Machine Shop Accessories, Tools & Instruments

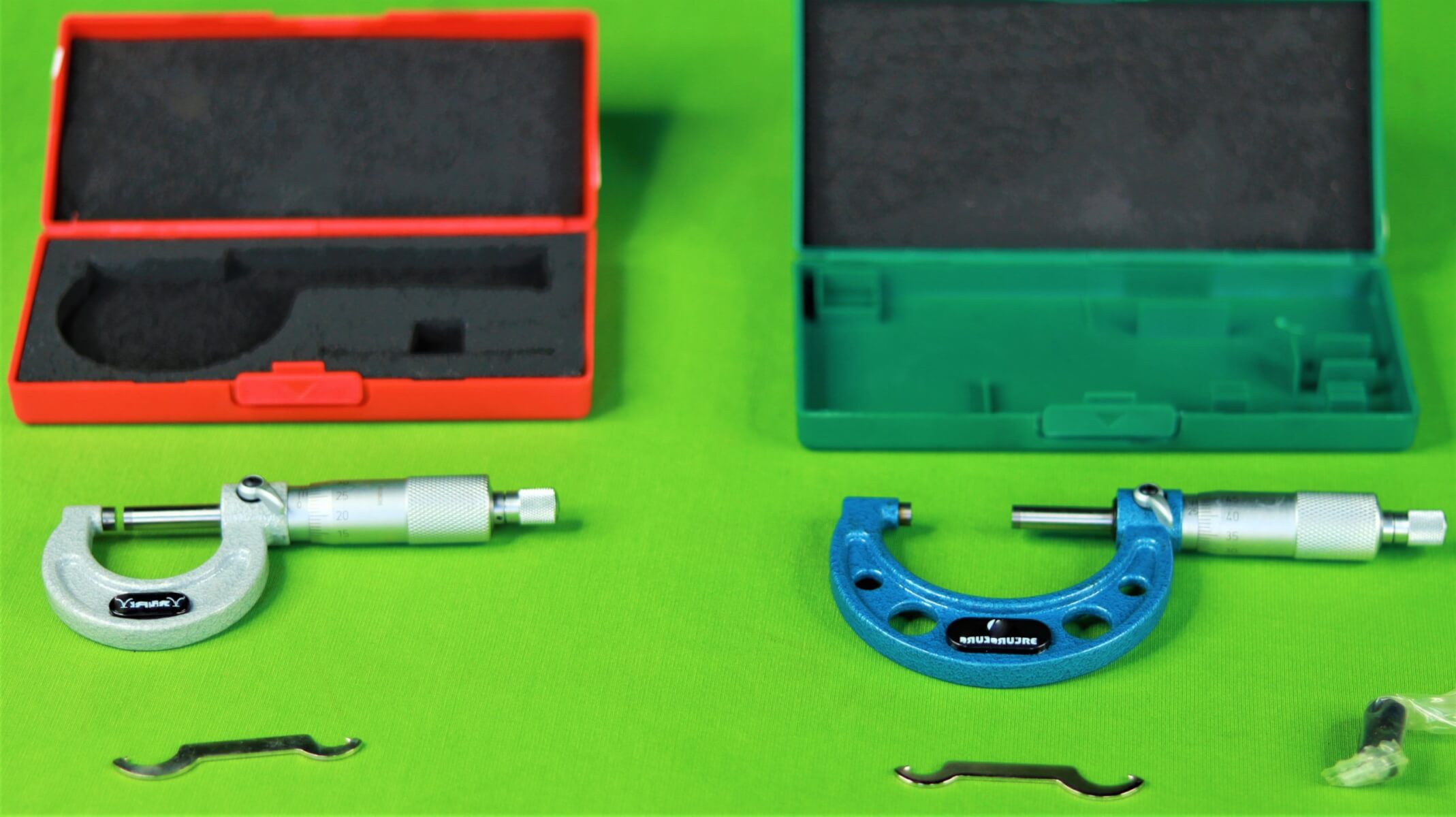

Micrometer : 50 To 75mm

Tag: Popular Tools

₹4,200

- Two Piece Set: 50 To 75mm / 75 To 100mm

- Size :- 0-25 mm

- Accuracy:- 0.01 mm

- Differentiate power:- 0.01 mm

- Maximum measurement speed:- 1 mm

- Easy to use

- Accurate measurement

A micrometer is a precision instrument used to measure small distances with great accuracy. It’s commonly used in machining, mechanical engineering, and metalworking to measure the thickness, diameter, or length of an object. There are different types of micrometers, such as outside micrometers, inside micrometers, and depth micrometers, each designed for specific measurement tasks. Here’s a detailed guide on how to use a micrometer effectively:

TYPES OF MICROMETERS

- Outside Micrometer: Measures the external dimensions of an object (e.g., diameter of a shaft).

- Inside Micrometer: Measures the internal dimensions of an object (e.g., bore diameter).

- Depth Micrometer: Measures the depth of holes or grooves.

GENERAL STEPS FOR USING A MICROMETER

1. PREPARATION

- Clean the Micrometer: Ensure the micrometer is clean and free from debris or oil. Wipe the measuring faces and the anvil with a clean, dry cloth.

- Check Calibration: Confirm the micrometer is calibrated. Most micrometers come with a standard or calibration block for this purpose. Ensure it reads correctly on this standard.

2. ADJUST THE MICROMETER

- Opening the Micrometer: Rotate the thimble to open the micrometer. For outside micrometers, rotate until the measuring faces are wide enough to fit around the object. For inside micrometers, ensure the measuring faces can fit inside the object.

3. POSITION THE OBJECT

- For Outside Micrometers: Place the object between the measuring faces (anvil and spindle) of the micrometer.

- For Inside Micrometers: Insert the micrometer into the internal space or bore you wish to measure.

- For Depth Micrometers: Place the measuring rod into the hole or groove to measure its depth.

4. TAKE THE MEASUREMENT

- Bring the Faces Together: Gently rotate the thimble to bring the measuring faces into contact with the object. The contact should be light but firm, without excessive force, to avoid damaging the object or the micrometer.

- Use the Ratchet Stop (if available): Many micrometers have a ratchet or friction thimble to ensure consistent measuring pressure. Rotate the thimble until the ratchet clicks, indicating the correct pressure has been applied.

5. READ THE MEASUREMENT

- Read the Main Scale: The main scale (located on the sleeve of the micrometer) provides the primary measurement reading in millimeters or inches.

- Read the Thimble Scale: The thimble scale provides the additional fractional measurement. The combination of the main scale and thimble scale gives the total measurement.

- Calculate Total Measurement: Add the main scale reading to the thimble scale reading to get the final measurement.

6. RECORD AND VERIFY

- Record the Measurement: Note down the measurement for your records or compare it to your specifications.

- Verify Consistency: If needed, take multiple measurements to ensure consistency and accuracy.

TIPS FOR ACCURATE MEASUREMENT

- Handle Carefully: Avoid dropping or mishandling the micrometer, as it can affect accuracy and calibration.

- Consistent Pressure: Use consistent pressure when closing the micrometer to ensure accurate readings.

- Avoid Dirt and Debris: Keep the micrometer clean and free from contaminants to prevent measurement errors.

- Regular Calibration: Regularly check and calibrate the micrometer to ensure ongoing accuracy.

MAINTENANCE AND CARE

- Cleaning:

- Wipe the micrometer with a clean, dry cloth to remove any dirt or debris. For stubborn residues, use a non-abrasive cleaner.

- Ensure that the measuring faces are free from oil or grime, as this can affect accuracy.

- Lubrication:

- Apply a light machine oil to the threads and other moving parts periodically to keep the micrometer functioning smoothly.

- Storage:

- Store the micrometer in its protective case or a clean, dry place to avoid damage and contamination.

- Ensure that the micrometer is not exposed to extreme temperatures or humidity.

- Inspection:

- Regularly inspect the micrometer for any signs of wear or damage, and address any issues promptly to maintain accuracy.