Banka 30 – MINI / BENCH / BABY LATHE MACHINE – 3 Feet For Tool Room / Hobby Purpose – Chhoti Lathe – DIY Lathe

₹69,500

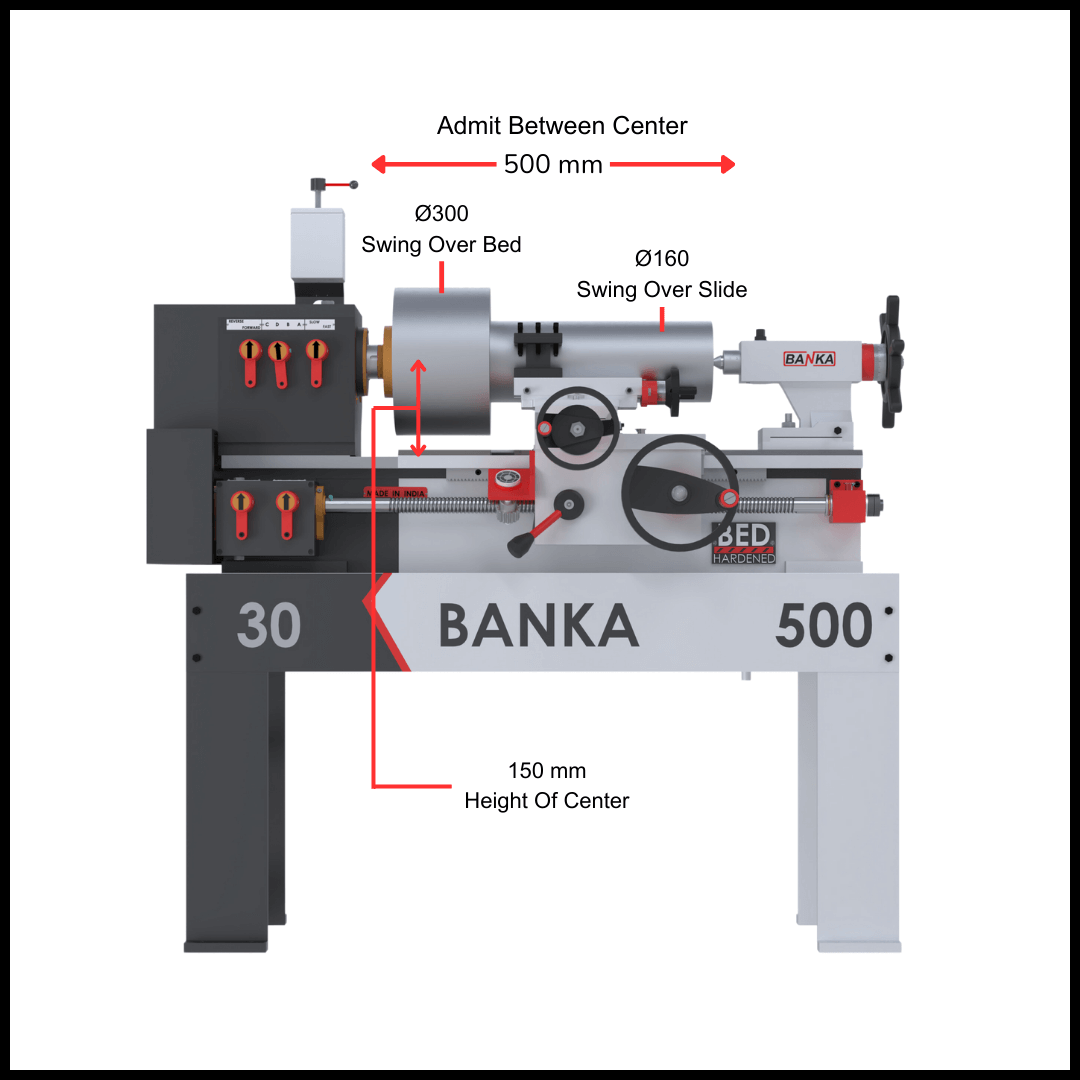

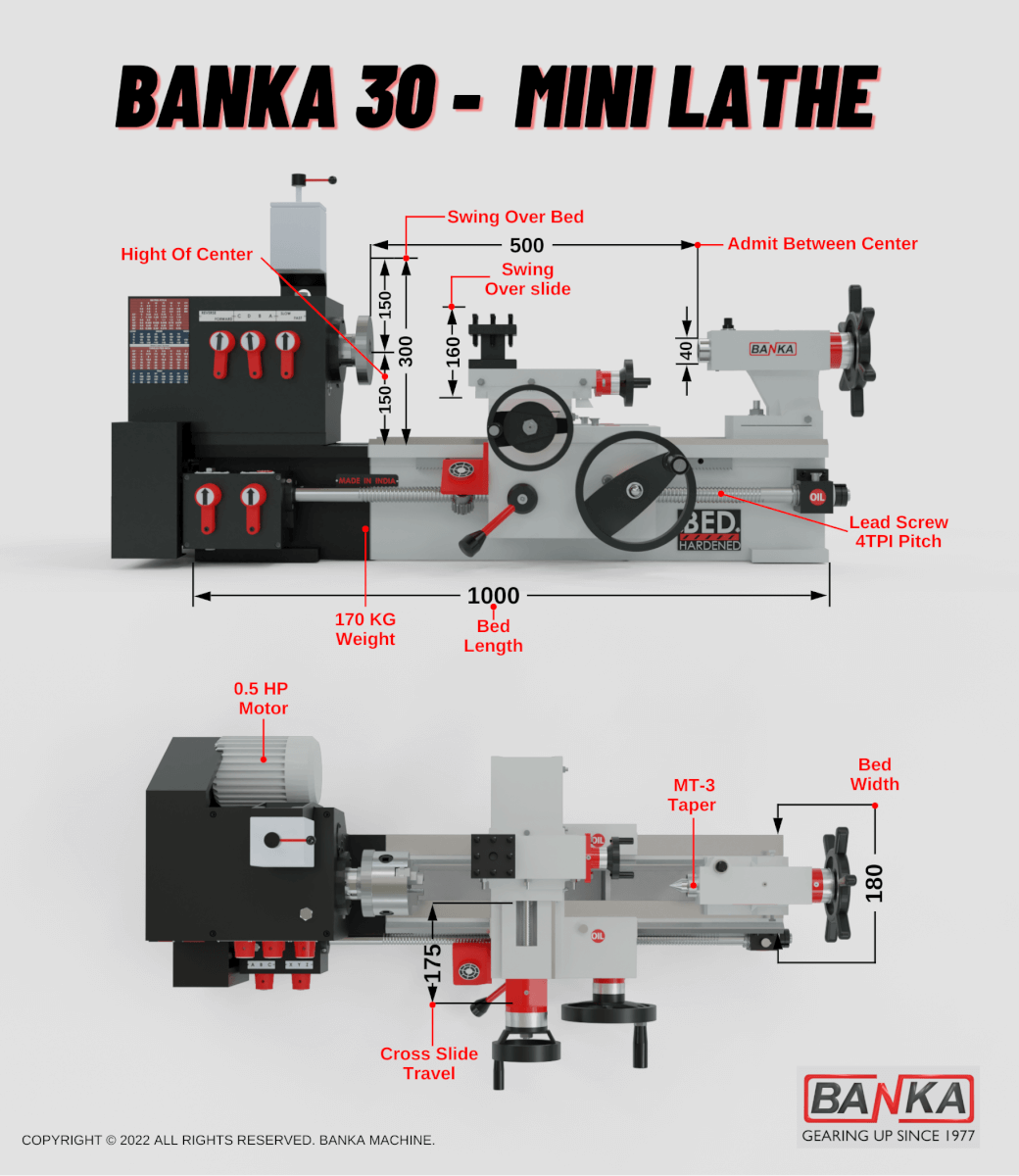

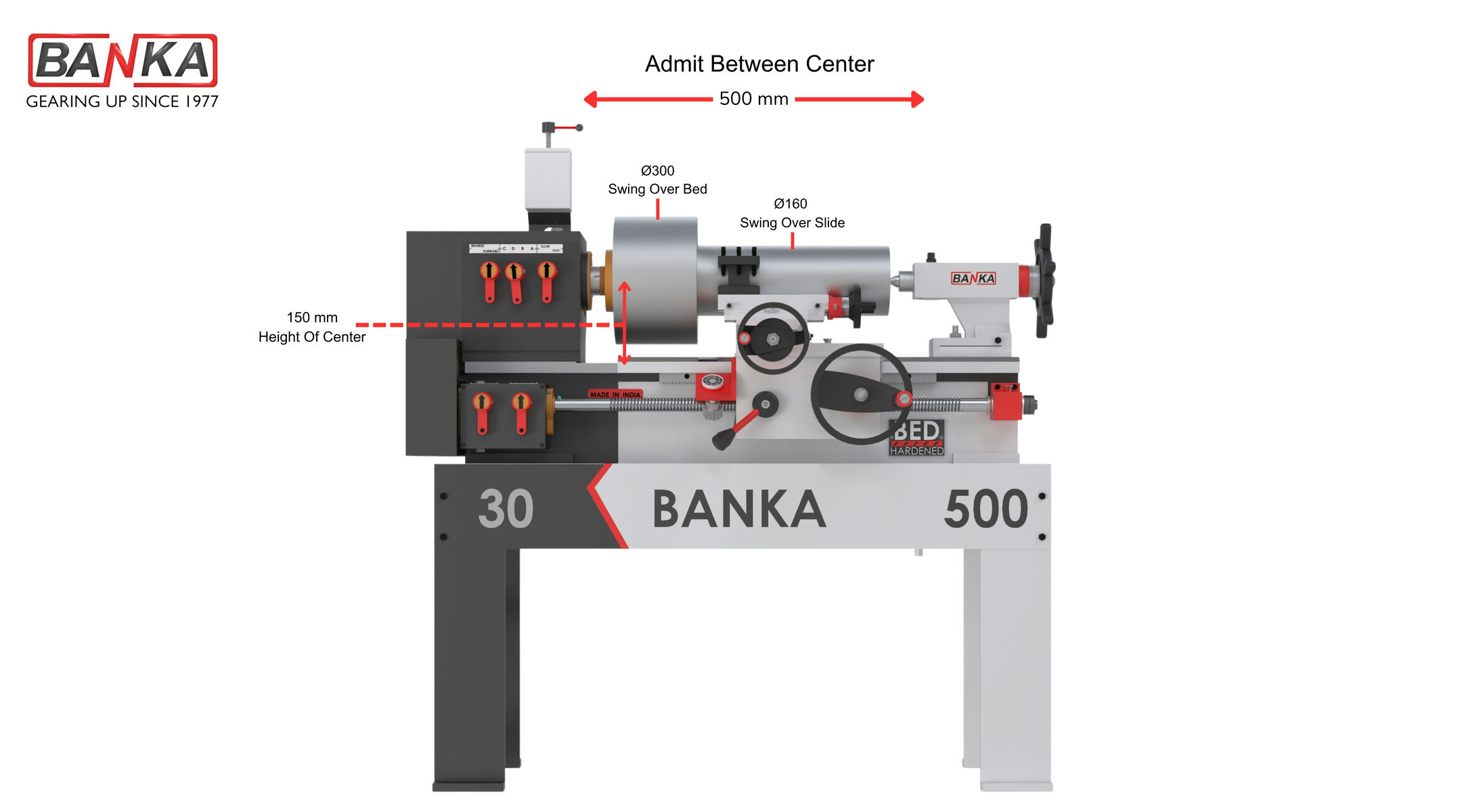

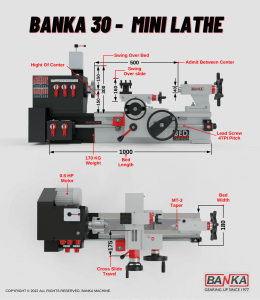

- Height Of Center: 150 mm

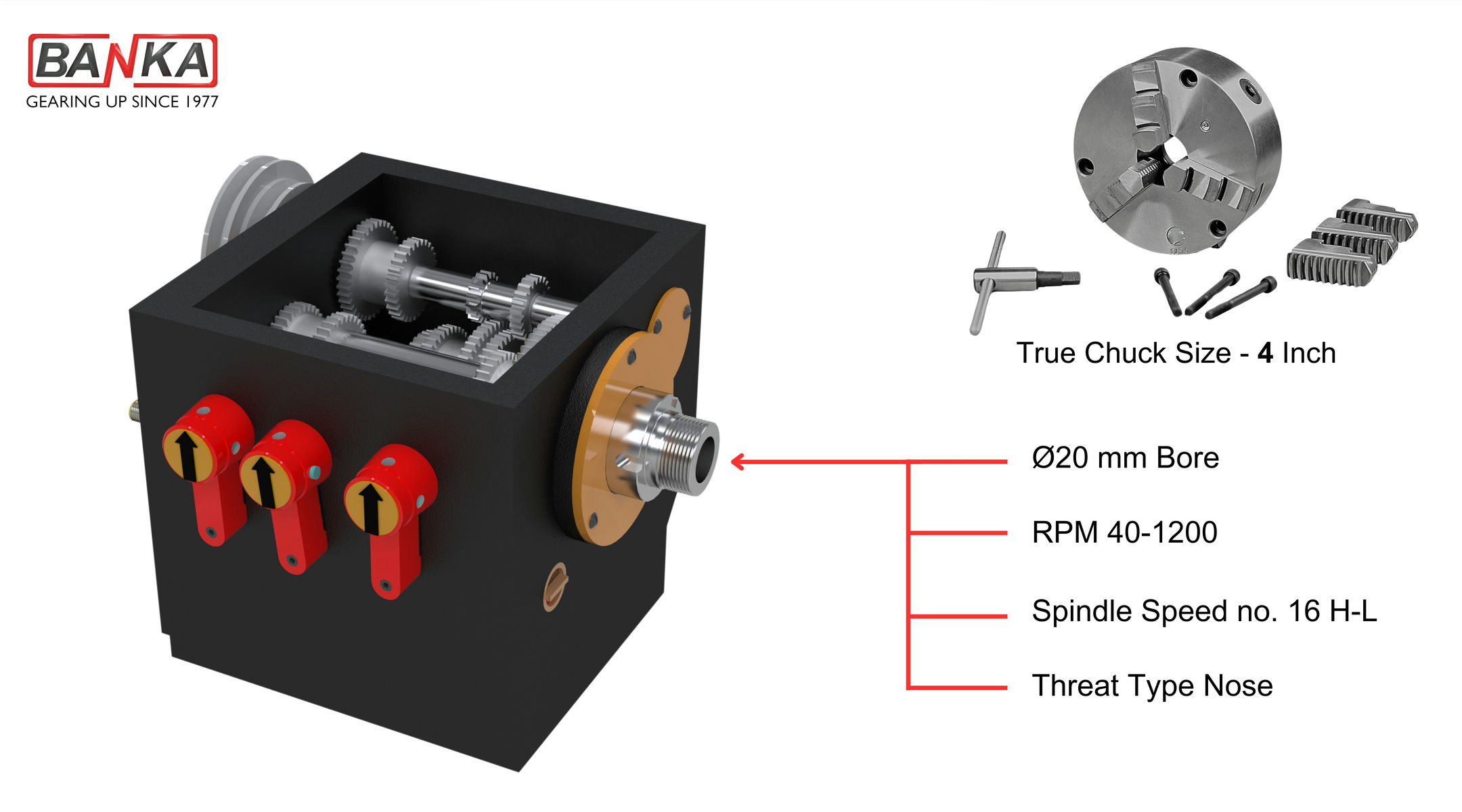

- Spindle Bore: 20 mm

- Admin Between Center: 500 mm

- Bed Length : 3 Feet

- Spindle Speed: 1200 RPM

- Bed Width: 180 mm

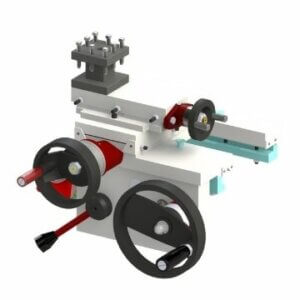

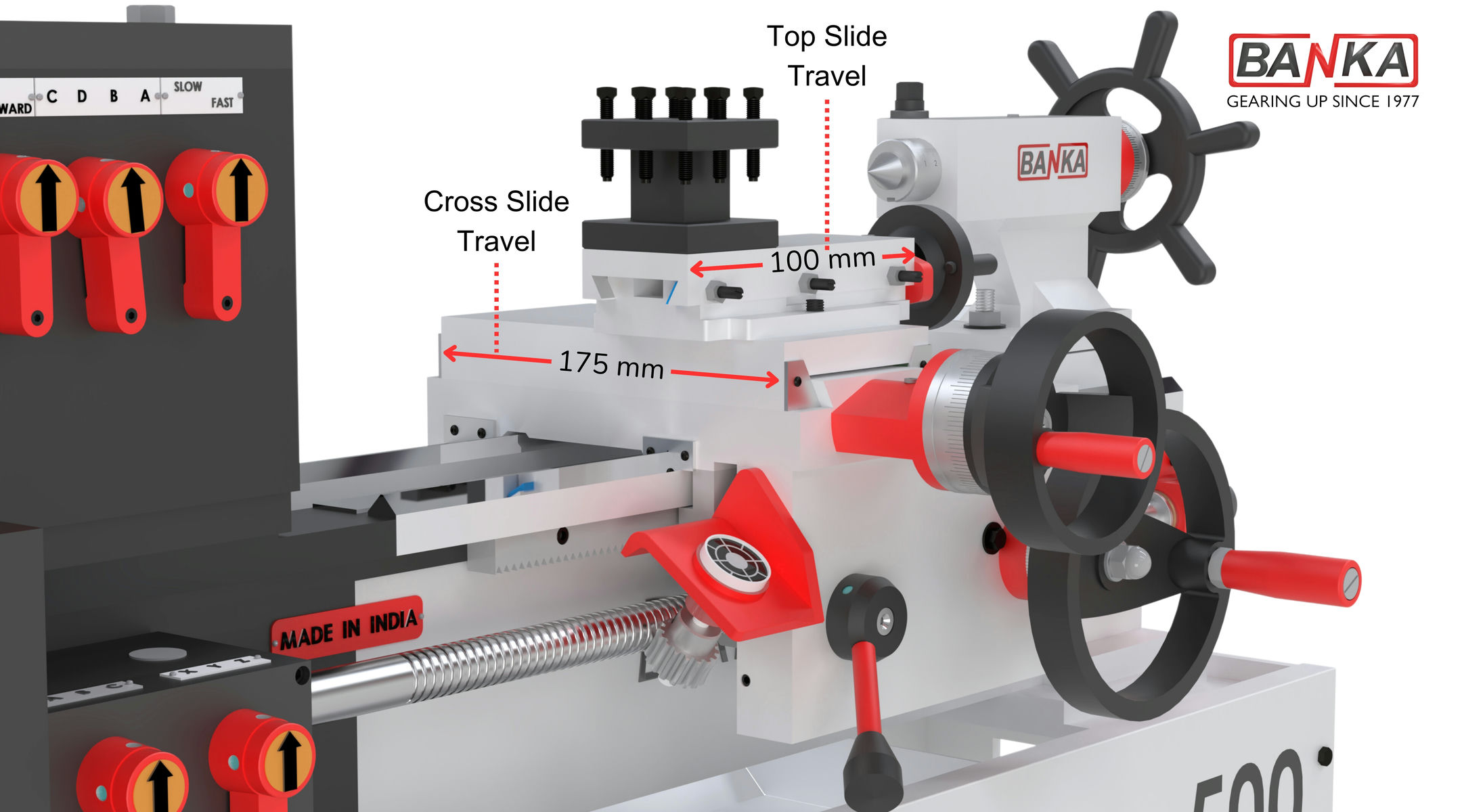

- Cross Slide Travel: 175 mm

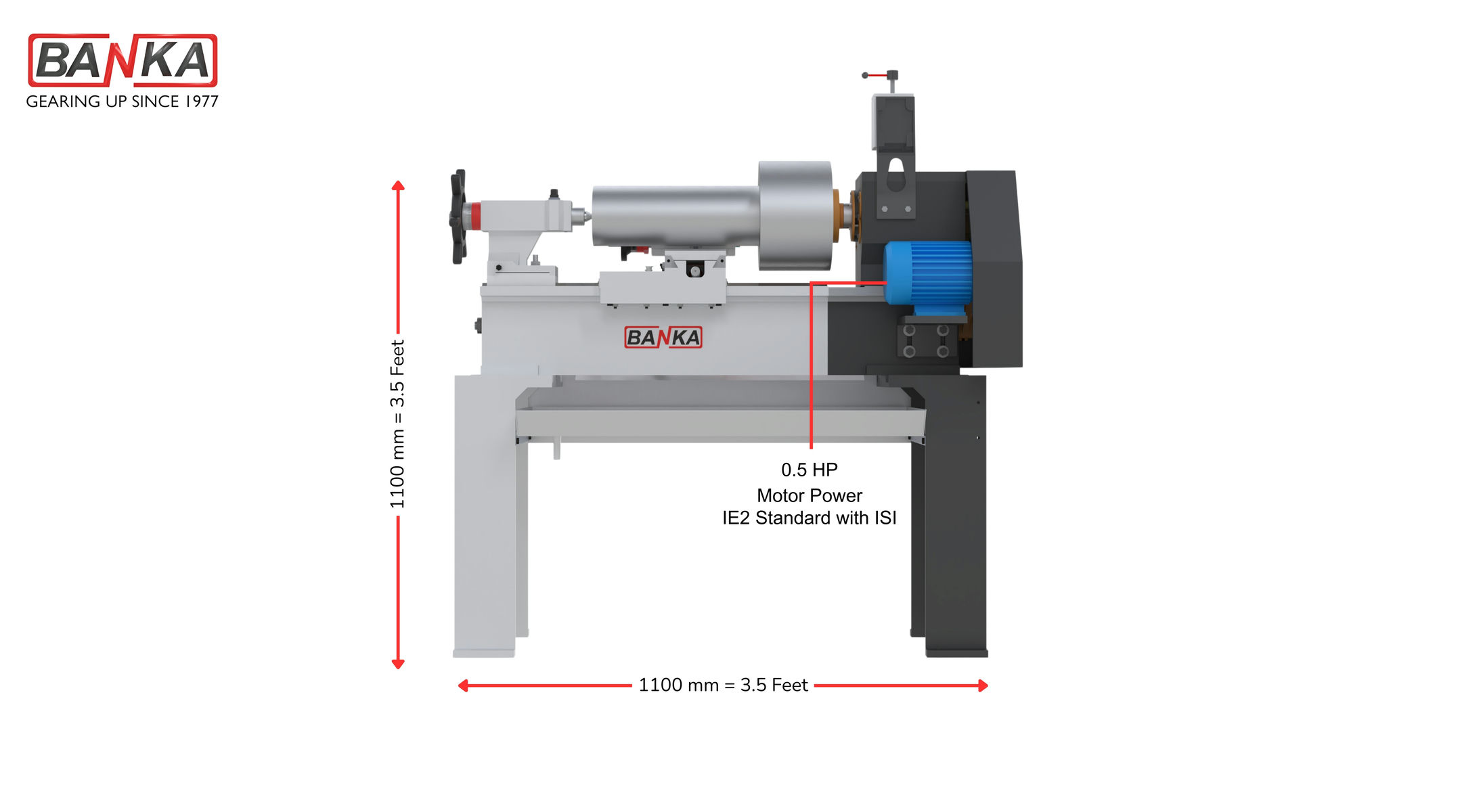

- Weight Approx: 170 KG

- 0.5 HP Motor 3 Phase or 1 Phase, R/F Switch, Square Tool Post included with the Machine.

- Without Leg Rs: 69, 500/- (Chuck and Motor Incluing)

- With Leg Rs 89,500/- (Chuck and Motor Incluing)

Essential Features :

| Particulars | Technical Specifications |

| Height of centers | 150 mm |

| Swing over Bed | 300 mm |

| Swing over side | 160 mm |

| Width of Bed | 180 mm |

| Spindle Bore | 20 |

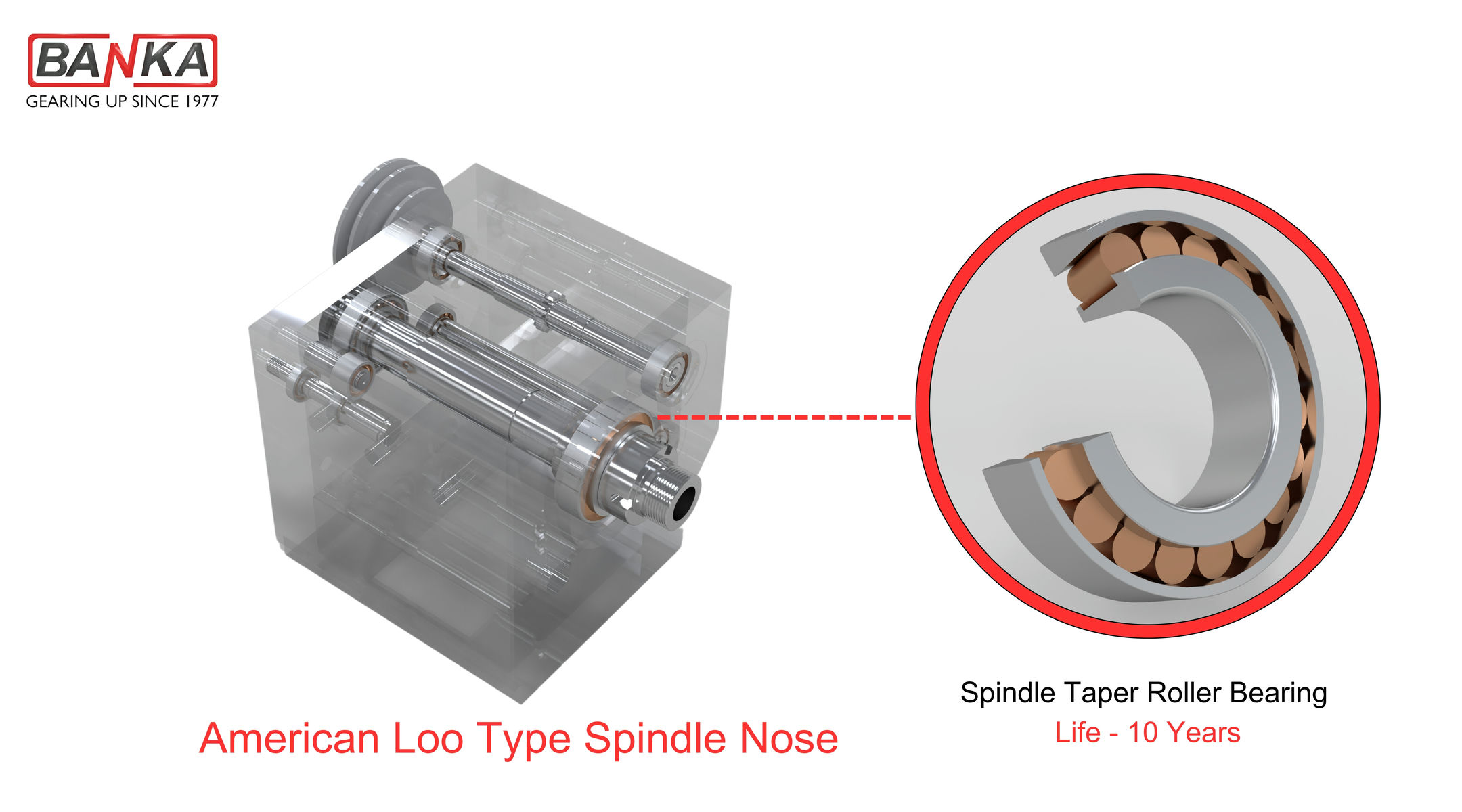

| Spindle Nose | M.T 3 |

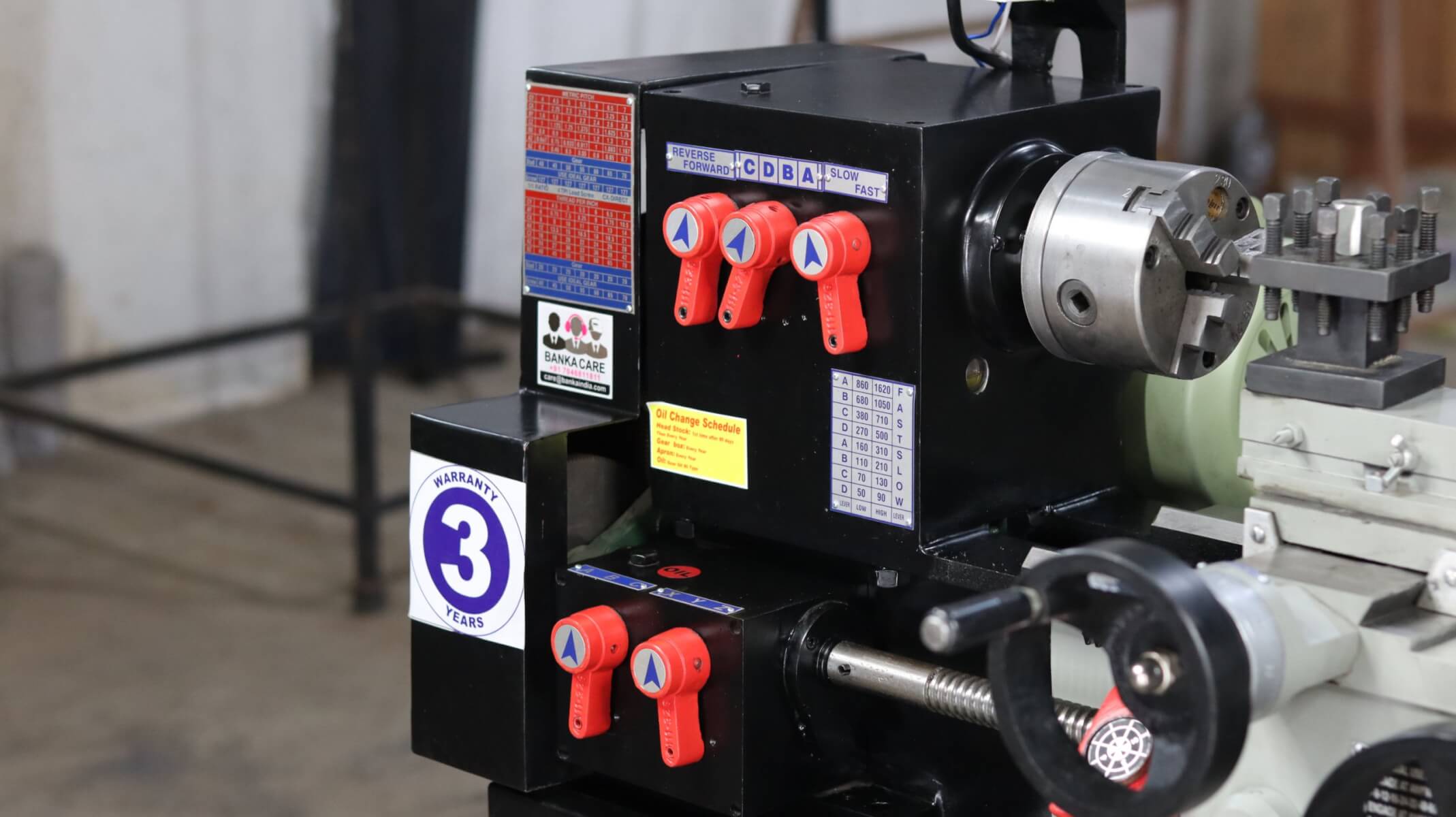

| Spindle Speed No. | 9 |

| RPM | 40-1200 |

| Cross Slide travel | 175 |

| Top Slide travel | No |

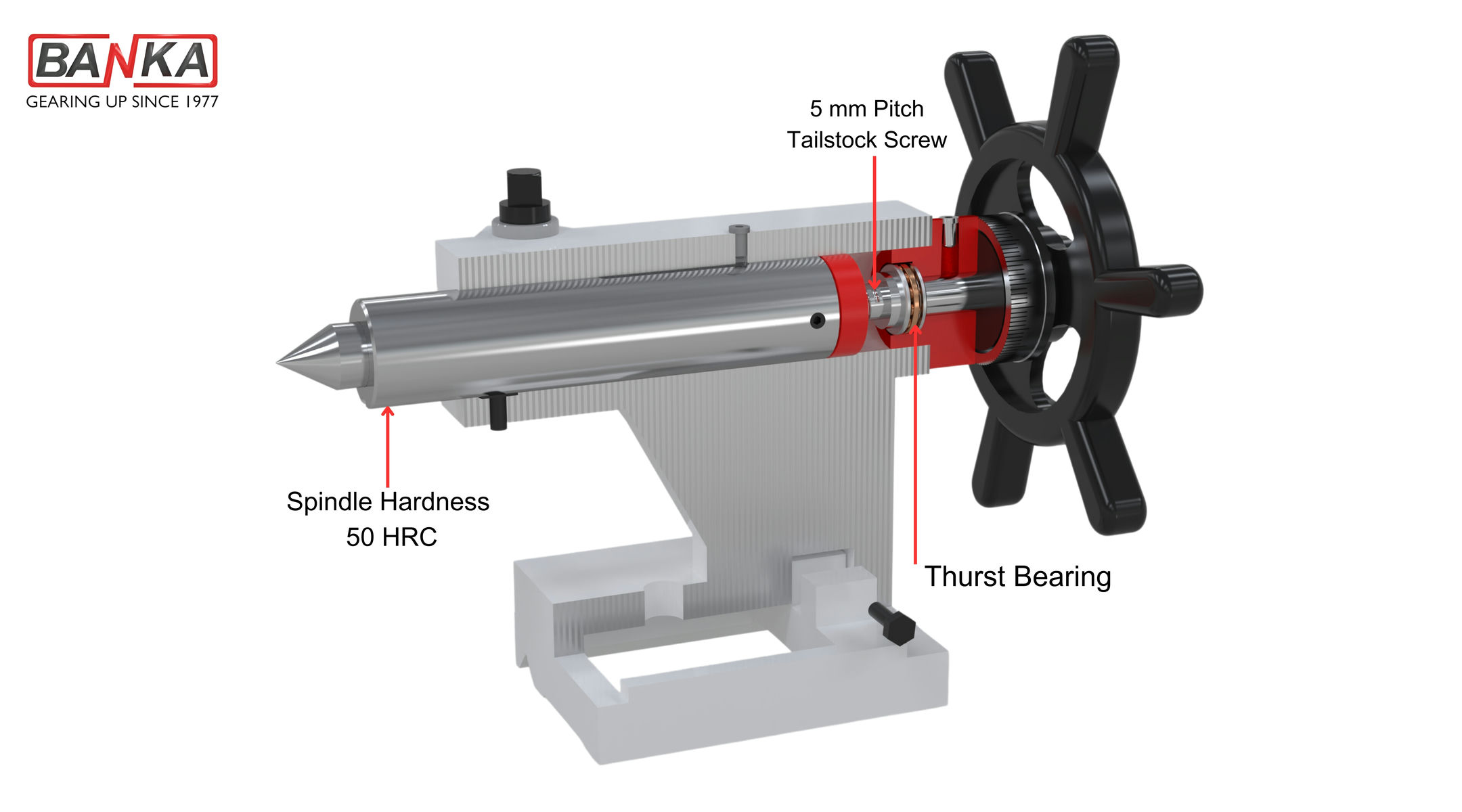

| Tailstock Sleeve | M.T.3 |

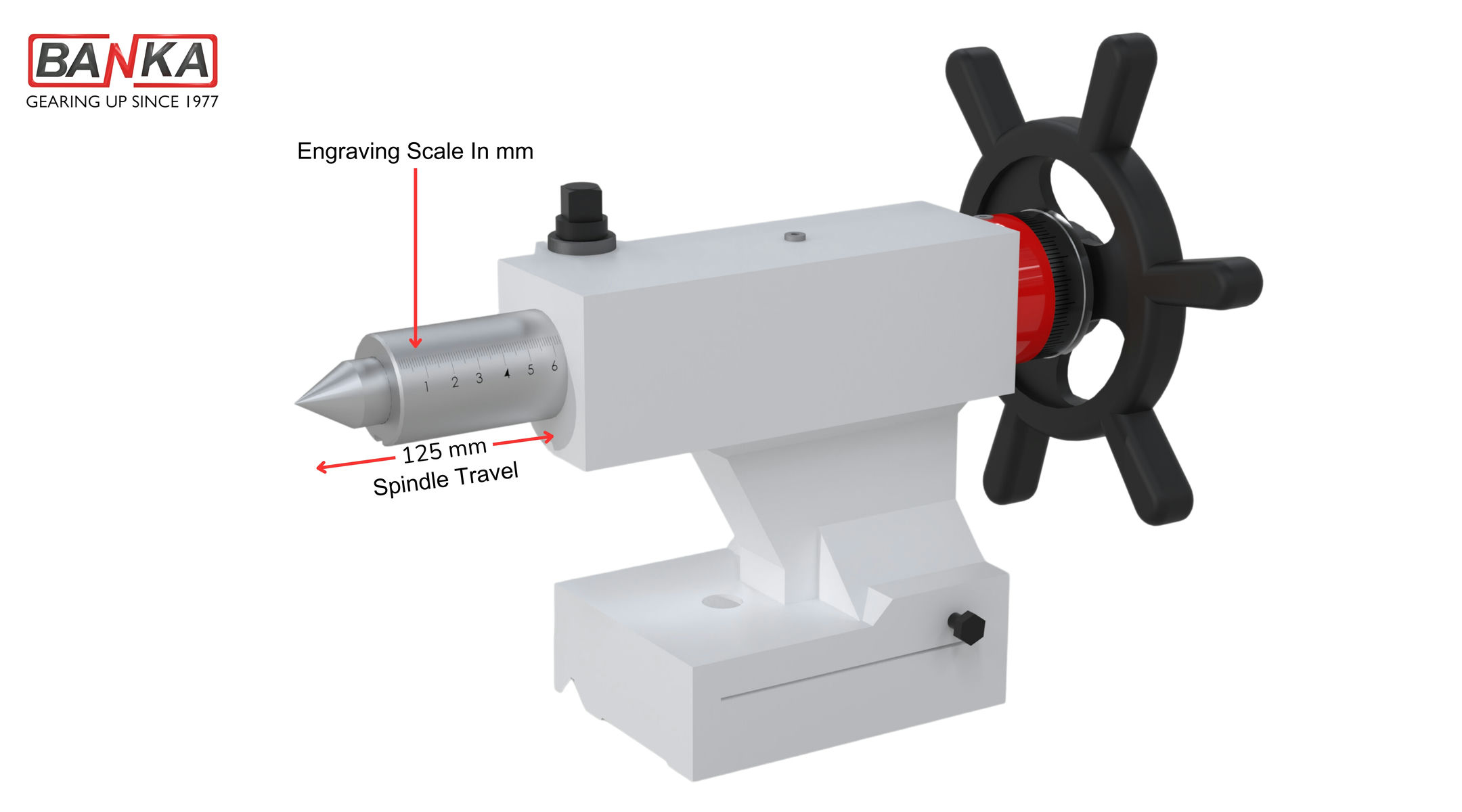

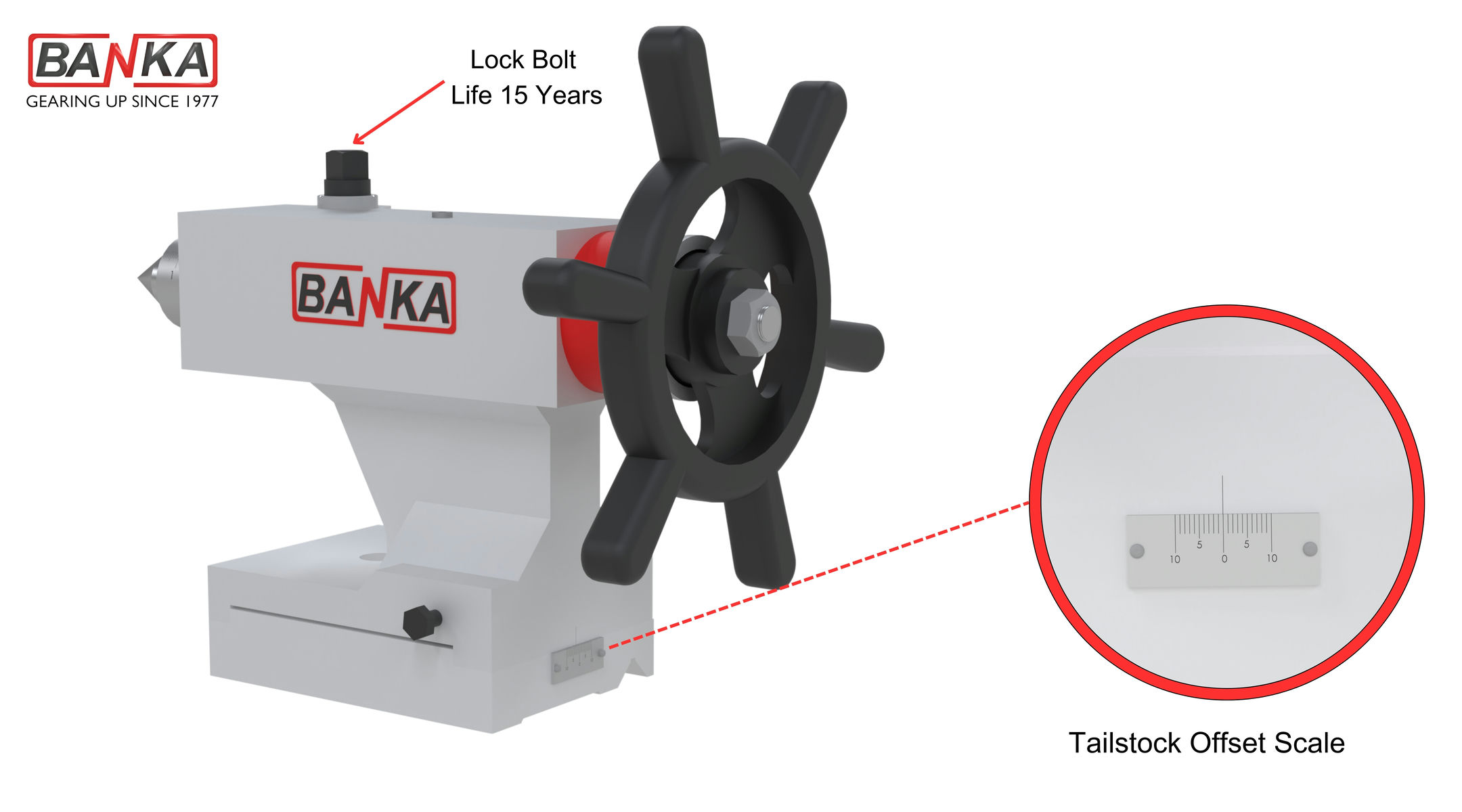

| Quill Dia./Travel | 40 |

| Tool Shank Section | 20 x 20 mm |

| Feeds Longitudinal | 60/0.08-1 |

| Feeds Transverse | 60/0.02-0.25 |

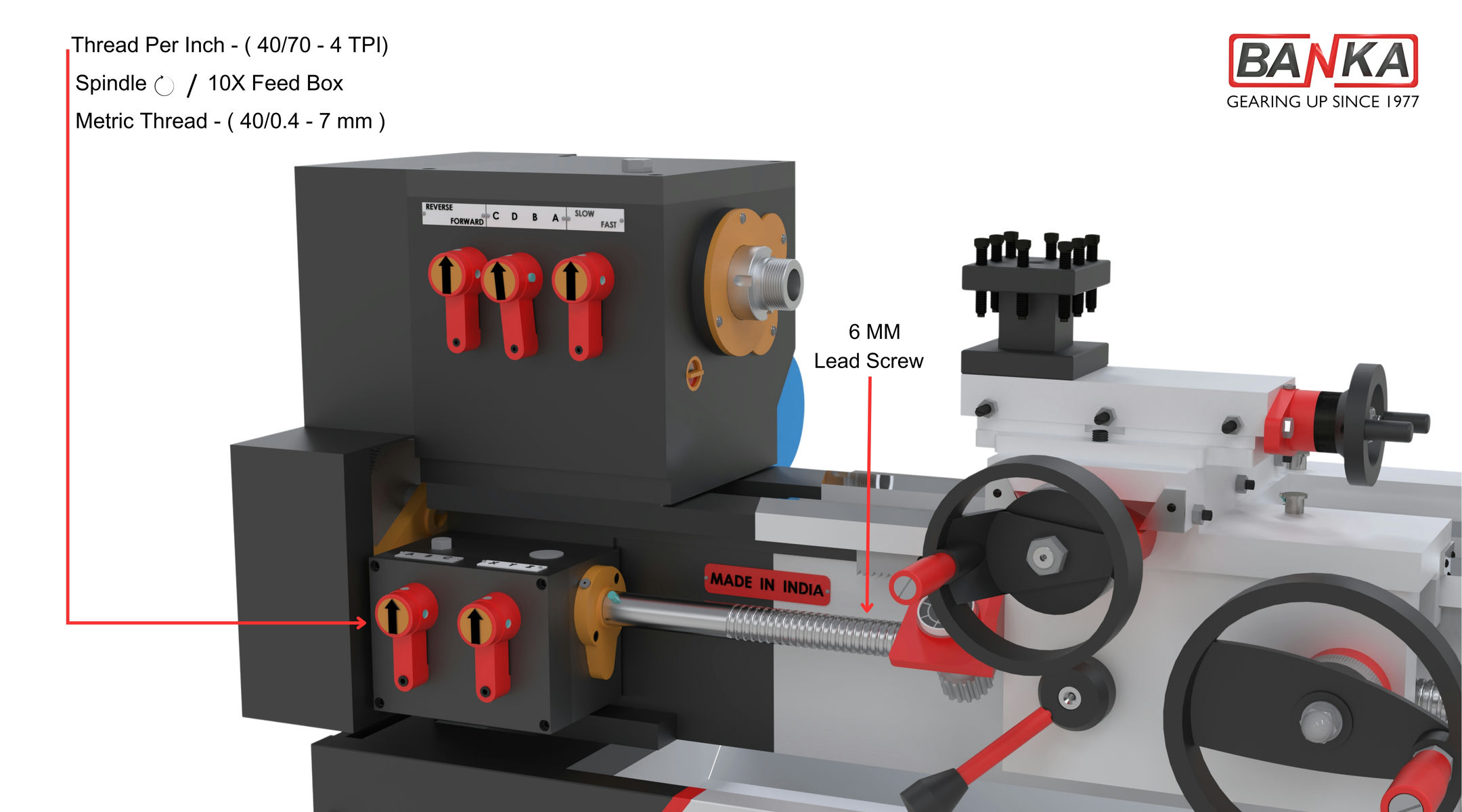

| Metric thread | 40/0.4-7 mm |

| Thread Per Inch | 40/70-4 TPI |

| Lead Screw | 4 TPI |

| Main Motor | 0.5 HP |

| Admit Between Center | 500 |

| Bed Length Feet | 3.2’ |

| Weight (Kg.) Appro. | 170 |

| BANKA 30: Mini Lathe Machine |

Get more, Spend less: BANKA 34 is cost effective. |

|

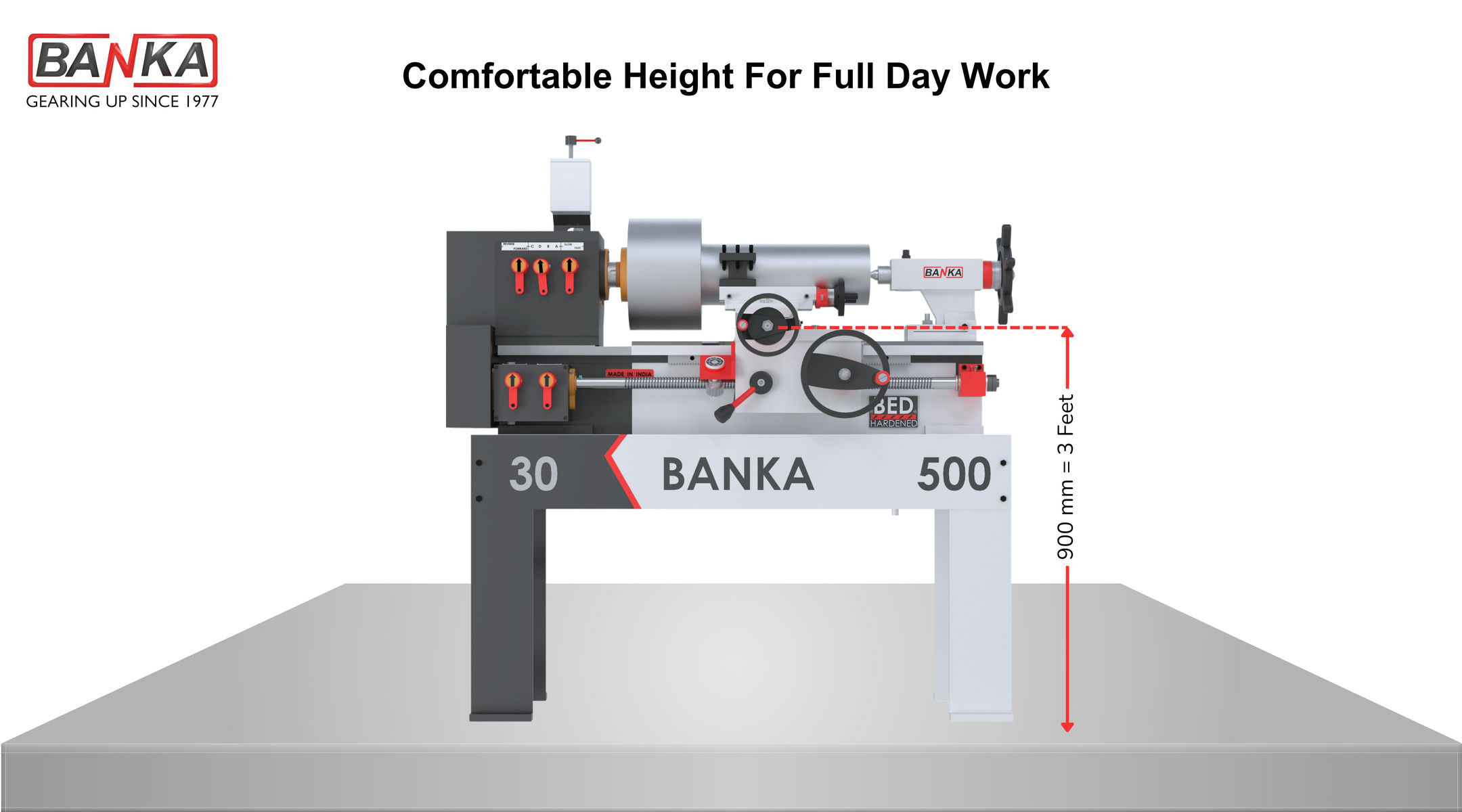

Some exclusive features of BANKA 30 lead customers to go for BANKA Bench Features are as follows:

BANKA Machine has 39 years of expertise in making reliable machine tools |

Our Lathe Machines are built with heavy rigid construction for increased durability and accuracy. When combining our manufacturing technique with accuracy, repeatability, and price, you can easily see why our lathes offer the best value in the market for new lathe equipment. |

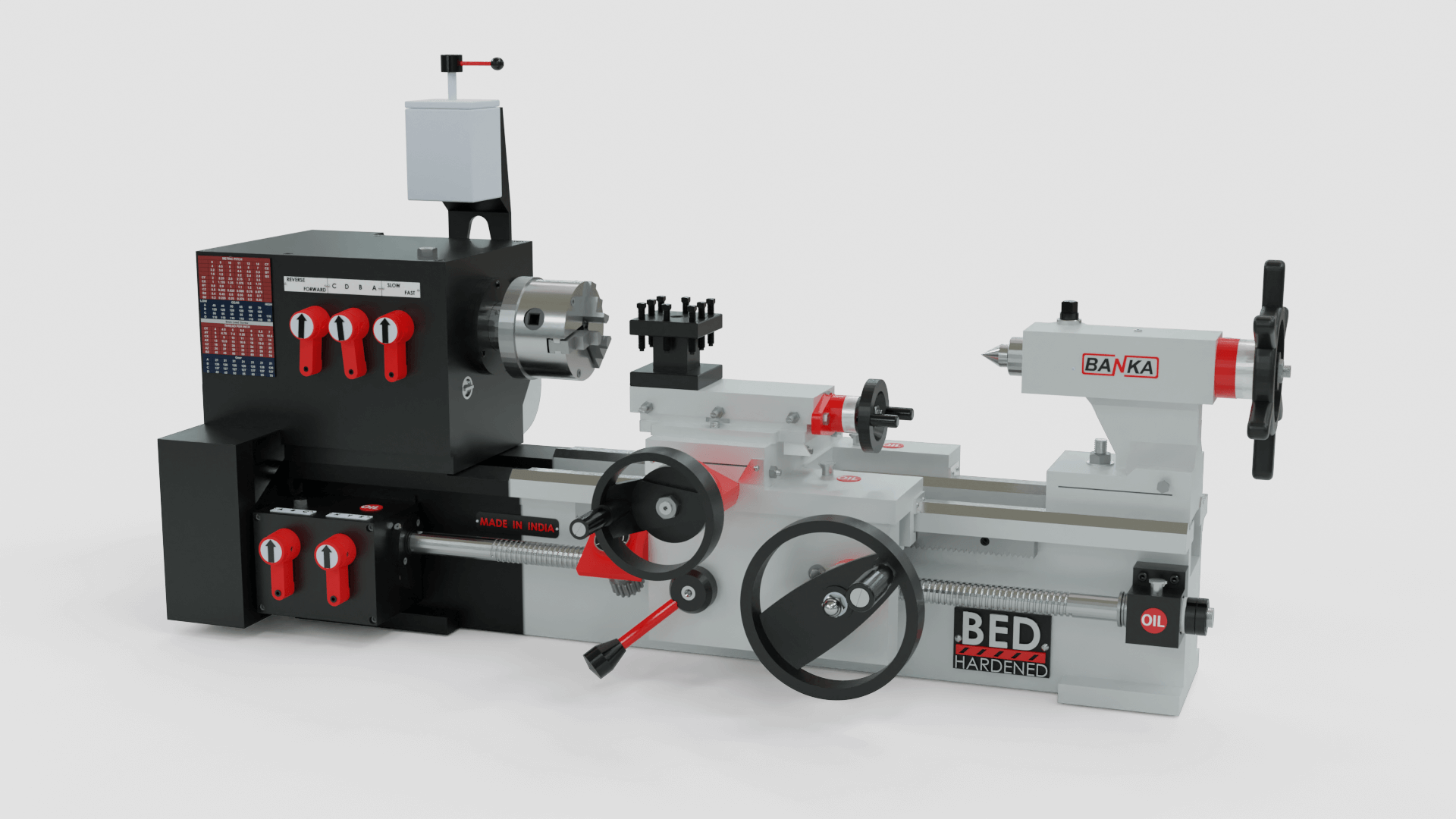

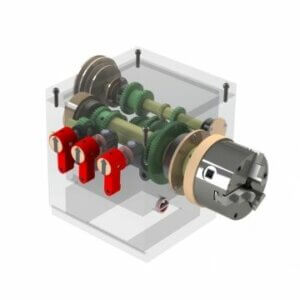

BANKA Mini Lathe Machine sets model illustration concerning compatibility of our

machines. Our expert engineers have poured all their expertise and experience to create a Miniature format of Lathe

Machine. The superior torque of the motors enables finer results during the operations on a workpiece. The headstock

is replaced by the direct belt drive in BANKA Mini Lathe Machine delivering an excellent outcome.

Small is beautiful. This miniature of Industrial Lathe Machine serves an extensive

support for shaping up wood, plastics, and other materials. BANKA Mini Lathe Machine is a very handy tool especially

when accurate dimensions are required on the workpiece. It carries speed ranging from 40 to 2050 RPM. It is

noteworthy to mention BANKA Mini Lathe Machine has complied with all International Standards.

Quality

Banka lathe is the best premium quality lathe, drill, mini lathe and milling manufacturer in India. Our future

depends on the dedication of individuals, to achieve one of the top charitable all gear lathe manufacturers in the

whole world.

Precision lathe machine quality demands are a must in all aspects of component

manufacturing. It requires a range of processing expertise, technologies, and application to provide consolidated

results to users. Innovative solutions & approaches provide the edge to have technological advancements and

necessary pace in tomorrow’s world. The lathe machines are prepared by expertise technical engineers.

Our lathes quality is maintained because of our step by step manufacturing process.

According to our manufacturing process, metal cutting lathe performance and accuracy are better than other

industrial lathe machine manufacturer. Another side our toolroom lathe is manufactured as per Indian Standard Test

by testing instruments like.

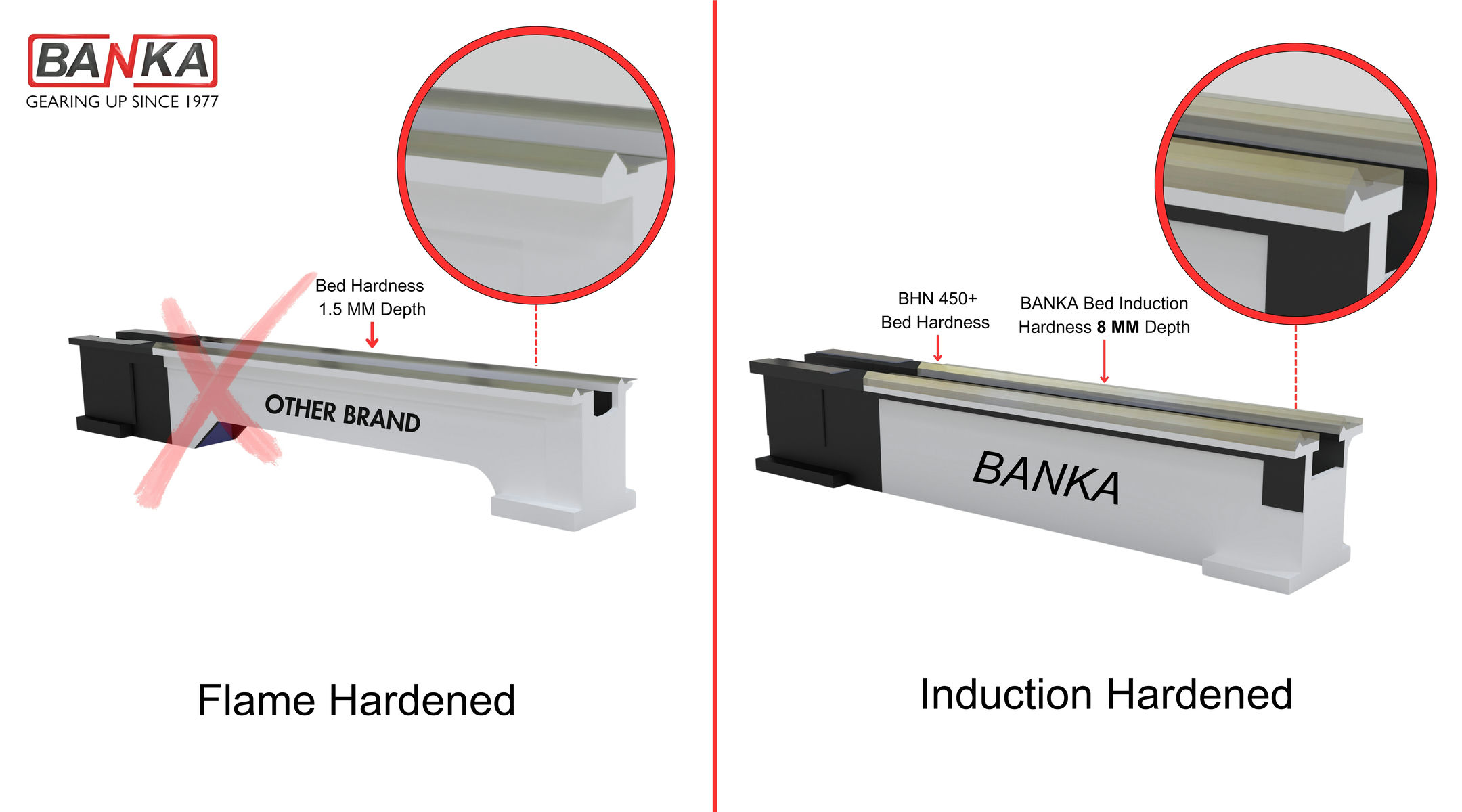

- Straight Edge Meter: It’s used in the automotive service and in engine lathe to

check the flatness of machined surfaces. - Spirit Level Precision: Generally, Spirit Level is used to check the level of the

heavy duty lathe machine and used to measure the inclination of an object. - Hardness Tester BHN Scale: It’s used to test the hardness of the bed. Our each

lathe machine’s hardness of the bed is 400 BHN as per IS test. - Tachometer RPM MPM: The tachometer is used to accurately measure spindle RPM

(Speed) of the lathe machines. - Sound Level Decibel Meter: As per the IS test our Tool lathe head sound is measured

by Decibel Meter and it should be up to 85 to 90 lbs. - Dial Indicator Micrometers: Dial Indicator Micrometers is used for precise

measurement of components which are done on the lathe. It’s also used to measure the apparent diameter of

celestial bodies or microscopic objects.

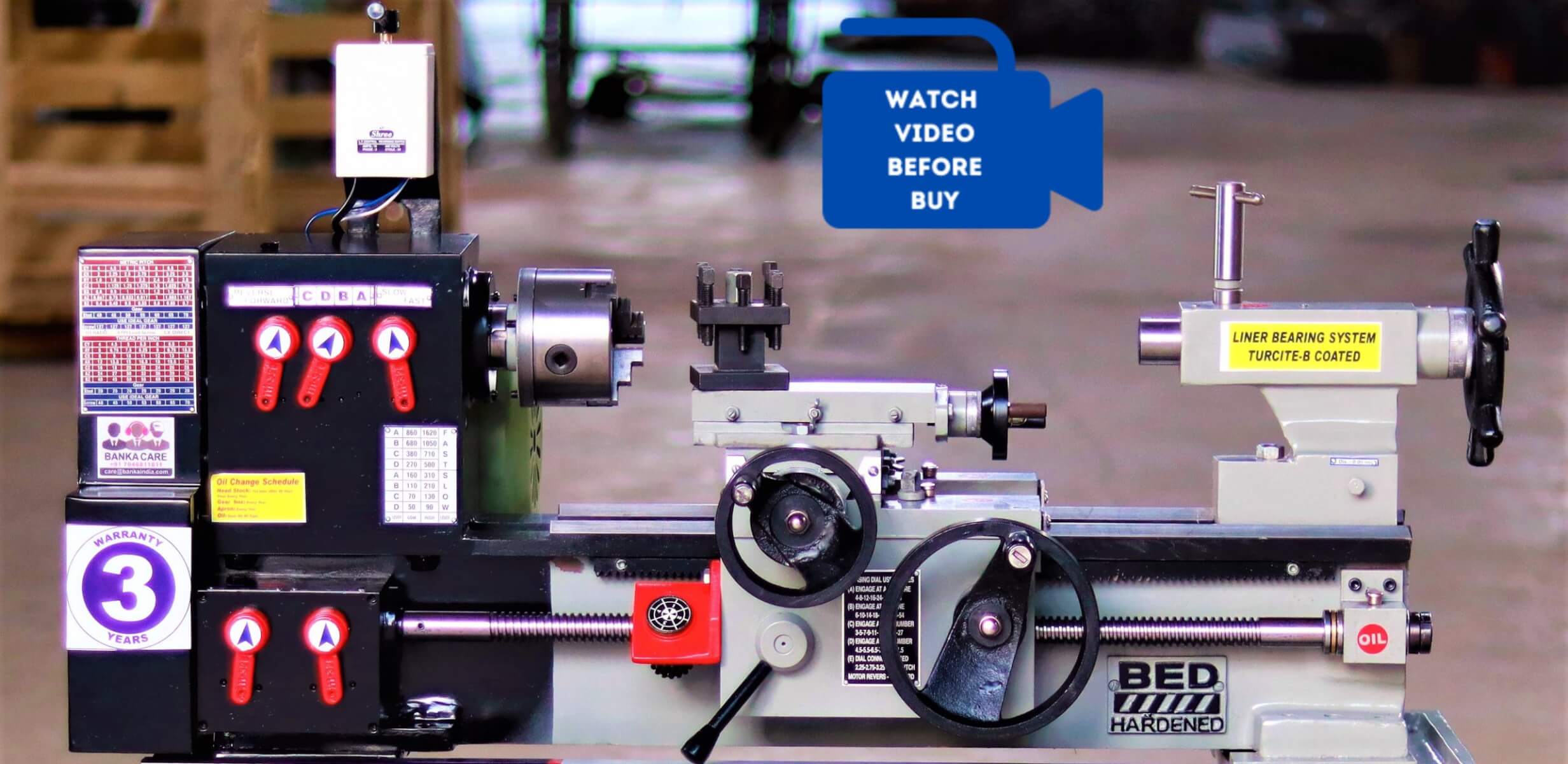

Salient Features:

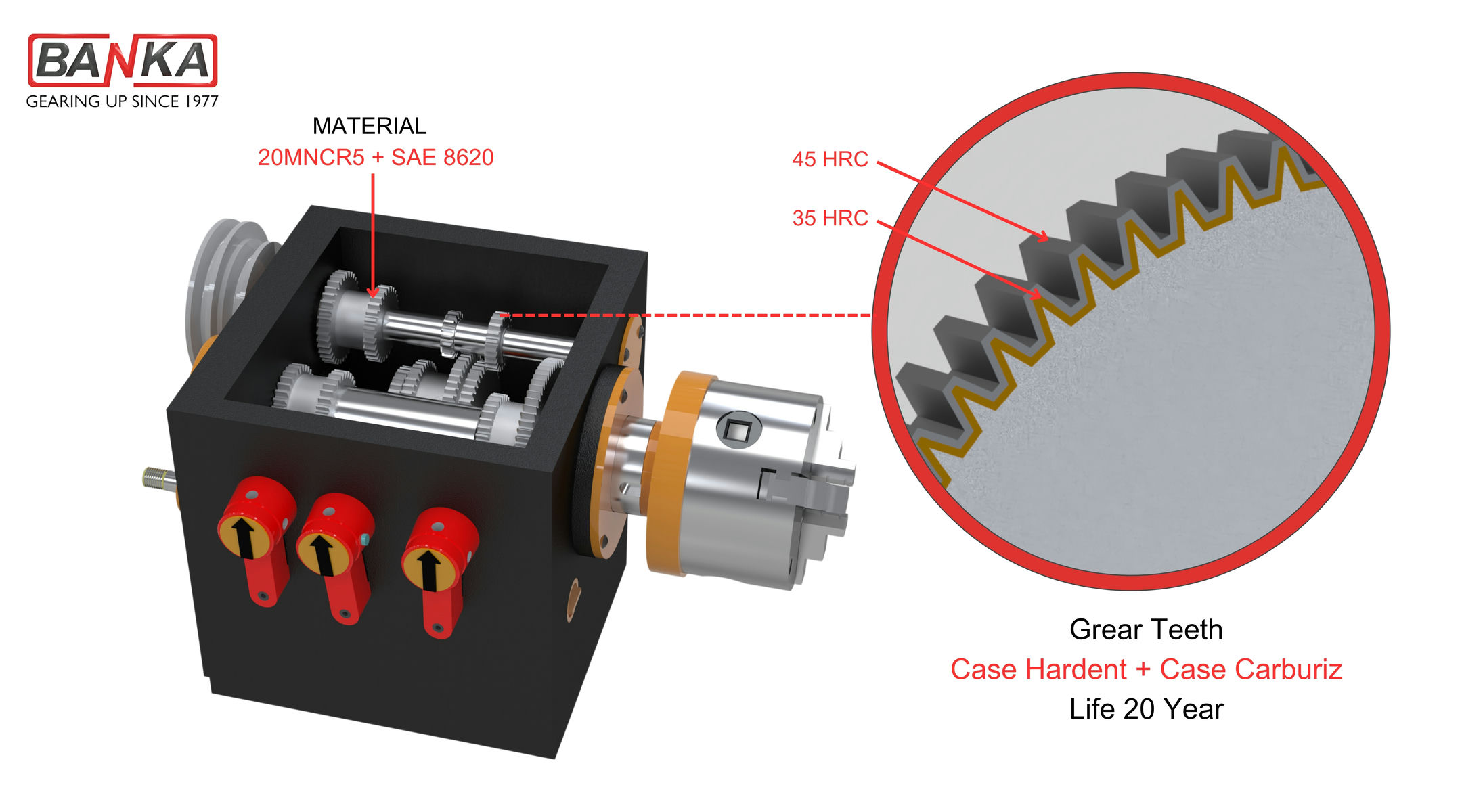

- Headstock and gearbox gears hardened and ground.

- Bedways hardened and ground up to 400BHN.

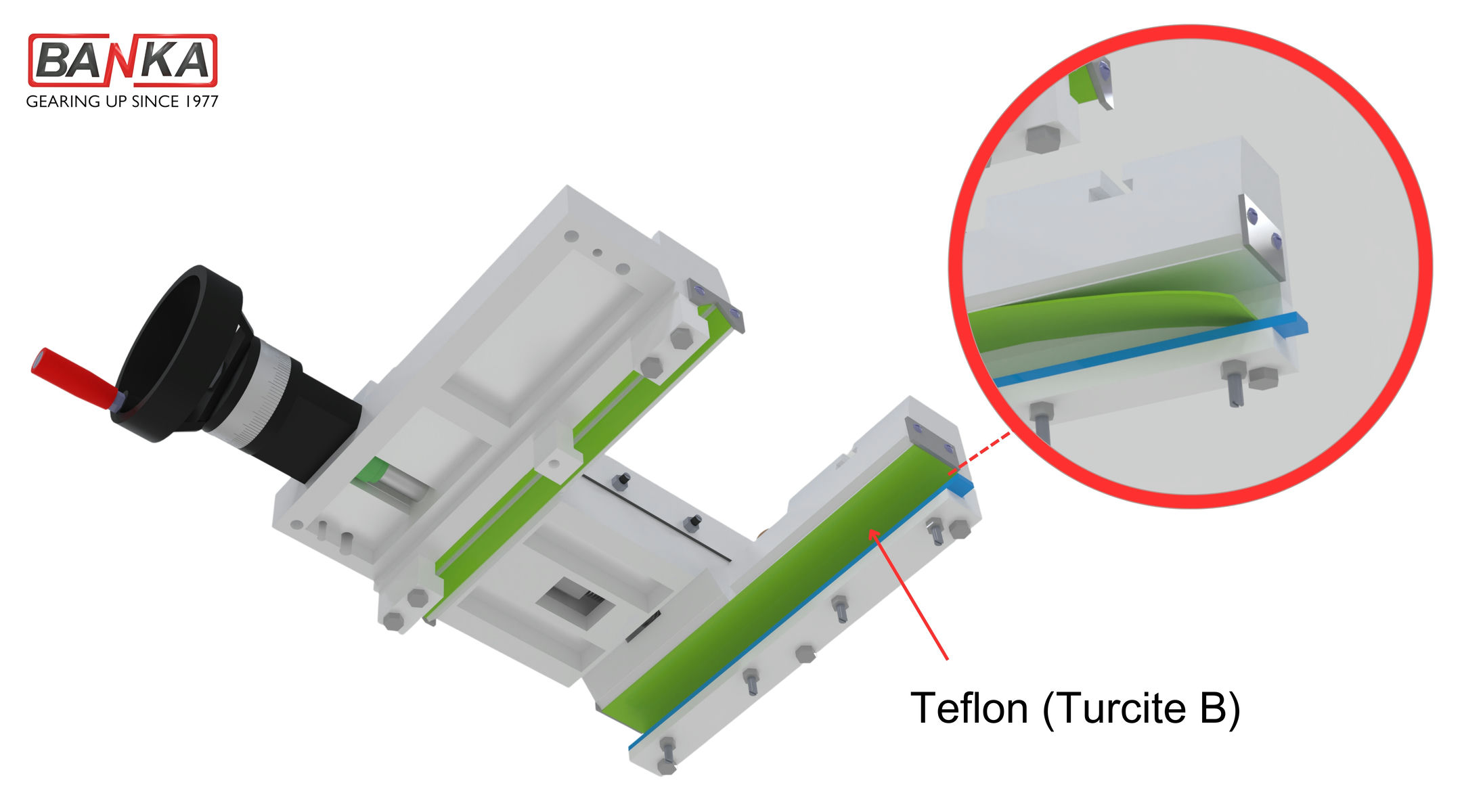

- Turcite B anti-friction material on carriageways.

- Control panel & magnetic brake (optionally available on request)

- The metric dial on the cross slide, Compound, and tailstock semi-universal gearbox provides inch and

metric thread without changing too many end trains gears. ( universal gearbox optional

available on request ) - Alloy steel Spindle molesting on taper roller bearings.

Notes:

- Mini Lathe is used only for workshop repairing work not for production work.

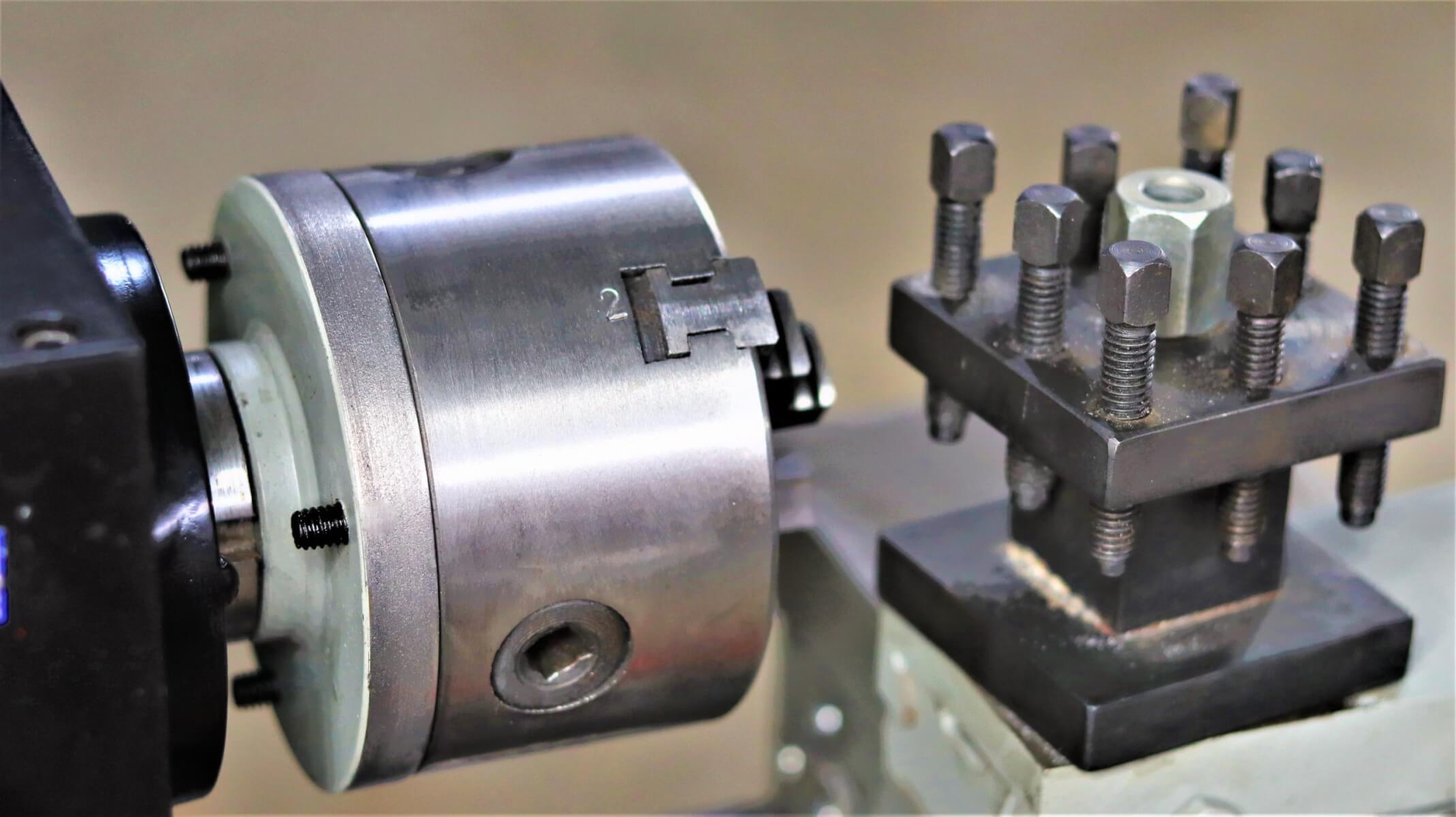

- In our Mini Lathe, only 4 inches True chuck(3 Jaws) can be fitted.

- We are providing the top slide in Mini Lathe.

| No | Accessories | Description |

| 1 | Manual Book |

All details are provided in this book like installation, maintenance, training, and parts. |

| 2 | Industrial Apron | Apron wear for safety and keep the small tools in that while operating machines. |

| 3 | Colour Brush | A tool to paint the machine or any other tools to repair while parts are damaged in transportation. |

| 4 | Oil Funnel |

A tool for filling and filtering the oil which is essential for machine. |

| 5 | Safety Glasses | To protect eyes while operating machines. |

| 6 | Spanner Set with Oil Can |

Tools used for maintenance and operating machine. |

| 7 | Allen Key Set | Useful tools when maintenance is required. |

| 8 | V-Belt | Useful to drive motor pulley and main pulley. |

| 9 | Change Gears | The operator has to change gears often while making threads as per mentioned in the thread chart. |

We are here to Help

you

Q1: For what purpose mini lathe can be used?

A: Mini lathe mostly used in a small workshop for repairing, for a hobby, for wood

working, vehicle repairing, in a rural area, in an orthopedic hospital and for bolt and nut manufacturing units.

.

Q2: What will be the warranty Period of this Lathe Machine?

A: We are providing 3 years warranty in our products. If there any parts damaged in your

machine than we also provide free parts service in warranty period by fastest courier service.

Q3: What is the weight of Banka 30 Lathe?

A: Our BANKA 30 is the most popular product in educational training institutes. BANKA 30 weight is approx 168 kgs.

Q4: Which accessories are included with Mini Lathe?

A: As we providing below accessories with Mini lathe machine.

- 0.5 HP Electric Motor – if we use Crompton mark motor instead of normal one, will save rs.3000/- yearly.

- 4″ True Chuck – also known as self-centring chuck, to make proper grip for the round type jobs.

- Coolant Pump – to improve tooling life and reduce job heating while heavy metal cutting.

- Revolving Centre – it also called a live centre, it is essential for between centers turning.

Related Products

SALE ₹10,000 OFF