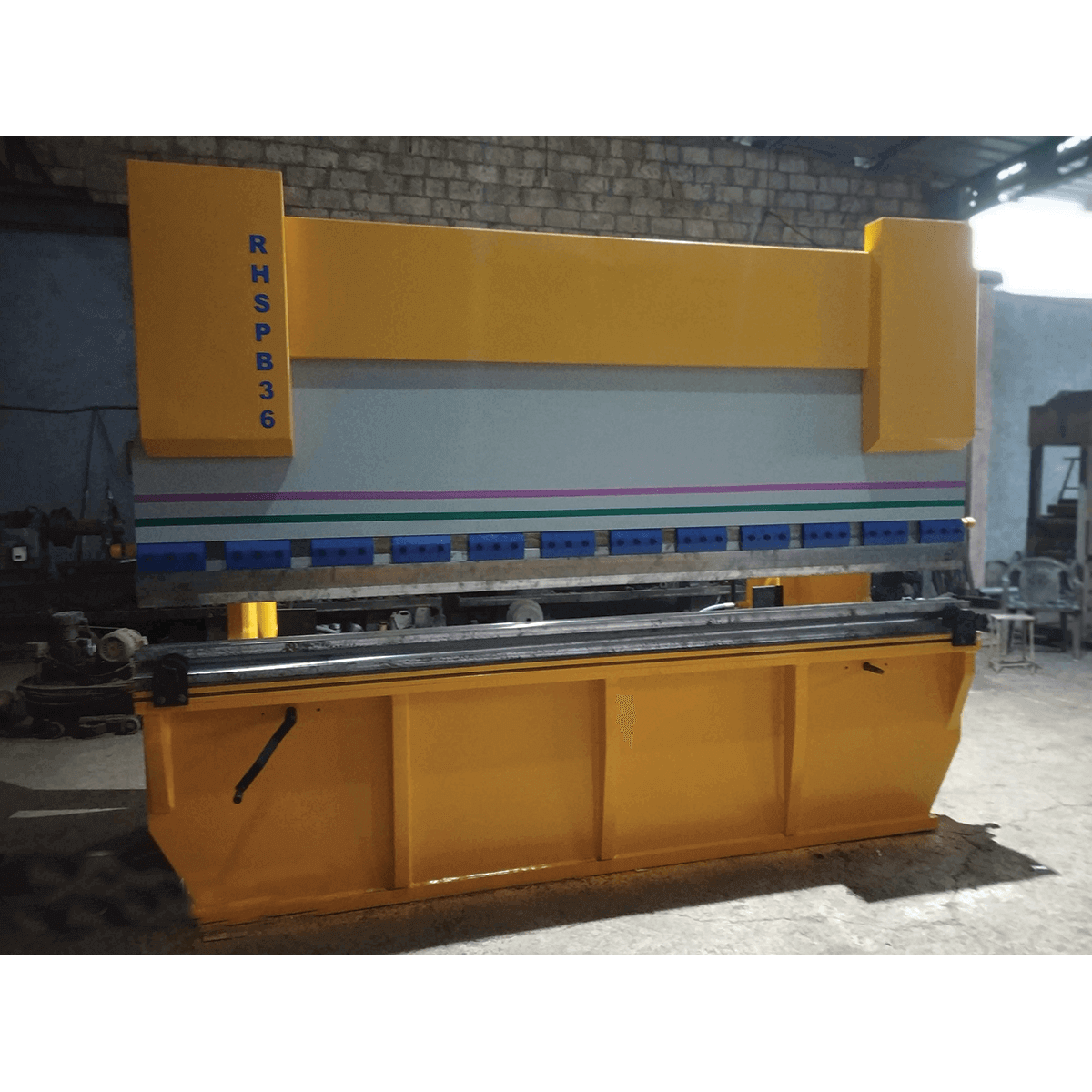

Mechanical Press Brake Machine – Sheet Cutting – Sheet Metal Cutting – Maximum Tonnage 20 To 120 – Manual Cutting – Bar And Plate Cutter

₹7,00,000

- Category : Workshop Machine / Cutting Machine

- Color : Bule & White Combo

- Bending Cap.(Length x Thick.) : 1525 x 1.6

- Stroke Length : 50

- Machine Height : 2150 mm

- Main Motor : 3 hp

Separate us from others

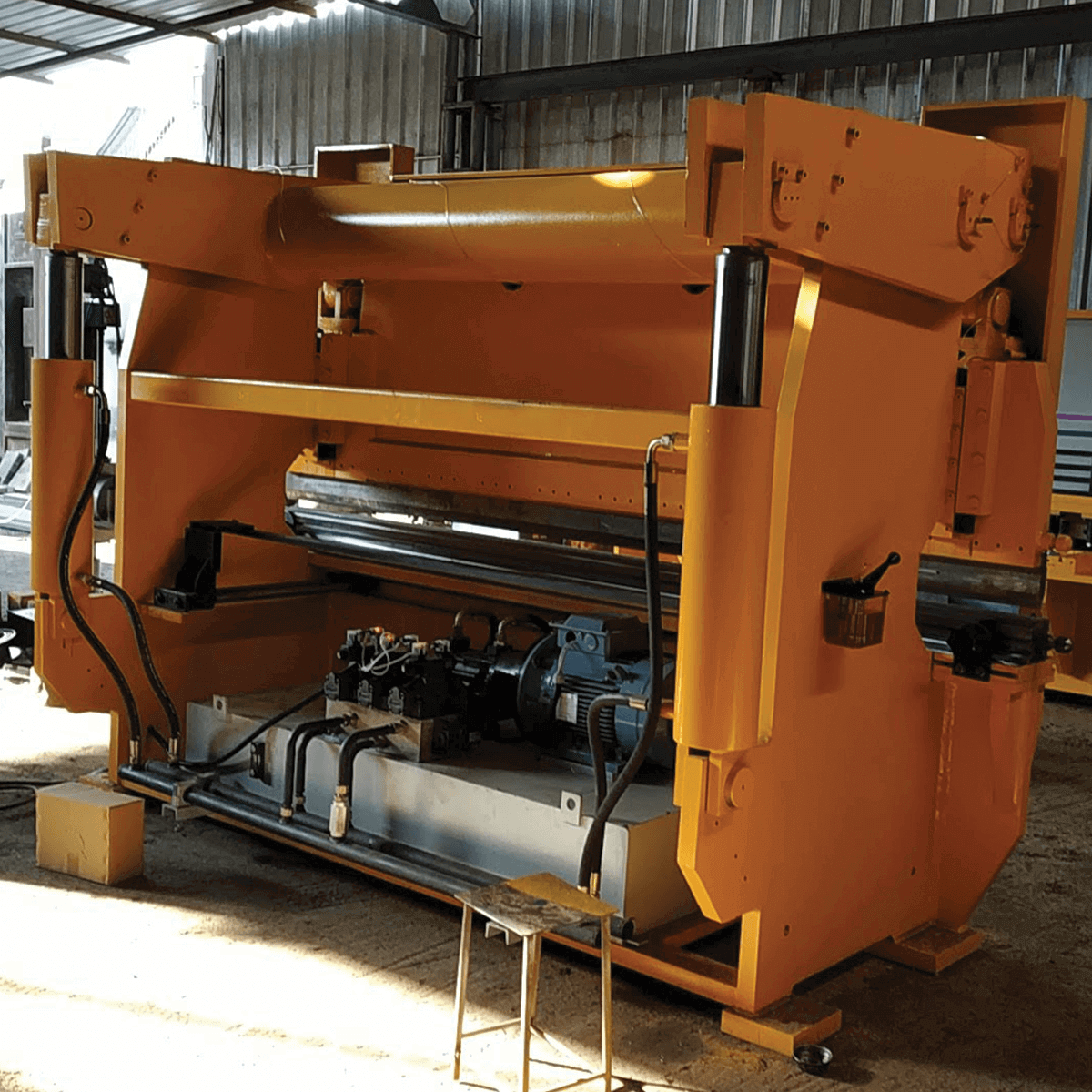

FRAME CONSTRUCTION:

Frame in made of steel fabricated construction of interlocked robust design. Machines are constructed with safeguards against undesired deflections and breakage. The frame distributes the stresses , supporting the bed directly on the frame. The double support shoe of frame gap provides extremely high rigidly, alignment, accuracy and keeps frame structure at right angles to the bed.

RAM & BED:

Ram & bed are straight and parallel of both the working surface under the rated load. The bed is accurately machined and upper surface is grinded to keep the die in correct alignment. The ram is guided and supported throughout the stroke by accurately machined guide ways.

LUBRICATION SYSTEM:

The lubrication system on a machine is an assurance for its trouble free running. The bearing parts are linked with high density polythene pipe- line spread at every point where lubrication is required.

CLUTCH AND BRAKE:

All “ACCURATE” Brands press brake are provided with high-torque low-inertia friction clutch, synchronized with heavy duty. The powerful disc type clutch is easily accessible, simple to adjust and picks the load from standing start and it frequent start & stop. The brake is interlocked with clutch to stop the ram immediately at any point of motion when the clutch is released. Clutch operating levers are designed in such a way that minimum engaging force is required at the pedal.

DRIVE SYSTEM:

Power is transmitted to the ram through two individual gear drives for uniform load distribution throughout the length. This also reduces the torsion stresses on the eccentric shaft. Electric motor used is of sufficient H.P. which reduces slowdown of flywheel and increases energy available per stroke. The gear and pinion are made out of carbon steel.

RAM ADJUSTMENT MECHANISM:

Motorized ram adjustment making is very easy to adjust the shut height to a desired value. The clutch offered easy operation in disconnecting either of right or left screws in order to set the ram in correct position. This mechanism facilities quick bending angle adjustment. Angular ram adjustment is made simple by incorporating a spring loaded dog clutch.

Helps you to find your goal

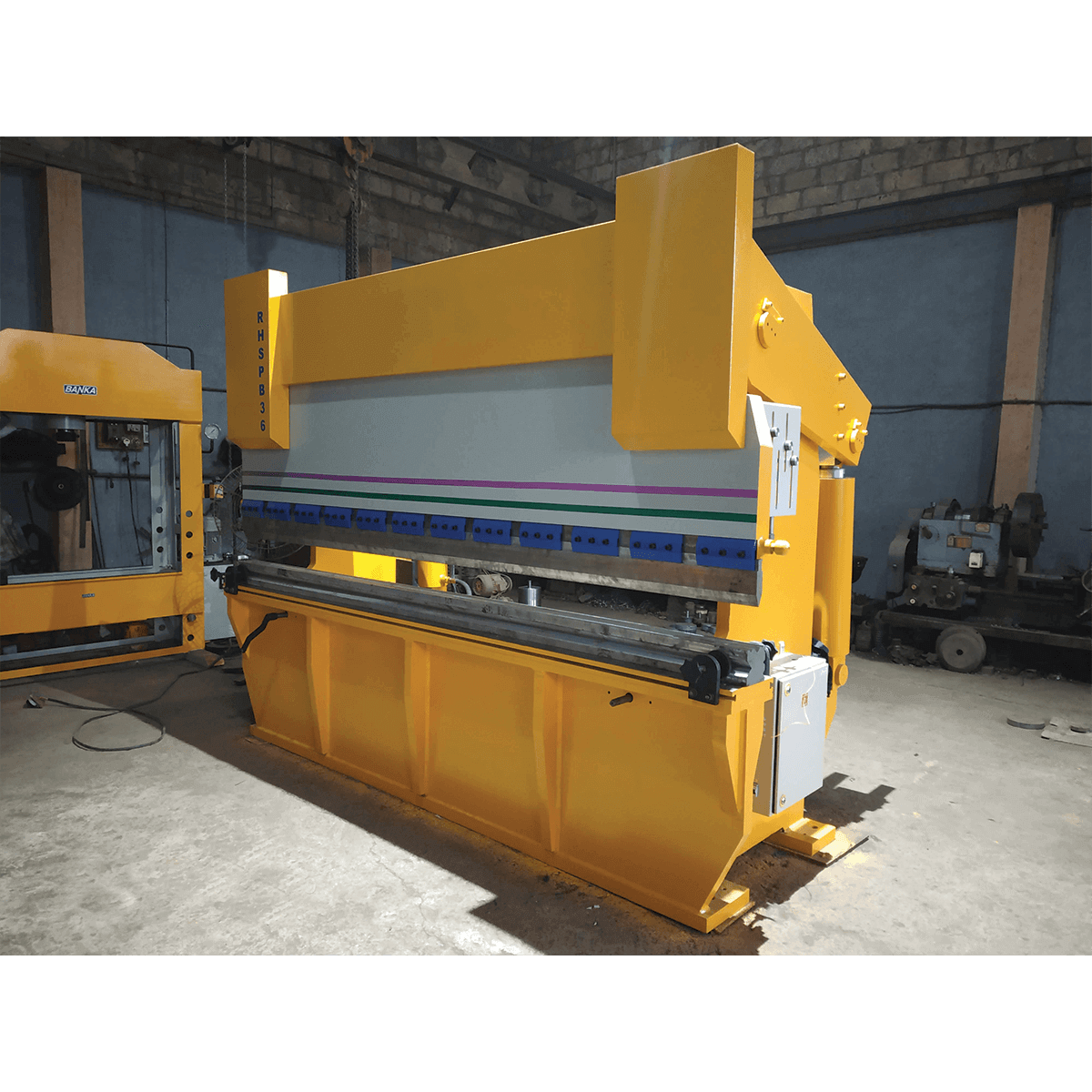

| MODEL NO. | RPB-1 | RPB-2 | RPB-3 | RPB-4 | RPB-5 | RPB-6 | RPB-7 |

| Capacity In Tons | 20 | 25 | 65 | 80 | 100 | 100 | 120 |

| Bending Cap.(Length x Thick.) | 1525×1.6 | 2030×1.6 | 2030×4 | 2540×3.25 | 2540×4.5 | 3125×3.25 | 2540×6 |

| Dis. Between Housing | 1120 | 1220 | 1220 | 1700 | 1700 | 1700 | 1700 |

| Stroke Length | 50 | 50 | 76 | 76 | 76 | 76 | 76 |

| Stroke Per Minute | 32 | 32 | 25 | 25 | 25 | 25 | 20 |

| RAM Adjustment | 25 | 25 | 25 | 25 | 25 | 22 | 22 |

| Shut Height Ram StrokeDown | 200 | 200 | 250 | 250 | 275 | 275 | 275 |

| Table Height | 760 | 760 | 800 | 800 | 800 | 800 | 900 |

| Main Motor HP | 3 | 5 | 7.5 | 10 | 15 | 15 | 20 |

| Ram Adjustment Motor HP | Manual | 1 | 1 | 1.5 | 2 | 2 | 2 |

| Die Space Length x Width | 1525×125 | 2030×125 | 2030×150 | 2540×150 | 2540×200 | 3125×200 | 2540×250 |

| Machine Length (LxR) | 1800 | 2300 | 2300 | 3050 | 3050 | 3250 | 3150 |

| Machine Width(FxB) | 1100 | 1100 | 1100 | 1600 | 1600 | 1750 | 1750 |

| Machine Height | 2150 | 2300 | 2300 | 2600 | 2600 | 3000 | 3100 |

Innovation with a Purpose

All dimensions are in MM.

- Power supply 400/440 volts, 3 phase, 50 cycle.

- As day to day improvements are contemplated for better performance of the machine, We reserve the rights to alter the specification without prior notice.

- All the machines undergo a thorough check-up by our expert engineers before dispatch to ensure their smooth and trouble free operation.

Lead us to serve more

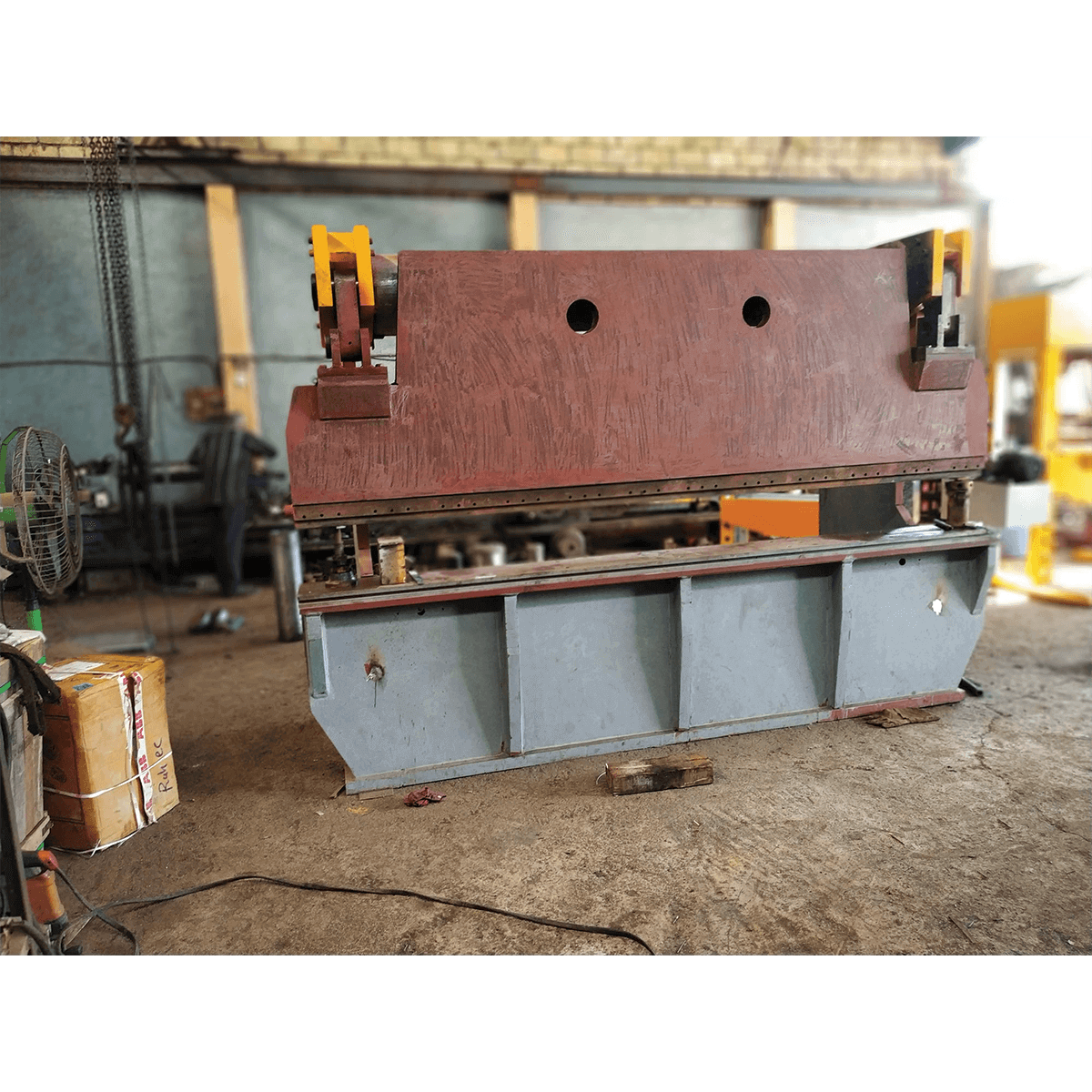

STANDARD SUPPLY:-

- Foot Pedal and Die Block Lifting Lin

- Self-lubricant System

- Motor Pulley

- Fly wheel & Gear guard

- Stroke Counter

- Standard “V” Block Punch

- Motor Mounting Bracket

OPTIONAL SUPPLY:-

- Motorized Back Gauge

- Automatic Lubrication System

- Vee-Belts

- Electric Motor & Starter / Control Panel Board

- Various Type of Die & Punch

- Foundation Bolts

We are here to Help you

1) What will be the warranty Period of this Press Machine?

A: Generally Suppliers of the lathe machine are providing only one year warranty period in the lathe machine. And it is not the proper return according to your investment. While We are providing 3 years warranty in our products. If there any parts damaged in your machine than we also provides free parts service in warranty period by fastest courier service.

2) How Many types are available in Press Machine?

A: 1) Hydraulic Press Machine

2) Power Press Machine

3) What are the models available in the Hydraulic press machine?

A :

Hydraulic press machine 5 ton capacity

Hydraulic press machine 15 ton capacity

Hydraulic press machine 25 ton capacity

Hydraulic press machine 40 ton capacity

Hydraulic press machine 60 ton capacity

Hydraulic press machine 75 ton capacity

Hydraulic press machine 100 ton capacity

4) What type of oil should I use in my Hydraulic Press Machine?

A: 68 Grade Oil

5) How much oil is used in my Hydraulic Press Machine?

A: 50 ltr.

6) Do you accept Domestic LC ?

A: Yes, accept domestic LC for 60 days on credit. Generally, our 75 % customers are purchasing Machine from us with 60 days Credit through a Simple Process of LC. When the Seller is Unknown or New to the Buyer, Letter of Credit is one good Alternative to do the Business with Such New Seller Because Buyer can Avoid Risk by such Letter. Letter of Credit is one Additional Benefit to the Buyer by which they can protect Loss against Goods and Finance Also.The buyer can build safeguards into the letter of credit, including inspection of the goods and quality control, and set production and delivery times.