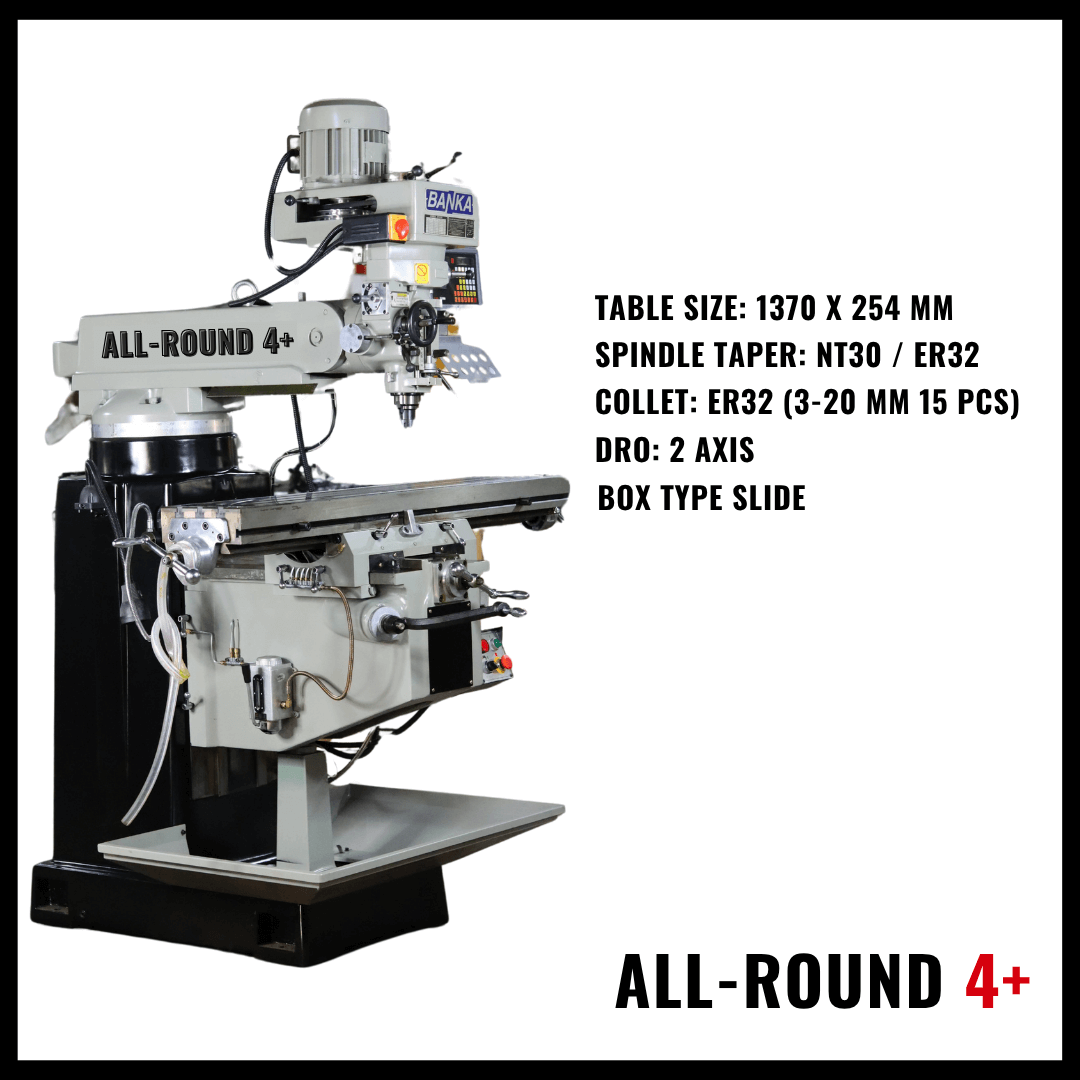

VERTICAL TURRET MILLING ALL ROUND 4+ DRO MILLING – M1TR TYPE

₹3,95,000 Original price was: ₹3,95,000.₹3,75,000Current price is: ₹3,75,000.

- TABLE SIZE 1370 x 254 MM

- SPINDLE TAPER NT30 / ER32

- COLLET ER32 (3-20 MM 15 Pcs)

- DRO : 2 AXIS

- X-AXIS TRAVEL 860 MM

- Y-AXIS TRAVEL 400 MM

- Z-AXIS TRAVEL 405 MM

- SPINDLE STEP 16

- SPINDLE SPEED 80-5440

- POWER 3Hp

- WEIGHT 1350 KG

Silent Features :

- The Nut Of The Milling Machine Screw Is Adjustable

- The Backlash Can Be Easily Set

- The Thread Of The Screw Is Grining In The Milling Machine (For Long Life And Precision)

- The M1TR (ALL ROUND 3) is a specific type of vertical milling machine known for its versatility and functionality in machining operations. Here are the silent features of the Vertical Milling M1TR machine:

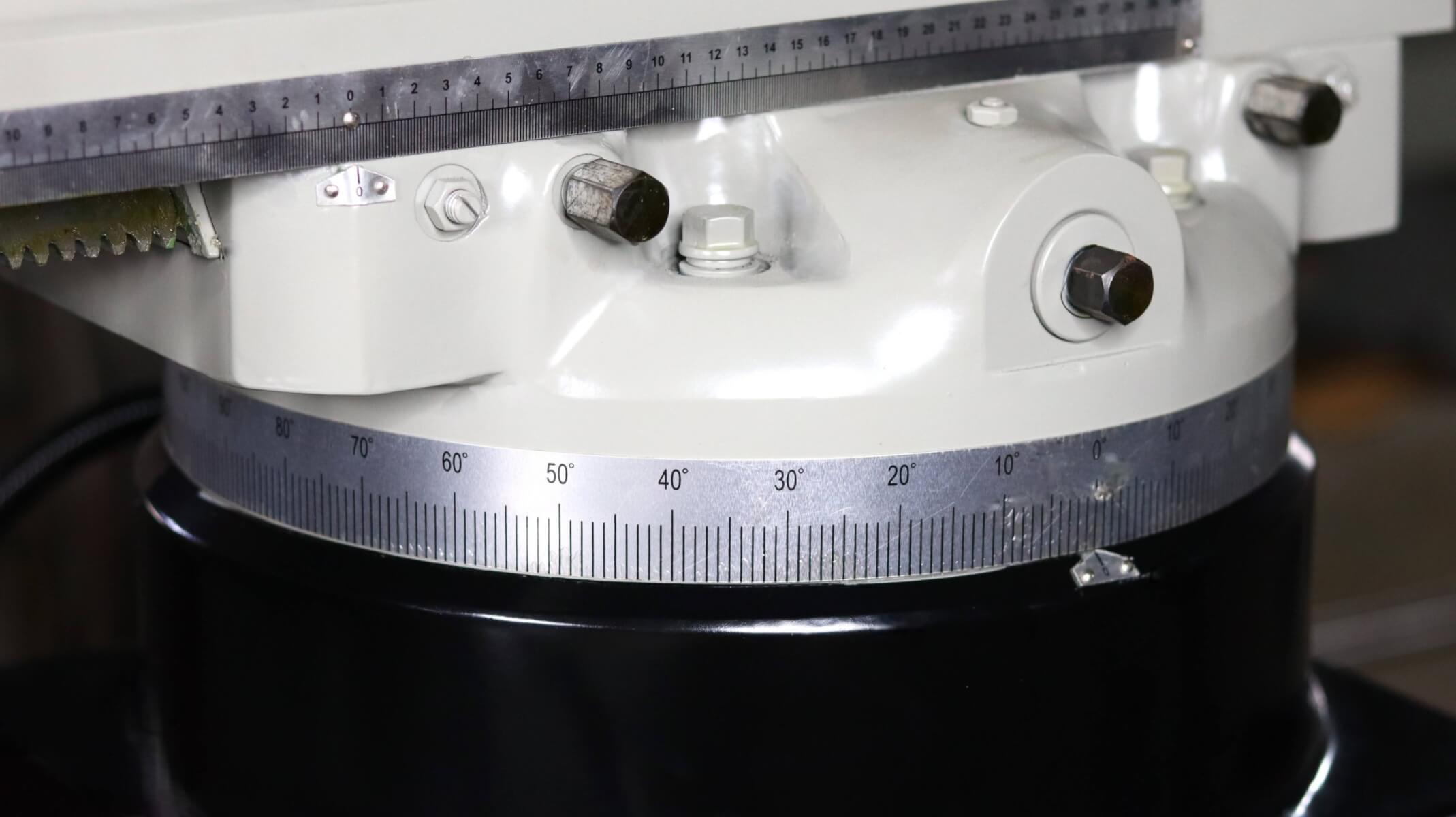

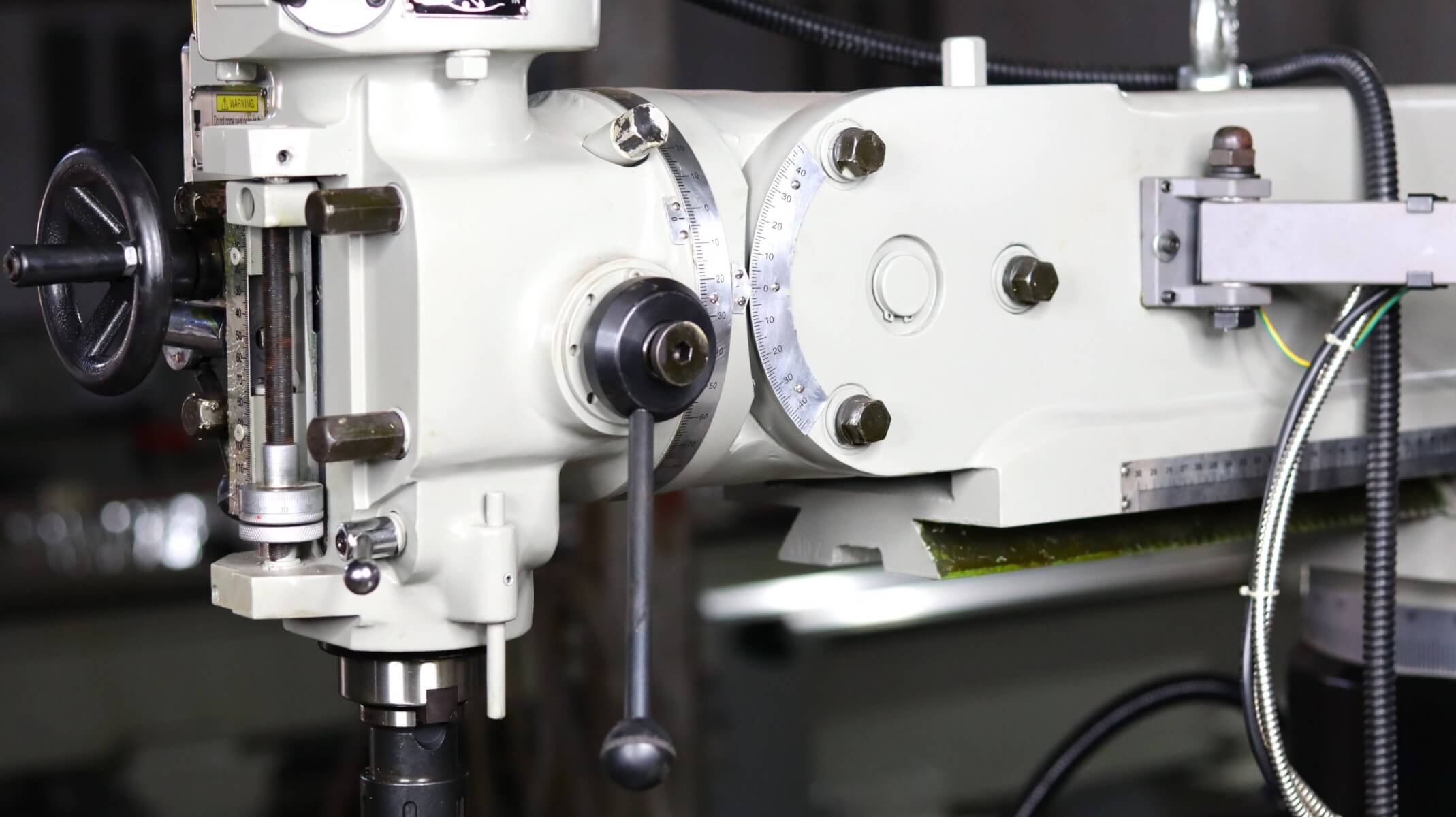

- Turret and Ram Design: The M1TR features a turret and ram design, allowing the head to swivel and move in multiple directions. This provides flexibility in machining complex parts.

- Swiveling Head: The head of the M1TR can swivel 45 degrees to the left and right, which enables angular milling and drilling operations.

- Variable Speed Control: The machine is equipped with a variable speed control system, allowing operators to adjust the spindle speed to match the requirements of different materials and cutting tools.

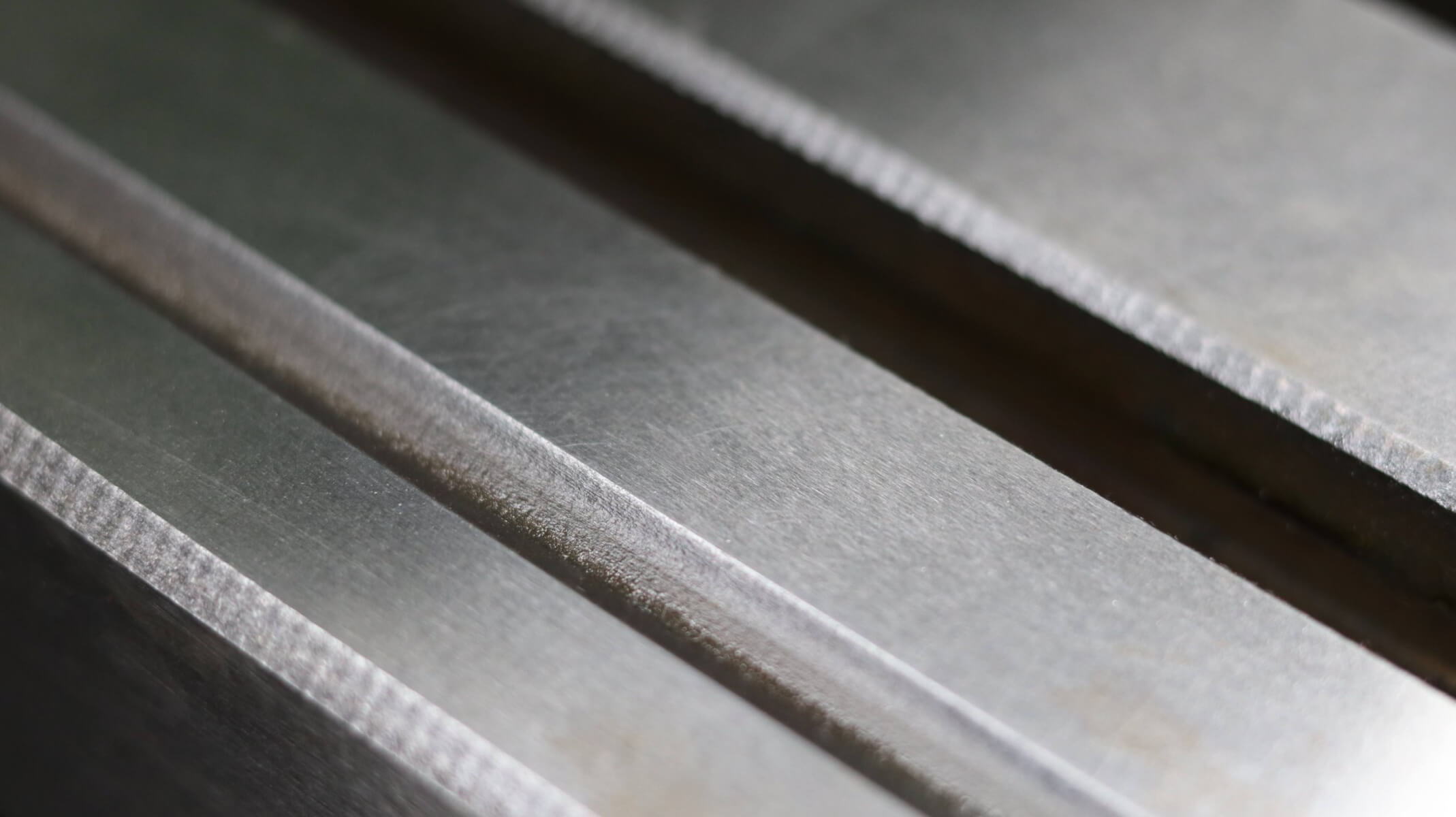

- Precision Ground Ways: The machine’s guideways are precision ground, ensuring smooth and accurate movement of the table and spindle.

- Manual and Automatic Operation: The M1TR can be operated both manually and automatically, providing flexibility for various machining tasks and operator preferences.

| MODEL | ALL ROUND 4+ |

| Table Size | 1370 x 254mm |

| T Slot | 3 x 16 mm |

| X Axis – Travel | 860 mm |

| Y Axis – Travel | 400 mm |

| Z Axis – Travel | 405 mm |

| X Axis Guidways | Dovetail Type |

| Y-Axis Guidways | Box Slide (Extra Strong With Vibration Free) |

| Z-Axis Guidways | Dovetail Type |

| Ram Travel | 580 mm |

| Spindle Taper | NT30(ER32) |

| Spindle Suitable For Collet Adaptor (Optional) | ER8 /ER11 / ER16 / ER20 / ER25 /ER32 |

| Collet Size | ER32 (3MM to 20MM) 15 Pcs |

| Quill Travel | 127 |

| Spindle Nose to Table | 70-470 mm |

| Had tilt Left & Right | +- 90 Degree |

| Had tilt Front & Back | +- 45 Degree |

| Spindle step number | 16 |

| Spindle Speed | 80-5440 rpm |

| Quill Feed | 0.04,0.08,0.15 |

| Power | 3 Hp |

| DRO | 2 Axis DRO |

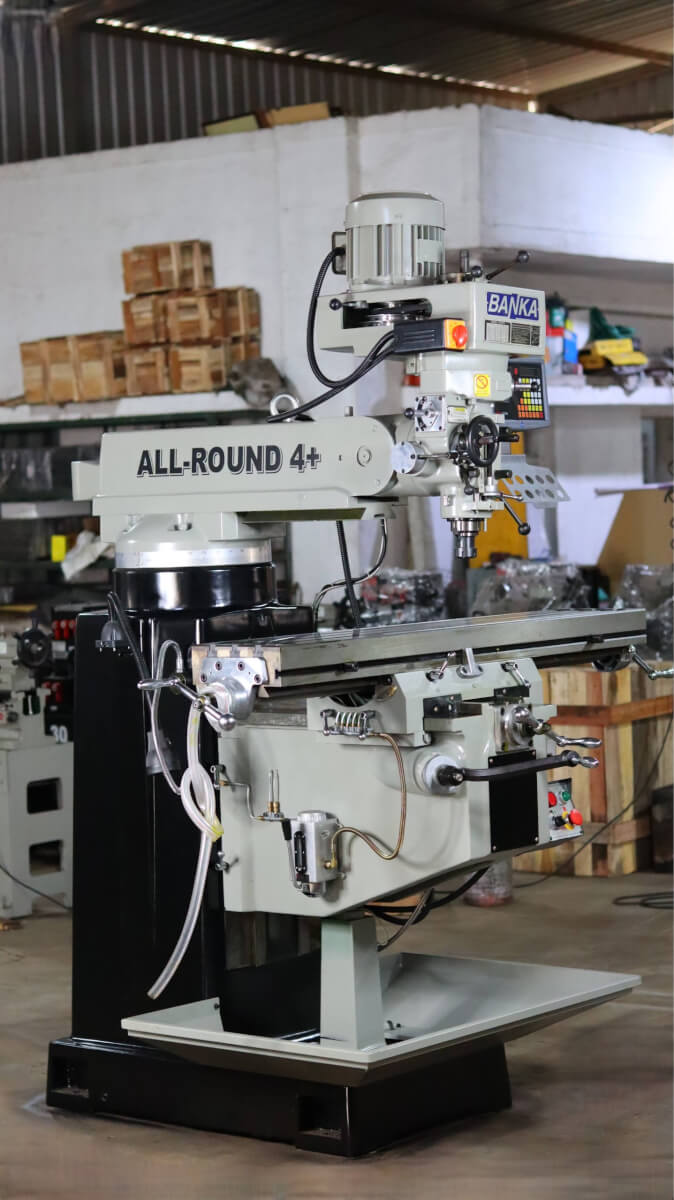

Vertical milling All Round 4+ machines are versatile tools used in machining operations to create and shape metal and other solid materials. Here are some key features and characteristics of vertical milling machines

Vertical Orientation: The spindle axis is vertically oriented, allowing for vertically oriented cutting tools. This setup enables the machine to perform operations where the workpiece remains stationary and the cutting tool moves vertically.

Table Movement: The worktable can move in multiple axes (X, Y, and Z) to accurately position the workpiece under the cutting tool. This movement allows for precise machining operations.

Spindle Speed Control: Vertical mills have variable speed controls for the spindle, allowing operators to adjust cutting speeds according to the machined material and the cutting tool used.

Digital Readouts (DRO): Modern vertical mills may include digital readouts that display the exact position of the worktable or cutting tool, aiding in precision machining.

Coolant System: Many machines have built-in coolant systems to lubricate and cool the cutting tool during machining, which helps extend tool life and improve surface finishes.

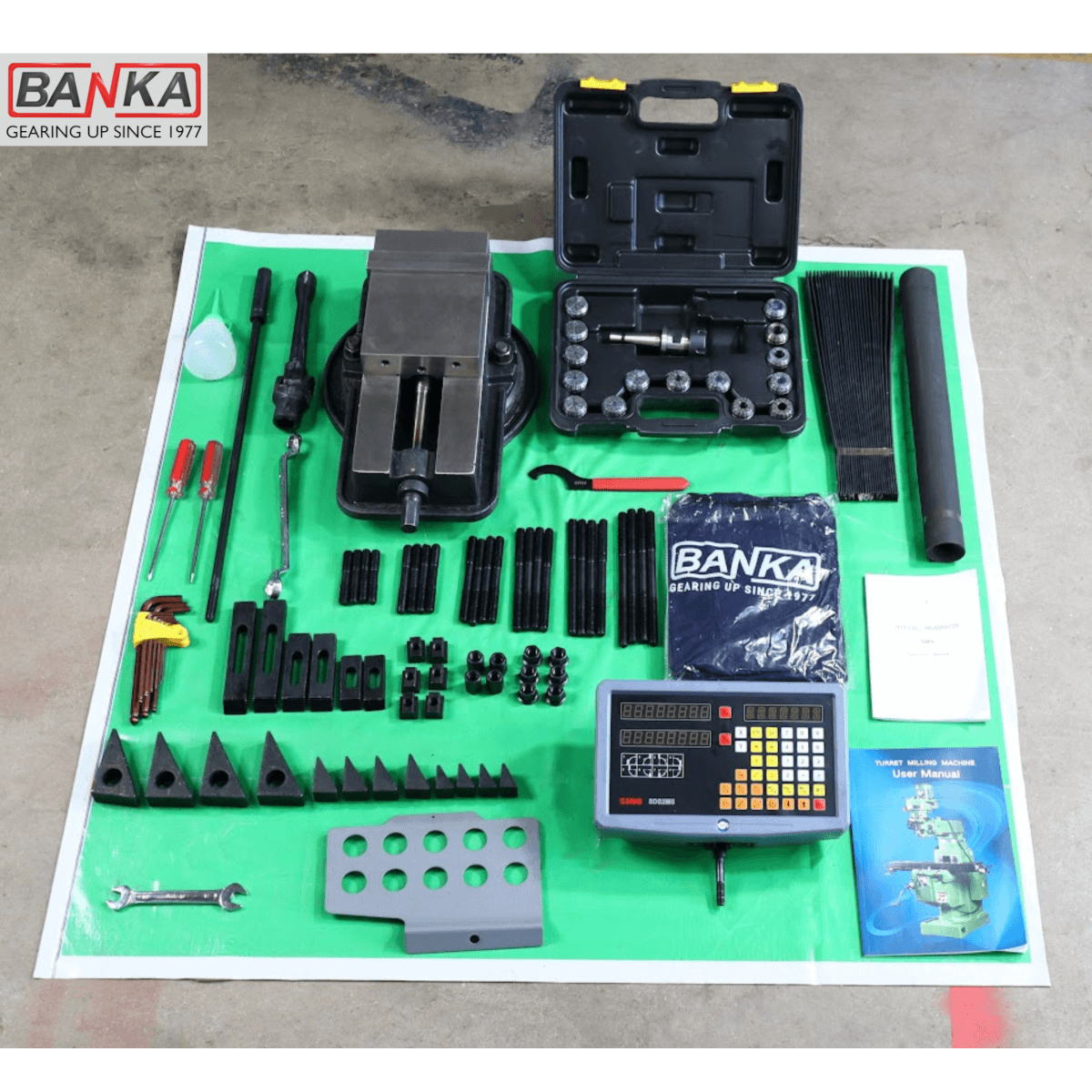

Standard Accessories:

- 2 – Axis DRO

- Coolant System

- Clamping Kit

- Collet Set ER32 (3MM to 20MM) 15 Pcs

- Machine Lamp

- Front & Rear Rubber Chip Guard

- Electrical Cabinet & Control Panel

- Drawbar

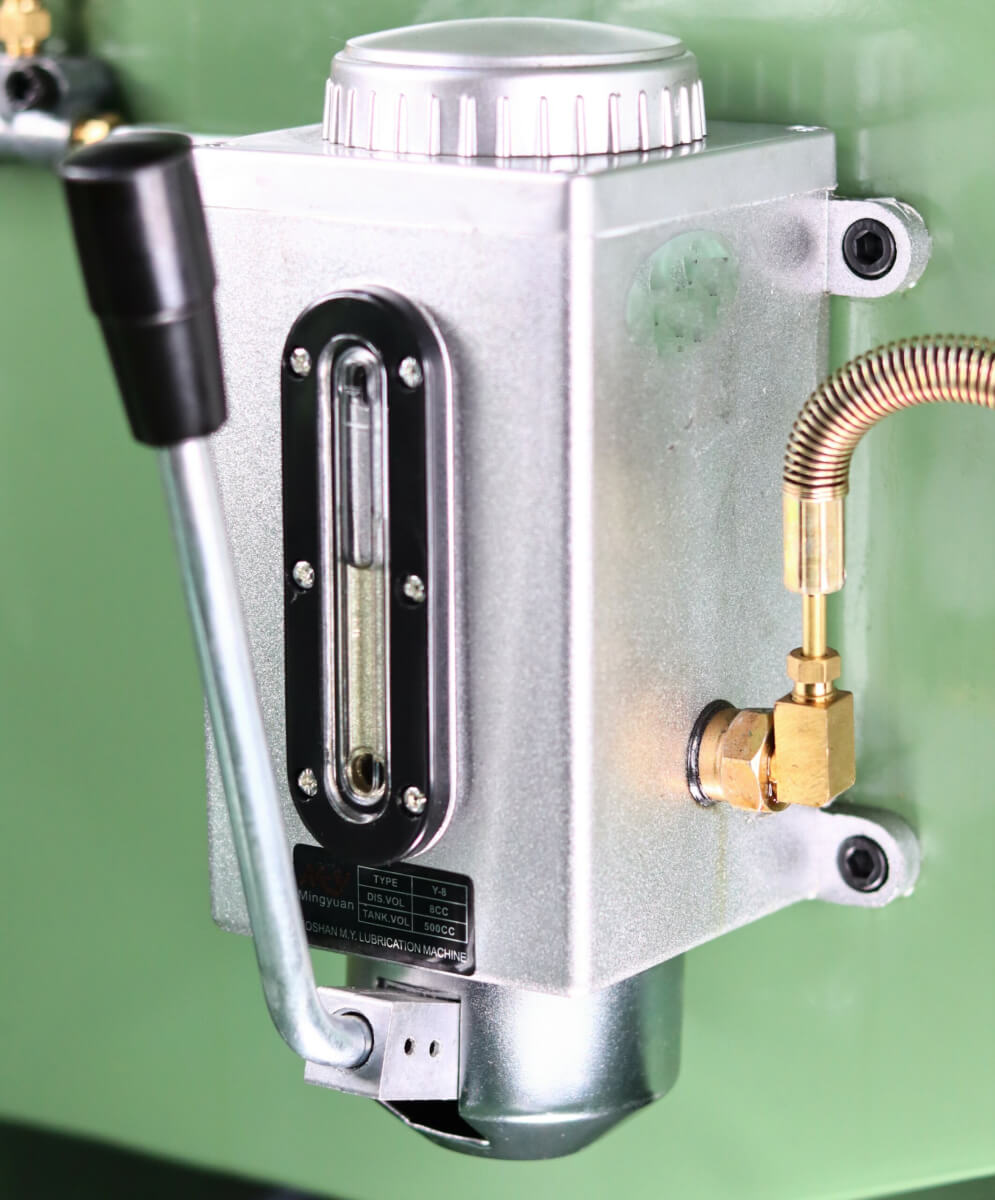

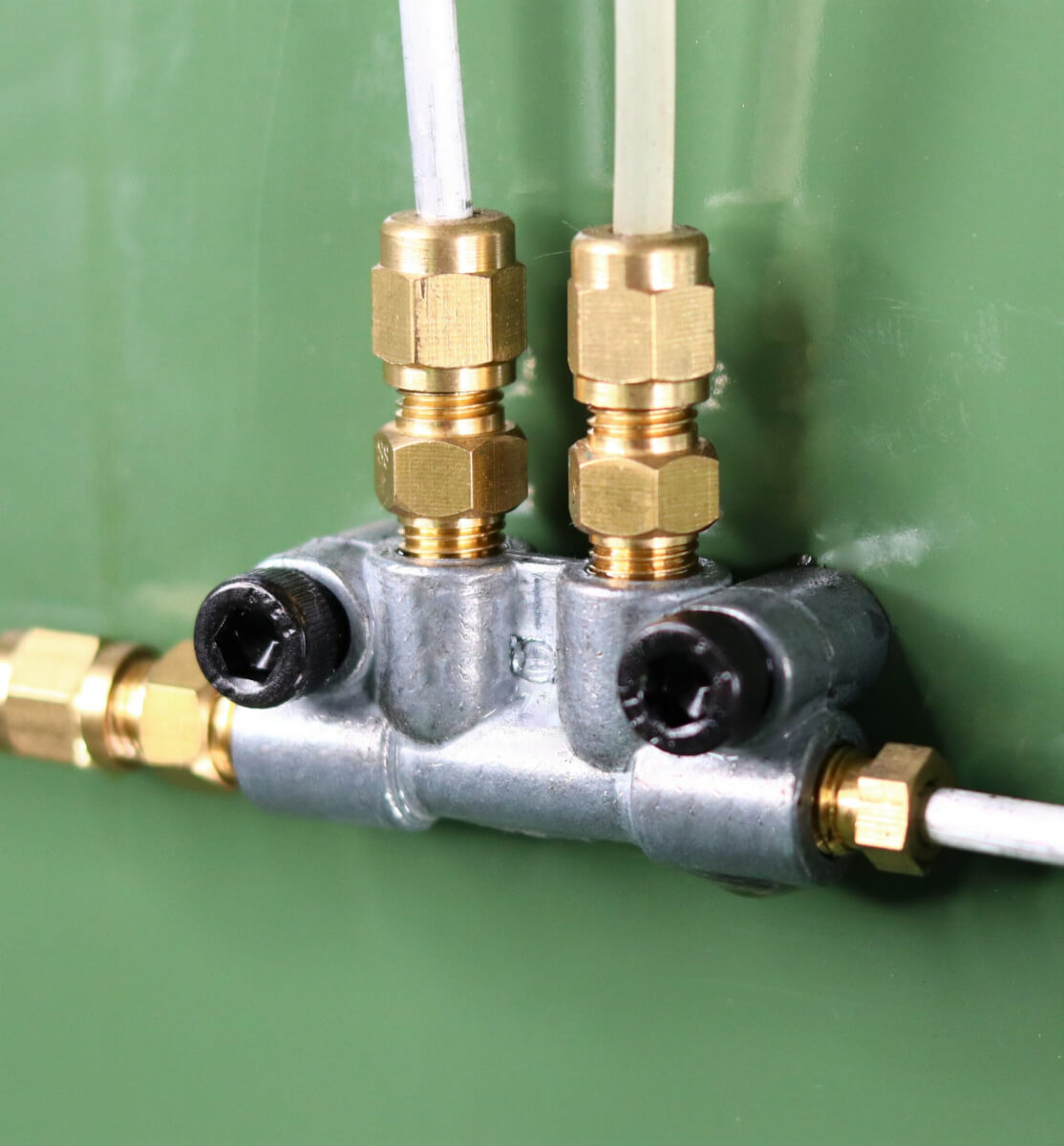

- One-Shot Lubrication System

- Tool Box

- Instruction Manual

- X-Axis Power Feed (Charges will be extra)

- Machine Vice

- Chip PAN

1. What is an M1TR Vertical Milling Machine?

The M1TR (Milling 1 Turret Ram) is a versatile vertical milling machine equipped with a turret head that can tilt and swivel in multiple directions. It allows precise machining, drilling, and boring operations on metal and other solid materials.

2. What are the key features of the M1TR milling machine?

Vertical head with variable speed or step pulley drive

Auto feed in X, Y, and Z axes (depending on model)

Swiveling head for angular machining

High precision table movement

Suitable for tool rooms, workshops, and production units

3. What are the typical table sizes and travel capacities?

Common table sizes are 1270 x 254 mm or 1370 x 305 mm, with longitudinal travel around 600–800 mm, cross travel around 300–400 mm, and vertical travel about 400–450 mm. (Exact dimensions vary by manufacturer.)

4. What type of operations can be performed on an M1TR Milling Machine?

The M1TR model can perform operations such as:

Face milling

Slotting

Drilling & boring

Gear cutting (with attachments)

Angular and contour milling

5. What maintenance is required for an M1TR Milling Machine?

Regular lubrication of slides and lead screws

Periodic checking of head alignment and backlash

Cleaning the table and ways after every operation

Ensuring proper tightening of belts and gibs

Scheduled inspection of electrical and lubrication systems