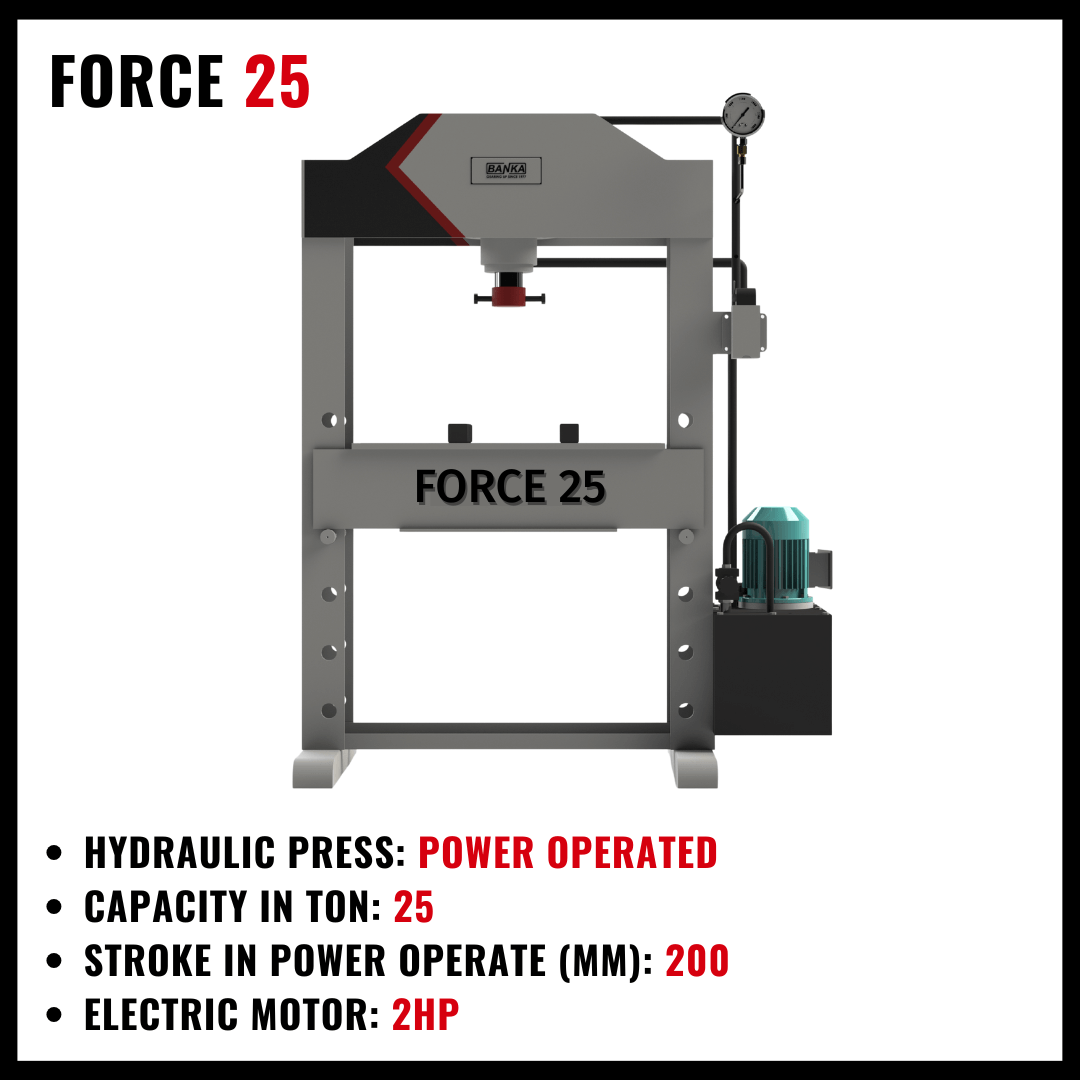

Hydraulic Press Machines High Precision & Heavy Duty – BANKA FORCE 25

₹1,25,000

- Hydraulic Press: Power Operated

- Capacity in Ton: 25

- Stroke in Power Operate (mm): 200

- Valve System: Double Valve Technology

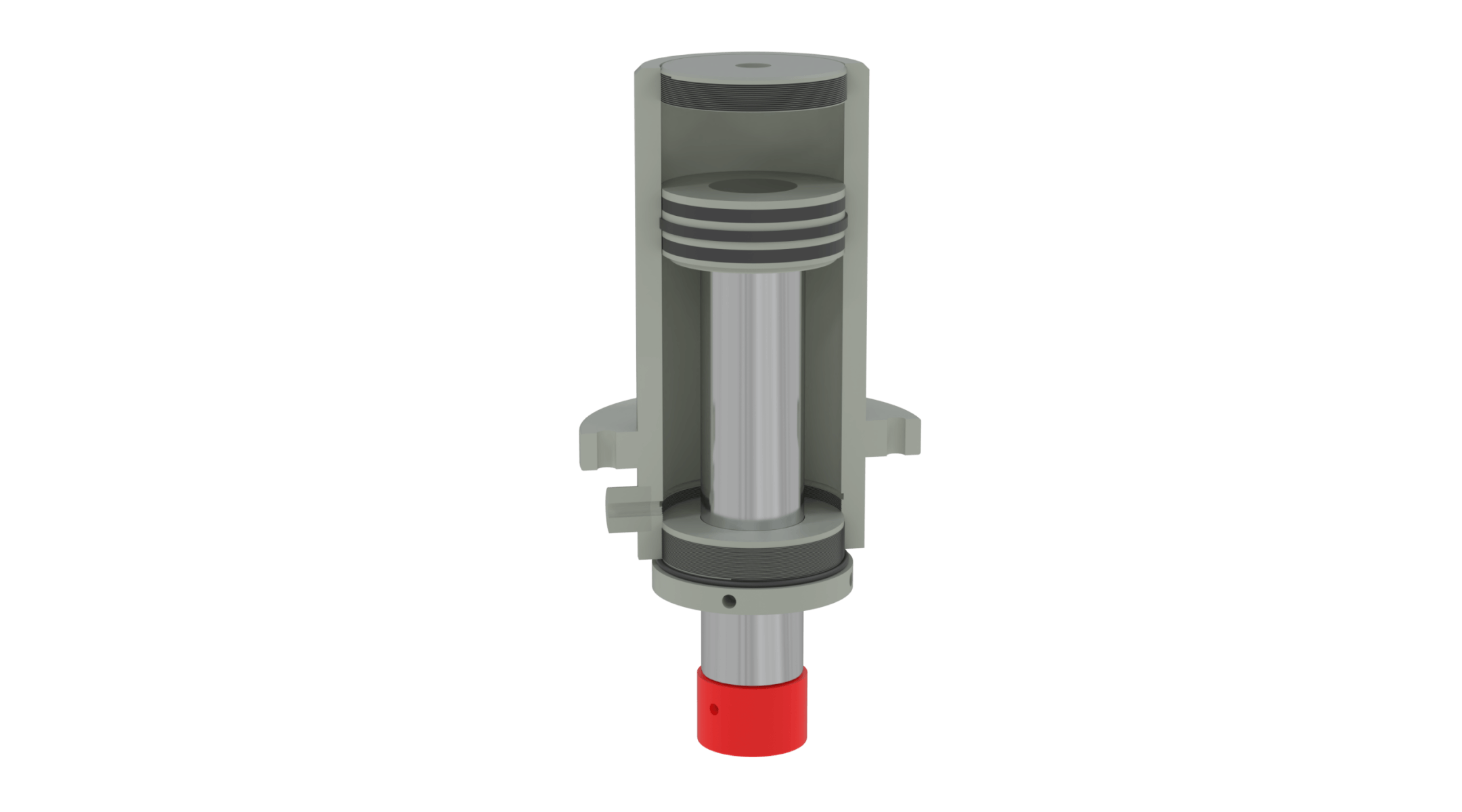

- Cylinder: Thread Type

- Electric Motor in: 2HP

- Weight: 475 kg.

- Color: Black & Off White

🔹 Hydraulic Press Machine Features

-

Robust Construction – Heavy-duty steel body frame for long-lasting durability.

-

High Pressing Capacity – Available in various tonnage (from 5 tons to 500+ tons) to suit different applications.

-

Precision Engineering – Ensures accurate pressing, bending, punching, and moulding operations.

-

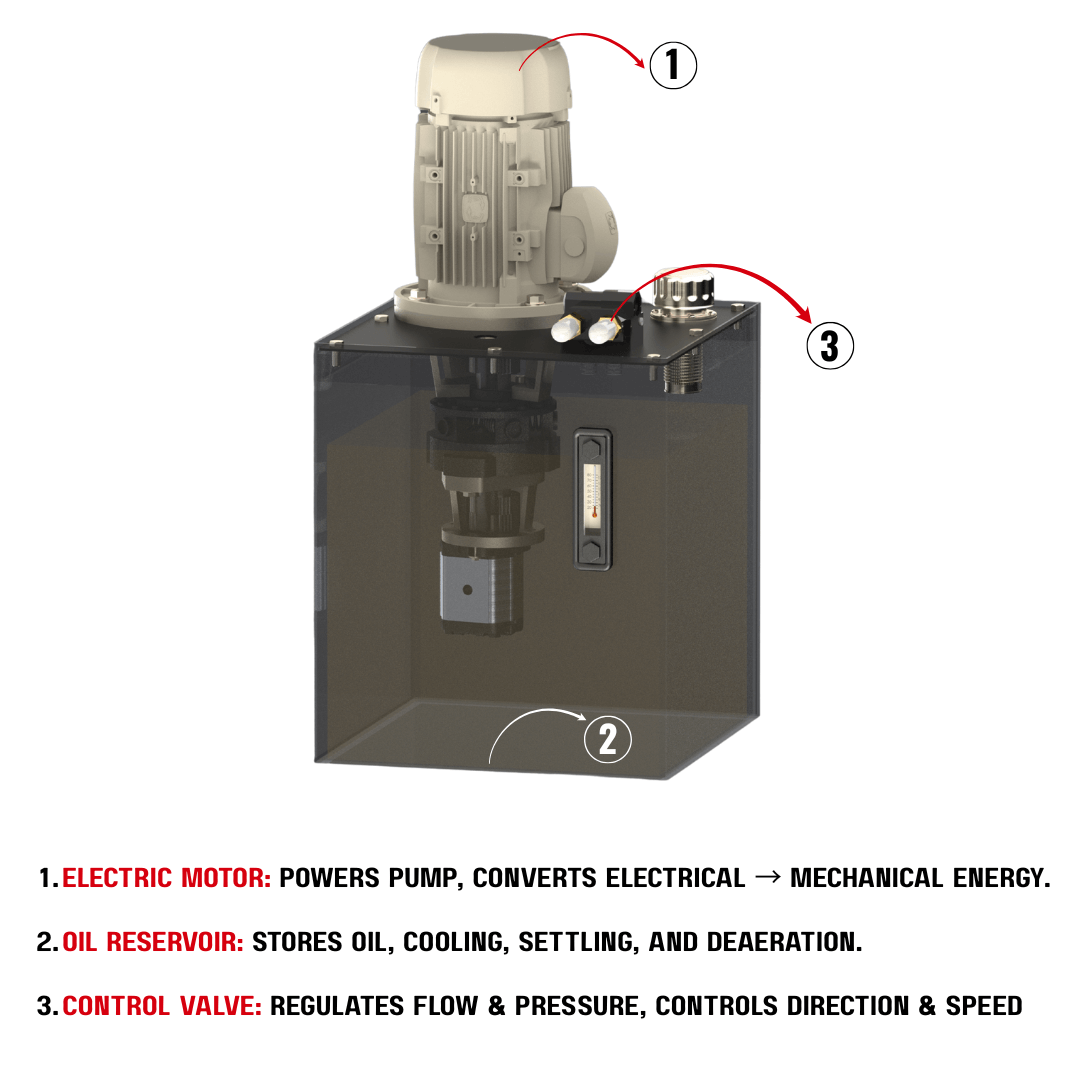

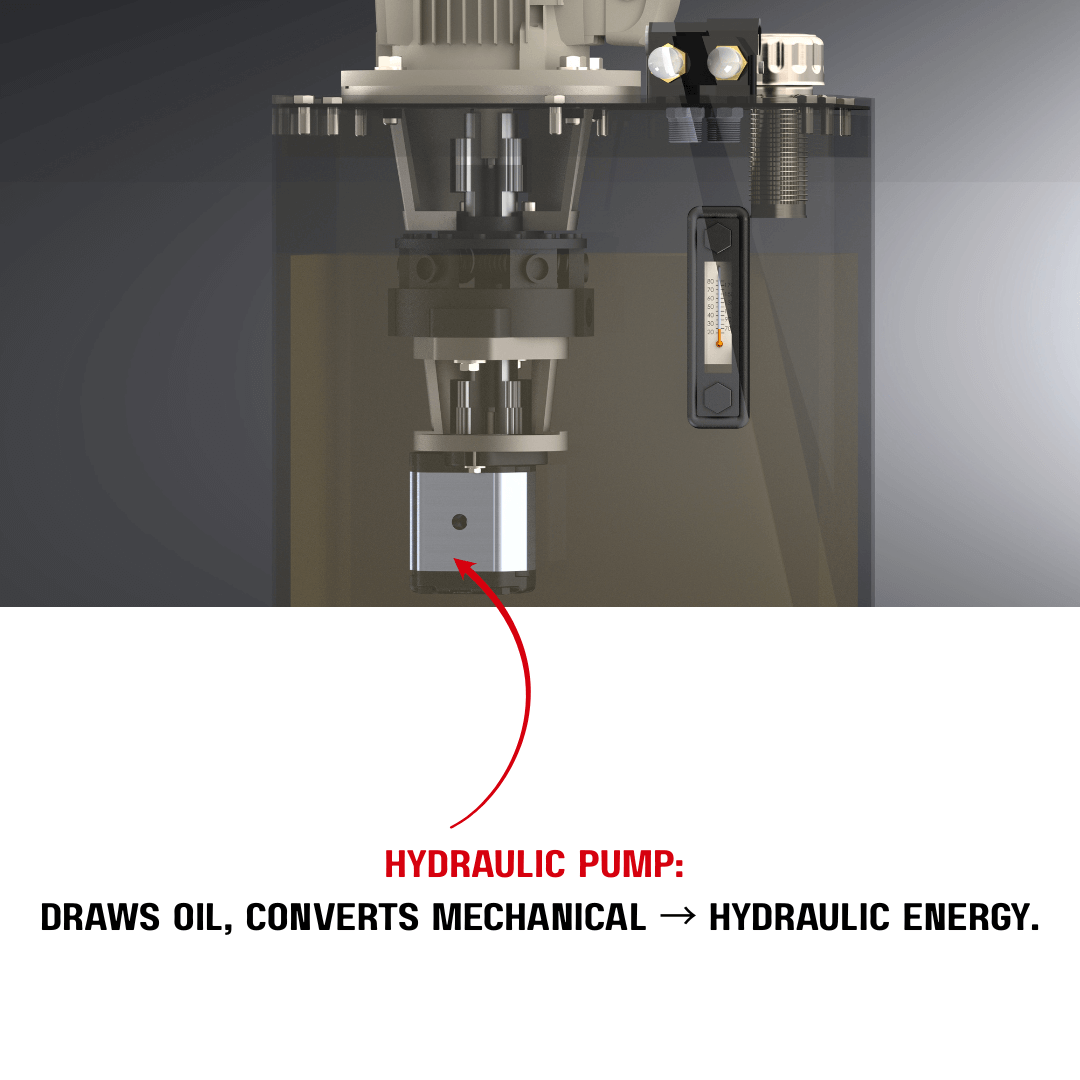

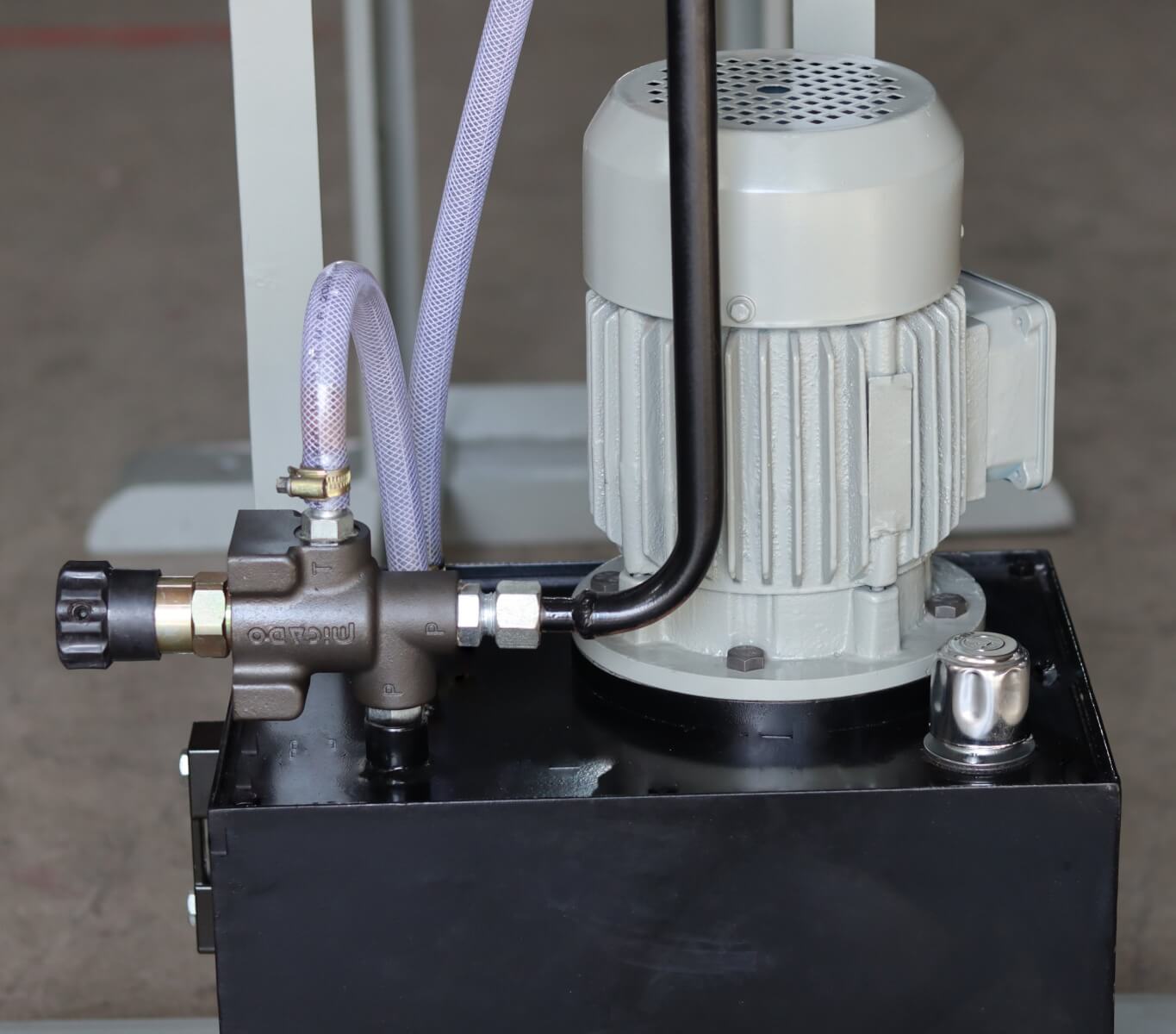

Hydraulic Power Pack – Fitted with high-quality pump, valves, and cylinders for smooth performance.

-

Adjustable Pressure & Stroke – Operator can easily control pressure and ram stroke as per job requirements.

-

Safety Features – Equipped with limit switches, overload protection, and an emergency stop system.

-

Low Noise & Vibration – Advanced hydraulic system reduces operational noise and vibrations.

-

Energy Efficient – Optimized hydraulic circuit for lower power consumption.

-

User-Friendly Operation – Easy control panel with push-button or PLC-based automation.

-

Versatile Applications – Suitable for sheet metal forming, deep drawing, punching, embossing, coining, rubber moulding, and other industrial processes.

-

Long Service Life – Hardened and ground piston rods & guide bushes ensure minimal wear.

-

Optional Attachments – Die cushion, ejector system, movable table, and automation integration available.

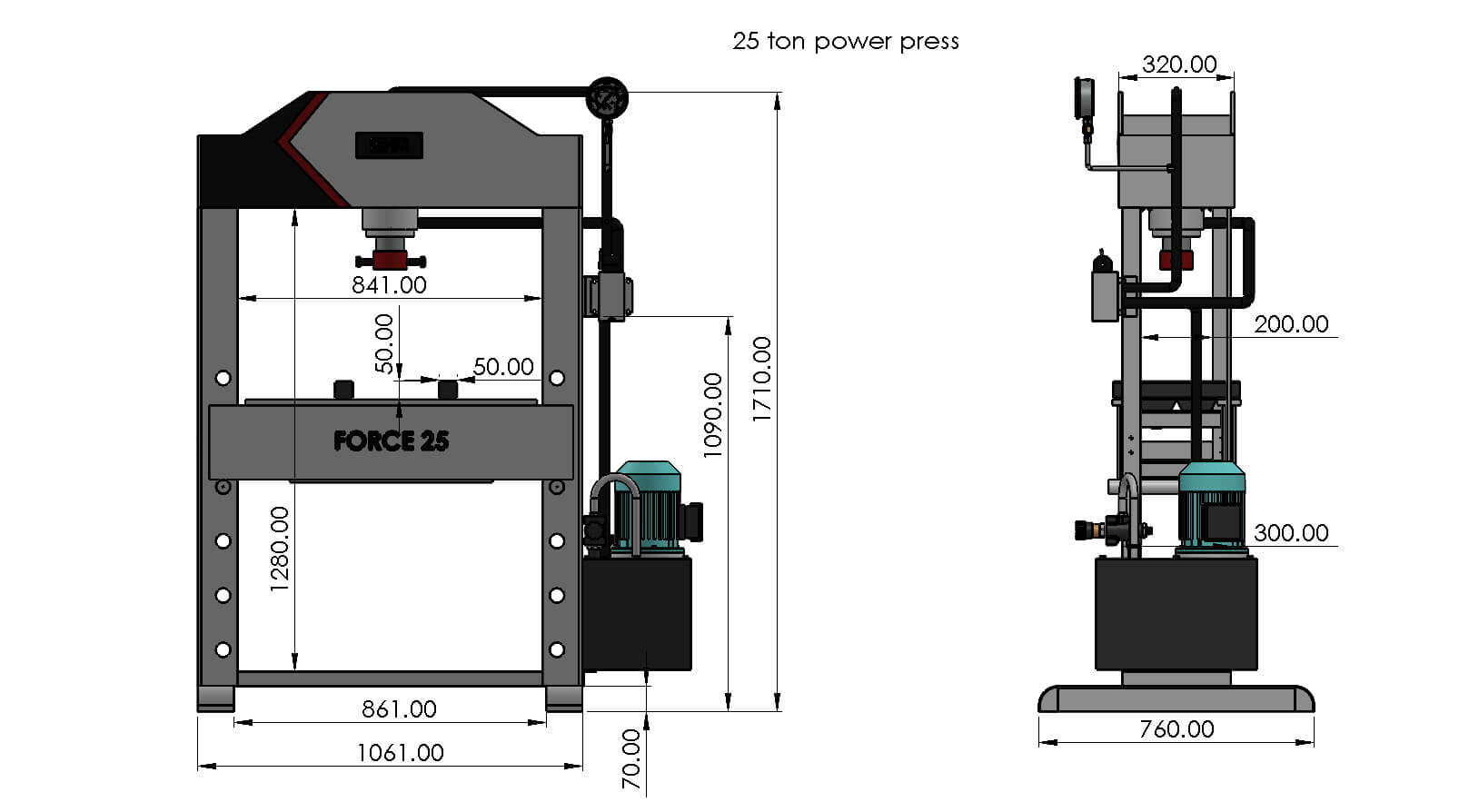

| MODEL DETAILS | FORCE 25 |

| Capacity (tons) | 25 |

| Stroke in Power Operate (mm) | 200 |

| Adjustment Daylight (min/max) (mm) | 175–800 |

| Distance Between Columns (mm) | 800 × 280 |

| Electric Motor (hp) | 2 |

| Working Pressure (kg/sq.cm) | 165 |

| Ram Speed – Approach (mm/sec) | Standard |

| Power Pressing (mm/sec) | 6 |

| Return (mm/sec) | 9 |

| Total Weight (kg) | 475 |

| Price | 125000 |

HYDRAULIC PRESS MACHINE DESCRIPTION

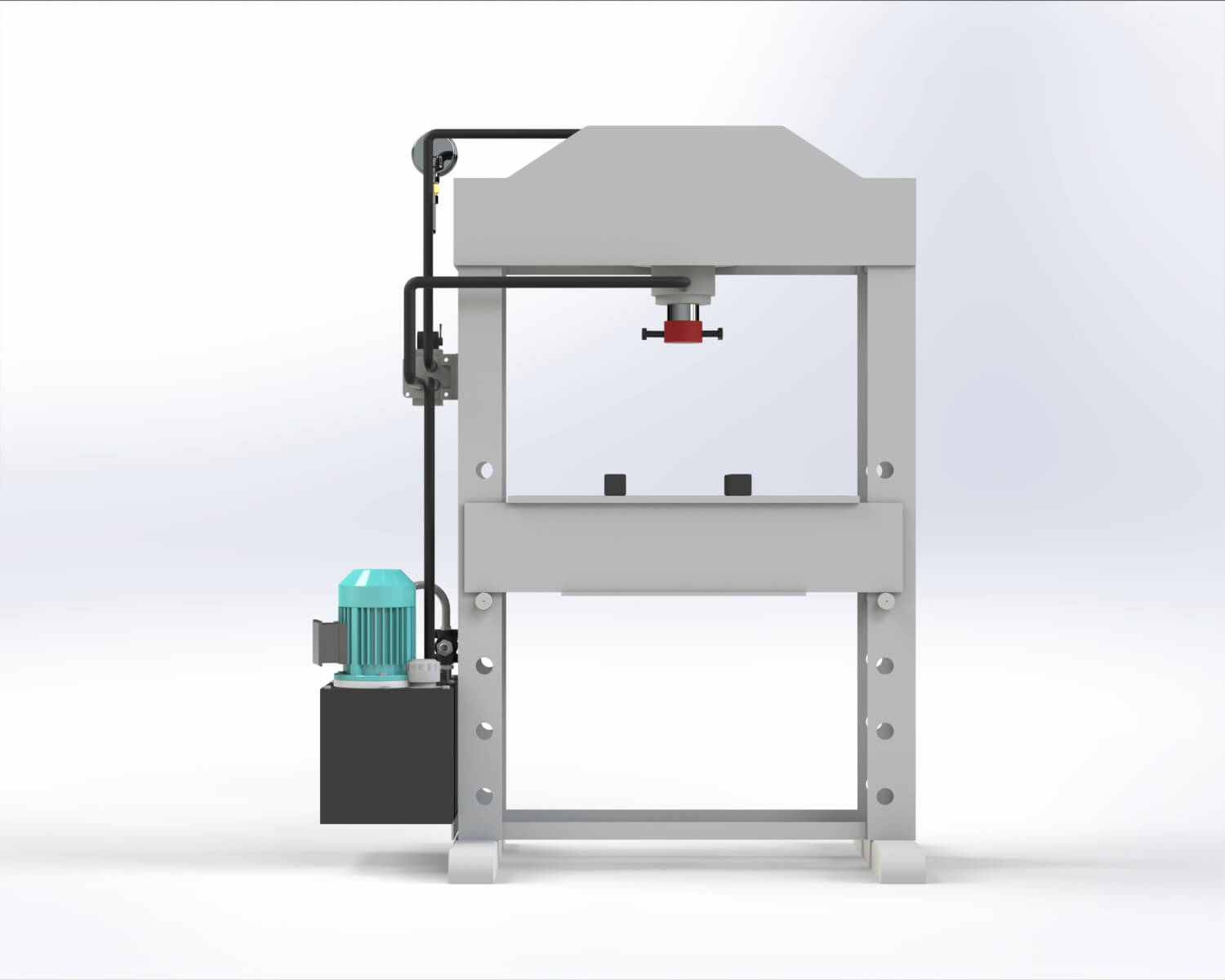

A Hydraulic Press Machine is a powerful and versatile industrial machine that uses a hydraulic cylinder to generate compressive force for shaping, bending, punching, pressing, deep drawing, embossing, and moulding operations. Designed with robust construction and advanced hydraulic technology, it delivers high precision, consistent performance, and long service life.

Our Hydraulic Presses are available in H-Type and custom-built models, ranging from light-duty to heavy-duty applications. They are equipped with a reliable hydraulic power pack, adjustable pressure settings, and safety features to ensure smooth, safe, and efficient operation.

Widely used in the automobile, aerospace, sheet metal, fabrication, electrical, and rubber moulding industries, these machines are suitable for both small workshops and large-scale manufacturing units.

With features like low noise, minimal maintenance, energy efficiency, and user-friendly operation, our Hydraulic Press Machines are an ideal solution for industries seeking high productivity and superior accuracy.

1. What is a Hydraulic Press Machine?

A hydraulic press is a machine that uses a hydraulic cylinder to generate compressive force. It works on Pascal’s law, which states that pressure applied to a confined fluid is transmitted equally in all directions.

2. What are the common uses of a Hydraulic Press?

Hydraulic presses are used in:

-

Sheet metal forming

-

Molding and punching

-

Straightening and bending

-

Assembling parts

-

Compaction of materials

3. What are the advantages of a Hydraulic Press over a Mechanical Press?

-

Provides higher force in a smaller size

-

Smooth and uniform pressing action

-

Adjustable stroke and pressure

-

Low noise and vibration

-

Capable of handling complex forming jobs

4. How is the capacity of a Hydraulic Press measured?

The capacity is measured in Tons (T) and is determined by the maximum force it can exert. For example, a 25 To 150 Ton Hydraulic Press can apply a maximum force equivalent to 150 tons.

5. What maintenance is required for a Hydraulic Press Machine?

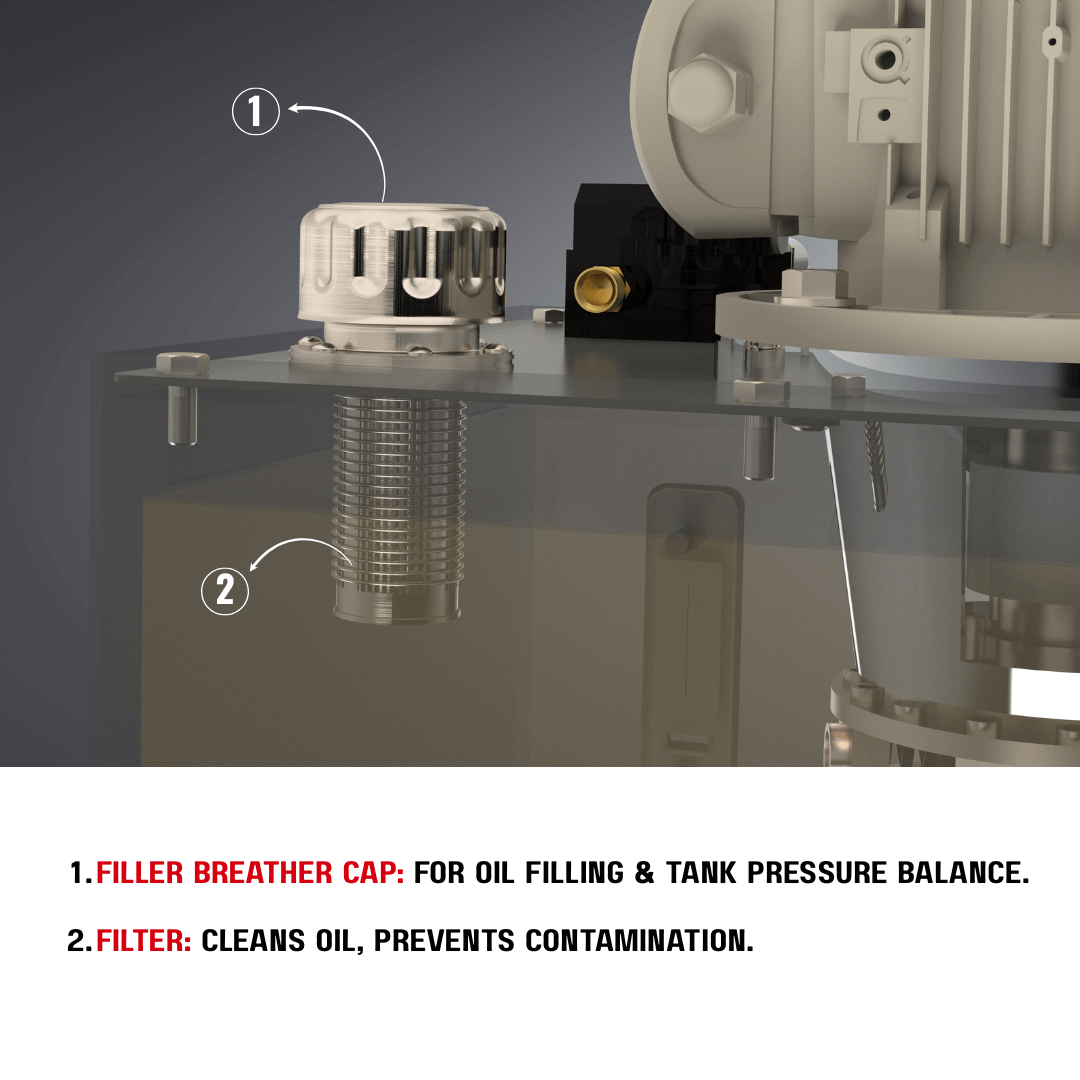

-

Regularly check and maintain hydraulic oil level and quality

-

Inspect hoses, seals, and cylinders for leaks

-

Keep the machine clean and lubricated

-

Monitor pressure gauges and safety valves

-

Schedule periodic servicing