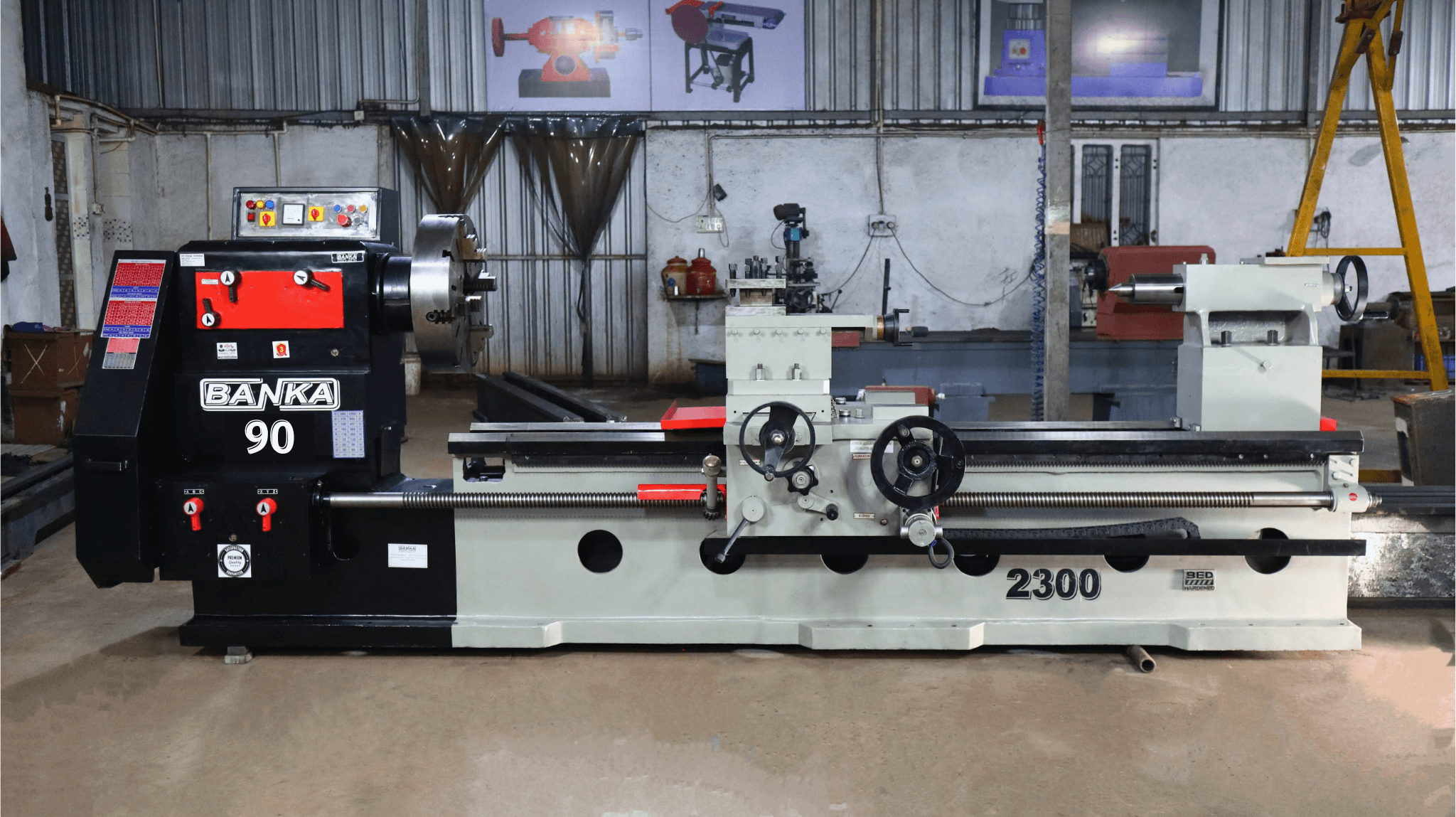

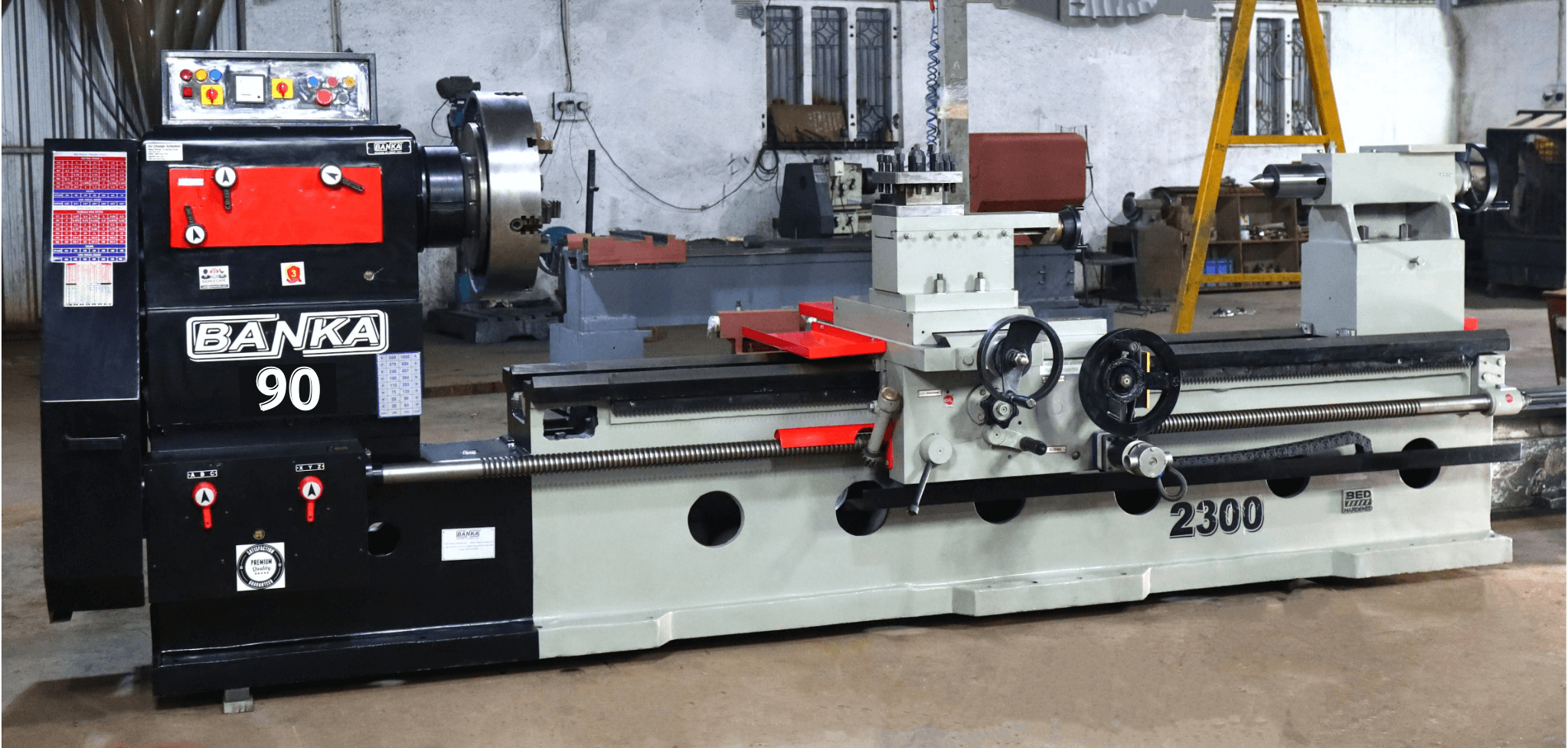

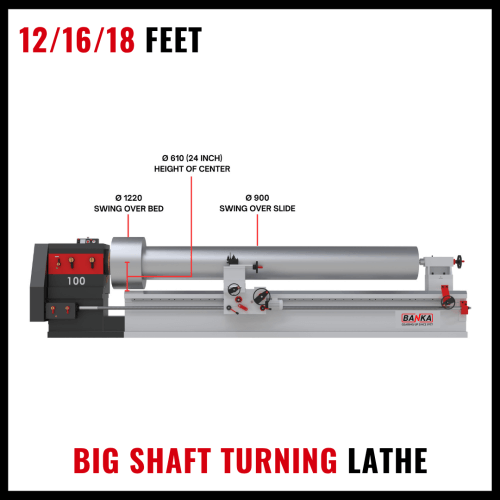

Heavy Duty Lathe Machine for Large Shaft Machining, Big Bore & Roll Turning – Model 90 BANKA

₹10,50,000

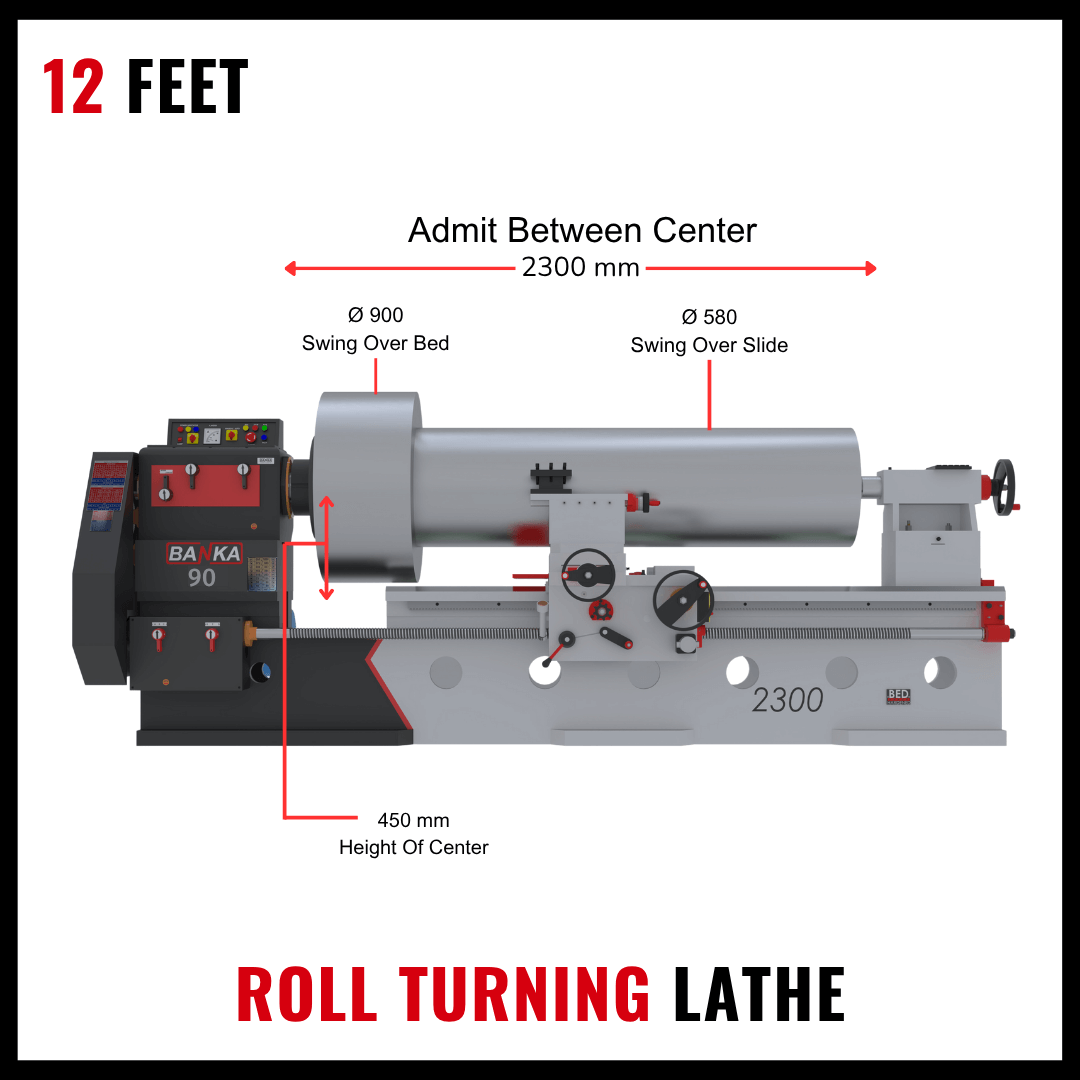

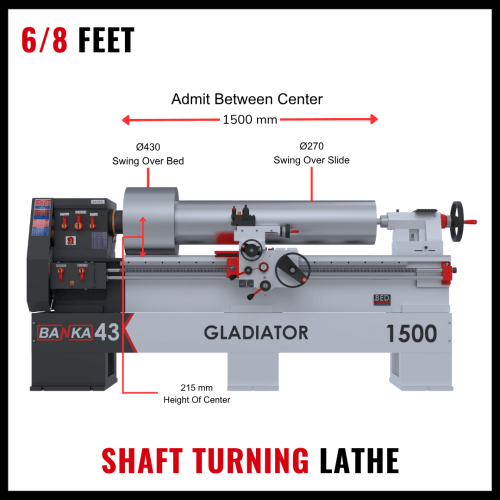

- Height of Center: 450mm

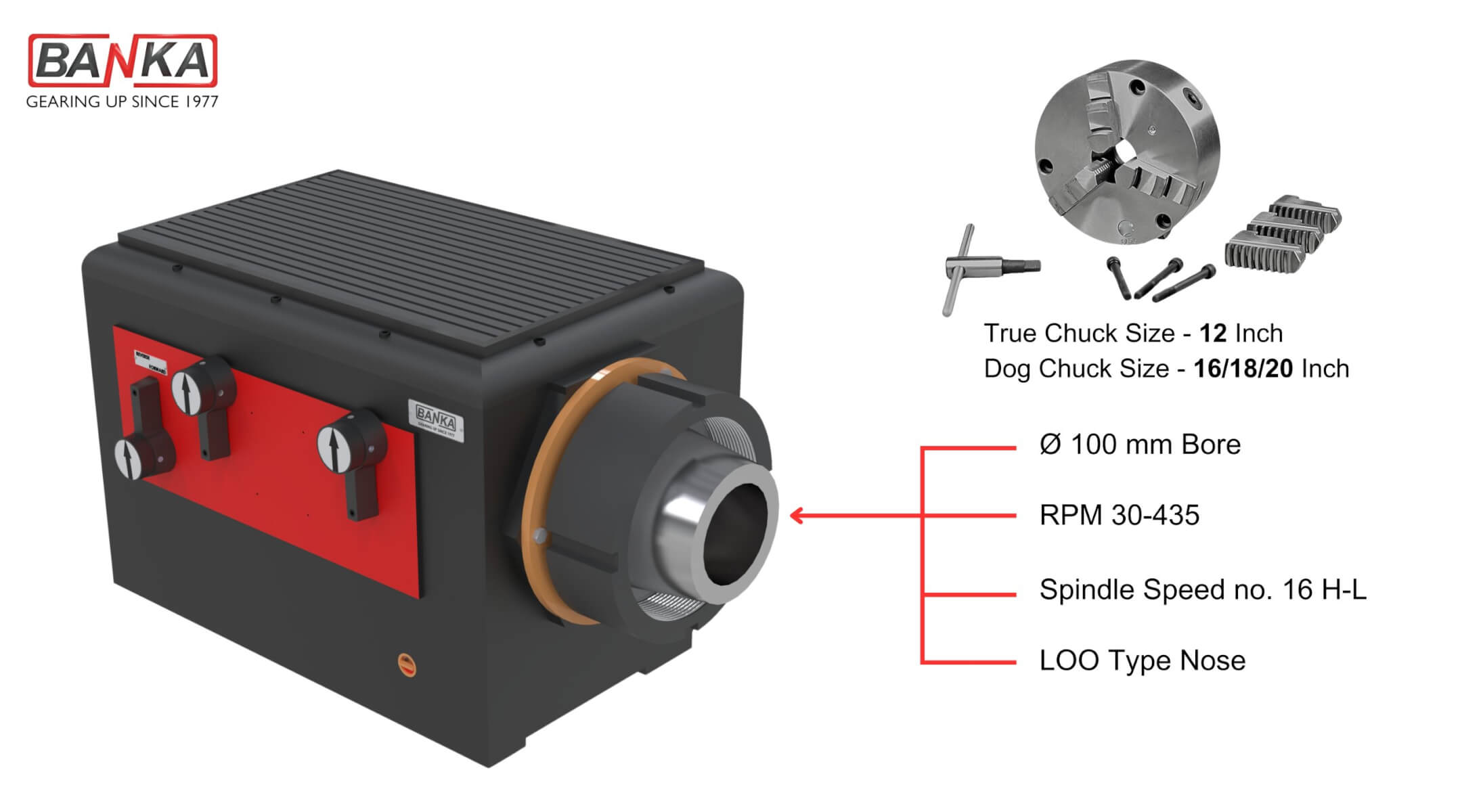

- Spindle Bore: 100 mm

- Admin Between Center: 2300MM

- Bed Length: 12

- Spindle Speed: 30-435 RPM

- Bed Width: 450mm Plano Bed

- Motor: 7.5HP

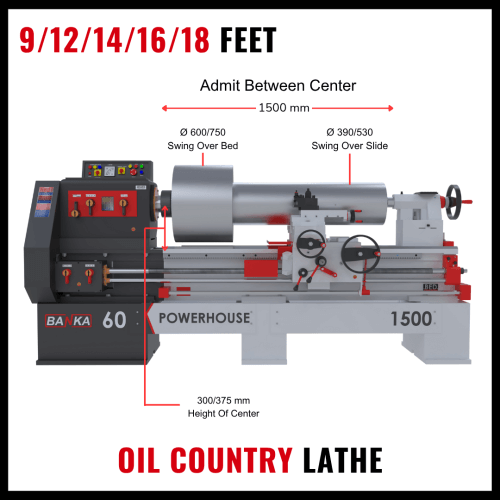

- Useful for the Oil Country Gulf pipe turning

Essential Features :

|

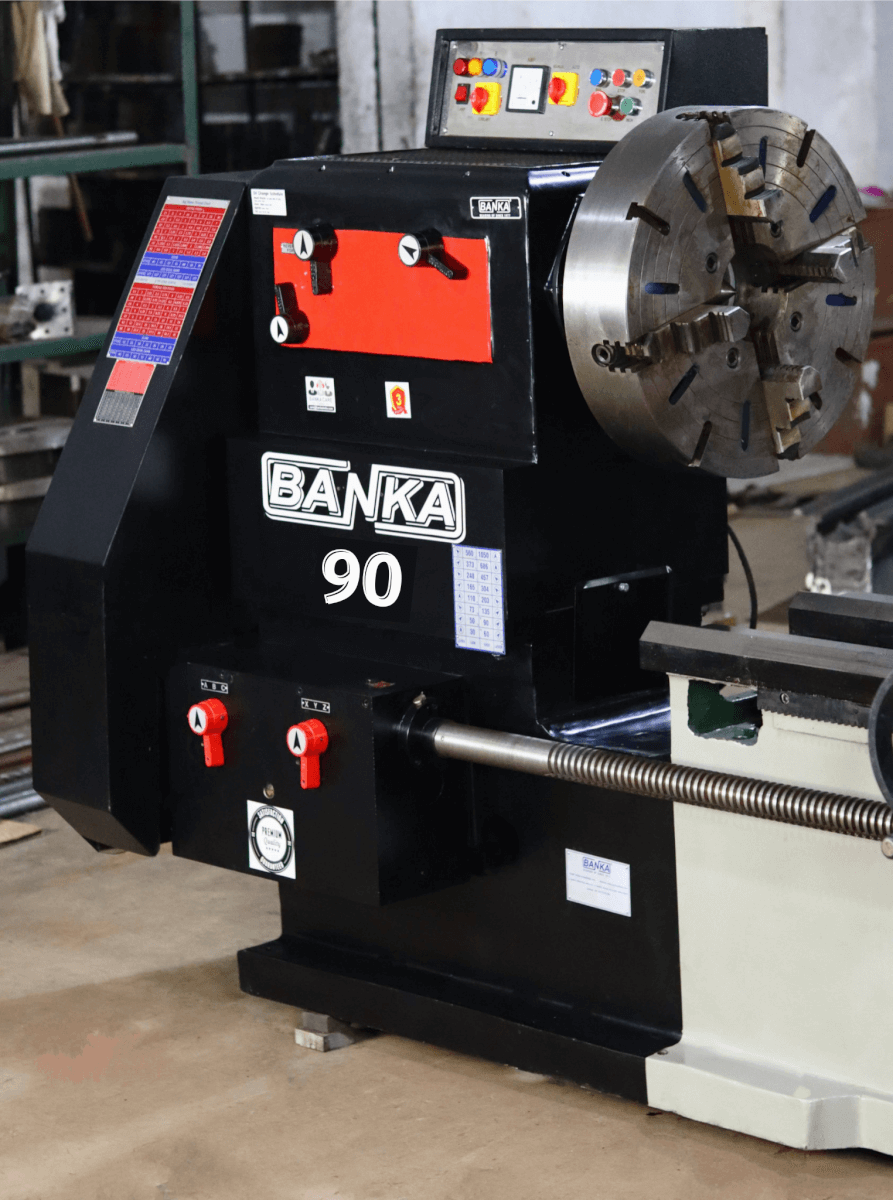

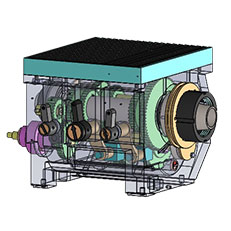

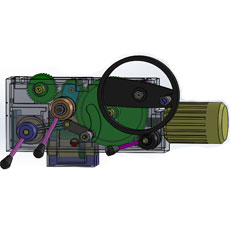

Headstock : The box-type constructed head stock with its rationally designed ridding arrangement gives a maximum rigidity performance free from thermal displacement and vibration. Its rigid-built hardened and ground spindle is supported in the sturdy headstock by super precision roller bearing and ball bearing, capable of heavy duty and high speed applications. All gears, splines, spindles are made from 20 MnCr5 material and hardened ground. |

|

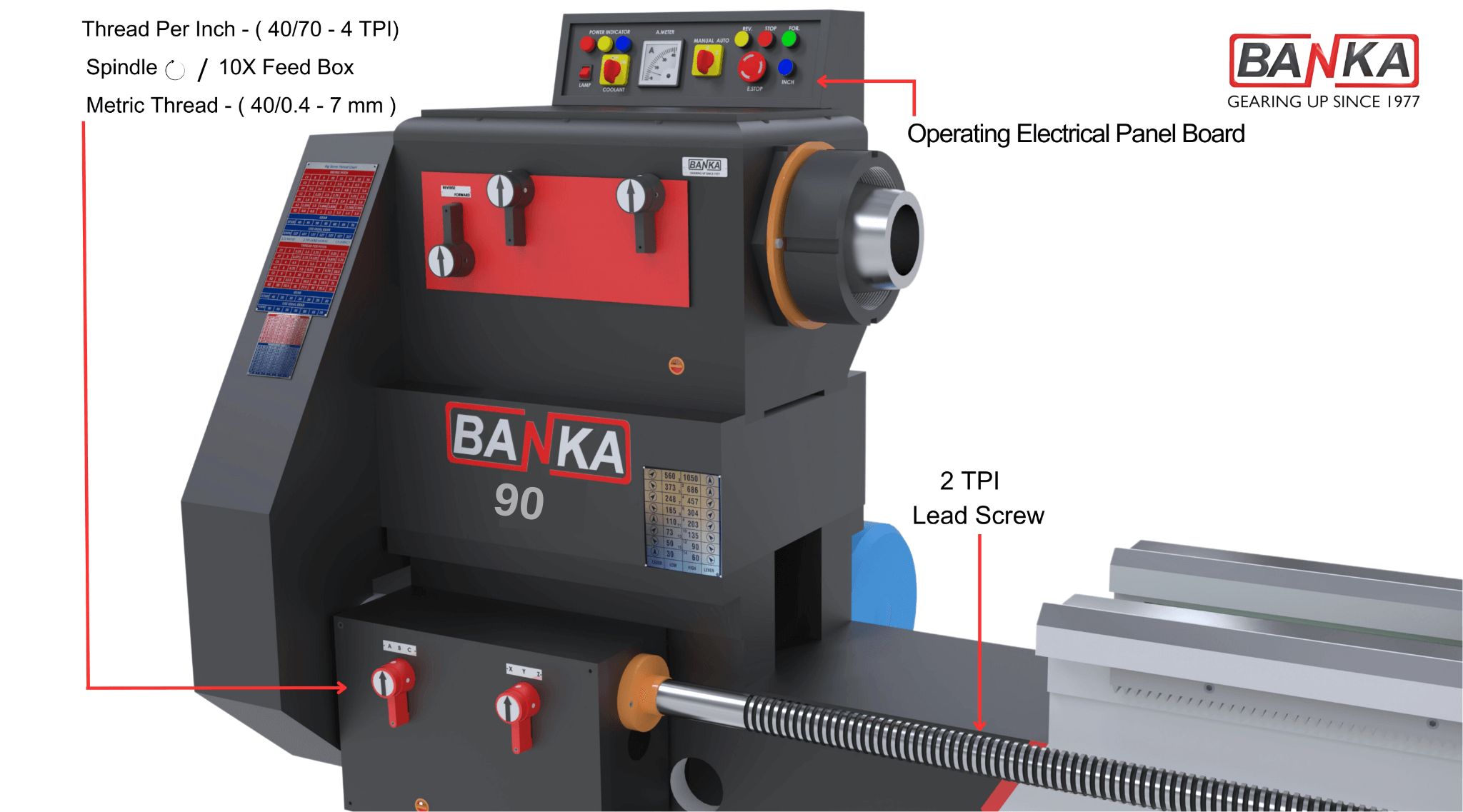

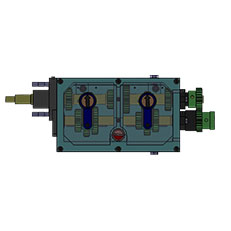

Gear Box : A specially designed gear mechanism is employed for this feed gear box. The easy-to-handle quick gear system provides an unusually wide range of feed and threads applications. Its outstanding feature is that each selection of feed and common used threads (in metric, inch, module or DP) is instantly achieved through the combined operation of two levers with changing gears. |

|

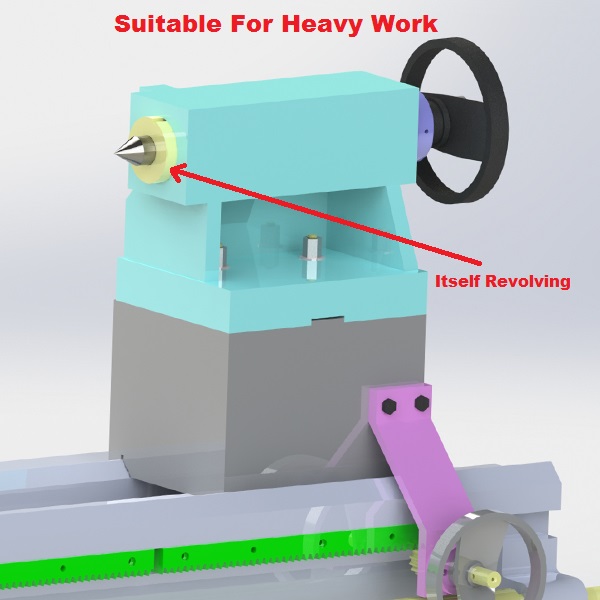

Tailstock : The sturdy construction of tailstock with its revolving ram is capable of stable accommodation of heavy work. Double locking system ensures powerful tailstock clamping. |

|

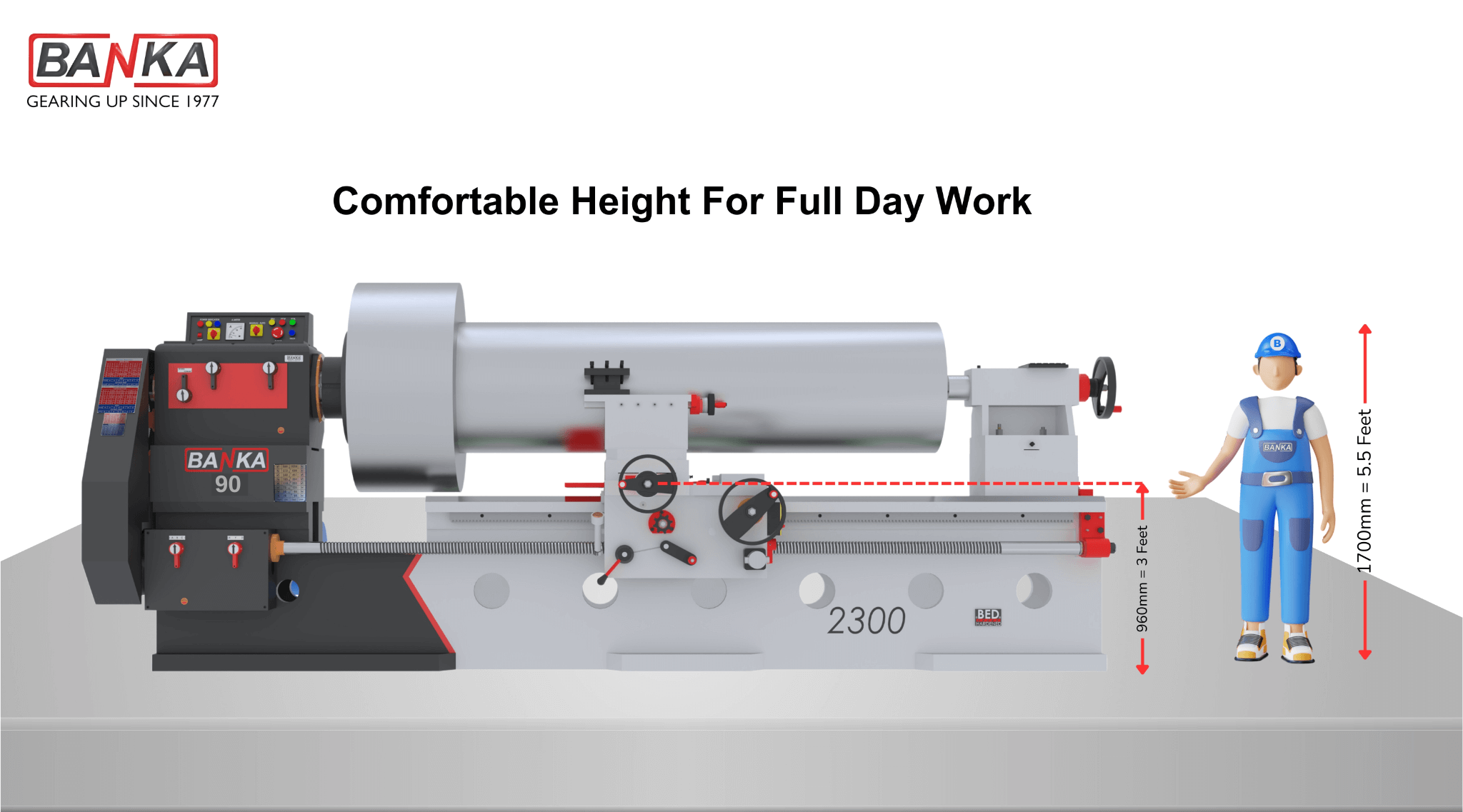

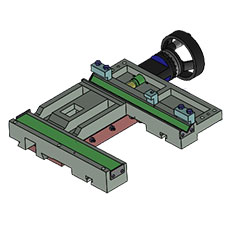

Apron Movement by motor : Apron designed to totally enclosed oil bath system and lever type arrangement for automatic feeds. Because the length of the lathe machine is too long as normal bed. While operating normally by wheel or handle operator feels tired, but in our motorized apron it will move by motor. |

|

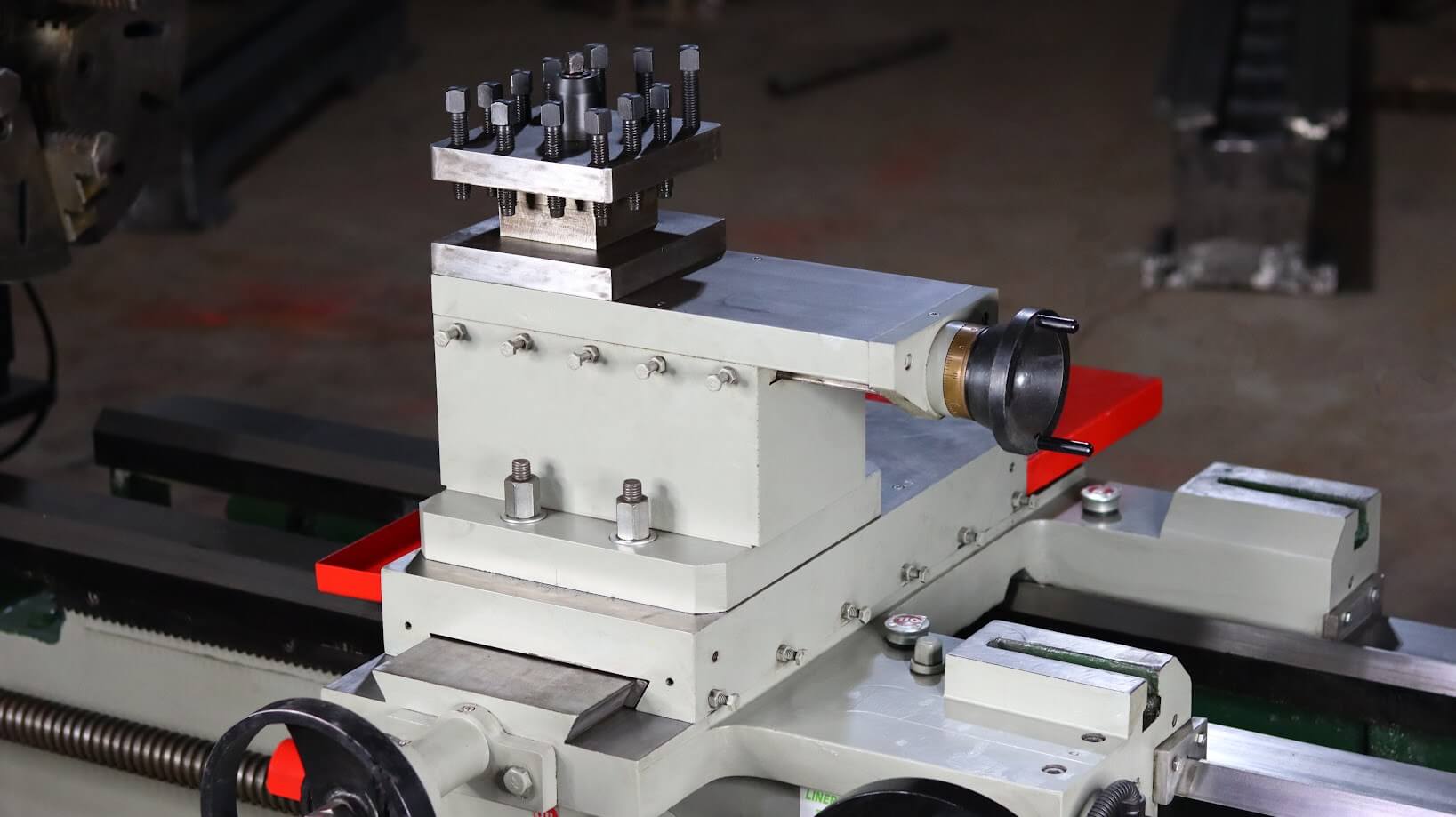

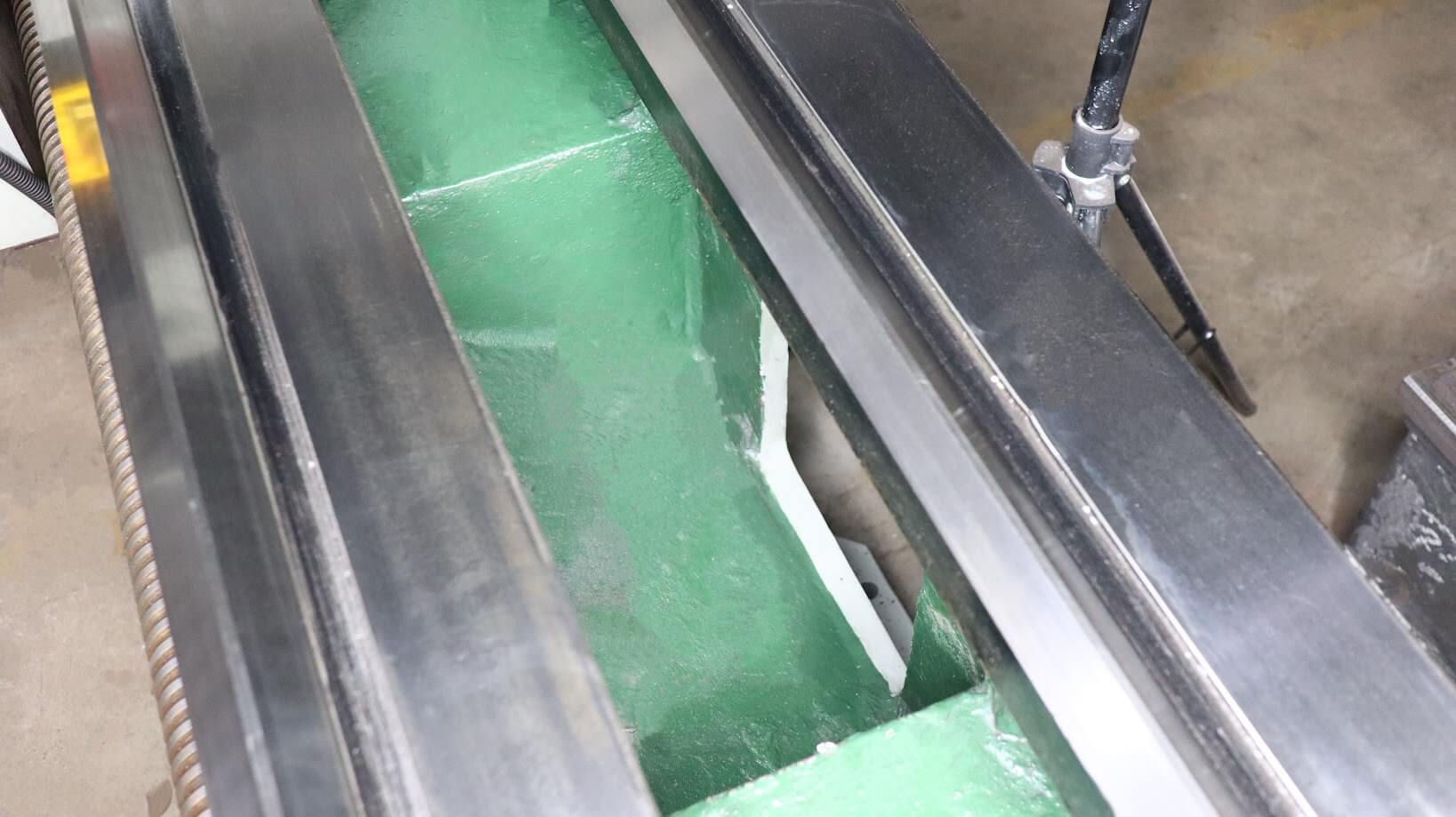

Carriage – Saddle : Turcite B Loner Bearing System coating between Carriage and Bed to provide extra cutting strength and long life accuracy. Also works as an Anti-Friction system and gives smooth movement of Carriage on Bed. |

Salient Features :

- Head stock gears hardened and ground.

- Gear box gear hardened and ground.

- Bedways hardened and ground up to 400 BHN.

- Turitical B anti- friction material on carriage ways.

- Control panel & magnetic brake (optional available on request)

- Metric dial on cross slide, Compound and tailstock semi universal gear box provides inch and metric thread without changing too many end trains gears.

- Spindle speeds 30 – 435 RPM in 16 H-L nos. spindle speeds.

- Alloy steel Spindle mounting on taper roller bearings.

| PARTICULER | MODEL 90-2300 |

| Height Of Centers | 450 MM |

| Swing Over Bed | 900 MM |

| Swing Over Slide | 580 MM |

| Width Of Bed | 455 MM |

| Spindle Bore | 100 MM |

| Spindle Nose | LOO TYPE |

| Spindle Speed No. | 16 H/L |

| RPM | 30-435 |

| Cross Slide Travel | 580 MM |

| Top Slide Travel | 250 MM |

| Tail Stock Sleeve | MT-5 |

| Quill Dia. / Travel | 100 / 230 MM |

| Tool Shank Section | 40 x 50 MM |

| Metric Thread | NO 49 Range 0.8-14 |

| Thread Per Inch | NO 49 Range 2-35 |

| Lead Screw | 2 TPI |

| Main Motor | 7.5 HP |

| Admit Between Center | 2300 |

| Bed Length Feet | 12′ |

| Weight (Kg.) Approx. | 3500 |

| Swing in Gap | 1050 MM |

| Gap Size | 150 MM |

| Price in RS. | Rs. 10,50,000/- |

Quality : Our lathes quality is maintained because of our step by step manufacturing process. According to our manufacturing process, metal cutting lathe performance and accuracy are better than other industrial lathe machine manufacturer.Our toolroom lathe is manufactured as per Indian Standard test by testing instruments like,

Straight Edge:A straightedge is a tool with an edge free-form curves or straight, used for transcribing straight lines. Straightedges are used in the automotive service and machining industry to check the flatness of machined mating surfaces and concave & convex. True straightness can in some cases be checked by using a laser line level as an optical straightedge: it can illuminate an accurately straight line on a flat surface such as the edge of a plank or shelf. It effects in the production schedule, time schedule, time saving and increase the quality of our products.

Spirit Level Precision: Generally, an engineer’s spirit level is used to level machines, although they may be used to level large workpieces on machines such as planers. Spirit levels are also used in building construction by carpenters and masons. A precision level is used to check the installation of precision machines in two axes. A lathe is manufactured with its base in a level plane. Small milling machines are often roughly leveled but large mills are installed level. Periodically check the level to ensure contained lathe accuracy by using Spirit Level accuracy of 0.05 mm/mt. According to IS Test Chart machine must be accurately leveled up to 0.02 mm per meter.

Hardness Tester BHN Scale: Hardness measurements quantify the resistance of a material to plastic deformation. hardness tests compose the majority of processes used to determine material hardness, and can be divided into two classes: macro-indentation and micro-indentation tests. It’s used to test the hardness of the bed. Our each lathe machine’s hardness of the bed is 400 BHN as per IS test. The main advantages of the hardness test are that extremely accurate readings can be taken, and just one type of indenter is used for all types of metals and surface treatments.

Tachometer RPM MPM: Tachometer RPM Meter is an instrument measuring the rotation speed of a shaft or disk, as in a lathe machine, drill machine, milling machine and other machinery. The tachometer is used to accurately measure spindle RPM (Speed) of the lathe machines. Just attach a reflective sticker to the rotating part and point the red laser beam on the mark from a safe distance.

Sound Level Decibel Meter: As per the IS test our Tool lathe head sound is measured by Decibel Meter and it should be up to 85 to 90 dB. In every lathe machine, it should be 85 dB and our each lathe machine noise level is under 85 dB.

Dial Indicator Micrometers: Dial Indicator Micrometers is used for precise measurement of components which are done on the lathe. It’s also used to measure the apparent diameter of celestial bodies or microscopic objects.

Screw Thread Special Tester: With Screw thread tester we can test the Pitch accuracy test. One end of the tester, a dial gauge has been attached and the other end has a point attached that measures screw thread.

FREE ACCESSORIES

- Center Adopter

- Dead Center

- Thread Dial Indicator

- Change Gear

- Motor Stand

- V Belt

- Motor Pulley

- Spanner Set

- Chip Collector Tray

- Vibration Pads

- First Fill Oil

- Manual Book

- Wheel & Handle Set

- Clutch Stick With Knob

- Chuck Plate

- Switch Stand

- Chuck Spanner

- Eye Procteter Glass

- Colour Can

- Apron

- Machine Lamp