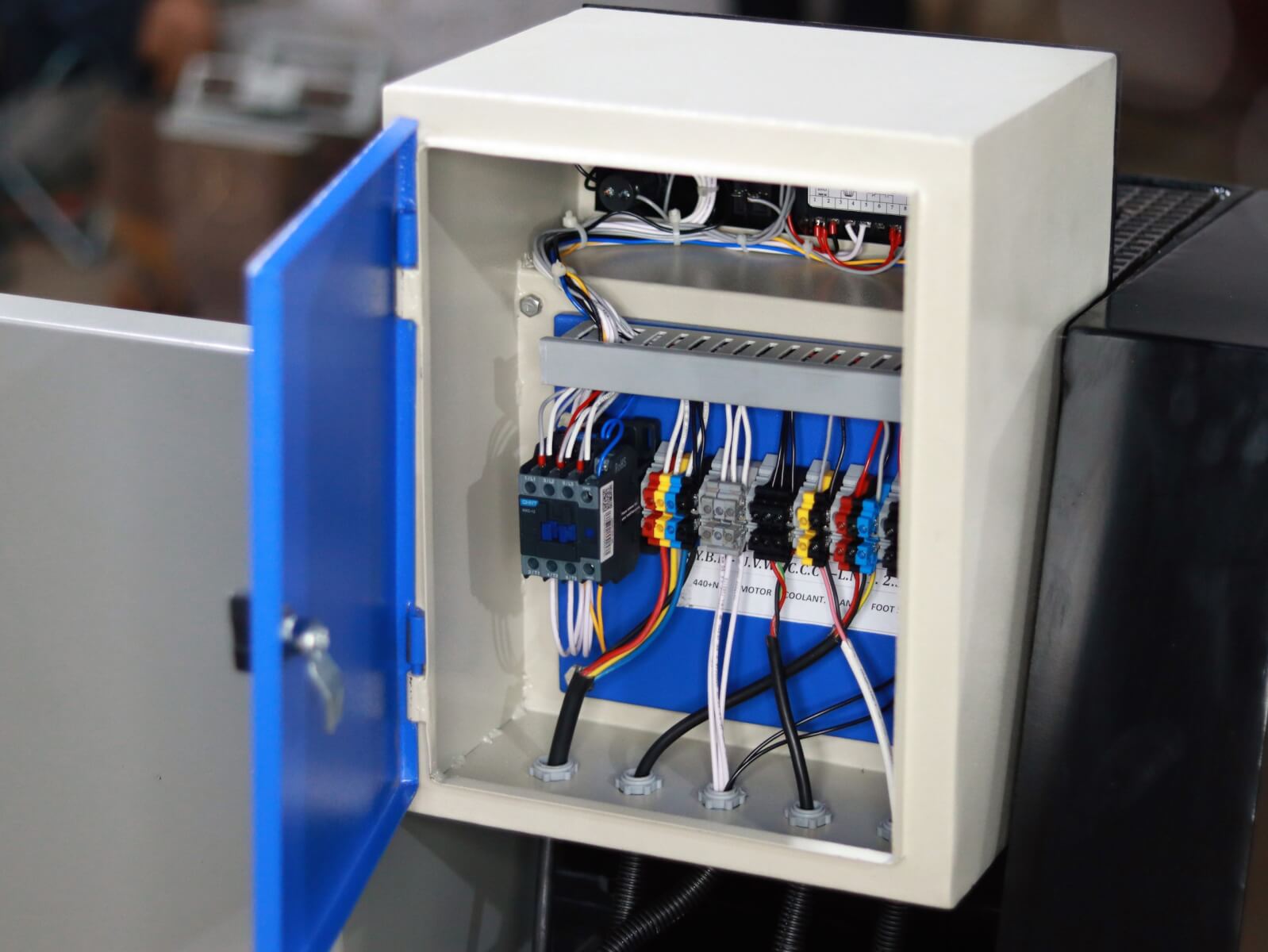

Control Panel Board

₹7,500

-A control panel is a flat, often vertical, area where control or monitoring instruments are displayed. They are found in factories to monitor and control machines or production lines and in places such as Older control panels are most often equipped with push buttons and analog instruments, whereas today in many are used for monitoring and control purposes. – Emergency STOP Button – Increased Production – Overload Protection – Inching System – Single Phase Preventer – Extra 2 Speed R/F Switch

A control panel is a flat, often vertical, area where control or monitoring instruments are displayed. They are found in factories to monitor and control machines or production lines and in places such as Older control panels are most often equipped with push buttons and analog instruments, whereas today in many are used for monitoring and control purposes.

Control panel is a cabinet which contains electrical components to control the motors and equipments.

Electrical controls on front panel

- Directional switch: Reverse – Neutral – Forward

- AC power pilot lamp

- Selector switch: 1=Lathe – 0=Neutral – 2=Mill (optional)

- Motor power: 0=Off – 1=On

- Emergency Stop button: In=Stop – Out=Normal

During normal lathe operation, the directional switch is turned to the right (Forward) position and the Selector switch is turned to the left (1 or Lathe) position. The spindle normally is controlled using the red and green push buttons,Green (1) to start and Red (0) to stop. However, individual operating preferences may vary. I sometimes leave the Green button depressed and use the directional switch to start and stop the lathe. When cutting threads, this makes it easy to change the carriage direction. I’m not sure if there is any disadvantage with that method, but it has worked well for me so far.

For additional safety, the Red / Green push button is relay-controlled. If the chuck safety cover is lifted while the lathe is running, the safety relay trips and the lathe comes to a stop. The same is true if the drive train access door is opened. To restart the lathe, the chuck cover and/or access door must be closed.

I was surprised to discover that the lathe can be started by pressing and holding in the Green button even when the safety cover is raised or the access door is open. If the button is pressed while the chuck key is in the chuck, this could lead to the type of accident that the cover is intended to prevent. I will recommend to Sieg that this be corrected.

Should an emergency condition occur during operation, the lathe can quickly be stopped by punching down on the Emergency Stop (ES) button. This action cuts off power to the motor and locks the cap of the ES button in the depressed position. After the emergency condition has been resolved, rotating the button clockwise, as indicated by the arrows, releases the button to restore the lathe to normal operation.

ADVANTAGES :

- Operator can stop the machine immediately.

- It’s will reduces the risk factor.

- More over it’s given advantage while AC power flow is high.

PRODUCT DESCRIPTION :-

- Emergency STOP Button

- Increased Production

- Overload Protection

- Inching System

- Single Phase Preventer

- Extra 2 Speed R/F Switch

- Weight :- 6Kg

- For Model 34 (Rs 7500 & 10500)

- For Model 40 (Rs 1500 To 17000)

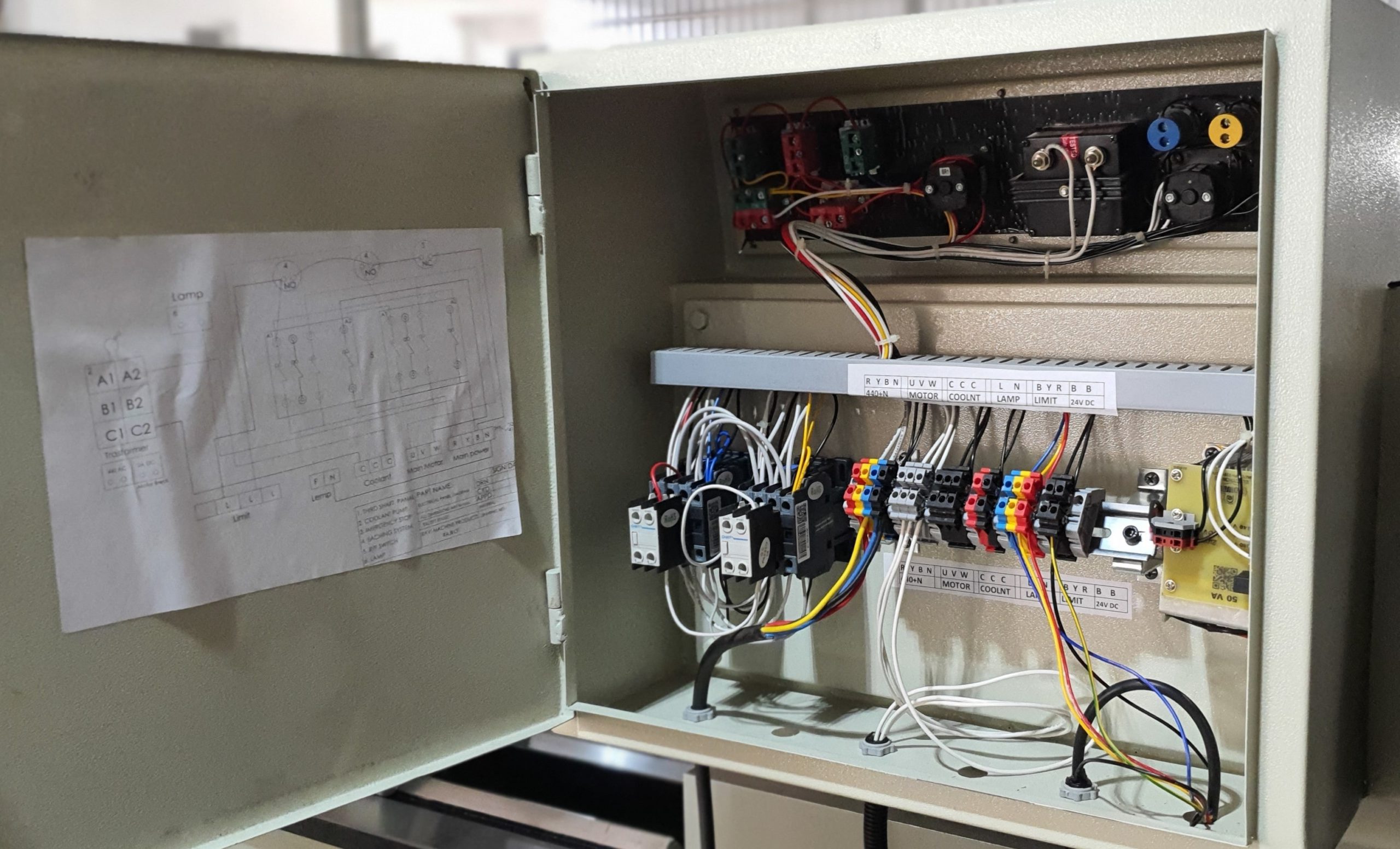

OVER LOAD RELAY:

Over load relay is for the protection of motor from the over load. It senses the load current and trips if it exceeds the limit. Current limit has to be set manually. It should be 80% of the full load current.

CONTACTOR:

Contactor is an essential component in the control panel. It actuates when the signal from the controller (PLC, Relay logic) comes. It is similar to relay. It is costlier than relay. It is used for a higher load.

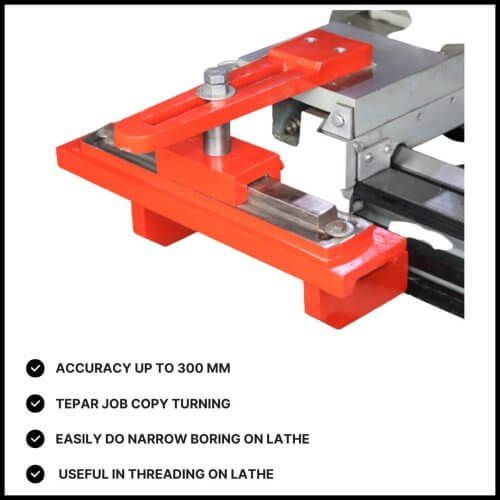

Related Products

Taper Turning Attachment For Lathe Machine