Accessories for Milling machines, Machine Shop Accessories, Tools & Instruments

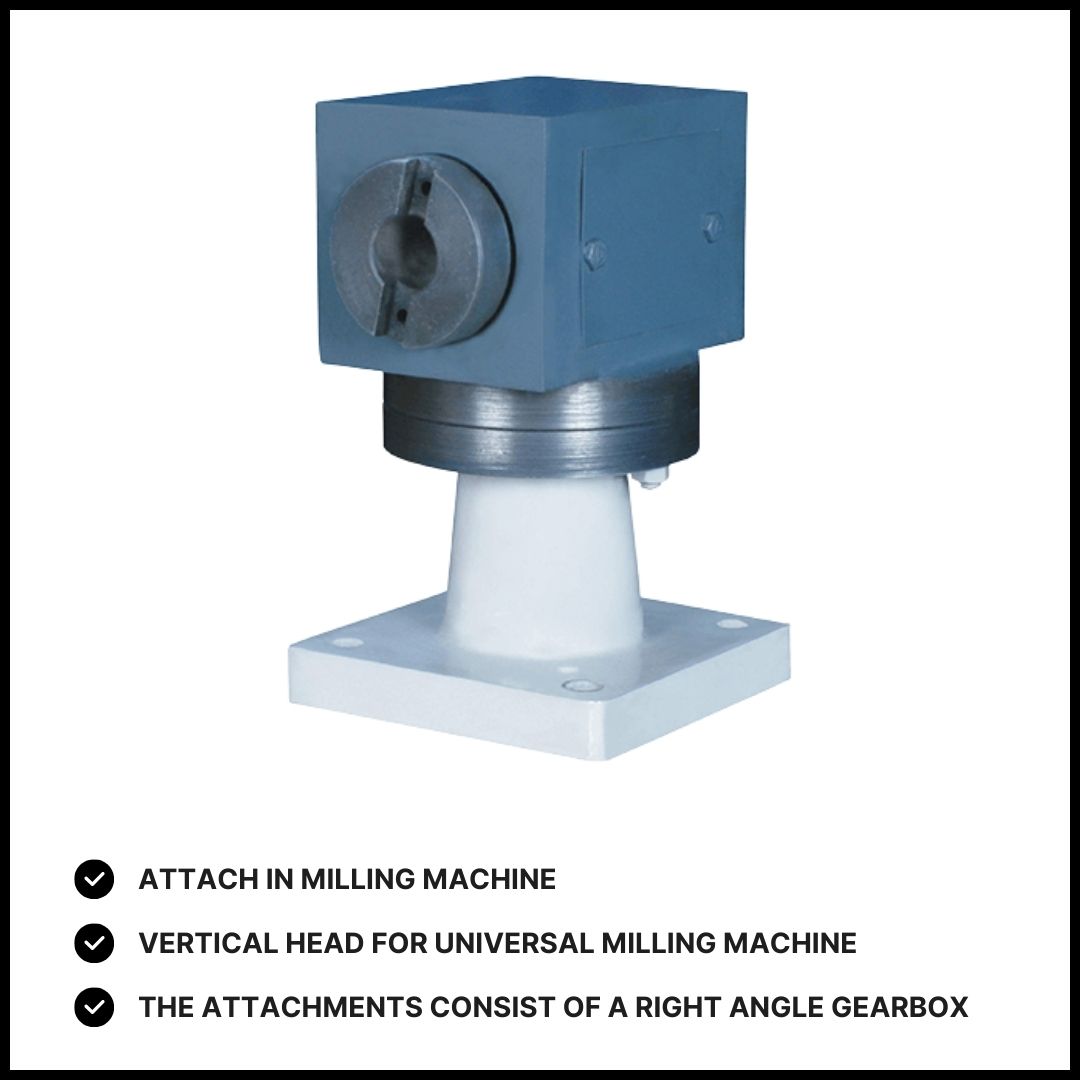

Milling – Vertical Head (Attachment)

Tag: Popular Tools

₹11,500

- Vertical Head for Universal Milling Machine

- Attach in Milling machine

- Cutting spindle acids from horizontal to vertical for performing specific operation

- The attachments consist of a right angle gearbox,

- Colour – Gray & White

A vertical head attachment for a milling machine is a versatile tool that enhances the machine’s capabilities, allowing it to perform a variety of tasks that a standard horizontal milling machine might not handle as efficiently. Here’s a guide on how to use it effectively:

Overview

Vertical Head Attachment: This accessory converts a horizontal milling machine into a vertical milling machine. It’s especially useful for operations such as drilling, boring, and face milling.

Installation

- Preparation:

- Ensure the milling machine is powered off and unplugged before installation.

- Clean the machine and the vertical head attachment to remove any debris or contaminants.

- Mounting the Vertical Head:

- Remove the Horizontal Arbor: If present, take off the horizontal arbor or any attachments connected to it.

- Install the Vertical Head: Attach the vertical head to the machine’s spindle or overarm. Align it properly according to the manufacturer’s instructions.

- Secure the Attachment: Use the appropriate bolts or clamping mechanisms to secure the vertical head firmly.

- Alignment:

- Make sure the vertical head is perpendicular to the table. Misalignment can affect precision and lead to poor machining results.

- Check the vertical head’s alignment with a dial indicator or a similar precision tool if needed.

Operation

- Setup:

- Select the Tooling: Choose the appropriate end mill or drill bit for the operation you intend to perform.

- Adjust Speed and Feed Rates: Set the spindle speed and feed rates based on the material and tool being used. Refer to the tooling manufacturer’s recommendations.

- Positioning:

- Adjust the Head Position: Move the vertical head up or down and tilt it if necessary to achieve the desired cutting angle.

- Table Positioning: Adjust the workpiece on the table to position it correctly relative to the cutting tool.

- Cutting:

- Start the Machine: Power up the milling machine and carefully start the spindle.

- Perform the Operation: Feed the workpiece into the cutting tool at the appropriate speed and feed rate. Ensure to monitor the process closely to avoid any issues.

- Safety:

- Always wear appropriate personal protective equipment (PPE) such as safety glasses and hearing protection.

- Keep hands clear of moving parts and ensure all safety guards are in place.

Related Products

Sale

Most Popular