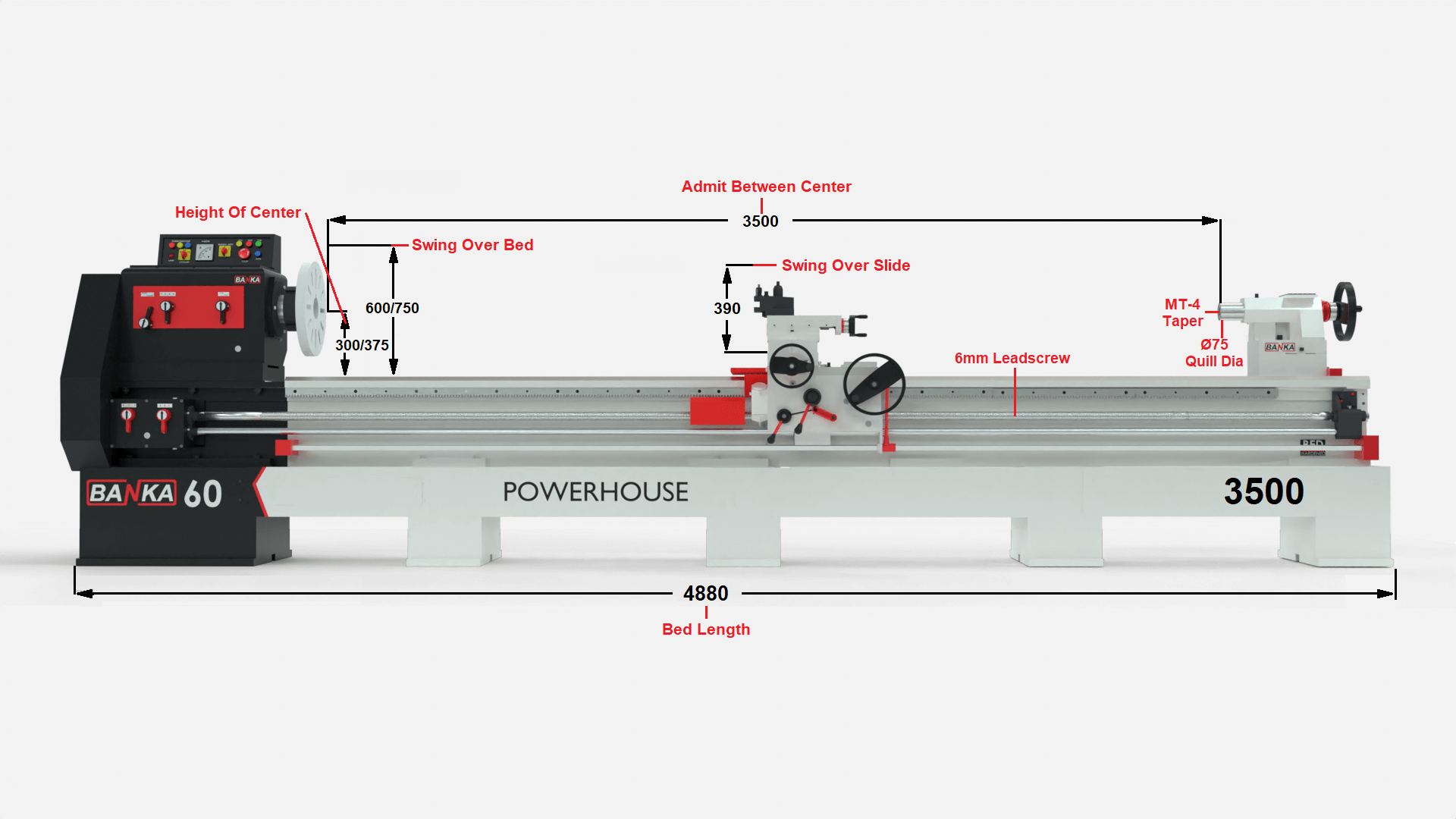

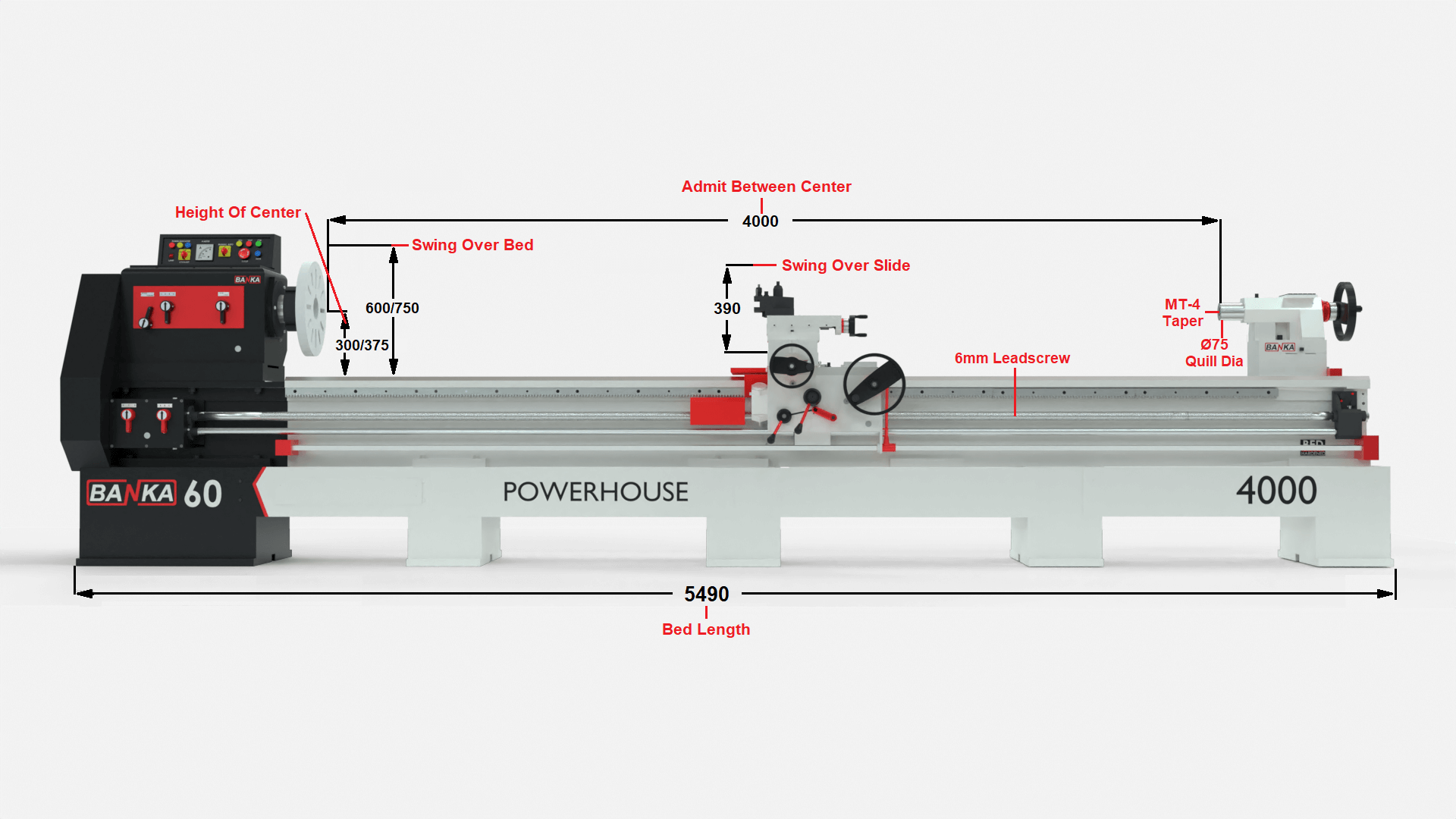

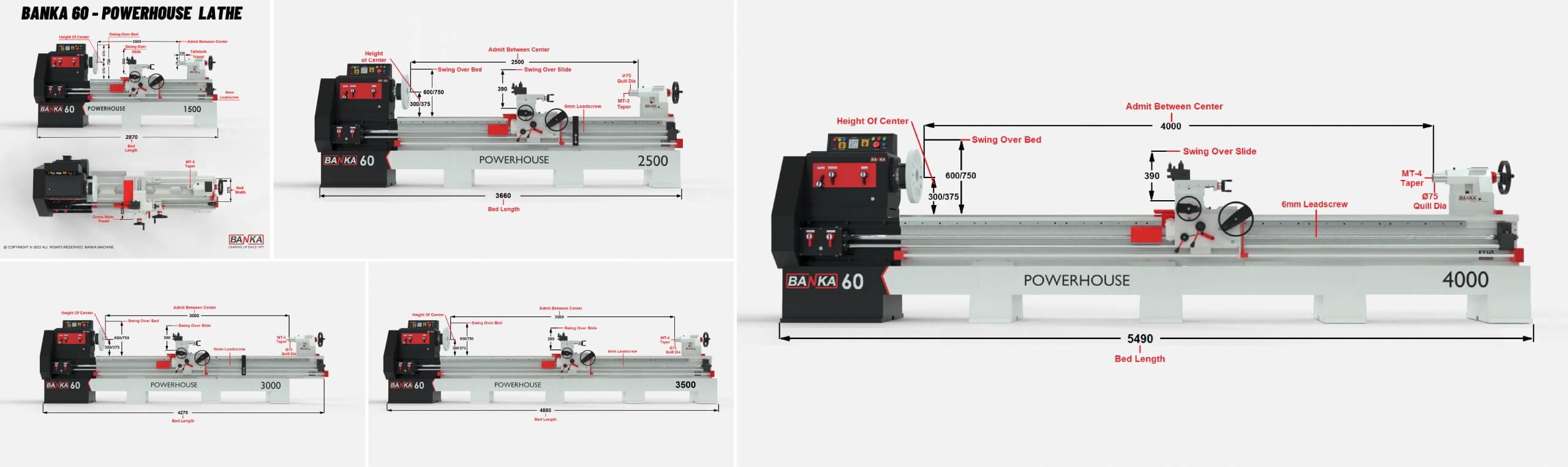

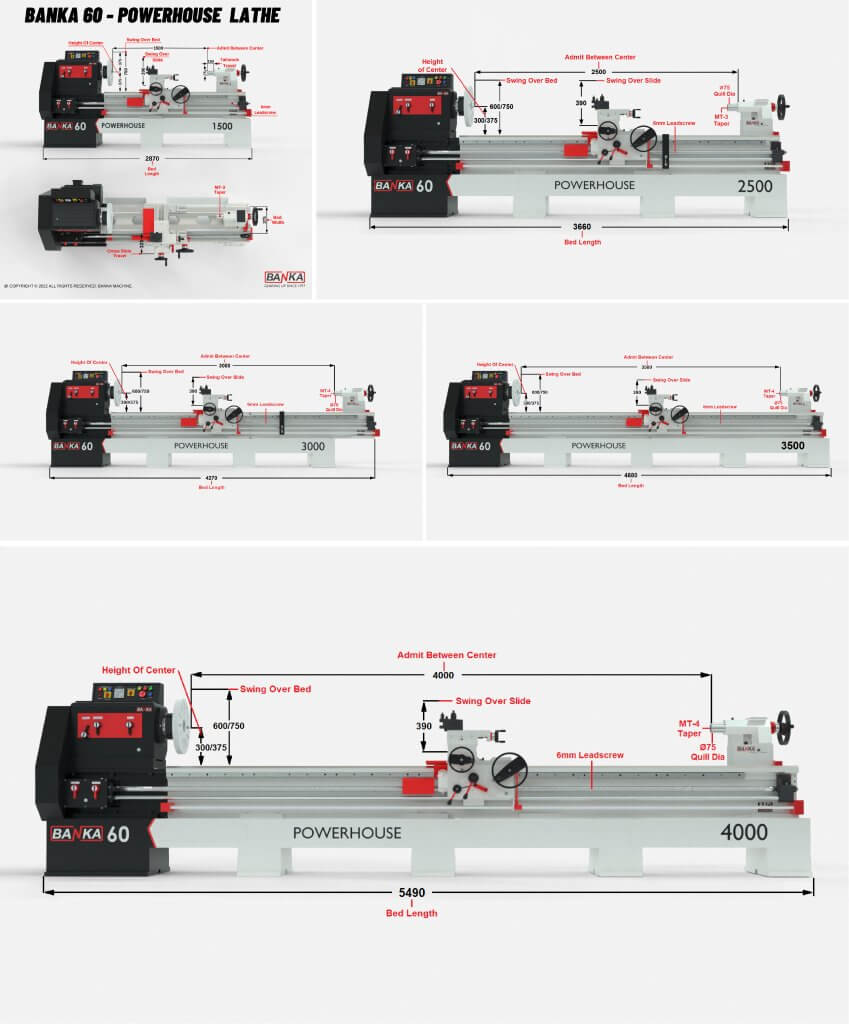

- Admin Between Center: 1500/2500/3000/3500 mm

- Bed Length: 9/12/14/16 Feet

- Spindle Speed: 1050 RPM

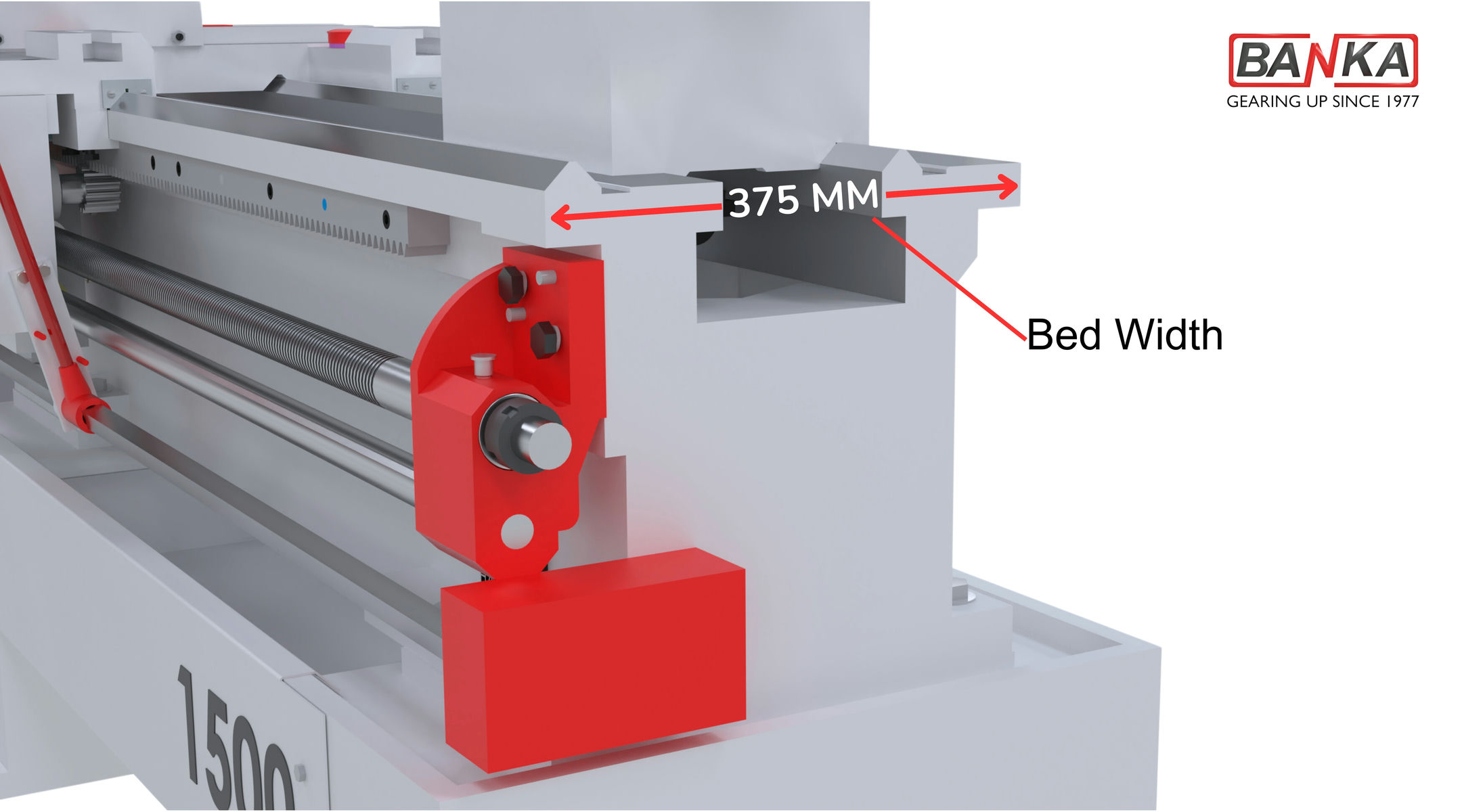

- Bed Width: 375 mm

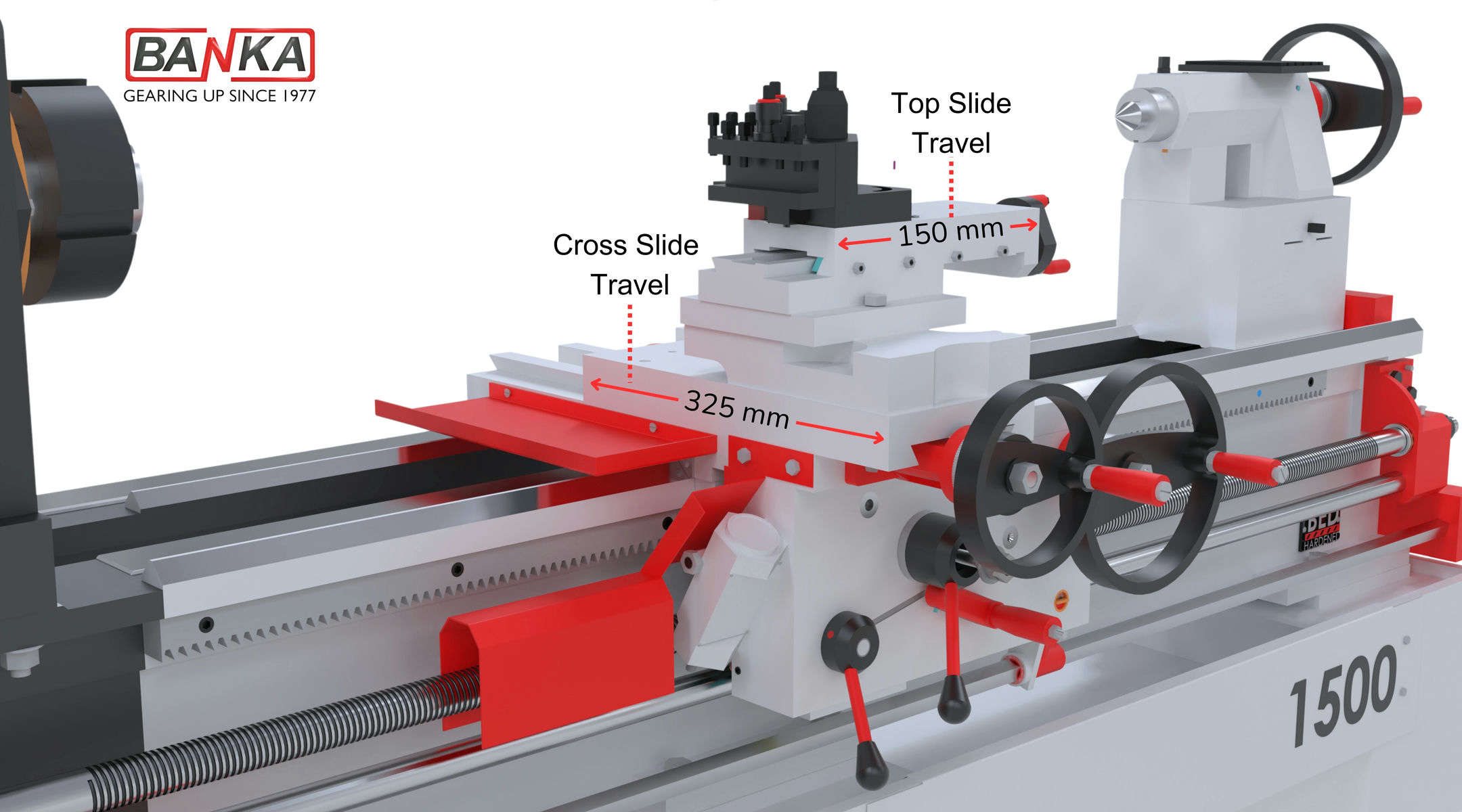

- Cross Slide Travel: 325 mm

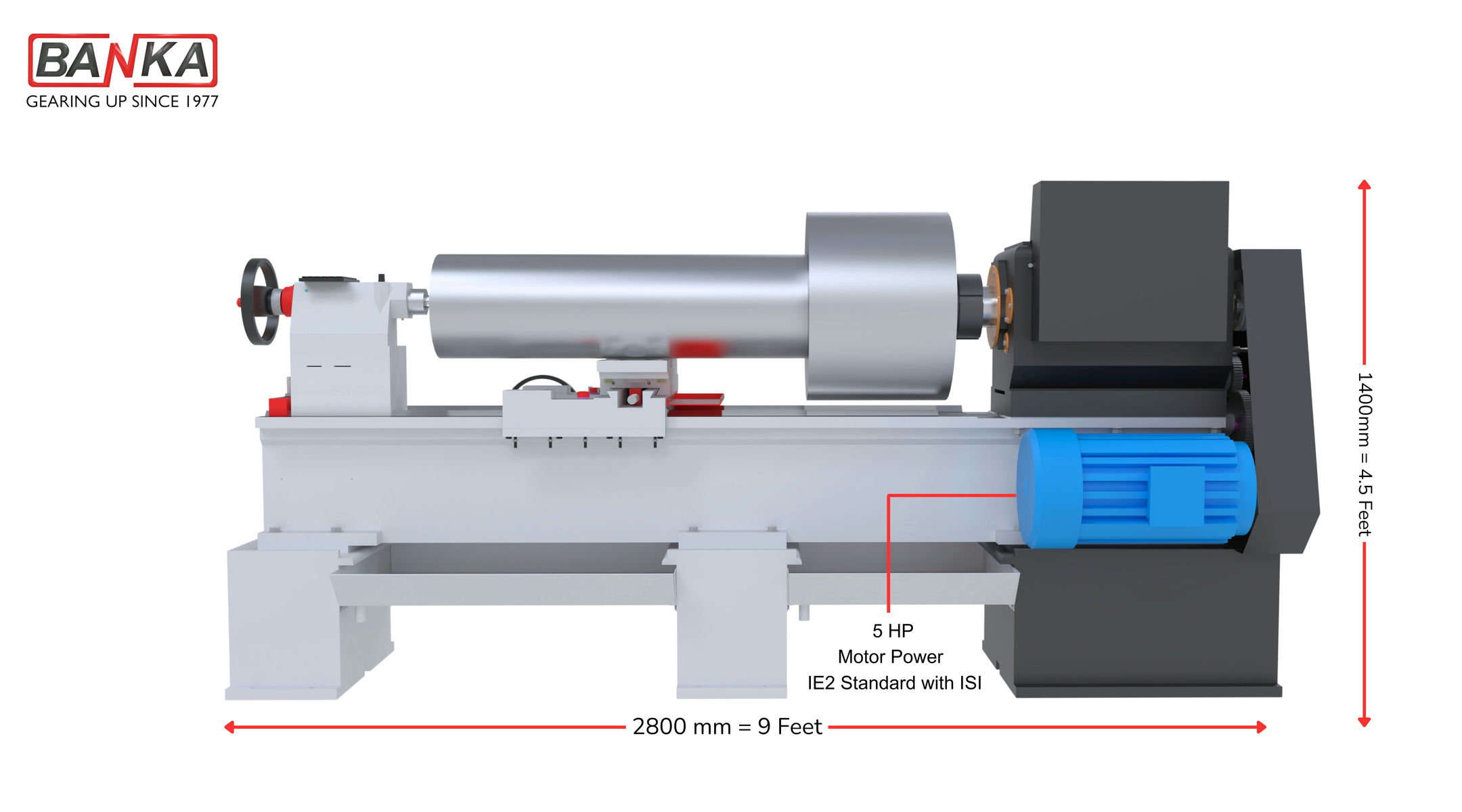

- Motor: 5 HP

Essential Features :

|

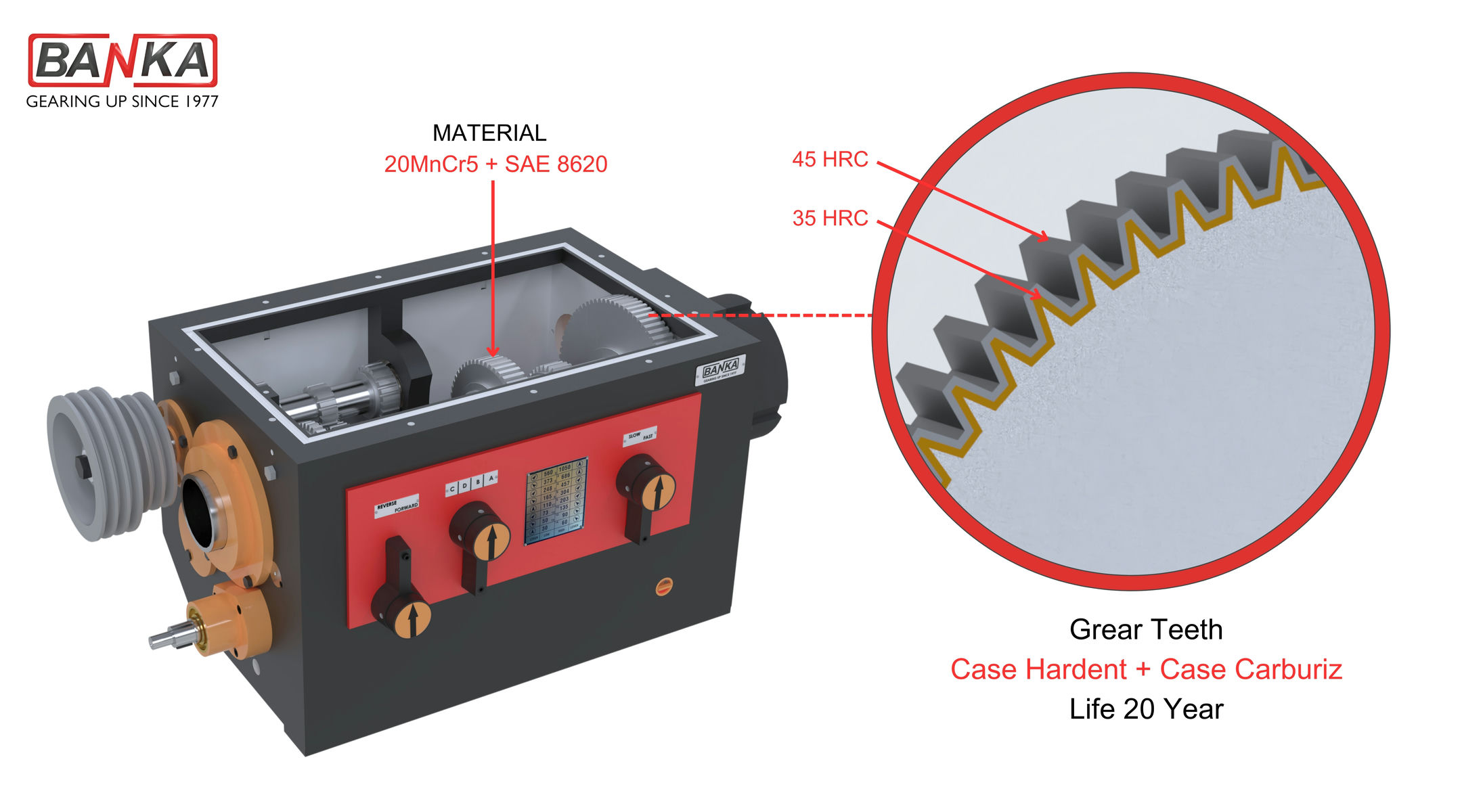

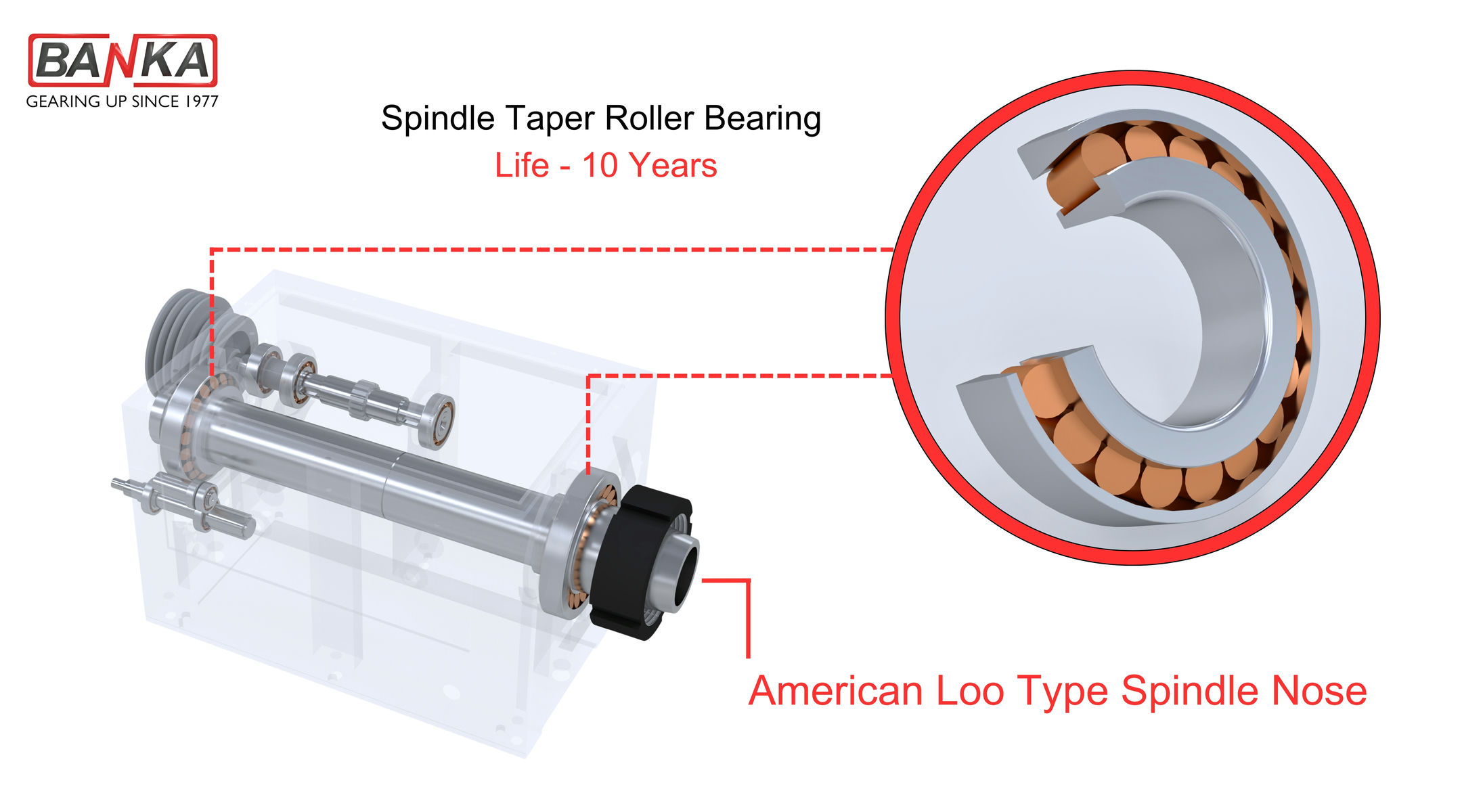

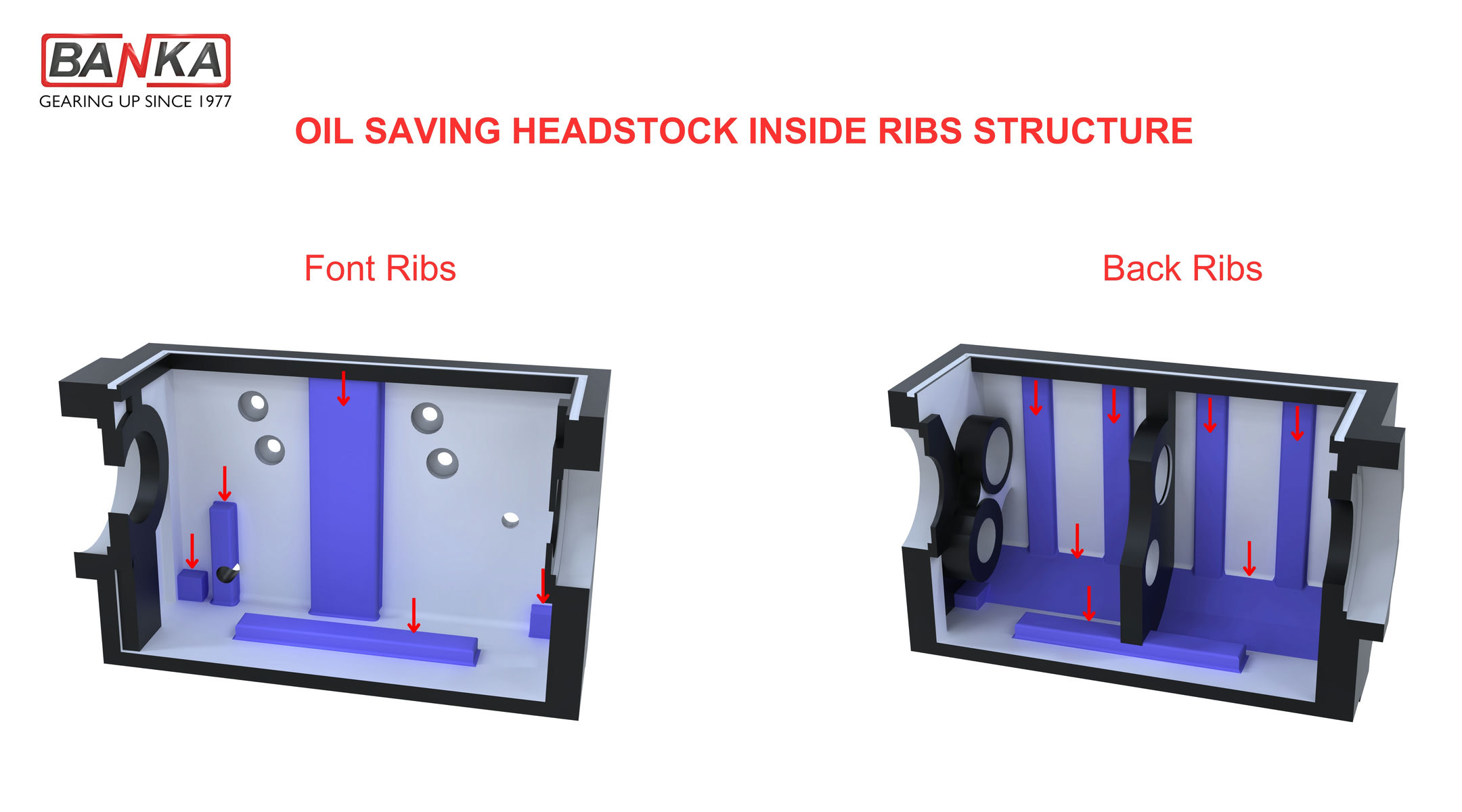

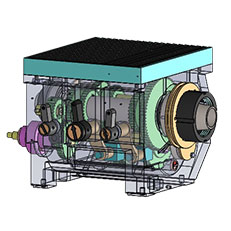

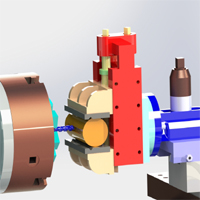

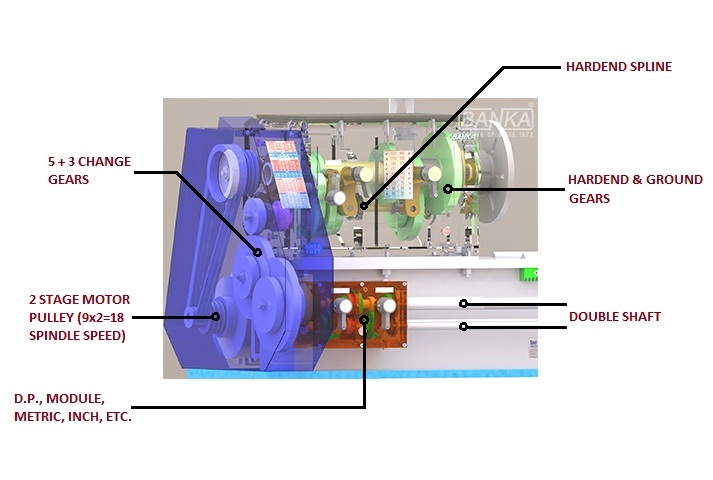

Headstock : The box-type constructed headstock with its rationally designed ridding arrangement gives a maximum rigidity performance free from thermal displacement and vibration.Its rigid-built hardened and ground spindle is supported in the study headstock by super precision roller bearing and ball bearing, capable of heavy duty and high sped applications. All gears, splines, spindles are made from 20 MnCr5 material and hardened ground. |

|

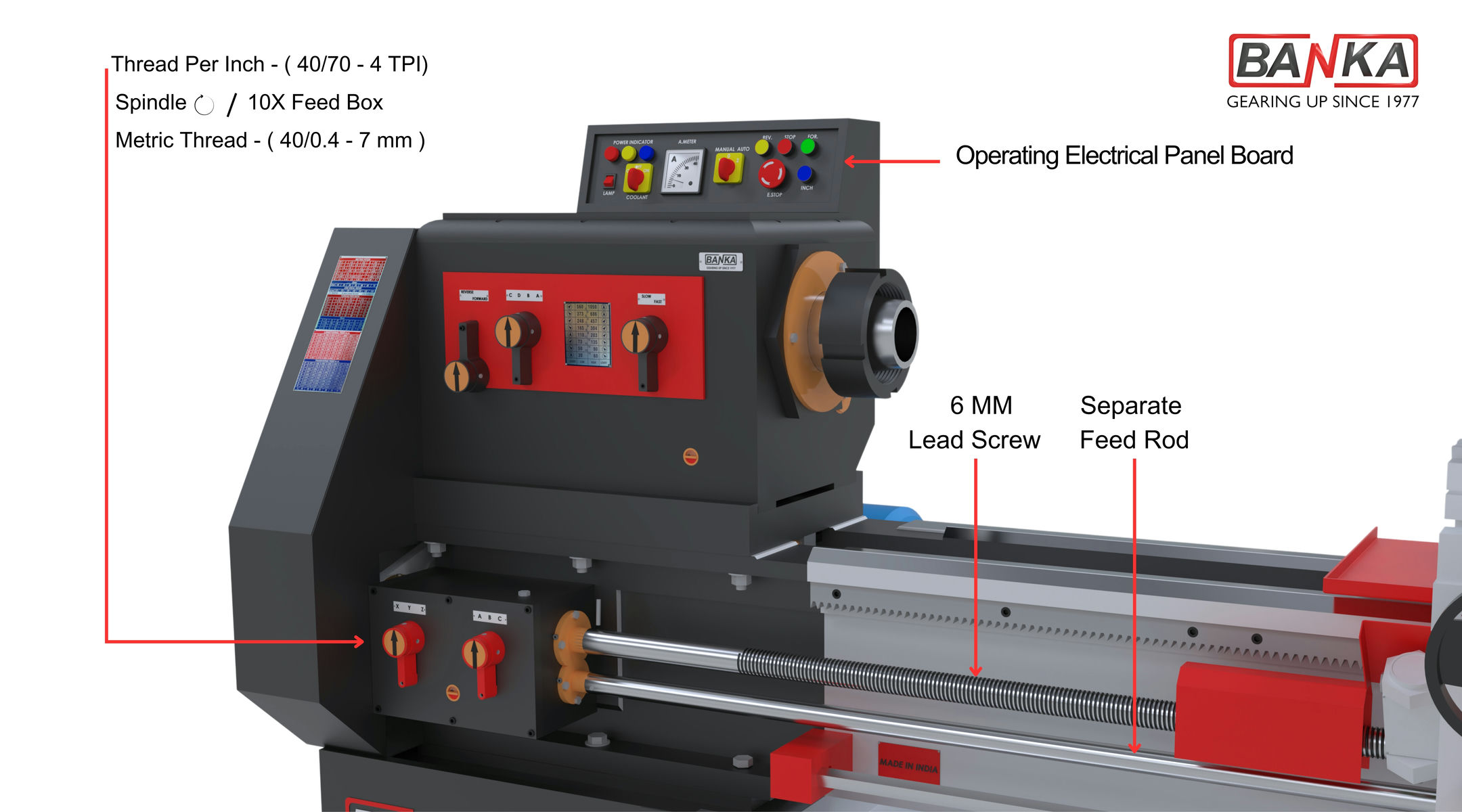

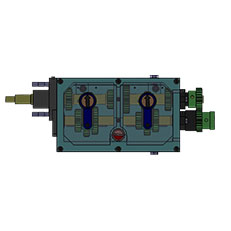

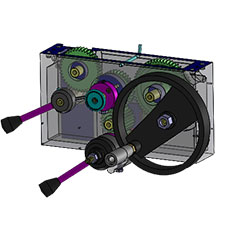

Gear Box : A specially designed gear mechanism is employed for this feed gear box. The easy to handle quick gear system provides an unusually wide range of feed and threads applications. Its outstanding features are that each selection of feed and commonly used threads (in metric, inch, module and DP) is instantly achieved through the combined operation of two levers with changing gears. |

|

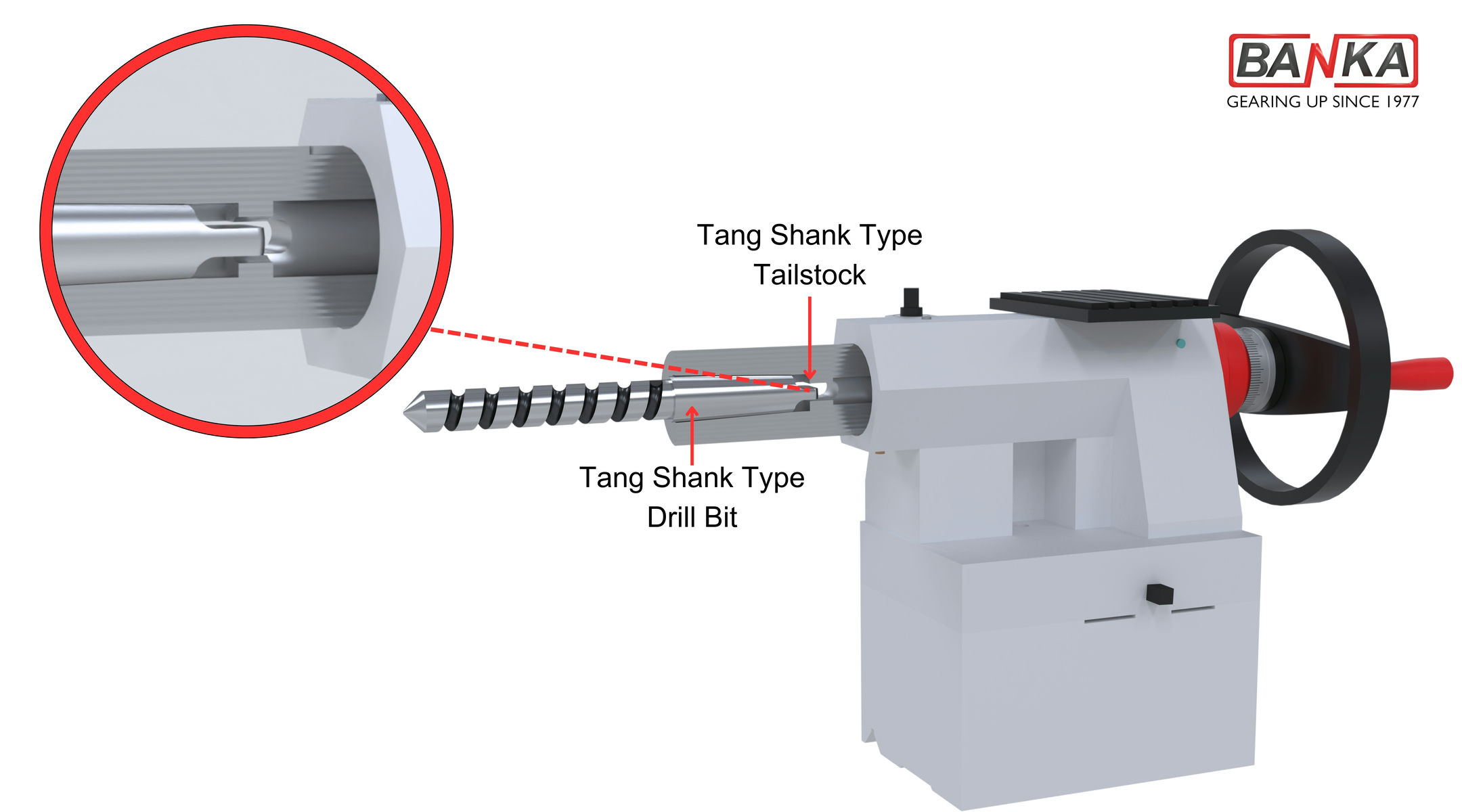

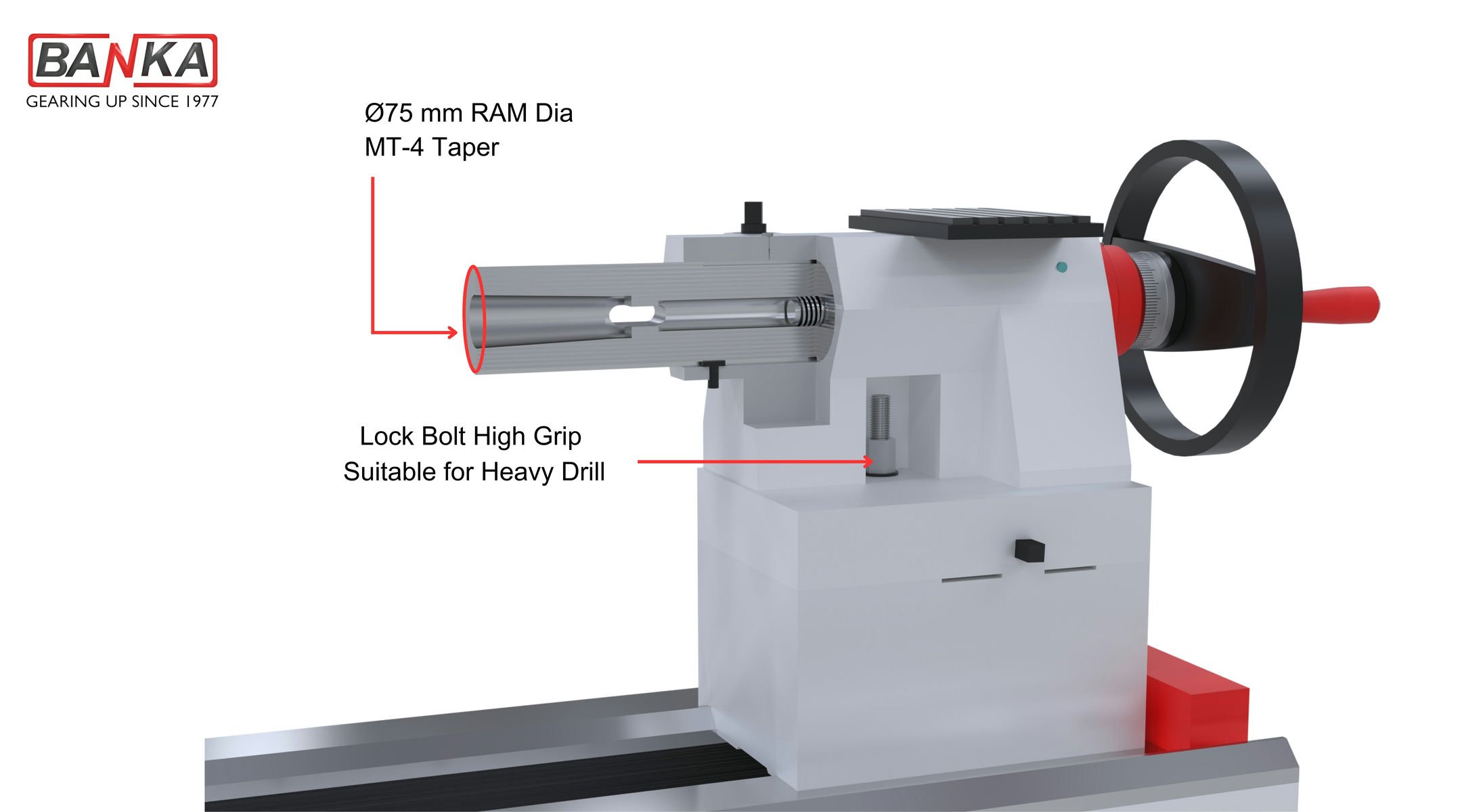

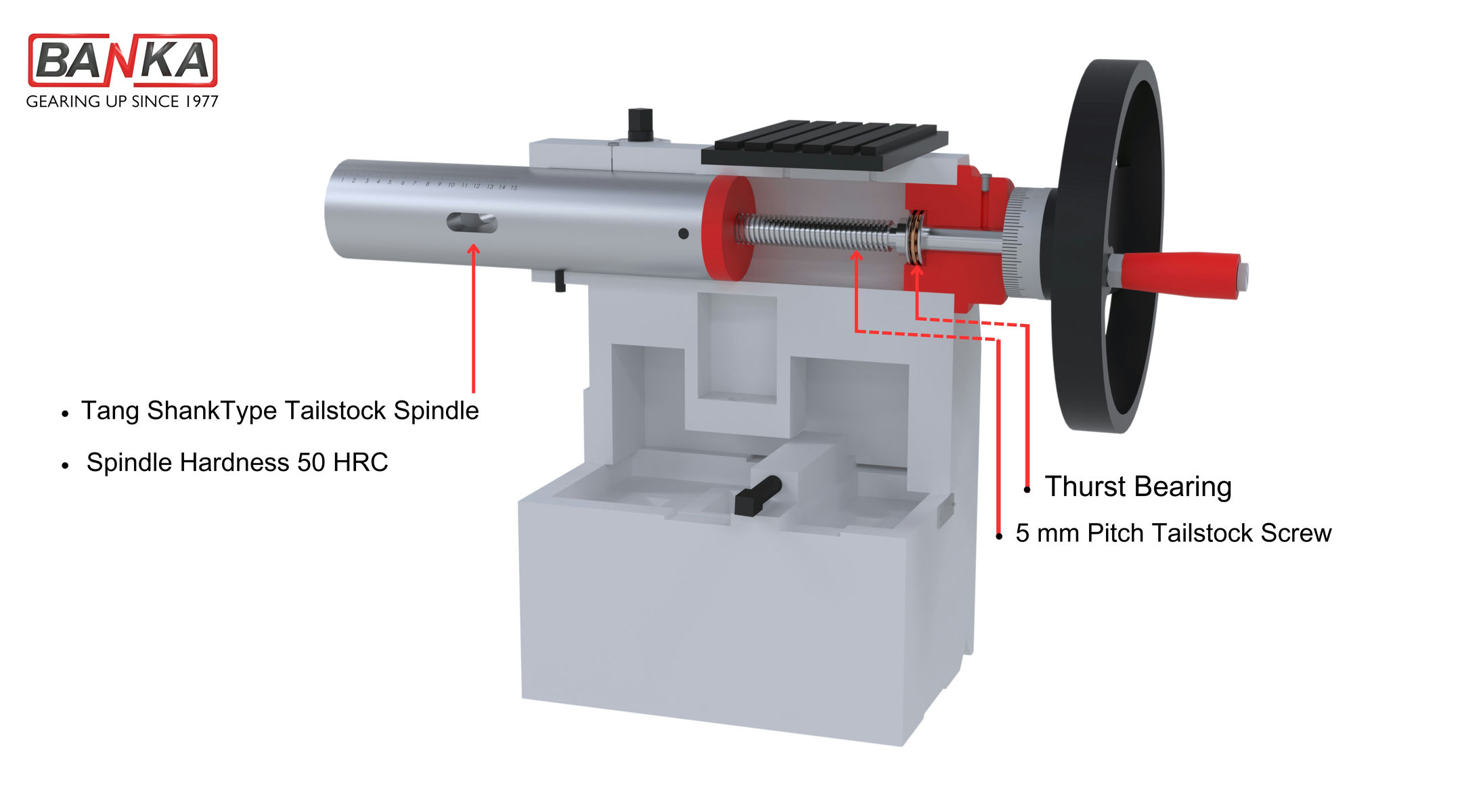

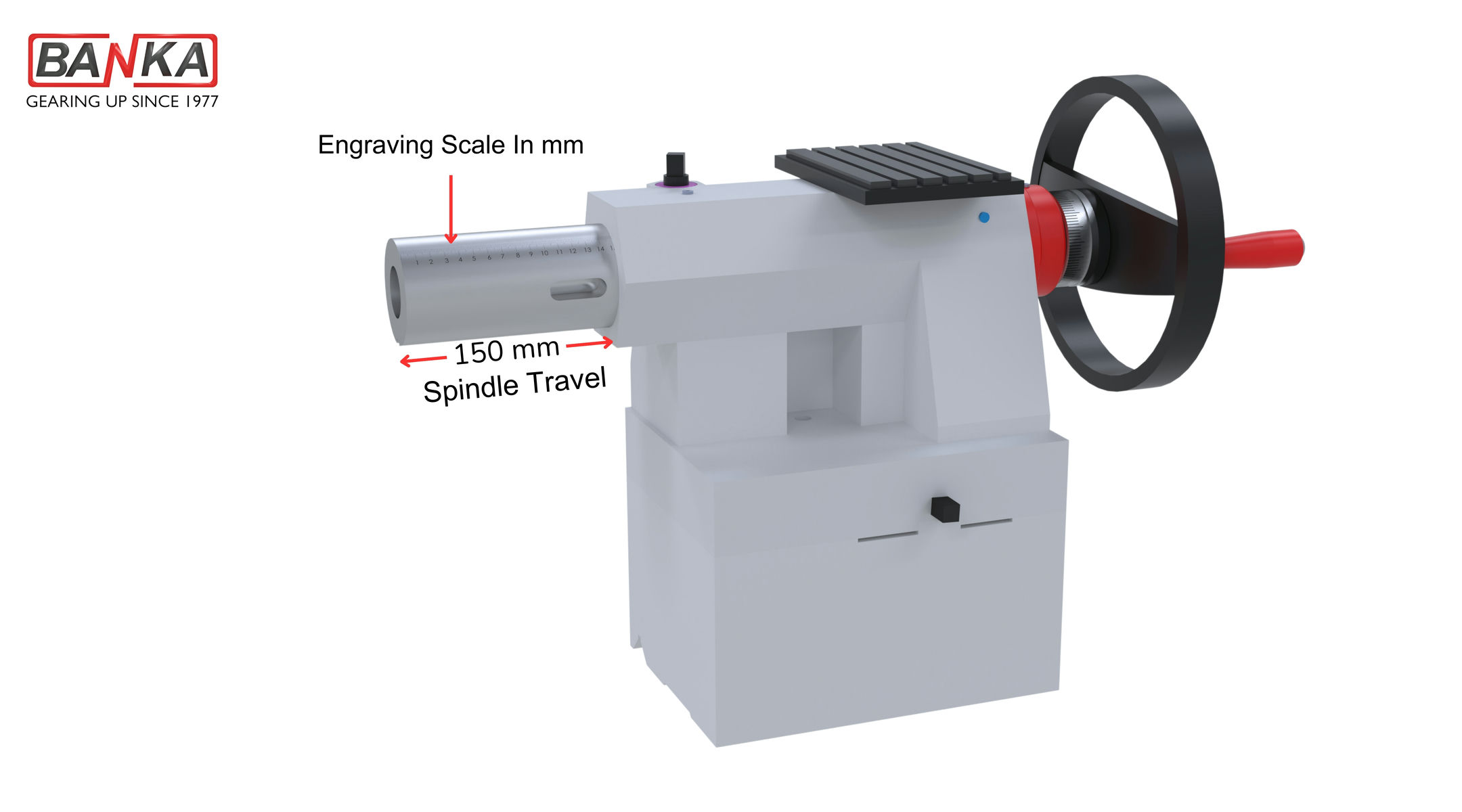

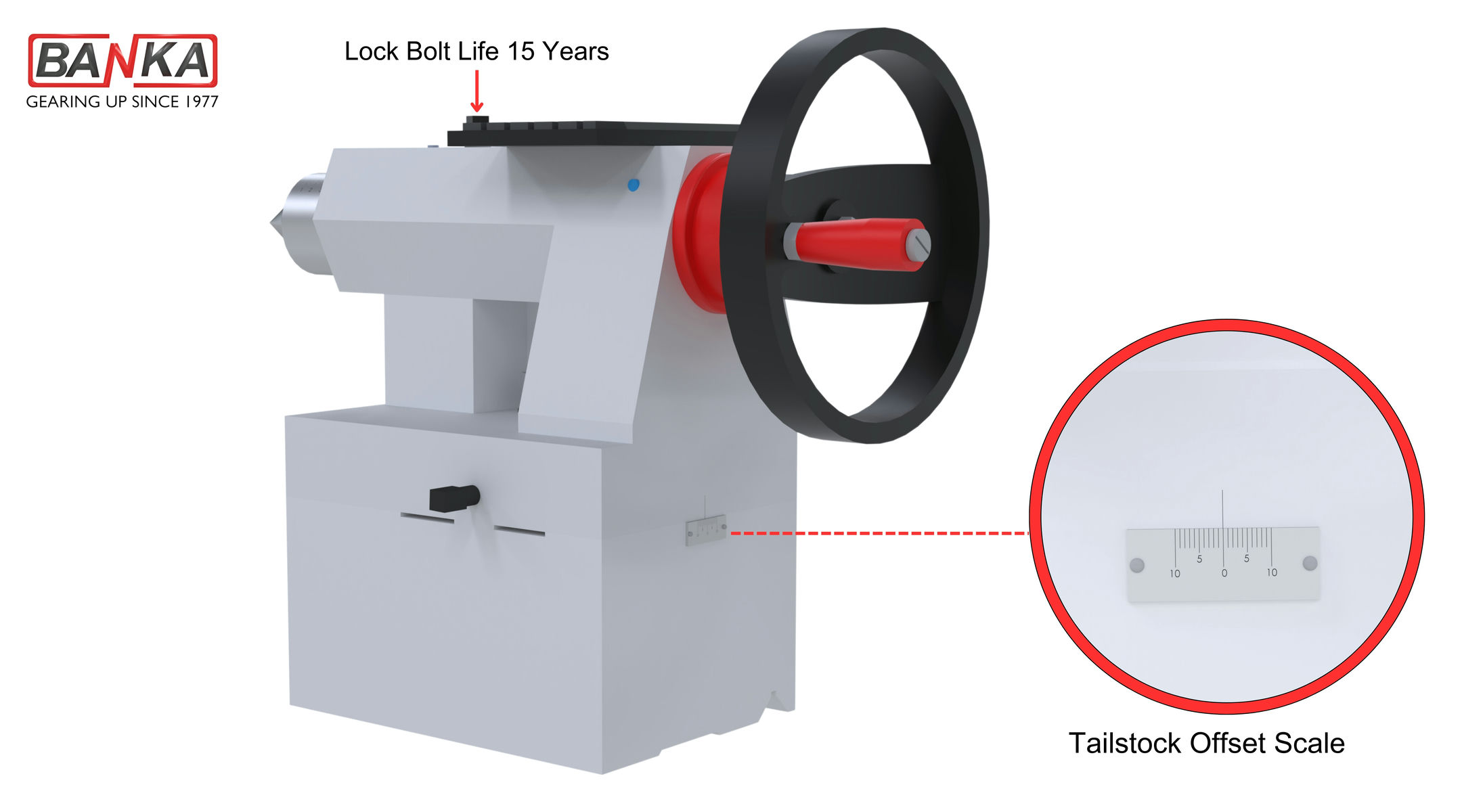

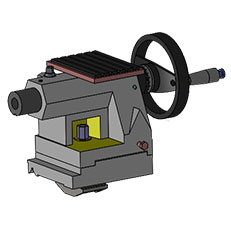

Tailstock : The sturdy construction of tailstock with Tang Shank type tailstock sleeve is capable of stable accommodation of heavy work.Double locking system ensures powerful tailstock clamping. |

|

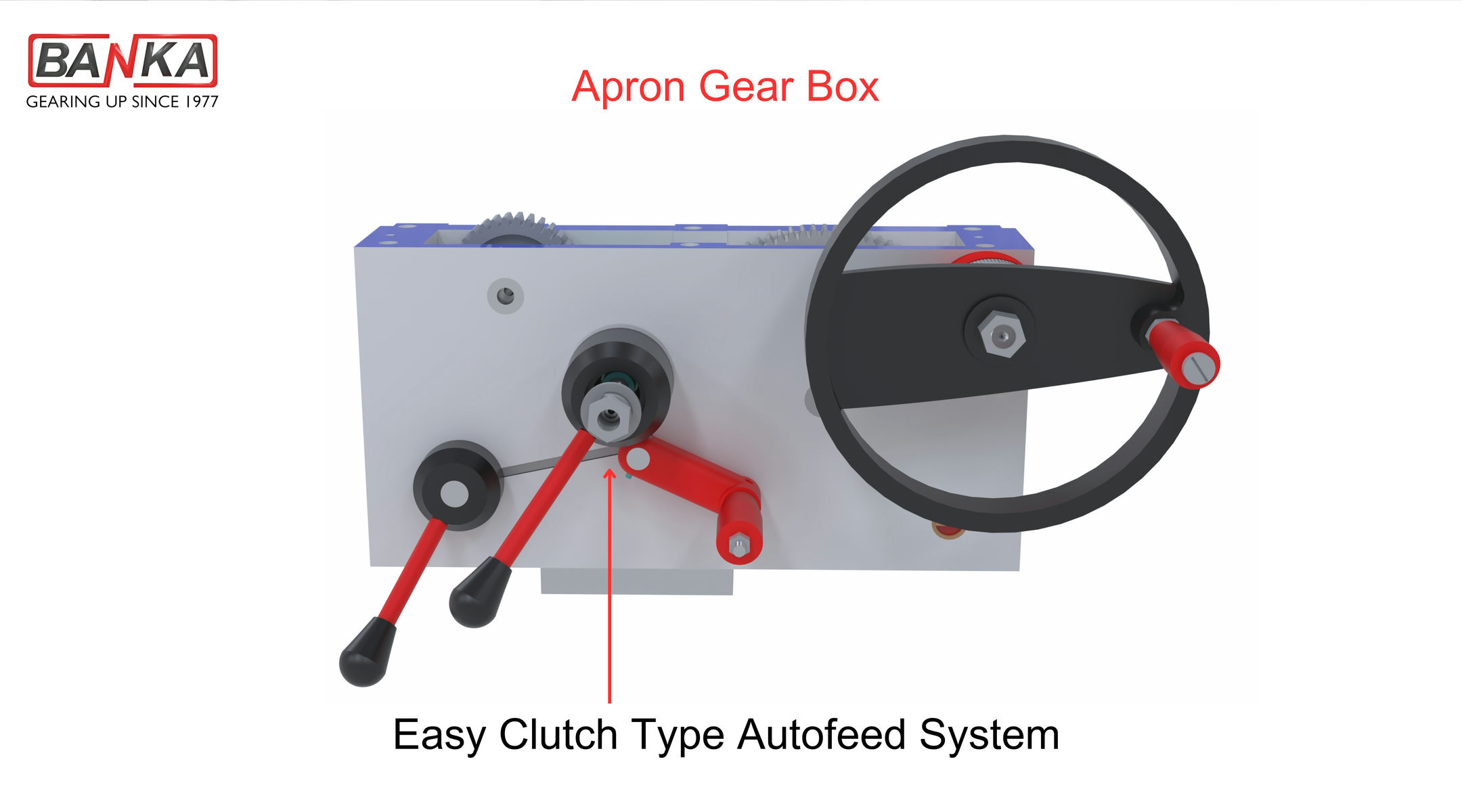

Apron: Apron designed to totally enclosed oil bath system and lever type arrangement for automatic feeds. BANKA is providing self-handle which is used to run the machine in auto. This feature is very much usefully while operator will run the machine in auto, if an accident will occur then self-handle will automatically release and apron will stop immediately. It will reduce the further damage of gears and other risks. |

|

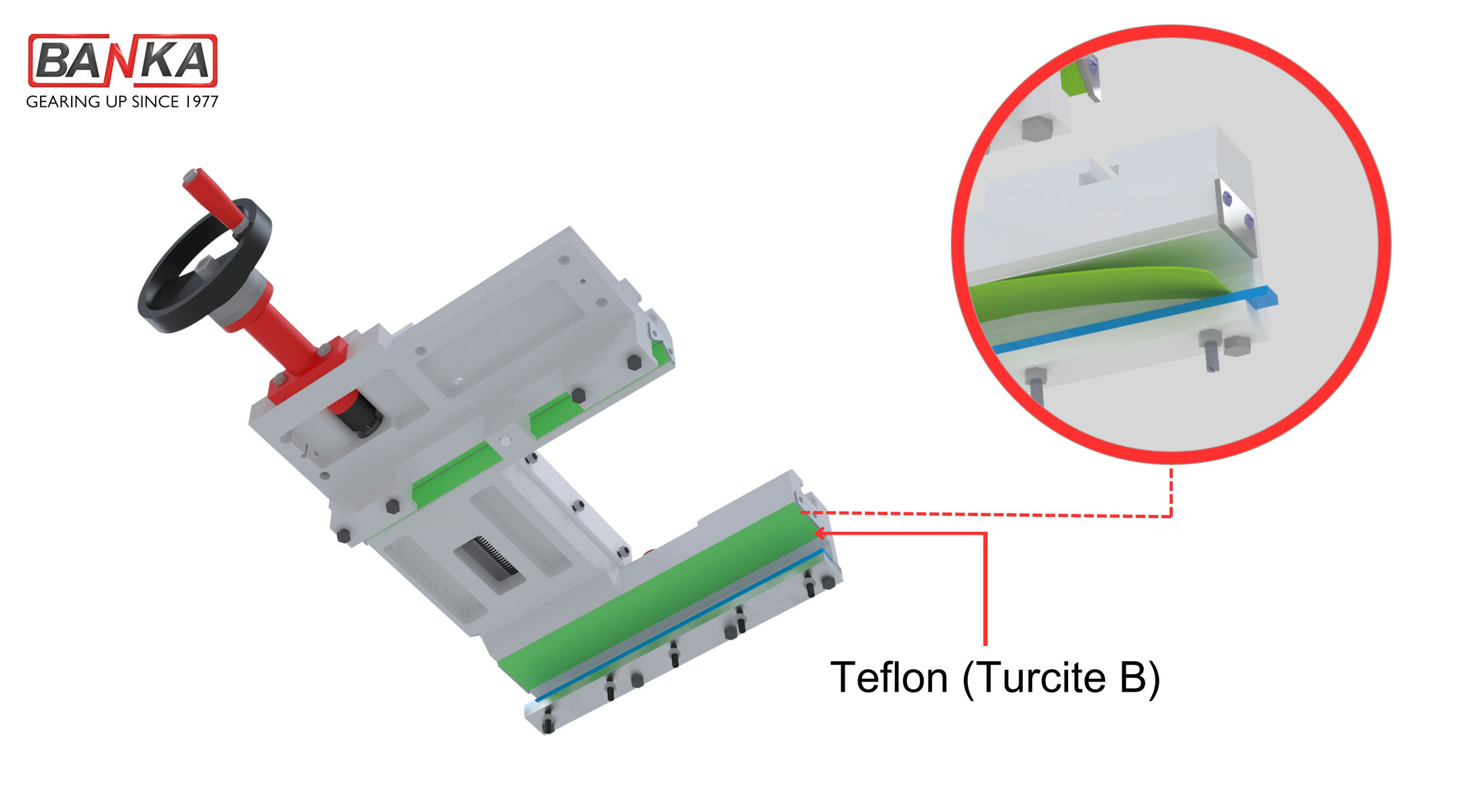

Carriage – Saddle: Turcite B Loner Bearing System coating between Carriage and Bed to provide extra cutting strength and long life accuracy. Also, it’s working as an anti-Friction system and gives smooth movement of Carriage on Bed. Without Turcite B bed accuracy will reduce up to 150 to 200 micron after 5 to 6 years. |

|

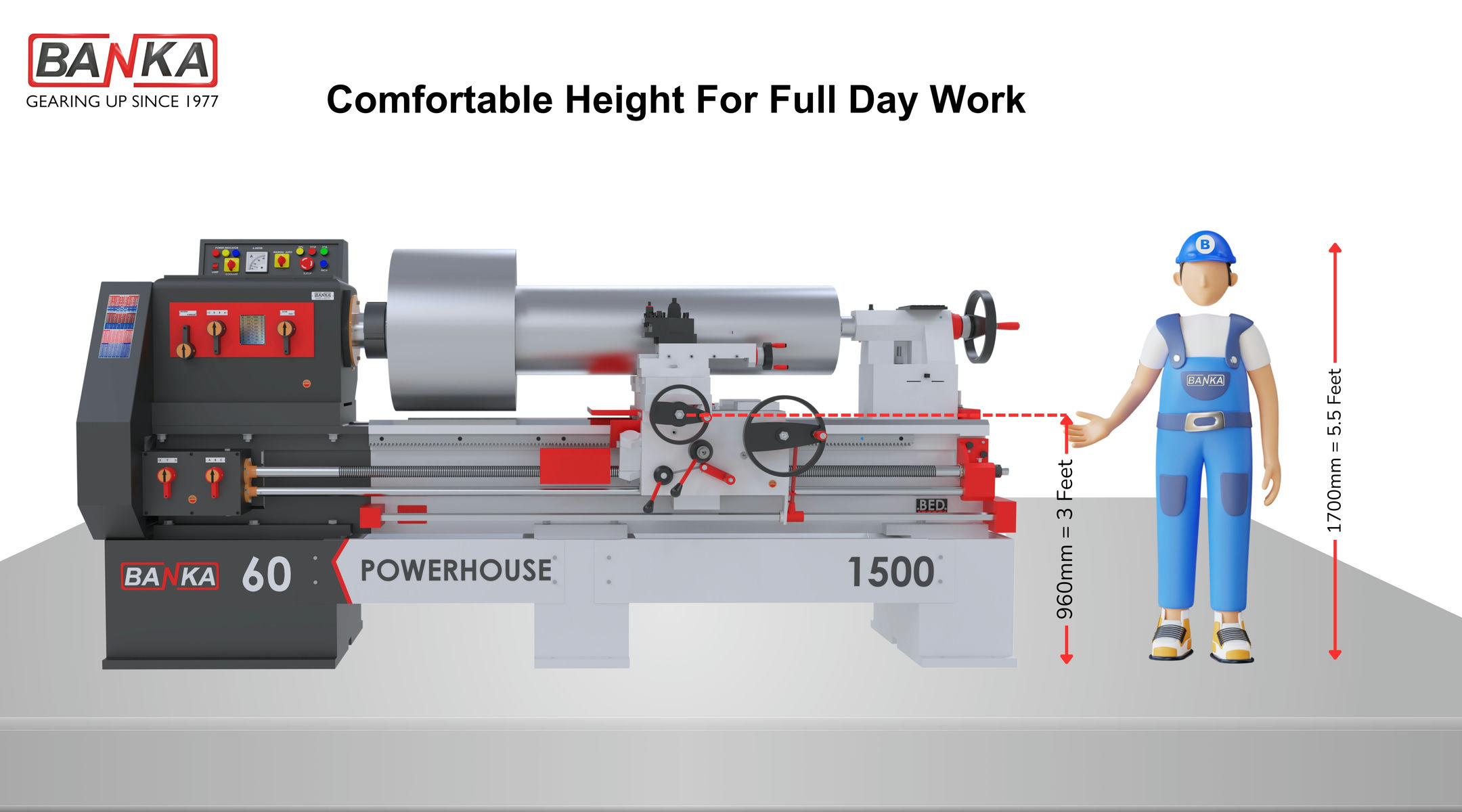

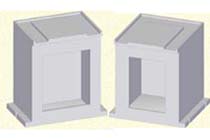

Leg : Legs having an appropriate wall thickness and robust design gives high rigidity and anti-vibration strength. |

|

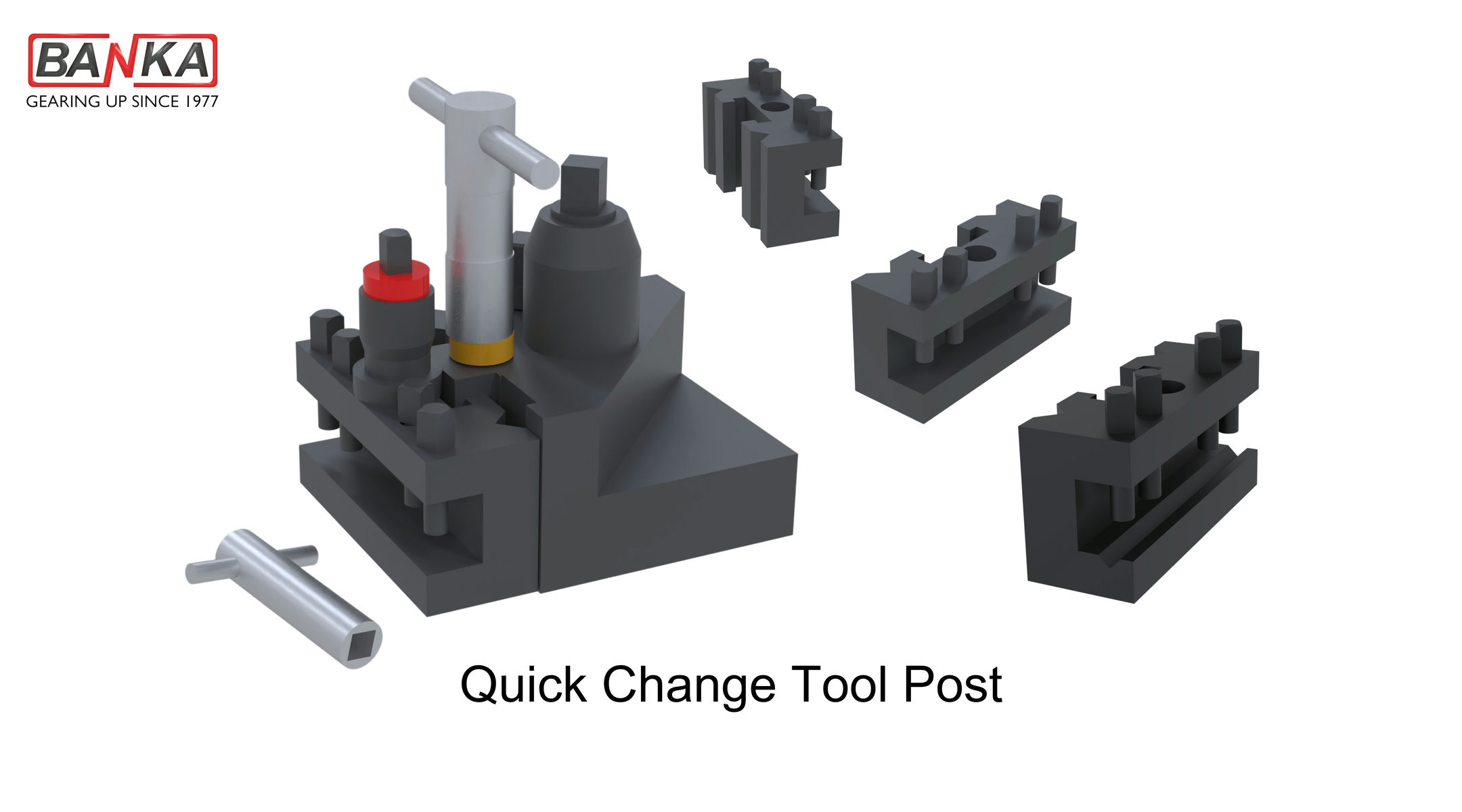

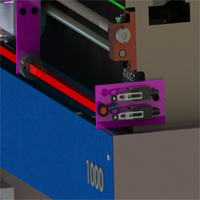

Quick Change Tool Post: In production engineering, the big advantage of a quick change tool post is that you don’t have to change the tools in tool post, just have to change the holders which already had set on the tool holder. It is time saving and increases the production. It’s safe and simple process while operation and has guaranteed lasting repetitive accuracy. Quick change tool post working parts are hardened and precision grounded. |

|

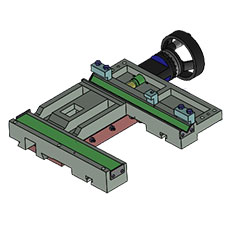

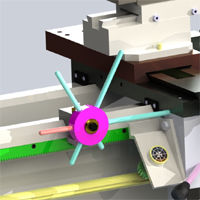

Carriage Stopper: Carriage Stopper is useful to stop carriage each time at a proper place as you have set. It also is known as the linear stopper. You can set six stoppers in carriage stopper as per your requirement. It is generally used in shaft turning works. |

|

Keyway Jaw: Keyway Jaw is used to make small keyways. Our Keyway vice is designed and developed as per the prevailing market trends and industry requirements. We are using high-grade raw material and precision engineering components to fabricate these machines. Owing to this, our range ensures high performance, reliability, efficiency, low maintenance requirements and durability. |

|

Third Shaft: The third Shaft is used in long lathe machines, suitable in above 7 feet length. It’s fitted with the bed of precision lathe machine below feed shaft. A handle has attached with the apron which is connected with Third Shaft, by which operator can stop the machine or can do reverse and forward operation at the time of turning the lengthy jobs. It saves the operator time, increases the production, easy to operate and maintenance accuracy. |

|

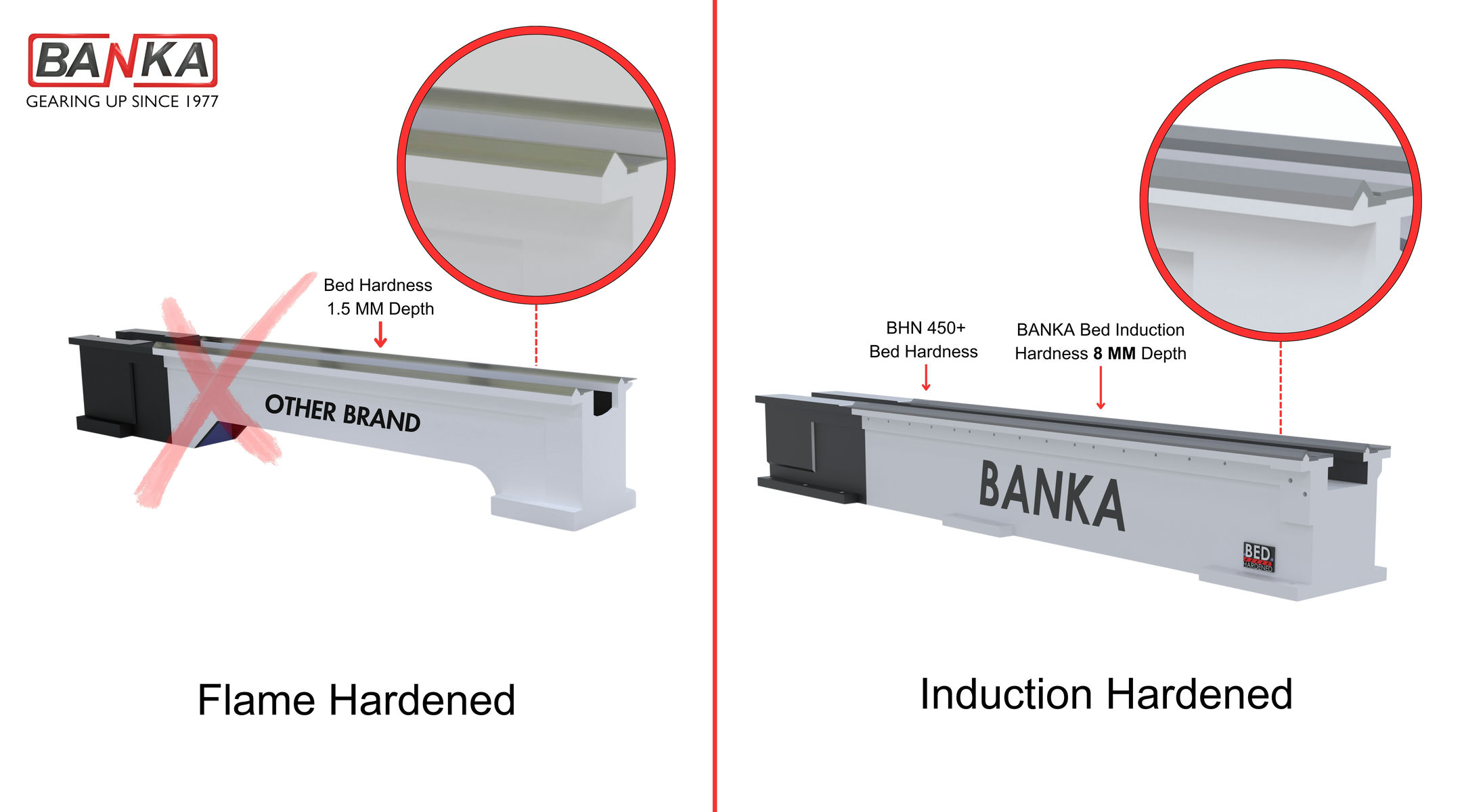

Hyperbolic Wall Bed: In heavy duty lathe, we provide Hyperbolic Wall Bed bed made from 25-grade casting and flame hardened up to 400 BHN. It is 2V & 2 Flate Special hyperbolic Bridge which gives extra rigidity and easy chip removal. |

Salient Features :-

- Headstock and gearbox gears hardened and ground.

- Bedways hardened and ground up to 400BHN.

- Turcite B anti- friction material on carriageways.

- Control panel & magnetic brake (optionally available on request)

- The metric dial on cross slide, Compound, and tailstock semi-universal gear box provides inch and metric thread without changing too many end trains gears.( universal gearbox optional available on request )

- Spindle speeds 48-1535 RPM in 16 H-L nos. spindle speeds.

- Alloy steel Spindle molesting on taper roller bearings.

- American LOO type spindle nose available on request.

| MACHINE TECHNICAL DETAILS | BANKA 60-1500 – Rs 4,75,000 | BANKA 60-2500 – Rs 6,15,000 | BANKA 60-3000 – Rs 6,45,000 | BANKA 60-3500 – Rs 7,25,000 |

BANKA 60-4000 – Rs 8,25,000 |

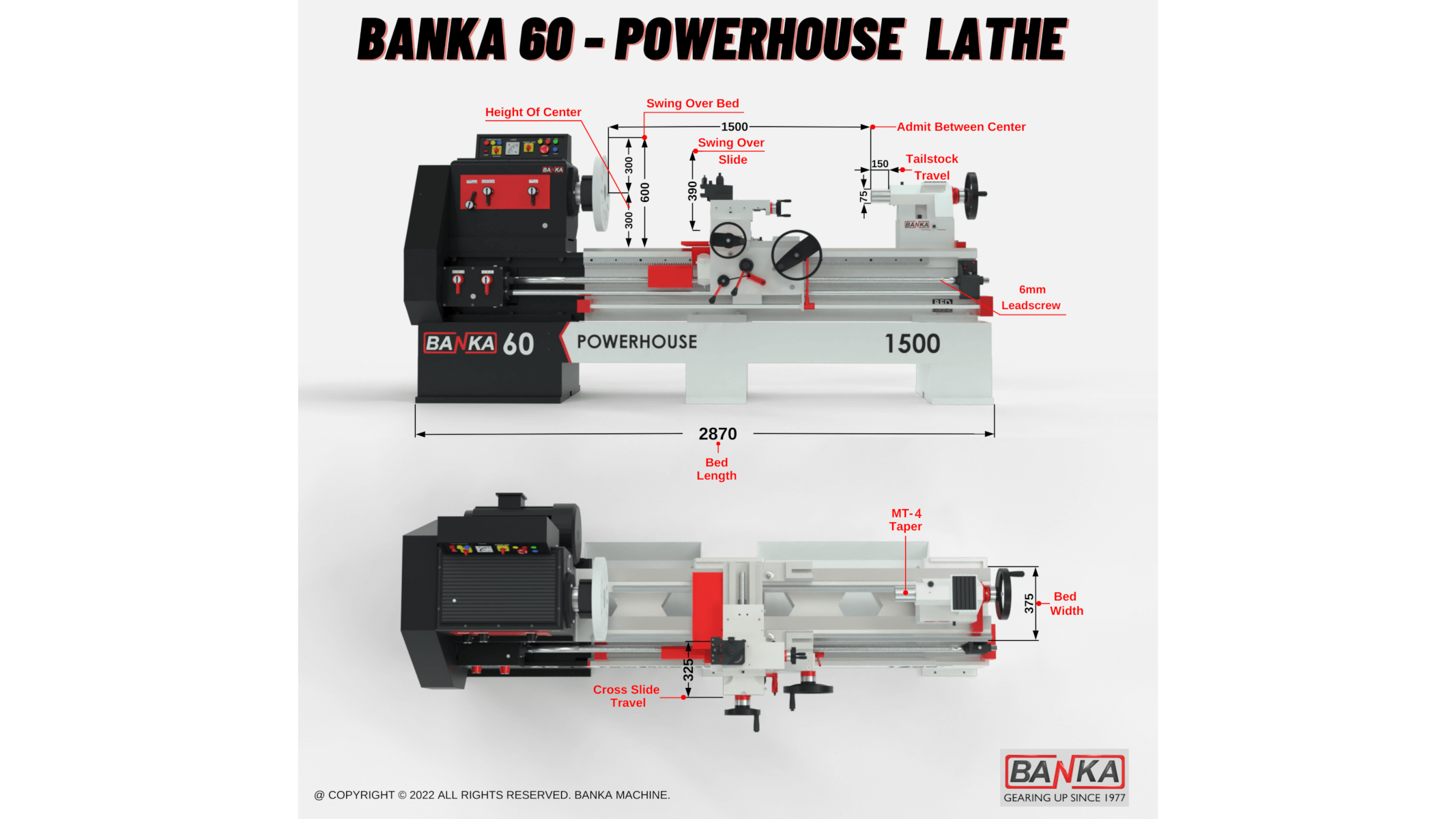

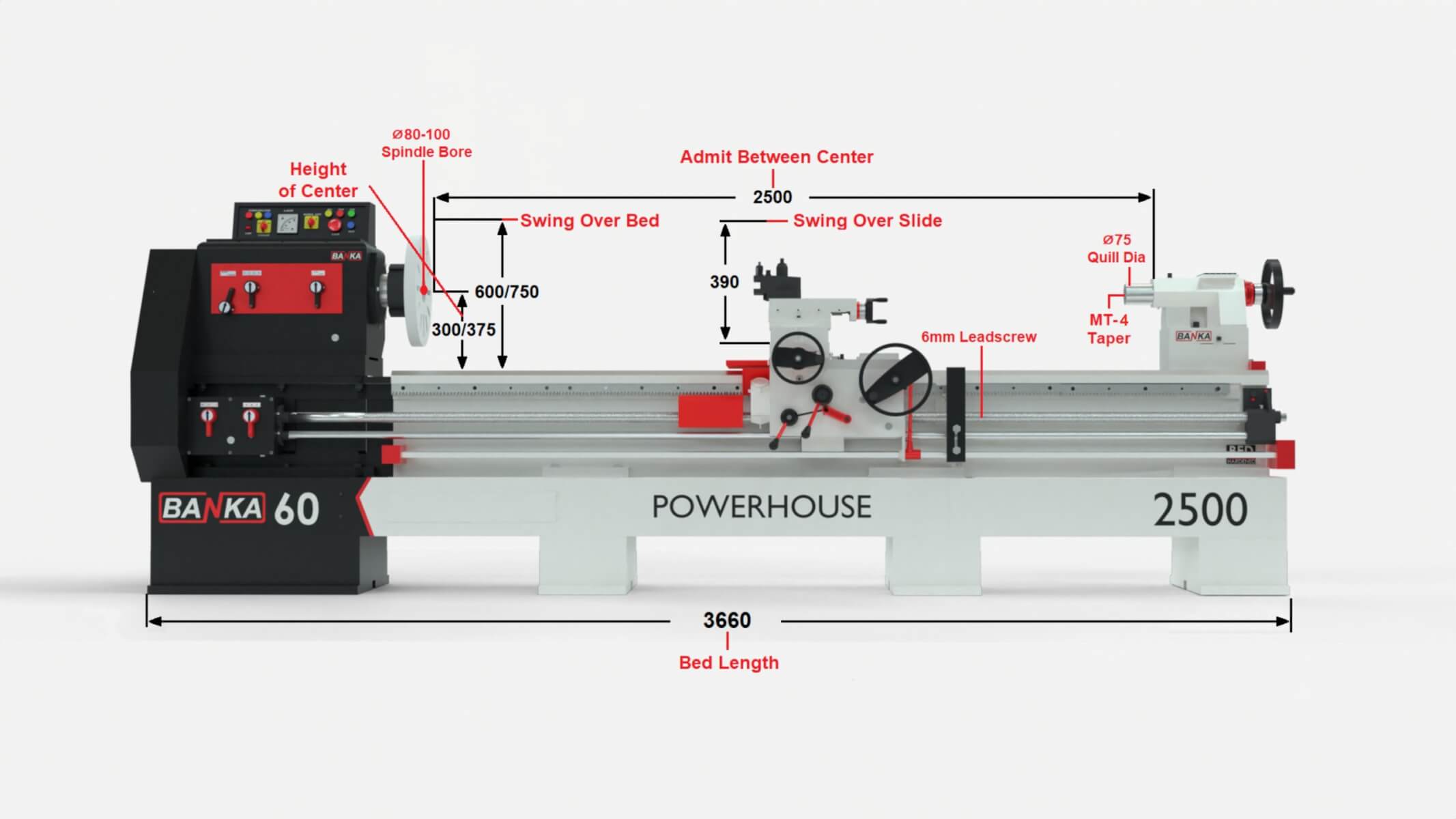

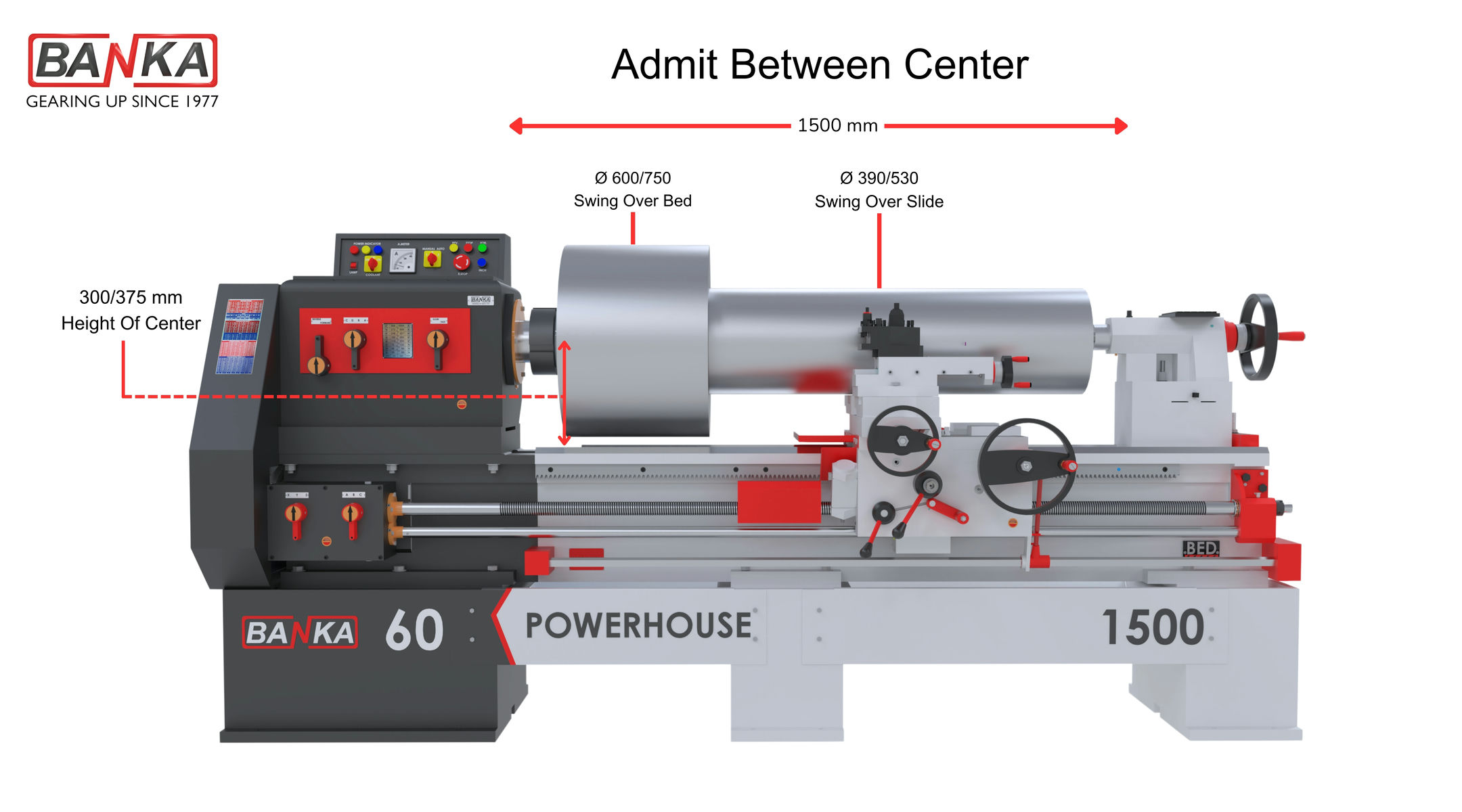

| Height Of Centers – MM | 300 /375 | 300 /375 | 300 /375 | 300 /375 | 300 /375 |

| Swing Over Bed – MM | 600 / 750 | 600 / 750 | 600 / 750 | 600 / 750 | 600 / 750 |

| Swing Over Slide – MM | 390 | 390 | 390 | 390 | 390 |

| Width Of Bed – MM | 375 | 375 | 375 | 375 | 375 |

| Spindle Bore | 80/100 | 80/100 | 80/100 | 100 | 100 |

| Spindle Nose | LOO Type | LOO Type | LOO Type | LOO Type | LOO Type |

| Spindle Speed No. | 16 H-L | 16 H-L | 16 H-L | 16 H-L | 16 H-L |

| RPM | 30-1050 | 30-1050 | 30-1050 | 30-440 | 30-440 |

| Cross Slide Travel | 325 | 325 | 325 | 325 | 325 |

| Top Slide Travel | 150 | 150 | 150 | 150 | 150 |

| Tail Stock Sleeve | MT – 4 | MT – 4 | MT – 4 | MT – 4 | MT – 4 |

| Quill Dia. / Travel | 75/150 | 75/150 | 75/150 | 75/150 | 75/150 |

| Tool Shank Section | 25 X 25 mm | 25 X 25 mm | 25 X 25 mm | 25 X 25 mm | 25 X 25 mm |

| Feed Longitudinal | 60/0.08-1 | 60/0.08-1 | 60/0.08-1 | 60/0.08-1 | 60/0.08-1 |

| Feed Transverse | 60/0.02-0.25 | 60/0.02-0.25 | 60/0.02-0.25 | 60/0.02-0.25 | 60/0.02-0.25 |

| Metric Thread | 40/0.4-7 mm | 40/0.4-7 mm | 40/0.4-7 mm | 40/0.4-7 mm | 40/0.4-7 mm |

| Thread Per Inch | 45/70-4 TPI | 45/70-4 TPI | 45/70-4 TPI | 45/70-4 TPI | 45/70-4 TPI |

| Lead Screw | 6 mm | 6 mm | 6 mm | 6 mm | 6 mm |

| Main Motor | 3.7 KW / 5 HP | 3.7 KW / 5 HP | 3.7 KW / 5 HP | 5.2 KW / 7 HP | 5.2 KW / 7 HP |

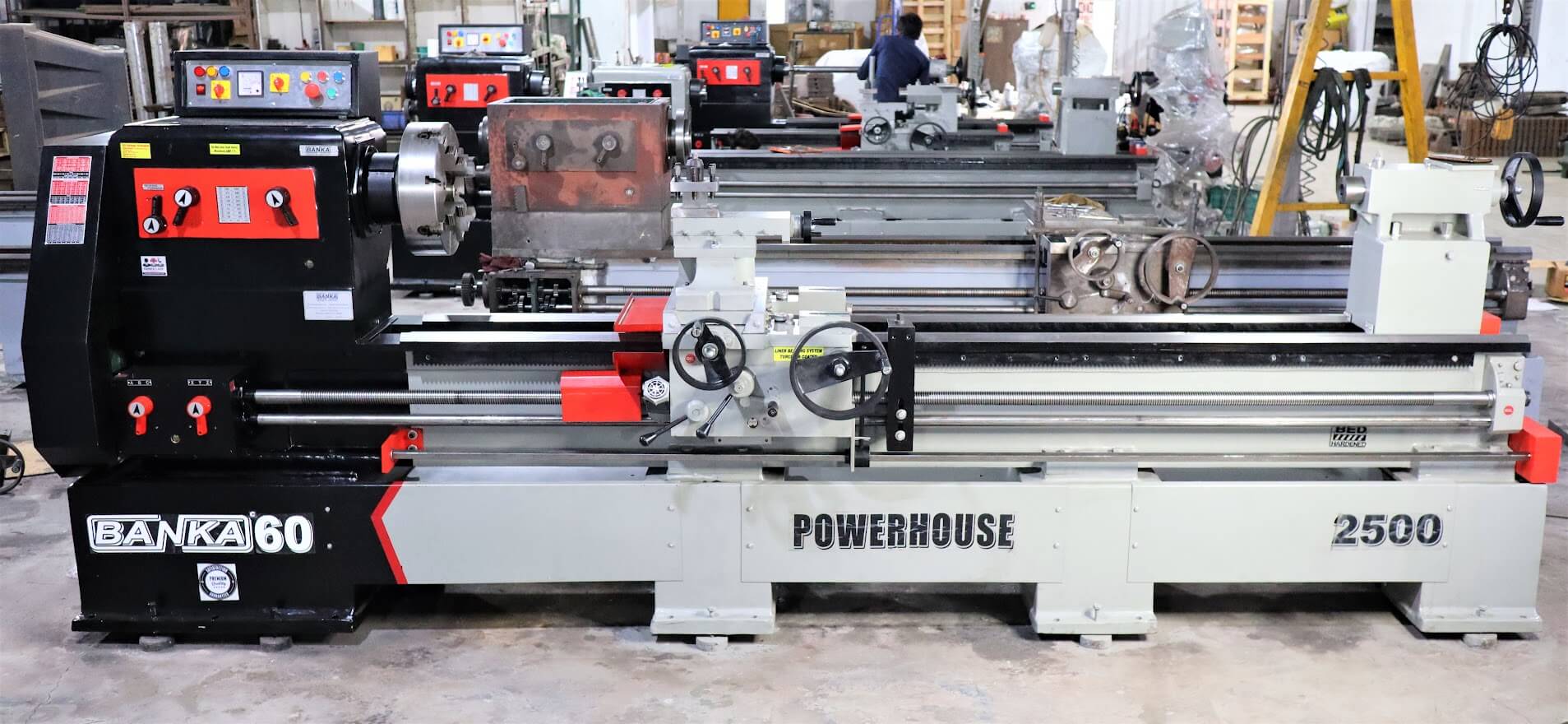

| Admit Between Center | 1500 | 2500 | 3000 | 3500 | 4000 |

| Bed Length Feet | 9′ | 12′ | 14′ | 16′ | 18′ |

| Weight (Kg.) Approx. | 1900 | 2300 | 2600 | 2900 | 3500 |

|

Spindle Bore (OPTIONAL) | 100 MM |

| Spindle Type | LOO TYPE | |

| Price | Rs.35000 to 50000 Extra Cost |

| BANKA 60: USP of this Lathe Machine |

Get more, Spend less : BANKA 60 is cost effective. |

|

Some exclusive features of BANKA 60 leads customers to go for BANKA 60. Features are as follows: 1) Spindle RPM : 30-1050 2) Accuracy : As per IS Standard 3) Power : 5 HP Electrical Motor BANKA Machine has 30 years of expertise in making reliable machine |

Our Lathe Machines are built with heavy rigid construction for increased durability and accuracy. When combining our manufacturing technique with accuracy, repeatability and price, you can easily see why our lathes offer the best value in the market for new lathe equipment. |

Quality :

Our lathes quality is maintained because of our step by step manufacturing process. According to our manufacturing

process, metal cutting lathe performance and accuracy are better than other industrial lathe machine manufacturer.

Our toolroom lathe is manufactured as per Indian Standard test

by testing instruments like,

Straight Edge:

A straightedge is a tool with an edge free-form curves or straight, used for

transcribing straight lines. Straightedges are used in the automotive service and machining industry to check the

flatness of machined mating surfaces and concave & convex. True straightness can in some cases be checked

by using a laser line level as an optical straightedge: it can illuminate an accurately straight line on a flat

surface such as the edge of a plank or shelf. It effects in the production schedule, time schedule, time saving and

increase the quality of our products.

Spirit Level Precision:

Generally, an engineer’s spirit

level is used to level machines, although they may be used to level large workpieces on

machines such as planers. Spirit levels are also used in building construction by carpenters and masons. A precision

level is used to check the installation of precision machines in two

axes. A lathe is manufactured with its base in a level plane. Small milling machines are

often roughly leveled but large mills are installed level. Periodically check the level to ensure contained lathe accuracy by

using Spirit Level accuracy of 0.05 mm/mt. According to IS Test Chart machine must be accurately leveled up to

0.02 mm per meter.

Hardness Tester BHN Scale:

Hardness measurements quantify the resistance of a material to plastic deformation.

hardness tests compose the majority of processes used to determine material hardness, and can be divided into two

classes: macro-indentation and micro-indentation tests. It’s used to test the hardness of the bed. Our each lathe

machine’s hardness of the bed is 400 BHN as per IS test. The

main advantages of the hardness test are that extremely accurate readings can be taken, and just one type of

indenter is used for all types of metals and surface treatments.

Tachometer RPM MPM:

Tachometer RPM Meter is an instrument measuring the rotation speed of a shaft or disk, as in a lathe machine, drill

machine, milling machine and other machinery. The tachometer is used to accurately measure spindle RPM (Speed) of the lathe machines. Just

attach a reflective sticker to the rotating part and point the red laser beam on the mark from a safe distance.

Sound Level Decibel Meter:

As per the IS test our Tool lathe head sound is measured by Decibel Meter and it should

be up to 85 to 90 dB. In every lathe machine, it should be 85

dB and our each lathe machine noise level is under 85 dB.

Dial Indicator Micrometers:

Dial Indicator Micrometers is used for precise

measurement of components which are done on the lathe. It’s also used to measure the

apparent diameter of celestial bodies or microscopic objects.

Screw Thread Special Tester:

With Screw thread tester we can test the Pitch

accuracy test. One end of the tester, a dial gauge has attached and the other end a point

has attached which measures screw thread.

Spindle Torque:

The simplest form of torque wrench consists of a long lever arm between the handle and

the wrench head, made of a material which bends elastically in response to

applied torque. The mechanical indicator is connected to the head of the lathe machine.

Which measures the torque of the machine’s spindle.

Amperemeter:

It is used to measures the current in a circuit is to break the circuit open and insert

an “ammeter” in line with the circuit so that all electrons

flowing through the circuit also have to go through the meter. When an ammeter is placed in series with a circuit,

it ideally drops no voltage as current goes through Lathe

machine main motor.

Banka lathe is the best premium quality lathe, drill, mini lathe, milling machine

manufacturer in indiaIndia. Our future depends on the dedication of individuals, to achieve one of the top

charitable all gear lathe manufacturers in the whole world. Precision lathe machine quality demands are a must in

all aspects of component manufacturing. It requires a range of processing expertise, technologies, and application

to provide consolidated results to users. Innovative solutions

& approaches provide the edge to have technological advancements and necessary pace in tomorrow’s world. The

lathe machines are prepared by expertise technical engineers.

System of Making :

We are using a software for making

designs, patterns, and drawings, according to that we give job

works at outsources. We are not manufacturing any parts on our floor because it disturbs our

manufacturing schedule and wasting our time. We assembled all the assembly parts and sub-assembly parts on our floor

if there any rejection in any parts that we never compromise in our

quality. In next stage when all assembly and all sub-assembly were assembled our quality

control department will inspect the same, who are expertized and

skilled with years of experiences. Quality control team strictly inspect all the parts with

its material, tolerance, and reference as per drawings and inspection reports.

We are using the material with 20MnCr5 or SAE

8620 grade casting in Gear, Lock Nut, Spindle which was passed through from Hardening process in pit type gas carburizing furnance with PID

Controller. Machine’s Headstock has bored in WMW Boring machine and bed also passed on with flame

hardening process up to 400 BHN. WMW planning machine used to

make a rough cut in machine bed and after this process, it will go for finishing the process. In next step bed will

pass on grinding process by METISAN USA make surface grinding machine.

Maintenance Schedule :

Our service engineers are working continuously as

per their planned schedule of installation and service for your lathe machines. The main

principle of maintenance schedule is to provide customer timely service and to reduce the breakdowns. We are

providing service according to your usage and criticality of

your lathe machine. The customer can get the benefit of free of cost

maintenance and less timing consuming. Our long experience of the machine tools business and

working with thousands of machines enables our highly skilled and experienced

service engineers are always ready to serve the service

for their customer any time.